The global wire mesh market is experiencing robust growth, driven by rising demand across industries such as filtration, aerospace, automotive, and construction. According to a report by Mordor Intelligence, the global wire mesh market was valued at USD 8.67 billion in 2023 and is projected to reach USD 11.33 billion by 2029, growing at a CAGR of over 4.5% during the forecast period. This expansion is fueled by increasing industrialization, stringent regulatory standards requiring high-performance filtration systems, and the growing adoption of precision-engineered mesh in manufacturing processes. Brass wire mesh, known for its corrosion resistance, electrical conductivity, and durability, represents a key segment within this market due to its versatility in both decorative and technical applications. With demand on the rise, a select group of manufacturers have emerged as leaders in innovation, quality, and global reach. Below, we highlight the top nine brass wire mesh manufacturers shaping the industry through technological advancement and consistent product performance.

Top 9 Brass Wire Mesh Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Brass Wire Mesh

Domain Est. 1997

Website: twpinc.com

Key Highlights: Shop high-quality brass wire mesh for industrial use, filtration and separation, construction, and DIY and home improvement projects….

#2 Brass Mesh Manufacturers

Domain Est. 2000

Website: brassmesh.com

Key Highlights: Hightop is one of the brass mesh manufacturers and suppliers. We have been in the field of metal mesh manufacturing for 20 years and have a rich product line….

#3 Wire Mesh Manufacturers

Domain Est. 2001

Website: wire-cloth.net

Key Highlights: Instantly discover the leading wire mesh manufacturers and suppliers in the USA producing ISO certified products made from premium materials for unbeatable ……

#4 Brass Mesh and Copper Mesh for Decorative Mesh

Domain Est. 2010

Website: brasswiremesh.net

Key Highlights: Brass/Copper Wire Mesh for Filter and Faraday Cage. Boegger Industech Limited is a professional manufacturer in producing brass and copper wire mesh….

#5 Brass Wire Mesh Supplier

Domain Est. 2013

Website: samaterials.com

Key Highlights: Starting from $100.00 In stockBrass Wire Mesh FAQs. Q1: What is brass wire mesh? Brass wire mesh is a woven grid of brass wires, which is an alloy primarily consisting of copper an…

#6 Wire Cloth Man

Domain Est. 2002

Website: wireclothman.com

Key Highlights: Wire Cloth Man is the source for all things wire mesh –from product inventory to your questions, answered….

#7 Brass Wire Mesh

Domain Est. 2007

Website: darbywiremesh.com

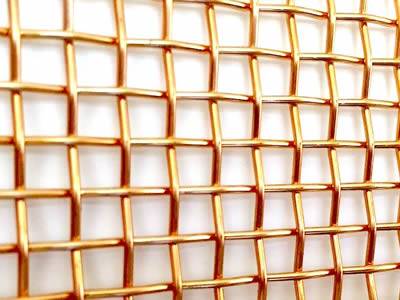

Key Highlights: Brass woven wire mesh is commonly often used in filtration and separation applications. It is abrasion resistant and harder than copper mesh….

#8 Brass Wire Mesh

Domain Est. 2011

Website: iwimesh.net

Key Highlights: This brass woven wire mesh is an alloy of zinc and copper and possess lower electrical conductivity in comparison to copper….

#9 Brass Woven Wire Mesh

Domain Est. 2019

Website: dongfumesh.com

Key Highlights: Versatile and durable, brass wire mesh is perfect for various applications, including filtration, decoration, and insect screens. Get yours today!…

Expert Sourcing Insights for Brass Wire Mesh

H2: 2026 Market Trends for Brass Wire Mesh

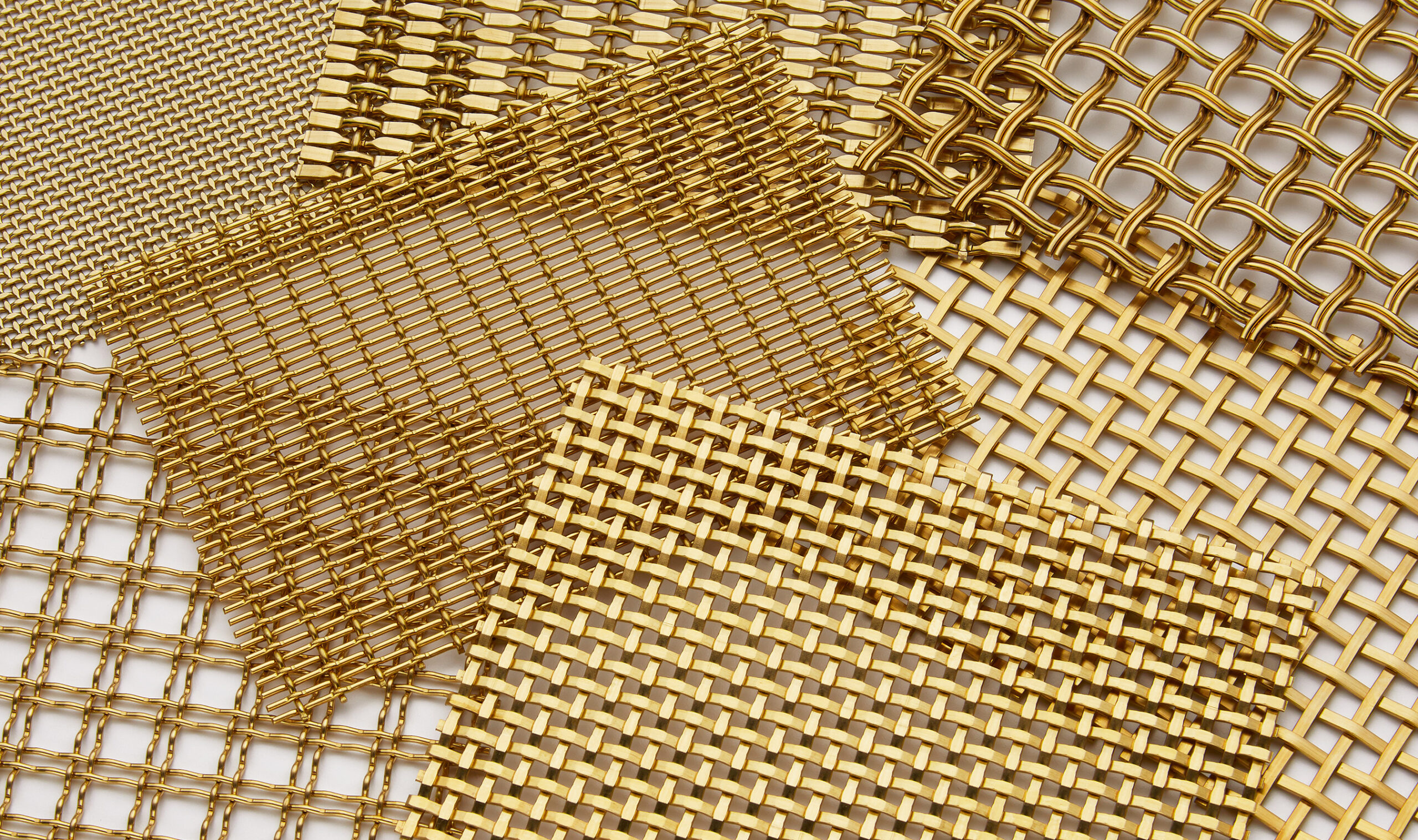

The global brass wire mesh market is poised for steady growth through 2026, driven by a confluence of industrial demand, technological advancements, and evolving applications across key sectors. Brass wire mesh—a corrosion-resistant, conductive, and malleable material composed primarily of copper and zinc—continues to gain traction in niche and high-performance applications. The following analysis outlines the projected market trends shaping the brass wire mesh industry in 2026.

-

Rising Demand in Filtration and Screening Applications

Brass wire mesh is increasingly favored in precision filtration systems, especially in chemical processing, pharmaceuticals, and food & beverage industries, due to its resistance to oxidation and non-sparking properties. The push for higher purity standards and regulatory compliance in these sectors is expected to boost demand for brass mesh filters and strainers by 2026. -

Expansion in Architectural and Decorative Uses

Architectural trends emphasizing sustainable and aesthetically pleasing materials are elevating the use of brass wire mesh in façades, interior design, and acoustic panels. Its golden luster, combined with durability and recyclability, makes it a preferred choice for modern green buildings. The growing adoption of brass mesh in luxury residential and commercial projects, especially in North America and Europe, will contribute significantly to market growth. -

Growth in Electrical and Electromagnetic Shielding

With the proliferation of 5G infrastructure, IoT devices, and electronic equipment, electromagnetic interference (EMI) shielding has become critical. Brass wire mesh offers excellent conductivity and shielding effectiveness, making it ideal for use in enclosures, gaskets, and RF shielding applications. This segment is expected to witness accelerated growth through 2026, particularly in the automotive and telecommunications industries. -

Advancements in Manufacturing and Weaving Technologies

Innovations in precision weaving and automated manufacturing are enabling the production of finer, more consistent brass wire mesh with customized specifications. Improved production efficiency is reducing costs and expanding the feasibility of brass mesh in cost-sensitive applications. By 2026, smart manufacturing and Industry 4.0 integration will likely enhance quality control and supply chain responsiveness. -

Sustainability and Recycling Initiatives

As environmental regulations tighten globally, the recyclability of brass—an alloy with high recovery rates—is becoming a competitive advantage. Manufacturers are increasingly adopting closed-loop recycling systems and promoting eco-friendly production processes. This sustainability angle is expected to influence procurement decisions, particularly among environmentally conscious industries. -

Regional Market Dynamics

Asia-Pacific, led by China and India, is projected to dominate the brass wire mesh market by 2026 due to rapid industrialization, infrastructure development, and expanding manufacturing bases. Meanwhile, North America and Europe will grow steadily, driven by high-tech applications and retrofitting of older industrial systems with advanced filtration and shielding solutions. -

Supply Chain and Raw Material Challenges

Fluctuations in copper and zinc prices, along with geopolitical factors affecting mining output, may pose challenges to cost stability. However, long-term contracts, material substitution research, and supply diversification strategies are expected to mitigate these risks by 2026.

Conclusion

By 2026, the brass wire mesh market will be characterized by diversified applications, technological innovation, and a strong emphasis on sustainability. While competition from alternative materials like stainless steel and aluminum persists, brass’s unique combination of aesthetic appeal, conductivity, and corrosion resistance ensures its continued relevance. Strategic investments in R&D, customization, and eco-efficient production will be crucial for market participants aiming to capture emerging opportunities.

Common Pitfalls When Sourcing Brass Wire Mesh (Quality, IP)

Sourcing brass wire mesh involves several potential pitfalls, particularly concerning material quality, specifications, and intellectual property (IP) considerations. Being aware of these can help avoid costly mistakes, production delays, or legal issues.

Inconsistent Material Quality and Composition

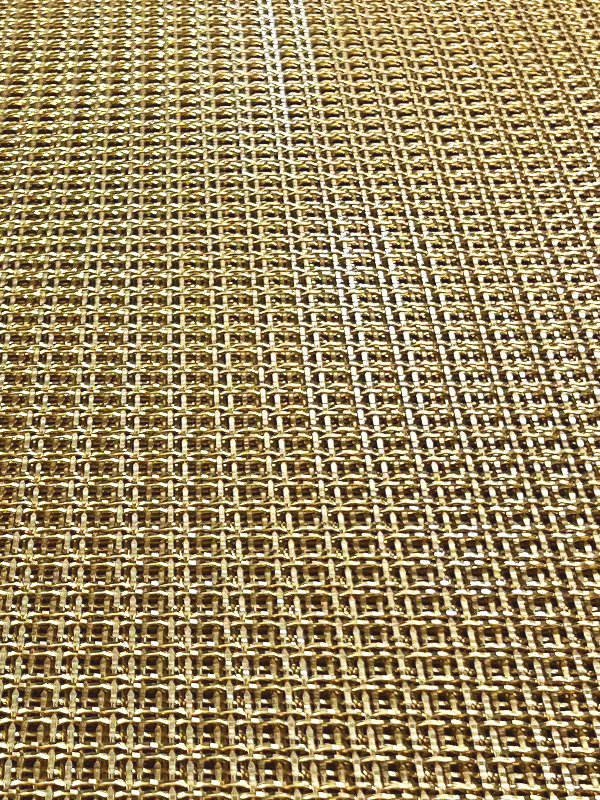

One of the most frequent issues is receiving brass wire mesh that does not meet the specified alloy composition (e.g., C26000, C27000). Suppliers may use substandard brass blends or recycled materials, leading to poor corrosion resistance, inconsistent tensile strength, or inadequate conductivity. Always demand certified material test reports (MTRs) and conduct third-party lab verification if large volumes are involved.

Poor Mesh Uniformity and Dimensional Accuracy

Brass wire mesh must adhere to precise specifications for aperture size, wire diameter, and weave pattern (e.g., plain weave, twill weave). Inconsistent spacing or non-uniform openings can compromise filtration efficiency or structural integrity. Ensure suppliers follow ISO 4783 or ASTM E2016 standards and request sample inspection prior to bulk orders.

Inadequate Surface Finish and Corrosion Resistance

Some suppliers deliver mesh with surface oxides, burrs, or residues that impair performance—especially in sensitive applications like electronics or medical devices. Poor annealing or cleaning processes can also reduce corrosion resistance. Specify required surface treatments (e.g., passivation, bright annealing) and inspect for cleanliness and smoothness.

Misrepresentation of IP or Proprietary Weave Designs

Using patented mesh weaves or proprietary filtration patterns without authorization can lead to intellectual property infringement. Some suppliers may falsely claim compliance with patented technologies or replicate protected designs. Conduct due diligence on the supplier’s IP rights and obtain written confirmation that the product does not violate existing patents.

Lack of Traceability and Certification

Without proper traceability—such as lot numbering, mill certifications, or RoHS/REACH compliance documentation—quality issues become difficult to track and resolve. This is especially critical in regulated industries. Ensure the supplier provides full documentation and maintains quality management systems like ISO 9001.

Unverified Supplier Claims and Counterfeit Goods

Some overseas suppliers exaggerate capabilities or deliver counterfeit products labeled as high-grade brass. This includes false claims about temper (e.g., half-hard vs. full-hard) or wire drawing processes. Perform supplier audits, request production samples, and use independent inspection services when sourcing from unfamiliar vendors.

Logistics & Compliance Guide for Brass Wire Mesh

Overview

Brass wire mesh, a durable and corrosion-resistant material composed primarily of copper and zinc, is widely used in filtration, shielding, architectural design, and industrial applications. Ensuring efficient logistics and compliance with international and local regulations is critical for smooth import/export operations, safety, and legal adherence.

Classification & HS Code

Brass wire mesh is typically classified under the Harmonized System (HS) code 7410.21.00 or 7410.29.00, depending on composition and form:

– 7410.21.00: Woven wire cloth of brass, containing by weight ≥ 99.8% copper.

– 7410.29.00: Other woven wire cloth of brass.

Note: Confirm with local customs authorities, as classifications may vary by country and product specifications.

Packaging & Handling Requirements

Proper packaging ensures product integrity during transit:

– Standard Packaging: Rolls or sheets wrapped in water-resistant plastic or kraft paper, secured on wooden pallets.

– Labeling: Include product specifications (mesh size, wire diameter, alloy type), batch number, net weight, and handling instructions (e.g., “Fragile,” “Keep Dry”).

– Handling: Avoid exposure to moisture and corrosive environments. Store in dry, well-ventilated areas. Use protective gloves to prevent surface oxidation from skin oils.

Transportation & Shipping

- Modes of Transport: Suitable for road, rail, sea, and air freight. For sea freight, use moisture-barrier packaging to prevent saltwater corrosion.

- Container Requirements: Use dry, clean containers. Desiccants recommended for long-haul shipments.

- Weight & Dimensions: Provide accurate dimensions and weight for freight calculation. Typical roll sizes range from 1m to 1.5m wide and 30m long.

- Special Considerations: Avoid stacking heavy items on top of mesh rolls to prevent deformation.

Import/Export Documentation

Ensure all documentation is accurate and complete:

– Commercial Invoice

– Packing List

– Bill of Lading or Air Waybill

– Certificate of Origin (often required for preferential tariff treatment)

– Material Test Report (MTR) or Certificate of Conformance (CoC) detailing composition and mechanical properties

– Export Declaration (if applicable)

Regulatory Compliance

- REACH (EU): Register and disclose substances of very high concern (SVHC). Brass components (Cu, Zn) are generally compliant but verify alloy additives.

- RoHS (EU): Not typically restricted, as brass is exempt from lead restrictions under RoHS, but confirm lead content if below threshold limits.

- TSCA (USA): Ensure compliance with Toxic Substances Control Act; brass is generally compliant.

- Customs Valuation: Declare accurate transaction value. Avoid undervaluation to prevent delays or penalties.

Environmental & Safety Regulations

- Hazard Classification: Brass wire mesh is not classified as hazardous under GHS/CLP regulations.

- Waste Disposal: Recyclable material. Follow local regulations for metal recycling; do not dispose of in landfills.

- Worker Safety: Minimize dust during cutting; use PPE (masks, gloves) to prevent inhalation of metal particles.

Country-Specific Requirements

- USA: No import license required for brass mesh; subject to standard CBP clearance.

- EU: May require CE marking if used in construction or safety-critical applications.

- China: Requires CIQ inspection for certain metal products; check latest MOFCOM regulations.

- India: Subject to BIS certification if used in regulated applications; otherwise, standard customs clearance applies.

Insurance & Risk Management

- Insure shipments against loss, damage, and theft.

- Consider Incoterms® (e.g., FOB, CIF) clearly defined in contracts to allocate responsibility.

- Monitor geopolitical and port congestion risks, especially in key brass-producing or consuming regions.

Conclusion

Successful logistics and compliance for brass wire mesh depend on accurate classification, proper packaging, complete documentation, and adherence to regional regulations. Partnering with experienced freight forwarders and customs brokers familiar with metal goods can streamline global trade operations. Regularly review regulatory updates to maintain compliance and avoid shipment delays.

Conclusion for Sourcing Brass Wire Mesh

Sourcing brass wire mesh requires a strategic approach that balances material quality, supplier reliability, cost efficiency, and specific application requirements. Brass wire mesh, known for its corrosion resistance, electrical conductivity, aesthetic appeal, and acoustic properties, is widely used in industries such as aerospace, architecture, filtration, and decorative arts.

After evaluating key factors—including mesh specifications (aperture size, wire diameter, weave type), material composition (e.g., C26000 cartridge brass), certifications, and supplier credentials—it is evident that establishing partnerships with reputable manufacturers or distributors is crucial. Considerations such as minimum order quantities, lead times, and logistical support further influence sourcing decisions.

Moreover, conducting sample testing, verifying compliance with industry standards (such as ASTM or ISO), and negotiating favorable terms can ensure long-term supply chain stability. In markets with fluctuating brass prices due to copper and zinc volatility, adopting hedging strategies or long-term contracts may provide cost predictability.

In conclusion, successful sourcing of brass wire mesh hinges on thorough due diligence, clear communication with suppliers, and alignment with project-specific needs. By prioritizing quality, reliability, and cost-effectiveness, organizations can secure a consistent supply of brass wire mesh that meets technical and commercial objectives.