The global brass P-trap market is experiencing steady growth, driven by rising demand in residential, commercial, and industrial plumbing applications. According to Grand View Research, the global plumbing fixtures market size was valued at USD 69.3 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.2% from 2023 to 2030, with brass components such as P-traps benefiting from their durability, corrosion resistance, and compliance with sanitary standards. Additionally, increasing urbanization and infrastructure development in emerging economies are amplifying the need for reliable plumbing solutions. As the demand for high-quality, leak-proof drainage fittings grows, manufacturers specializing in precision-engineered brass P-traps are gaining prominence. This list highlights the top 8 brass P-trap manufacturers leading the industry through innovation, scalability, and adherence to international quality benchmarks.

Top 8 Brass P Trap Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 BrassCraft

Domain Est. 1995

Website: brasscraft.com

Key Highlights: This is Our Craft. BrassCraft produces high quality products plumbers depend on to make their business a success….

#2 Dearborn Brass Tubular Low

Domain Est. 1996

Website: oatey.com

Key Highlights: Dearborn Brass Tubular Low-Inlet P-Traps are manufactured in 17 gauge brass for use in tubular drain applications….

#3 T&S Brass

Domain Est. 1996

Website: tsbrass.com

Key Highlights: T&S Brass offers a full range of top quality foodservice, commercial, laboratory, and pet market faucets and fittings….

#4 P

Domain Est. 1999

Website: jonesstephens.com

Key Highlights: 1-1/2″ Chrome Plated Brass P-Trap with Shallow Escutcheon with Cleanout 17 Gauge P38012 Picture of 1-1/2″ Chrome Plated Milwaukee Style Trap 17 Gauge…

#5 1208C: 2 IN x 2 IN

Domain Est. 1999

Website: mcguiremfg.com

Key Highlights: Cast P-Trap Ground Joint Swivel with or without Cleanout. Style: L.A. Style … Cast brass. Notes. Each Depth_in: 6.75. Each Height_in: 2.625. Each Width_in ……

#6 P

Domain Est. 2000

Website: braxtonharris.com

Key Highlights: BPT112-CP. 1-1/2″ 17 Gauge Brass P-Trap- Chrome PlatedList Price $47.11. BPT112-FB. 1-1/2″ 17 Gauge Brass P-Trap- Flat BlackList Price ……

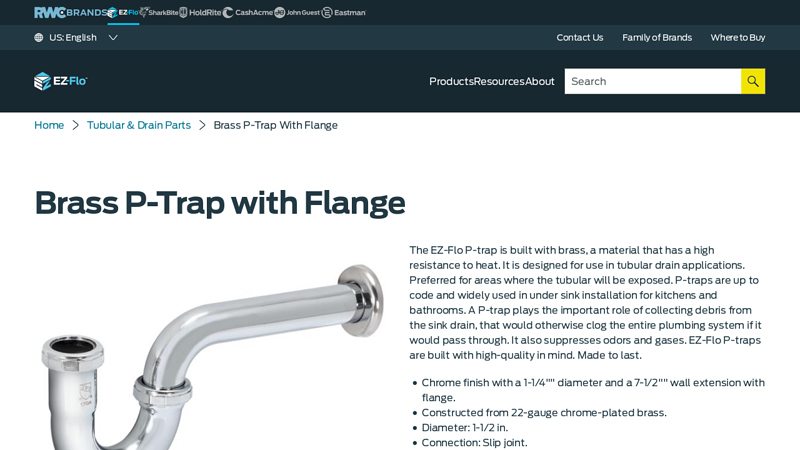

#7 Brass P

Domain Est. 2001

Website: ez-flo.net

Key Highlights: The EZ-Flo P-trap is built with brass, a material that has a high resistance to heat. It is designed for use in tubular drain applications….

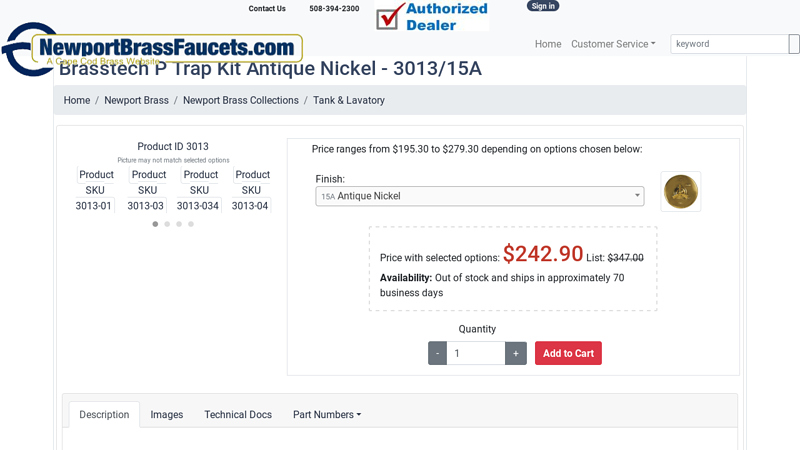

#8 Brasstech P Trap Kit Antique Nickel

Domain Est. 2004

Website: newportbrassfaucets.com

Key Highlights: Out of stock Rating 5.0 1 Available in a variety of finishes. Solid brass construction. P Trap – 1-1/2 in. x 1-1/2 in. 17 gauge (item 300 qty1) P Trap – Fits 1-1/2 in. or 1-1/4 i…

Expert Sourcing Insights for Brass P Trap

H2: 2026 Market Trends for Brass P-Trap

The global market for brass P-traps is poised for steady growth and transformation by 2026, driven by evolving construction practices, regulatory standards, and consumer preferences for durable, corrosion-resistant plumbing components. Below is an analysis of key trends shaping the brass P-trap market in 2026:

1. Rising Demand in Residential and Commercial Construction

Ongoing urbanization and infrastructure development, especially in emerging economies across Asia-Pacific, Latin America, and Africa, are boosting demand for high-quality plumbing fixtures. Brass P-traps, known for their durability and leak resistance, are increasingly preferred in both new construction and renovation projects. The expansion of smart homes and luxury housing segments further supports demand for premium brass fittings.

2. Shift Toward Sustainable and Corrosion-Resistant Materials

Environmental regulations and green building certifications (e.g., LEED, BREEAM) are encouraging the use of sustainable, long-lasting materials in plumbing systems. Brass, particularly lead-free brass alloys compliant with NSF/ANSI 61 and similar standards, is gaining favor over plastic alternatives due to its recyclability, resistance to high temperatures, and reduced environmental impact over its lifecycle.

3. Technological Advancements and Design Innovation

Manufacturers are incorporating precision engineering and anti-microbial coatings into brass P-traps to enhance hygiene and longevity. Additionally, modular and compact designs are being developed to accommodate modern bathroom and kitchen layouts, especially in space-constrained urban environments. These innovations are expected to differentiate premium brands in a competitive market.

4. Regulatory Compliance and Safety Standards

By 2026, stricter plumbing codes in North America, Europe, and parts of Asia will mandate the use of low-lead or lead-free brass components. This regulatory push is accelerating the transition from traditional brass to eco-brass and dezincification-resistant (DZR) alloys, ensuring safer drinking water systems and driving product upgrades.

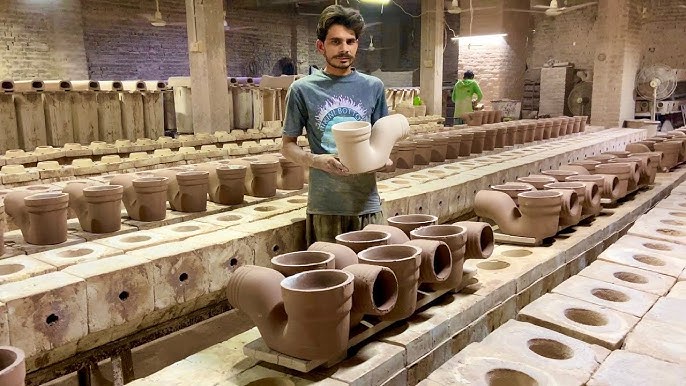

5. Supply Chain Resilience and Regional Manufacturing

Geopolitical uncertainties and post-pandemic supply chain disruptions have prompted manufacturers to localize production. India, China, and Turkey are emerging as key hubs for brass P-trap manufacturing, offering cost advantages and proximity to raw materials. This regional shift supports faster delivery times and reduced logistics costs.

6. Competitive Landscape and Market Consolidation

The market is witnessing increased consolidation, with major plumbing fixture companies acquiring niche brass component suppliers to vertically integrate and enhance product portfolios. At the same time, smaller players are focusing on customization and rapid prototyping to serve specialized architectural and design needs.

Conclusion

By 2026, the brass P-trap market will be characterized by innovation, sustainability, and compliance with global safety standards. While competition from plastic alternatives persists, brass remains the material of choice for high-performance and long-term plumbing solutions. Stakeholders who invest in eco-friendly materials, smart manufacturing, and regulatory alignment are likely to capture significant market share in the evolving global landscape.

Common Pitfalls When Sourcing Brass P-Trap – Quality and IP Concerns

Sourcing Brass P-Traps may seem straightforward, but overlooking key quality and intellectual property (IP) aspects can lead to performance failures, compliance issues, and legal risks. Here are the most common pitfalls to avoid:

Poor Material Quality and Composition

One of the biggest risks is receiving P-Traps made from substandard or misrepresented brass. Some suppliers may use low-grade brass alloys with high lead content or excessive impurities, which can:

- Compromise corrosion resistance and longevity

- Lead to premature leaks or structural failure

- Violate safety and environmental regulations (e.g., NSF/ANSI 61, lead-free mandates)

Always verify material certifications and demand proof of compliance with relevant standards.

Lack of Third-Party Certification

Many low-cost suppliers offer products without independent testing or certification. Uncertified P-Traps may not meet plumbing code requirements, leading to failed inspections or liability issues. Ensure products carry recognized certifications such as:

- NSF/ANSI 61 (drinking water system components)

- NSF/ANSI 372 (lead content compliance)

- UPC or cUPC (Uniform Plumbing Code)

Skipping this step risks non-compliance and potential recalls.

Inconsistent Manufacturing Tolerances

Poorly manufactured P-Traps often suffer from inconsistent threading, misaligned joints, or uneven wall thickness. These defects can result in:

- Difficult or improper installation

- Leaks at connection points

- Reduced flow efficiency

Inspect sample units for dimensional accuracy and thread quality before placing bulk orders.

Counterfeit or IP-Infringing Products

A significant risk when sourcing globally—especially from unverified suppliers—is receiving counterfeit or IP-infringing P-Traps. Some manufacturers copy patented designs, logos, or branding from reputable brands without authorization. Consequences include:

- Legal liability for importing or selling infringing products

- Seizure of goods by customs authorities

- Damage to brand reputation

Always vet suppliers thoroughly, request proof of design rights or licensing, and avoid suppliers offering “branded equivalents” at suspiciously low prices.

Inadequate Surface Finish and Corrosion Protection

Brass P-Traps should have a smooth, uniform finish to resist tarnishing and corrosion. Poor plating or polishing can lead to:

- Early oxidation or pitting

- Contamination of water supply

- Aesthetic defects in visible installations

Evaluate the surface treatment and, if applicable, confirm the presence of protective coatings like chrome plating.

Insufficient Documentation and Traceability

Reliable suppliers provide full product traceability, including material test reports (MTRs), compliance certificates, and batch numbers. Lack of documentation makes it difficult to:

- Verify authenticity and quality

- Respond to customer complaints or failures

- Meet regulatory audit requirements

Insist on complete documentation as part of your procurement process.

By proactively addressing these quality and IP-related pitfalls, you can ensure reliable performance, regulatory compliance, and legal safety when sourcing Brass P-Traps.

H2: Logistics & Compliance Guide for Brass P-Trap

Product Overview

The Brass P-Trap is a plumbing fixture commonly used in sink drainage systems to prevent sewer gases from entering buildings. Constructed from high-quality brass, it offers durability, corrosion resistance, and a polished finish suitable for both residential and commercial installations.

H2: Regulatory Compliance

1. Material Safety and Environmental Standards

– RoHS (Restriction of Hazardous Substances): Ensure the brass alloy used complies with RoHS directives, particularly limiting lead content in plumbing products. Many regions require lead-free compliance (e.g., <0.25% lead by weight in wetted surfaces).

– NSF/ANSI 61 and NSF/ANSI 372: Certification required for products in contact with drinking water. Verify that the Brass P-Trap is certified to NSF/ANSI 61 for health effects and NSF/ANSI 372 for lead content.

– EPA Safe Drinking Water Act (USA): Complies with the “Lead-Free” definition under the Reduction of Lead in Drinking Water Act (effective since 2014).

2. International Standards

– CE Marking (Europe): Required for sale in the European Economic Area (EEA). Indicates conformity with health, safety, and environmental protection standards.

– UKCA Marking (UK): Required for the UK market post-Brexit; may replace CE marking depending on regulations.

– WRAS Approval (UK): Certification by the Water Regulations Advisory Scheme ensures compliance with UK water supply regulations.

– AS/NZS 3500 (Australia/New Zealand): Must meet Australian standards for plumbing and drainage systems.

H2: Packaging and Labeling Requirements

- Product Labeling: Each unit must be clearly labeled with:

- Manufacturer name and country of origin

- Material composition (e.g., “DZR Brass” or “Lead-Free Brass”)

- Compliance marks (NSF, CE, WRAS, etc.)

- Model number and size (e.g., 1.25” or 32mm)

- Packaging: Use protective packaging to prevent scratches or deformation. Include installation instructions and compliance documentation.

H2: Import and Export Compliance

1. Harmonized System (HS) Code

– Recommended HS Code: 7412.10 – “Plumbing fixtures, of copper or copper alloys” (brass is a copper-zinc alloy).

Note: Confirm local tariff classification as codes may vary by country.

2. Customs Documentation

– Commercial Invoice

– Packing List

– Certificate of Origin

– Test Reports or Certifications (NSF, RoHS, etc.)

– Bill of Lading/Air Waybill

3. Import Restrictions

– Verify destination country’s plumbing code requirements. Some countries restrict or ban high-lead-content fixtures.

– Brazil, Canada, and Middle Eastern countries may require additional product certification (e.g., INMETRO, CSA, SASO).

H2: Shipping and Handling

- Weight & Dimensions: Standard Brass P-Trap (1.25″): approx. 0.5 kg, packaged size: 20 x 10 x 10 cm.

- Shipping Method: Suitable for air, sea, and ground freight. Use palletized shipments for bulk orders.

- Storage Conditions: Store in a dry, indoor environment to prevent oxidation or tarnishing. Avoid exposure to saltwater or high-humidity areas.

H2: Installation and Usage Compliance

- Must be installed in accordance with local plumbing codes (e.g., IPC – International Plumbing Code, UPC – Uniform Plumbing Code).

- Use only with compatible piping materials (PVC, copper, PEX) and appropriate sealants or thread tape (e.g., PTFE tape for threaded joints).

- Regular inspection recommended to ensure no leaks or buildup that could compromise function.

H2: Warranty and After-Sales Support

- Standard warranty: 5–10 years against manufacturing defects, depending on manufacturer.

- Provide technical support and replacement parts upon request.

- Maintain records of compliance certifications for audits or customer requests.

H2: Sustainability and End-of-Life

- Brass is 100% recyclable. Encourage proper disposal or recycling through metal reclamation programs.

- Comply with WEEE (Waste Electrical and Electronic Equipment) directives if applicable, though typically not required for standalone plumbing fittings.

Ensure all logistics and compliance procedures are regularly reviewed to reflect updates in international standards and regional regulations.

In conclusion, sourcing a brass P-trap requires careful consideration of quality, durability, corrosion resistance, and compliance with local plumbing codes. Brass P-traps offer superior strength and longevity compared to plastic alternatives, making them ideal for both residential and commercial applications, especially in high-moisture or high-usage environments. When sourcing, prioritize reputable suppliers or manufacturers that provide certified, lead-free brass options to ensure safety and regulatory compliance. Attention to correct sizing, finish (such as polished, brushed, or corrosion-resistant coating), and ease of installation will further ensure optimal performance. Overall, investing in a high-quality brass P-trap not only enhances the reliability of the plumbing system but also contributes to long-term cost savings through reduced maintenance and replacement needs.