The global brass hardware and medal manufacturing industry has experienced steady growth, driven by increasing demand across sectors such as awards and recognition, military honors, sports events, and decorative arts. According to Grand View Research, the global metal casting market—encompassing key brass fabrication processes—was valued at USD 138.4 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.1% from 2023 to 2030. A significant portion of this growth is attributed to the rising demand for customized brass components, including medals and commemorative plaques. Additionally, Mordor Intelligence projects increased regional production capacity in Asia-Pacific—particularly in India and China—where cost-effective manufacturing and skilled metalworking craftsmanship support the expansion of specialized brass product exporters. With global events reigniting demand for physical recognition symbols post-pandemic, the need for high-quality, durable, and intricately designed brass medals has surged. This backdrop sets the stage for identifying the top 10 brass medal manufacturers that combine precision engineering, scalability, and innovation to lead the market.

Top 10 Brass Medal Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

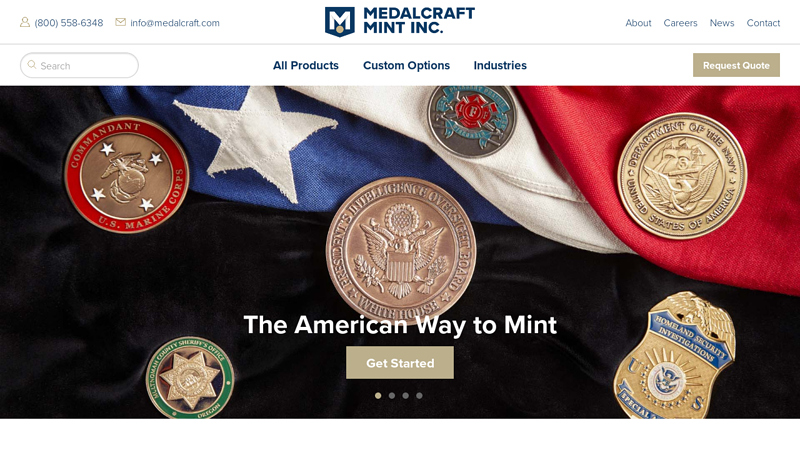

#1 Medalcraft Mint Inc.

Domain Est. 1997

Website: medalcraft.com

Key Highlights: Medalcraft Mint is proud to produce American-made medals, challenge coins and other custom-designed items for these dedicated individuals….

#2 Custom Challenge Coins and Fiesta Medals in San Antonio

Domain Est. 2002

Website: celebrateexcellence.com

Key Highlights: We are the nation’s highest rated designer and manufacturer for challenge coins, Fiesta medals & law enforcement badges….

#3 Custom Brass Medals Manufacturer from Faridabad

Domain Est. 2020

Website: aakritianos.com

Key Highlights: Manufacturer of Brass Medal – Custom Brass Medals, Gold Plated Sport Medal, Gold Plated Figure Holding Medal offered by Aakriti Anos Private Limited, ……

#4 Custom Brass Medals Manufacturer

Domain Est. 2022

Website: kingtaicrafts.com

Key Highlights: Custom Design Options for Brass Medals. At Kingtai, we offer fully customizable brass medals with options for color, size, design, shape, material, and logo….

#5 2 Inch Horse Themed Brass Medal in Gold, Silver, or Bronze with …

Domain Est. 1996

Website: classic-medallics.com

Key Highlights: 2–4 day delivery 30-day returnsOn the front of this 2 inch brass medal is an intricate engraving of the side profile of a horse, as well as an all encompassing laurel wreath that f…

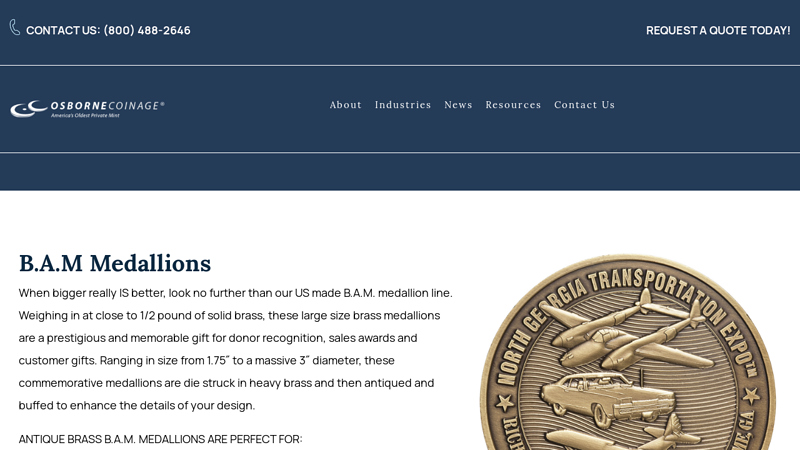

#6 Commemorative Brass Medallions

Domain Est. 1997

Website: osbornecoin.com

Key Highlights: Customize your own commermorative medallions from Osborne Coinage today. Our 1/2 pound B.A.M. brass medallions can be made with your own personal design….

#7 Solid Brass Plaque Archives • Medal Makers

Domain Est. 1999

Website: bigburymint.com

Key Highlights: 35-day returnsMilitary Medals and Medal Services / Products tagged “Solid Brass Plaque”. Solid Brass Plaque. Showing the single result….

#8 Absi Co – medaLit.com

Domain Est. 2011

Website: medalit.com

Key Highlights: Absi Co – medaLit.com | Awards | Trophies | Plaques | Medals | عبسي · Home · Shop Our Products · Absiclusive Awards · Majestic Awards · Ultimatum Decoration….

#9 Design Your Custom Medals & Medallions

Domain Est. 2024

Website: trailblazerbadges.com

Key Highlights: Explore Types of Custom Medals. Discover our most popular custom medallion categories for your organization. Die struck brass medallion for the University of ……

#10 List of Manufacturers of U.S. Metal Emblems

Domain Est. 2006

Website: usmilitariaforum.com

Key Highlights: This list is alphabetical. See the following post for a list by code number. This catalog primarily lists manufacturers of metal emblems….

Expert Sourcing Insights for Brass Medal

H2: Market Trends Analysis for Brass Medal in 2026

As of 2026, the market landscape for brass medals—widely used in athletic events, academic recognition, military honors, and commemorative awards—reflects a convergence of evolving consumer preferences, sustainable manufacturing practices, and digital integration. Key trends shaping the brass medal industry during this period include:

-

Sustainability and Ethical Sourcing

Environmental consciousness has become a dominant factor in procurement decisions across sectors. By 2026, demand for brass medals made from recycled or ethically sourced copper and zinc has surged. Organizations are increasingly requiring suppliers to provide certifications confirming low carbon footprint production and responsible mining practices. Brands offering eco-friendly packaging and transparent supply chains are gaining competitive advantage. -

Customization and Personalization

The rise of on-demand manufacturing and advanced engraving technologies (e.g., laser etching and 3D metal printing) has enabled high levels of customization. Clients now expect personalized brass medals with QR codes linking to digital certificates, athlete profiles, or event highlights. This trend is particularly strong in corporate wellness programs, school competitions, and niche sports events. -

Digital Integration and NFT-Linked Awards

A notable innovation in 2026 is the integration of physical brass medals with digital assets. Some organizations are issuing non-fungible tokens (NFTs) that correspond to physical medals, creating verifiable, collectible digital twins. This hybrid model enhances perceived value and appeals to younger demographics, especially in esports, tech conferences, and innovation awards. -

Cost Pressures and Material Alternatives

Fluctuations in global metal prices—particularly copper—have prompted some organizations to explore brass alternatives or thinner, lightweight designs without compromising aesthetic quality. However, authentic brass remains preferred for premium awards due to its traditional luster and weight, signaling prestige and permanence. -

Growth in Emerging Markets

Demand for brass medals is expanding rapidly in Asia-Pacific, Latin America, and Africa, driven by increased investment in sports infrastructure, education, and national recognition programs. Localized production hubs are emerging to serve these markets, reducing shipping times and import costs. -

E-Commerce and Direct-to-Consumer Platforms

Online platforms specializing in custom awards have gained traction, offering rapid turnaround, design tools, and AI-assisted visualization. In 2026, businesses that combine user-friendly digital interfaces with high-quality brass craftsmanship are capturing significant market share.

Conclusion:

By 2026, the brass medal market is characterized by innovation, sustainability, and digital augmentation. To remain competitive, manufacturers and distributors must embrace eco-conscious practices, invest in digital integration, and offer flexible customization options. Those aligning with these trends are well-positioned for growth in an increasingly values-driven and tech-enabled marketplace.

Common Pitfalls When Sourcing Brass Medals (Quality, IP)

Sourcing brass medals—whether for awards, souvenirs, or promotional items—can be fraught with challenges, particularly concerning quality consistency and intellectual property (IP) risks. Being aware of these pitfalls helps avoid costly mistakes and reputational damage.

Poor Material Quality and Finish

One of the most frequent issues is receiving brass medals that do not meet specified material standards. Some suppliers may use low-grade brass alloys or substitute materials like zinc alloy (pewter) coated to look like brass. This leads to premature tarnishing, chipping, or discoloration. Additionally, poor plating (e.g., inadequate lacquer coating) results in rapid oxidation and diminished appearance over time.

Inconsistent Manufacturing Tolerances

Mass production can lead to variations in weight, thickness, and dimensions. Even slight deviations affect how the medals feel and present. Inconsistent polishing, engraving depth, or color matching in enamel fills also undermine perceived value and brand image.

Lack of Quality Control Oversight

Relying solely on supplier promises without third-party inspections or pre-shipment checks increases the risk of receiving substandard batches. Without defined quality benchmarks and verification processes, defects may go unnoticed until delivery.

Intellectual Property Infringement

Using copyrighted designs, logos, emblems, or likenesses without proper authorization is a serious legal risk. Some suppliers may offer to replicate popular designs or trademarks, but doing so without licenses exposes the buyer to lawsuits, customs seizures, and damage to brand integrity.

Unauthorized Design Replication by Suppliers

After providing a custom design, there’s a risk that unscrupulous suppliers reproduce and sell the same or similar medals to competitors. Without strong contractual IP protections (e.g., non-disclosure agreements and design ownership clauses), your unique design may quickly lose exclusivity.

Inadequate Documentation for IP Clearance

Failing to document permission rights for fonts, artwork, or organizational symbols can lead to disputes down the line. Always ensure written proof of licensing or permission, especially when medals include third-party content.

Misleading Claims About Origin or Authenticity

Some suppliers may falsely claim medals are “solid brass” or “handcrafted” when they are actually stamped or plated base metals. These misrepresentations can mislead customers and violate advertising standards.

Mitigation Strategies

To avoid these pitfalls:

– Request material certifications and conduct lab testing if necessary.

– Implement clear quality specifications and conduct pre-production samples.

– Perform third-party inspections before shipment.

– Secure written IP rights and include strong clauses in supplier contracts.

– Verify all design elements are either original or properly licensed.

– Work with reputable suppliers who respect IP and have proven quality control processes.

Proactive due diligence in both quality assurance and intellectual property protection ensures that your brass medals reflect the intended prestige and legality.

Logistics & Compliance Guide for Brass Medal

This guide outlines the essential logistics and compliance considerations for handling, transporting, and managing brass medals to ensure adherence to regulatory standards, maintain product quality, and support efficient operations.

Product Handling and Storage

Brass medals must be stored in a clean, dry, and temperature-controlled environment to prevent tarnishing, corrosion, or surface damage. Avoid exposure to high humidity, direct sunlight, or corrosive chemicals. Store medals in protective packaging—such as poly bags, padded containers, or anti-tarnish wraps—and keep them off the floor on shelving units. Implement a first-in, first-out (FIFO) inventory system to minimize long-term storage and ensure freshness of protective coatings.

Packaging Standards

All brass medals should be individually wrapped or cushioned to prevent scratching or impact damage during transit. Use rigid outer packaging such as corrugated cardboard boxes with internal dividers or foam inserts. Clearly label packages with handling instructions, including “Fragile,” “This Side Up,” and contents description. Include product identifiers (e.g., SKU, batch number) on both internal and external packaging for traceability.

Domestic and International Shipping

When shipping domestically or internationally, ensure compliance with carrier requirements and postal regulations. For international shipments, prepare accurate commercial invoices detailing product description, value, weight, country of origin (typically where final manufacturing or assembly occurs), and Harmonized System (HS) code—commonly 7418.19 for brass articles not otherwise specified. Brass products may be subject to import duties or restrictions depending on destination country; verify these in advance.

Regulatory Compliance

Brass medals must comply with relevant material and safety regulations, especially if intended for use by children or as wearable items. Confirm that brass alloy composition adheres to restrictions on lead content under regulations such as the U.S. Consumer Product Safety Improvement Act (CPSIA) or the EU’s REACH and RoHS directives. Maintain documentation of material certifications and third-party test reports where applicable.

Customs Documentation and Export Controls

Prepare complete export documentation including packing lists, commercial invoices, and certificates of origin. Classify the product correctly under the appropriate export control classification number (ECCN), though most decorative brass medals fall under EAR99 (no specific license required). Ensure compliance with anti-dumping or trade restriction rules, particularly when sourcing raw materials or manufacturing from certain countries.

Labeling and Marking Requirements

Brass medals should be permanently marked with necessary identifiers such as manufacturer name, country of origin, and any required safety or certification marks. Packaging must include language-compliant labeling for the destination market (e.g., English for U.S., French for Canada, CE marking for EU). Avoid misleading claims about metal purity unless independently verified.

Environmental and Ethical Considerations

Source brass materials from suppliers that adhere to responsible mining and recycling practices. Document compliance with environmental standards such as ISO 14001 where possible. Ensure labor practices in the supply chain meet ethical standards, including adherence to local labor laws and avoidance of conflict materials.

Recordkeeping and Audit Readiness

Maintain organized records of all compliance documentation, shipping manifests, material test results, and export filings for a minimum of five years. Conduct periodic internal audits to verify adherence to logistics and compliance protocols. Be prepared to provide documentation upon request from customs authorities, regulatory bodies, or certification agencies.

Incident Response and Non-Conformance

Establish procedures for handling non-conforming products, shipping errors, or customs delays. Document root causes, implement corrective actions, and communicate with affected parties promptly. Retain records of all corrective and preventive actions (CAPA) for audit purposes.

Conclusion for Sourcing Brass Medals

In conclusion, sourcing brass medals requires a careful balance of quality, cost, customization, and reliable supply chain management. Brass remains a preferred material due to its durability, classic aesthetic, and versatility for engraving or plating. When selecting a supplier, it is essential to evaluate factors such as material purity, production capabilities, lead times, and compliance with environmental and ethical standards.

Establishing relationships with reputable manufacturers—whether domestic or overseas—can ensure consistent quality and timely delivery. Additionally, clear communication regarding design specifications, finishes (such as polished, antiqued, or gold-plated), and packaging requirements is crucial to achieving the desired end product.

Ultimately, a strategic sourcing approach that considers both short-term needs and long-term goals will lead to successful procurement of brass medals that meet functional, aesthetic, and budgetary requirements for events, awards, or commemorative purposes.