The global architectural hardware market, driven by rising residential and commercial construction, has seen steady expansion in recent years. According to a 2023 report by Grand View Research, the global door hardware market was valued at USD 33.5 billion and is expected to grow at a compound annual growth rate (CAGR) of 6.8% from 2023 to 2030. A key driver in this growth is the increasing demand for premium, durable, and aesthetically appealing materials—brass being a top choice due to its corrosion resistance, longevity, and timeless elegance. Mordor Intelligence projects a similar trajectory, noting that urbanization and remodeling activities in emerging economies are accelerating demand for high-quality brass fixtures, particularly in doors and entryways. As a result, manufacturers specializing in brass doors are gaining prominence, combining craftsmanship with modern engineering to meet evolving design and security standards. In this context, identifying the top players becomes essential for architects, builders, and homeowners seeking value and durability. Here’s a look at the top 10 brass door manufacturers shaping the industry through innovation, quality, and market reach.

Top 10 Brass Door Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Baldwin Hardware

Domain Est. 1998

Website: baldwinhardware.com

Key Highlights: Baldwin Hardware is a leading provider of high-quality, stylish and durable door and cabinet hardware for both residential and commercial applications….

#2

Domain Est. 1998

Website: chicagobrass.com

Key Highlights: Chicago Brass Architectural hardware is a door hardware and cabinet hardware distributor with showrooms in Minneapolis, Minnesota, and Chicago.Lines distributed ……

#3 Newport Brass

Domain Est. 1998

Website: newportbrass.com

Key Highlights: Newport Brass Crafts Timeless Kitchen, Bath, and Shower Fixtures, Blending Heritage with Modern Refinement. Each Faucet, Shower System, and Tub Fitting is ……

#4 Baldwin Brass Hardware A Cape Cod Brass Site

Domain Est. 2000

Website: baldwinbrasshardware.com

Key Highlights: Baldwin Brass Hardware Quality Service and Selection. Authorized Dealer and Preferred Showroom. Baldwin’s #1 Distributor!…

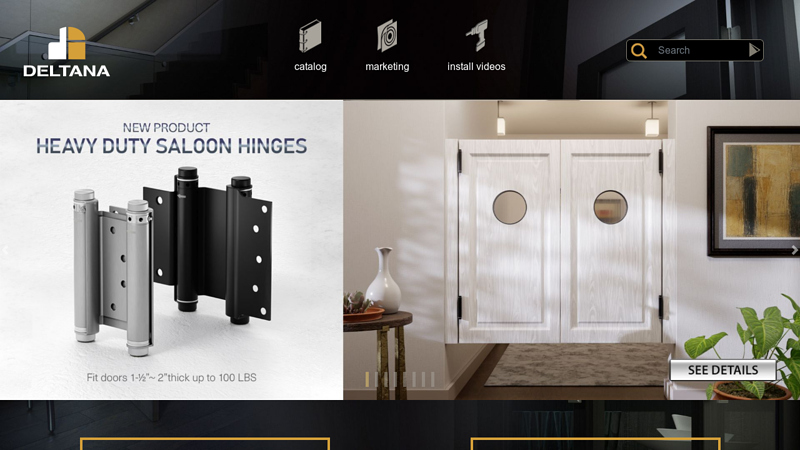

#5 to Deltana Enterprises

Domain Est. 2002

Website: deltana.net

Key Highlights: Deltana inventories America’s largest selection of architectural and door hardware in over nine fine finishes made from solid brass, zinc, aluminum, steel and ……

#6 Brass & Bronze Clad Doors & Frames

Domain Est. 2003

Website: ambico.com

Key Highlights: AMBICO’s brass and bronze clad doors offer elegant and durable solutions for upscale environments. Perfect for adding a touch of luxury to any space….

#7 Solid Brass, Hand

Domain Est. 2006

Website: josephgiles.com

Key Highlights: Decorative Door Hardware. Lever Handles, Door Knobs, Hinges & Sliding Door Fittings. Functional Door Hardware. Locks, Latches, Rebate Kits, Cylinders ……

#8 Door Hardware

Domain Est. 2009

Website: brandinobrass.com

Key Highlights: Brandino Brass Co. 2824 Central Avenue. Birmingham, AL, 35209. United States. 205-978-8900….

#9 Baldwin Hardware Direct

Domain Est. 2011

Website: baldwinhardwaredirect.com

Key Highlights: Browse our catalog of high-quality Baldwin hardware online. We carry doorknobs, locks, levers, touchscreen entrances, and other handcrafted home ……

#10 Water Street Brass

Domain Est. 2012

Website: waterstreetbrass.com

Key Highlights: We manufacture solid brass furniture, cabinet and door hardware for fine homes. With over 27 standard finishes, our hardware is ideal for all styles and ……

Expert Sourcing Insights for Brass Door

2026 Market Trends for Brass Door Hardware

The brass door hardware market in 2026 is poised for significant evolution, driven by shifting consumer preferences, technological advancements, and broader economic and environmental forces. Understanding these key trends is crucial for manufacturers, suppliers, and retailers to remain competitive and capitalize on emerging opportunities.

Sustainability and Responsible Sourcing Will Be Paramount

Environmental consciousness is no longer a niche concern but a mainstream driver of purchasing decisions. By 2026, consumers and commercial specifiers will demand demonstrable proof of sustainability. This includes:

* Traceable & Recycled Brass: Demand for brass hardware made from high percentages of recycled content (post-industrial and post-consumer) will surge. Certifications like Cradle to Cradle or EPDs (Environmental Product Declarations) will become essential for premium brands. Transparency in the supply chain, proving ethical mining practices and low environmental impact, will be a key differentiator.

* Durability as Sustainability: The inherent longevity of brass, especially solid brass, will be heavily marketed as a sustainable choice. Emphasis will shift from disposable fashion to timeless, repairable fixtures that reduce waste over decades.

* Low-Impact Finishes: Water-based, VOC-free, and non-toxic finishing processes will be standard. Consumers will scrutinize the environmental and health impacts of plating and coating methods.

Design: Fusion of Timeless Elegance and Modern Innovation

The aesthetic landscape will balance enduring appeal with contemporary desires:

* Modern Interpretations of Classic Styles: While traditional designs (e.g., Victorian, Art Deco) will persist, expect sleek, minimalist interpretations. Think clean lines, geometric shapes, and subtle detailing in polished, brushed, or dark brass finishes.

* Matte and Dark Finishes Dominate: Brushed brass (especially with a warmer tone) and sophisticated dark finishes like blackened brass, oil-rubbed bronze (often brass-based), and anthracite will continue their strong growth, favored for their modern, sophisticated, and fingerprint-resistant qualities.

* Increased Personalization: Demand for customization – unique sizes, bespoke designs, monogramming, and mixed finishes (e.g., brass knob on a satin nickel base) – will grow, particularly in high-end residential and boutique hospitality sectors.

Smart Integration and Enhanced Functionality

Technology will increasingly merge with traditional hardware:

* Smart Locks with Brass Aesthetics: The rise of smart locks (keyless entry, app control, biometrics) won’t diminish brass’s appeal. Instead, manufacturers will focus on integrating smart mechanisms behind premium brass escutcheons, knobs, and levers. The visible hardware will retain its luxurious brass finish while offering modern security and convenience.

* Focus on Ergonomics and Accessibility: Designs will prioritize ease of use, incorporating better ergonomics, lever handles (ADA-compliant), and features catering to aging-in-place and universal design principles. Brass’s malleability allows for comfortable shaping.

* Enhanced Security Features: Beyond smart tech, demand for robust physical security (ANSI Grade 1 locks, reinforced strike plates, pick-resistant mechanisms) integrated into brass hardware will remain strong, especially in urban areas.

E-commerce and Direct-to-Consumer (DTC) Channels Accelerate

The purchasing journey is transforming:

* Visual Discovery Online: High-quality 3D renderings, AR (Augmented Reality) tools allowing users to “visualize” brass hardware on their own doors via smartphone, and detailed finish comparisons online will be critical for conversion.

* DTC Growth: Established brass hardware brands and new entrants will leverage DTC models to offer competitive pricing, better margins, and direct customer relationships, bypassing traditional trade channels.

* B2B2C Platforms: Integration with online interior design platforms and home renovation marketplaces will become important for reaching consumers during the planning phase.

Economic and Supply Chain Resilience

The market will navigate ongoing challenges:

* Price Volatility Management: Fluctuations in copper prices (a primary component of brass) will necessitate strategic sourcing, hedging, and potentially tiered product lines (solid brass vs. brass-plated zinc alloy) to cater to different price points.

* Supply Chain Diversification: Geopolitical tensions and past disruptions will push manufacturers to diversify sourcing and manufacturing locations to mitigate risks, potentially impacting costs and lead times.

* Focus on Value over Cheapness: While budget options exist, the premium segment (solid brass) will emphasize craftsmanship, longevity, and sustainability as justifying higher price points, appealing to consumers investing in home value and quality.

In conclusion, the 2026 brass door hardware market will reward brands that successfully blend sustainable practices, innovative design (especially in finishes), seamless smart technology integration, and robust e-commerce capabilities. Success will hinge on demonstrating authenticity, quality, and adaptability in a market increasingly defined by conscious consumption and digital engagement.

Common Pitfalls Sourcing Brass Doors (Quality, IP)

Sourcing brass doors—whether for residential, commercial, or luxury applications—requires careful consideration of both material quality and intellectual property (IP) concerns. Overlooking these aspects can lead to compromised durability, aesthetic inconsistencies, legal issues, or reputational damage. Below are common pitfalls to avoid:

Poor Material Quality and Brass Authenticity

One of the most frequent issues when sourcing brass doors is receiving products that do not meet the expected quality standards. Many suppliers offer “brass-finished” or “brass-plated” doors instead of solid brass, leading to premature wear, tarnishing, or corrosion. Solid brass doors are more durable and maintain their value over time, but they are also more expensive. Buyers may be misled by visual similarity without verifying the core material.

Additionally, inconsistencies in alloy composition (e.g., varying copper-zinc ratios) can affect color, strength, and resistance to environmental factors—especially in coastal or high-humidity areas. Lack of proper certification or material test reports (MTRs) increases the risk of substandard products.

Inadequate or Misrepresented IP Protection

Brass door designs, especially those with intricate craftsmanship or branded architectural elements, may be protected by intellectual property rights such as design patents, copyrights, or trademarks. A major pitfall arises when buyers unknowingly source doors that replicate patented or copyrighted designs without proper licensing.

This is particularly common when sourcing from overseas manufacturers or third-party suppliers who replicate high-end European or designer door styles. Purchasing and installing such doors can expose the buyer or project to legal liability, including cease-and-desist orders, fines, or forced removal of the product.

Lack of Compliance with IP Laws in Global Sourcing

When sourcing internationally—especially from regions with lax IP enforcement—buyers may inadvertently support counterfeit or pirated products. While the price may be attractive, the long-term risks include legal exposure and damage to brand reputation, especially in commercial or luxury developments where original design integrity is paramount.

Insufficient Due Diligence on Suppliers

Failing to verify a supplier’s credibility, production capabilities, and adherence to IP laws increases the likelihood of encountering quality defects or IP violations. Many suppliers may not disclose the true origin of designs or materials, making it difficult to trace authenticity or legal compliance.

No Clear Contracts Addressing Quality and IP Rights

Procurement agreements that do not explicitly define material specifications (e.g., solid brass vs. plated) or include IP indemnification clauses leave buyers vulnerable. Without clear terms, recourse in case of disputes is limited, and enforcement can be costly—especially across international jurisdictions.

Conclusion

To mitigate these risks, buyers should:

– Require material certifications and conduct third-party testing when necessary.

– Verify the originality of designs and request proof of IP compliance.

– Work with reputable suppliers who provide transparent sourcing and legal documentation.

– Include detailed quality and IP clauses in procurement contracts.

Proactive due diligence ensures both the longevity of the product and legal safety in the supply chain.

Logistics & Compliance Guide for Brass Door

This guide outlines the essential logistics and compliance considerations for managing the movement, storage, and regulatory adherence of brass door products throughout the supply chain. Ensuring compliance and efficient logistics helps prevent delays, reduce costs, and maintain product quality.

Product Classification and Material Requirements

Brass doors are typically composed of copper-zinc alloys and may include other materials such as steel reinforcements, glass, or wood components. Accurate classification under international trade codes is critical. Use Harmonized System (HS) codes such as 8302.41 (doors, windows, and their frames, of brass) for customs declarations. Ensure brass content meets relevant industry standards (e.g., ASTM B283 for cast brass) and environmental regulations regarding heavy metals.

Packaging and Handling Standards

Proper packaging is essential to prevent scratches, dents, and corrosion during transit. Use moisture-resistant wrapping, corner protectors, and sturdy wooden crates or pallets for large units. Clearly label packages with handling instructions (e.g., “Fragile,” “This Side Up”) and include product identification, batch numbers, and safety warnings. Avoid direct contact between brass surfaces and corrosive materials during storage and transport.

Domestic and International Shipping

For domestic shipments within the U.S. or EU, adhere to carrier-specific guidelines and transportation safety rules. For international shipping, prepare complete documentation including commercial invoices, packing lists, and certificates of origin. Confirm compliance with destination country import regulations. Consider Incoterms (e.g., FOB, CIF) to define responsibility for shipping and insurance. Use freight forwarders experienced in handling metal architectural products.

Customs Clearance and Duties

Ensure all import/export documentation is accurate and submitted in advance to avoid customs delays. Provide detailed product descriptions, material composition, country of origin, and declared value. Be aware of applicable tariffs, anti-dumping duties, or trade restrictions on brass products in target markets. Maintain records for audit purposes for a minimum of five years, as required by most customs authorities.

Environmental and Safety Compliance

Brass doors may contain trace elements regulated under environmental laws such as REACH (EU) or TSCA (U.S.). Confirm compliance with restrictions on substances like lead content (e.g., <0.25% lead for “lead-free brass” in potable water applications, per U.S. Safe Drinking Water Act). Provide Safety Data Sheets (SDS) when required. Follow OSHA guidelines for workplace handling during manufacturing and warehousing.

Quality Control and Certification

Implement quality assurance protocols at manufacturing and pre-shipment stages. Conduct inspections for dimensional accuracy, surface finish, and mechanical performance. Where applicable, obtain third-party certifications (e.g., CE marking for Europe, ANSI/AAMA for U.S. performance standards). Retain inspection reports and test certificates to support compliance claims.

Storage and Inventory Management

Store brass doors in dry, climate-controlled environments to prevent tarnishing or moisture damage. Elevate products off the floor and use protective coverings. Follow first-in, first-out (FIFO) inventory practices to minimize long-term storage risks. Monitor storage conditions regularly and document environmental readings if required for compliance.

Regulatory Updates and Audits

Assign a compliance officer or team to monitor changes in trade policies, environmental regulations, and building codes affecting brass door products. Conduct periodic internal audits of logistics processes and documentation. Stay informed about sanctions, tariff changes, or new import requirements in key markets to ensure ongoing compliance.

Conclusion

Effective logistics and compliance management for brass doors requires attention to material standards, accurate documentation, proper handling, and adherence to international regulations. By following this guide, businesses can ensure smooth operations, minimize legal risks, and deliver high-quality products reliably to customers worldwide.

Conclusion for Sourcing Brass Doors:

Sourcing brass doors requires a strategic approach that balances quality, cost, durability, and aesthetic appeal. After evaluating various suppliers, manufacturing methods, and market options, it is evident that selecting the right brass door involves considering factors such as material composition (solid brass vs. brass-clad), craftsmanship, finish options, and compliance with industry standards. Direct sourcing from reputable manufacturers—especially in regions known for metal craftsmanship—can offer cost advantages and customization opportunities, while local suppliers may provide faster delivery and easier communication.

Additionally, attention should be given to long-term value, including maintenance requirements, corrosion resistance, and architectural compatibility. Establishing strong supplier relationships, conducting thorough quality inspections, and requesting product samples are essential steps to ensure reliability and satisfaction.

In conclusion, a well-informed sourcing strategy that prioritizes quality, sustainability, and total cost of ownership will lead to the successful acquisition of brass doors that meet both functional needs and design expectations.