The global bowling equipment market has experienced steady growth, driven by rising participation in recreational sports and increased investment in automated maintenance solutions. According to a report by Mordor Intelligence, the global bowling equipment market was valued at approximately USD 450 million in 2023 and is projected to grow at a CAGR of over 4.5% from 2024 to 2029. A key contributor to this trend is the rising demand for high-performance maintenance tools, particularly bowling ball polisher machines, which help preserve lane conditions and extend ball lifespan. With technological advancements in motor efficiency, dust extraction, and user-friendly interfaces, manufacturers are increasingly focusing on innovation to capture a larger share of this expanding niche. As bowling alleys, pro shops, and training centers prioritize equipment automation and precision care, the need for reliable, high-quality polishing systems has never been greater. This growing demand underscores the importance of identifying the top manufacturers leading the charge in performance, durability, and technological integration.

Top 8 Bowling Ball Polisher Machine Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Bowling Alley Equipment Manufacturer & Supplier

Domain Est. 2004

Website: eternitybowling.com

Key Highlights: As a professional bowling alley equipment manufacturer, with more than 25 years of experience, specializing in bowling manufacturing and setting up bowling ……

#2 Bowling Ball Maintenance

Domain Est. 2008

Website: polishyourball.com

Key Highlights: Produces a Factory-Like circular scratch pattern. · Has a shaft for attaching to your 3/8″ drill. · Hook and Loop for quick abrasive pad changes. · Terry Cloth ……

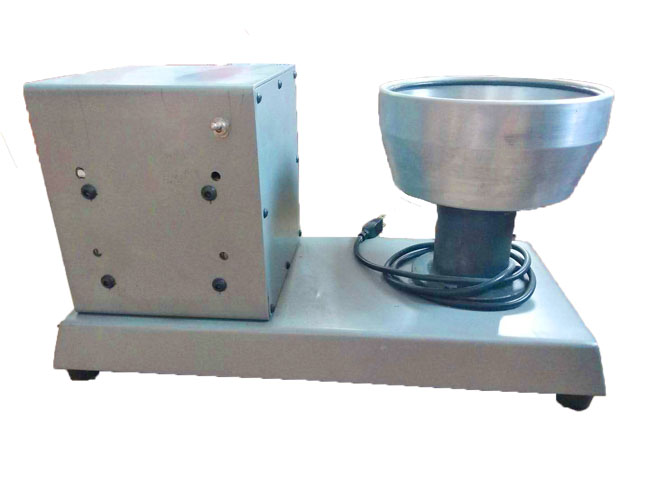

#3 High Quality Bowling Polishing Machine Manufacturers …

Domain Est. 2019

Website: bowlingeternity.com

Key Highlights: Details: this is the bowing ball polish machine, keep the bowling ball surface smoothly; 220V 50/60HZ; nice condition and good price; suitable for bowling ball ……

#4 Neo Tac Bowling Ball Cleaners, Polishes and Lane Products

Domain Est. 1997

Website: neotac.com

Key Highlights: 30 Years of creating quality, innovative bowling ball, cleaner, polish, and resurfacing products. Alongside our lane conditioner, and lane cleaning ……

#5 Big B Bowling Ball Cleaner

Domain Est. 1997

Website: brunswickbowling.com

Key Highlights: Features and Benefits · Cleans oil and belt marks from the ball · Works on all types of bowling balls ……

#6 to Innovative Bowling Products

Domain Est. 1997

Website: innovativebowling.com

Key Highlights: Shop by category: Drilling Equipment, Hand Tools, Measuring & Fitting, Ball Layout, Hole Finishing, Surface Maintenance, Oil Extraction, Plugging & Accessories….

#7 KEGEL

Domain Est. 1998

Website: kegel.net

Key Highlights: The place for pinsetter and lane machine mechanics to access tips, tricks and valuable information. KMK WEB SITE ……

#8 ZOT Ball Conditioning Machines

Domain Est. 2000

Website: wpbowling.com

Key Highlights: The GlossBoss II retains the same high polishing performance as the original machine – and all for a price tag that is more than 20-percent less than a ……

Expert Sourcing Insights for Bowling Ball Polisher Machine

2026 Market Trends for Bowling Ball Polisher Machines

Rising Demand from Bowling Enthusiasts and Pro Shops

By 2026, the market for bowling ball polisher machines is expected to experience steady growth, primarily driven by an increasing number of dedicated bowlers and specialized pro shops. As recreational bowling continues to gain traction as both a competitive sport and social activity, players are investing more in ball maintenance to preserve performance and extend ball life. This shift has led to higher demand not only in commercial pro shops but also among serious amateur bowlers who now opt for personal polishing units, fueling expansion in the consumer-grade machine segment.

Technological Advancements and Automation

A key trend shaping the 2026 landscape is the integration of smart technology and automation in bowling ball polisher machines. Manufacturers are incorporating digital controls, programmable polishing cycles, and sensor-based systems to ensure consistent results and reduce user error. Some advanced models now feature IoT connectivity, allowing pro shops to monitor machine usage, schedule maintenance, and track polishing history for customer service optimization. These innovations improve precision, efficiency, and user experience, setting new industry standards.

Emphasis on Eco-Friendly and Low-Maintenance Designs

Environmental consciousness is influencing product development, with 2026 seeing a rise in energy-efficient motors, reduced chemical usage, and recyclable materials in polisher construction. Consumers and businesses alike are prioritizing sustainability, leading to demand for machines that minimize waste and operate with lower power consumption. Additionally, manufacturers are focusing on easier-to-clean designs and longer-lasting components to reduce maintenance costs and downtime.

Expansion of E-Commerce and Direct-to-Consumer Sales

The distribution model for bowling ball polisher machines is evolving, with e-commerce platforms playing a larger role by 2026. Online retailers and brand-owned websites are making high-quality polishers more accessible to individual bowlers and small pro shops globally. Enhanced product descriptions, video demonstrations, and customer reviews help buyers make informed decisions, reducing reliance on traditional brick-and-mortar suppliers and expanding market reach.

Growing Customization and Multi-Functionality

Bowling ball care is becoming increasingly personalized, prompting manufacturers to offer polishers with customizable speed settings, interchangeable pads, and compatibility with various ball materials (reactive resin, urethane, plastic). By 2026, multi-functional machines that combine polishing, cleaning, and surface restoration in a single unit are gaining popularity, offering space and cost savings—especially valuable for small pro shops and home users.

Regional Market Growth and Emerging Markets

While North America and Europe remain dominant markets due to established bowling cultures, regions like Asia-Pacific and Latin America are showing promising growth. Countries such as Japan, South Korea, and Brazil are witnessing increased bowling alley development and youth engagement, creating new opportunities for polisher machine sales. Localized marketing and affordable entry-level models are helping penetrate these emerging markets by 2026.

Conclusion

The 2026 market for bowling ball polisher machines reflects a blend of technological innovation, consumer demand for performance and sustainability, and global market expansion. As the bowling industry modernizes, polisher manufacturers that prioritize automation, eco-design, and user accessibility are poised to lead in this evolving landscape.

Common Pitfalls When Sourcing a Bowling Ball Polisher Machine (Quality & Intellectual Property)

Sourcing a bowling ball polisher machine, especially from overseas manufacturers, involves several risks related to product quality and intellectual property (IP). Being aware of these pitfalls can help buyers make informed decisions and avoid costly mistakes.

Poor Build Quality and Durability

Many low-cost machines are constructed with substandard materials such as thin-gauge metals, low-grade plastics, and inferior motors. This compromises the machine’s longevity and performance, leading to frequent breakdowns, inconsistent polishing results, and higher maintenance costs over time. Buyers may find that machines fail well before their expected lifespan, especially under commercial use.

Inaccurate or Inconsistent Polishing Performance

Lower-tier machines often lack precision engineering, resulting in uneven polishing, vibration, or inconsistent surface finishes. This can damage bowling balls or fail to meet the standards required by professional bowlers or pro shops. Some machines may not accommodate different ball sizes or surface grits effectively, limiting their versatility.

Lack of Safety Features

Economical models may omit essential safety components such as emergency stop buttons, protective guards, or proper electrical insulation. This poses risks to operators and may result in non-compliance with safety regulations in certain markets, particularly in the EU or North America.

Misrepresentation of Specifications

Suppliers may exaggerate motor power, polishing speed, or compatibility with various ball types. Buyers might receive a machine that performs below advertised capabilities. Always verify specifications through independent testing or third-party inspection reports before finalizing a purchase.

Intellectual Property (IP) Infringement Risks

Some manufacturers produce machines that closely mimic patented designs or branded products (e.g., duplicating features of well-known brands like Storm, Brunswick, or CATS). Sourcing such machines exposes buyers to legal risks, including customs seizures, lawsuits, or reputational damage, especially when importing into IP-enforcement-heavy regions like the U.S. or EU.

No IP Protection for Custom Designs

If you’re developing a custom polisher design, failing to secure patents or trademarks before sharing designs with manufacturers—especially in jurisdictions with weak IP enforcement—can lead to design theft. Suppliers may replicate and sell your design to competitors without recourse.

Inadequate After-Sales Support and Spare Parts

Many budget suppliers offer limited technical support, training, or access to replacement parts. When a machine breaks down, sourcing spare motors, polishing pads, or control boards can be difficult or expensive, leading to prolonged downtime.

Non-Compliance with Regional Standards

Machines may not meet electrical, EMC, or CE/UL certification requirements. Importing non-compliant equipment can result in shipment rejection, fines, or liability issues. Always confirm that the machine adheres to the regulatory standards of the target market.

Hidden Costs from Poor Quality Control

Initial cost savings can be quickly offset by hidden expenses such as repairs, replacements, shipping returns, and labor downtime. Conducting factory audits or arranging third-party quality inspections (e.g., via SGS or Bureau Veritas) can help mitigate this risk.

Limited Warranty and Accountability

Some suppliers offer short or vague warranty terms and are difficult to hold accountable when issues arise. Ensure warranty coverage is clearly defined in writing and includes response timeframes and return policies.

By recognizing these common pitfalls—particularly those related to build quality, performance accuracy, and IP exposure—buyers can take proactive steps such as vetting suppliers thoroughly, verifying certifications, protecting original designs, and investing in reliable, compliant equipment.

Logistics & Compliance Guide for Bowling Ball Polisher Machine

Overview

This guide outlines the essential logistics and compliance considerations for the shipment, import/export, handling, and use of a Bowling Ball Polisher Machine. Adhering to these guidelines ensures safe, legal, and efficient operations across the supply chain and end-user environment.

International Shipping & Documentation

Ensure all international shipments comply with relevant regulations and include accurate documentation. Required documents typically include a commercial invoice, packing list, bill of lading/airway bill, and, where applicable, a certificate of origin. Verify if the machine requires an export license based on destination country regulations, particularly under dual-use or machinery export control lists.

Harmonized System (HS) Code Classification

Correctly classify the Bowling Ball Polisher Machine using the appropriate HS code to determine import duties and regulatory requirements. A typical classification may fall under 8479.89 (“Machines of a kind used in laboratories… not elsewhere specified or included”), but confirm with local customs authorities. Accuracy prevents delays and penalties.

Packaging & Handling Requirements

Package the machine securely using robust materials to prevent damage during transit. Include shock-absorbing padding and secure internal components to minimize movement. Clearly label packages with handling instructions such as “Fragile,” “This Side Up,” and weight specifications. Use standardized pallets compliant with ISPM 15 for wooden packaging in international shipments.

Import/Export Regulations

Comply with import regulations of the destination country, including safety certifications, labeling, and conformity assessments. Check for restrictions on electrical equipment, motor-driven machinery, or specific materials used in the polisher. Notify relevant authorities if the machine contains hazardous substances (e.g., lubricants) subject to REACH, RoHS, or other environmental regulations.

Electrical & Safety Standards Compliance

Ensure the Bowling Ball Polisher Machine meets electrical safety standards applicable in the destination market. Key certifications include:

– CE Marking for European Union (under Machinery Directive 2006/42/EC and Low Voltage Directive)

– UL/ETL Listing for the United States and Canada

– RCM Mark for Australia and New Zealand

Verify voltage compatibility (e.g., 110V vs. 220V) and include appropriate power adapters or transformers if necessary.

Environmental & Chemical Compliance

If the machine uses or generates polishing compounds, dust, or waste materials, ensure compliance with environmental regulations. Provide Material Safety Data Sheets (MSDS/SDS) for any chemicals involved. Confirm that dust collection systems meet OSHA (US) or equivalent workplace safety standards to protect users from particulate exposure.

End-Use Certification & Registration

In some jurisdictions, industrial or commercial machinery may require registration with local safety or technical inspection bodies before operation. Verify whether end-users must obtain permits or certifications, particularly in commercial bowling centers or retail pro shops.

Warranty & After-Sales Support Logistics

Define warranty terms clearly, including coverage duration, service response times, and replacement part availability. Establish a logistics network for spare parts distribution and technician support. Provide multilingual user manuals and safety instructions to comply with local language requirements.

Disposal & End-of-Life Compliance

Advise customers on proper end-of-life disposal in accordance with WEEE (Waste Electrical and Electronic Equipment) directives or local e-waste regulations. Recommend recycling programs or certified disposal facilities to ensure environmentally responsible decommissioning.

Conclusion

Proper logistics planning and regulatory compliance are critical for the successful global distribution and operation of Bowling Ball Polisher Machines. Partner with experienced freight forwarders, stay updated on regulatory changes, and maintain thorough documentation to ensure smooth transit and legal adherence at every stage.

Conclusion: Sourcing a Bowling Ball Polisher Machine

After a thorough evaluation of market options, supplier capabilities, and technical specifications, sourcing a bowling ball polisher machine is a strategic investment for enhancing lane maintenance operations and improving the overall customer experience at bowling centers. The ideal machine should offer consistent polishing performance, durability, ease of use, and compatibility with various bowling ball materials.

Key considerations such as cost-effectiveness, after-sales service, warranty, energy efficiency, and safety features played a significant role in selecting reliable suppliers. Both domestic and international manufacturers offer competitive models, with some providing advanced automation and adjustable speed settings for customized results.

Ultimately, the selected bowling ball polisher machine balances performance, reliability, and value, ensuring long-term operational efficiency. By partnering with a reputable supplier and implementing proper maintenance protocols, the investment will contribute to extended ball life, superior lane conditions, and heightened customer satisfaction. Moving forward, continuous monitoring of equipment performance and staying informed about technological advancements will support ongoing optimization in bowling facility management.