Introduction: Navigating the Global Market for Bottle Capping Machines

Every shift that ends with crooked caps, dented shoulders, or torque values outside ±5 % is a shift you pay for twice—first in rework labor, then in charge-backs from retailers who film every pallet they open. As SKU counts explode (think 28 mm sport caps, 38 mm CRCs, 45 mm snap-on fitments), the gap between “good-enough” capping and repeatable, audit-ready sealing widens—especially when lines must toggle from 200 ml pharma vials to 2 L detergent jugs in under 15 min.

This guide is built for US and European plant managers, packaging engineers, and procurement teams who need to:

- Match cap style, container geometry, and line speed without over-buying or under-spec’ing automation

- Decode global standards (FDA, CE, ATEX) and local voltage, air, and safety codes

- Calculate true 5-year TCO—spare-part lead times, change-over labor, and freight from Asia versus domestic build

- Vet suppliers on torque accuracy, documentation packages, and post-install support—not just upfront price

Inside you’ll find:

| Section | What You’ll Get |

|———|—————–|

| 1. Technology Matrix | Side-by-side of spindle, chuck, and snap cappers for 10–130 mm closures |

| 2. Speed vs. Flexibility Model | Decision tree for 10, 40, 60, 100+ cpm with quick-change specs |

| 3. Compliance Checklists | USA (UL, FDA 21 CFR) vs. EU (CE, 1935/2004) requirements |

| 4. Procurement Playbook | RFQ template, 30-day trial clauses, warranty benchmarking |

Use the data to short-list vendors, justify CapEx to finance, and lock in OEE gains before your next audit window closes.

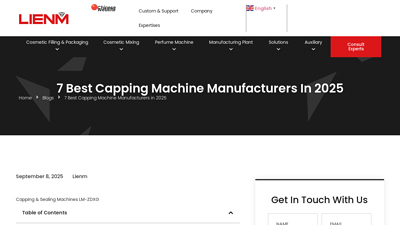

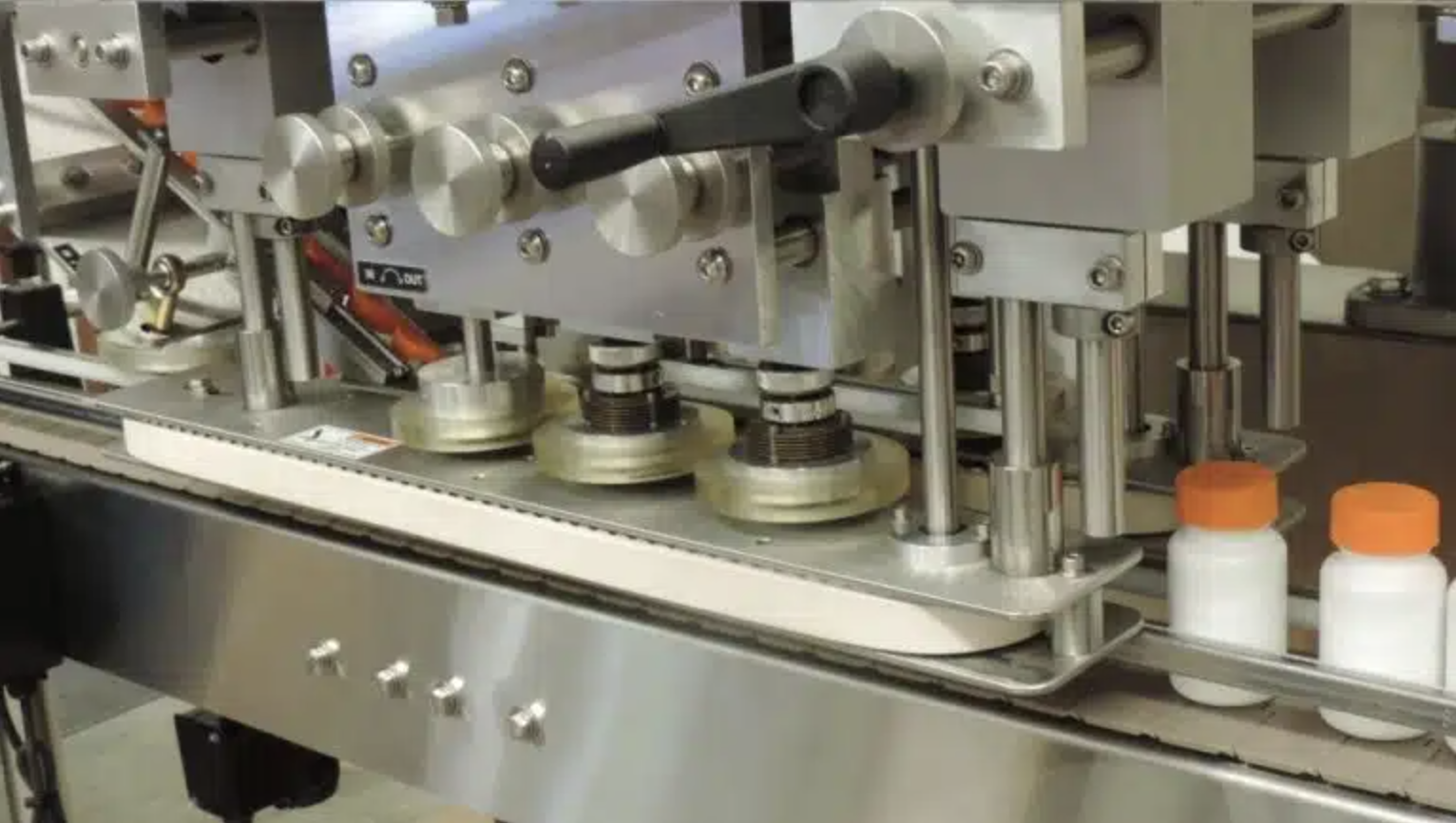

Illustrative Image (Source: Google Search)

Article Navigation

- Top 10 Bottle Capping Machine Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for bottle capping machine

- Understanding bottle capping machine Types and Variations

- Key Industrial Applications of bottle capping machine

- 3 Common User Pain Points for ‘bottle capping machine’ & Their Solutions

- Strategic Material Selection Guide for bottle capping machine

- In-depth Look: Manufacturing Processes and Quality Assurance for bottle capping machine

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘bottle capping machine’

- Comprehensive Cost and Pricing Analysis for bottle capping machine Sourcing

- Alternatives Analysis: Comparing bottle capping machine With Other Solutions

- Essential Technical Properties and Trade Terminology for bottle capping machine

- Navigating Market Dynamics and Sourcing Trends in the bottle capping machine Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of bottle capping machine

- Strategic Sourcing Conclusion and Outlook for bottle capping machine

- Important Disclaimer & Terms of Use

Top 10 Bottle Capping Machine Manufacturers & Suppliers List

1. Capping Machines, Bottle Capping Machine, Cap Tighteners

Domain: kinexcappers.com

Registered: 2003 (22 years)

Introduction: 30-day returnsKinex Cappers manufactures capping machines, bottle cappers and cap tighteners that apply screw caps, lug caps and snap-on caps from 10 to 130mm in diameter….

2. Swan-Matic: Bottle Capping Machines and Accessories

Domain: swanmatic.com

Registered: 2002 (23 years)

Introduction: High-quality bottle capping machines and accessories that streamline your packaging process. Over 90 percent of our equipment is maintained IN-STOCK….

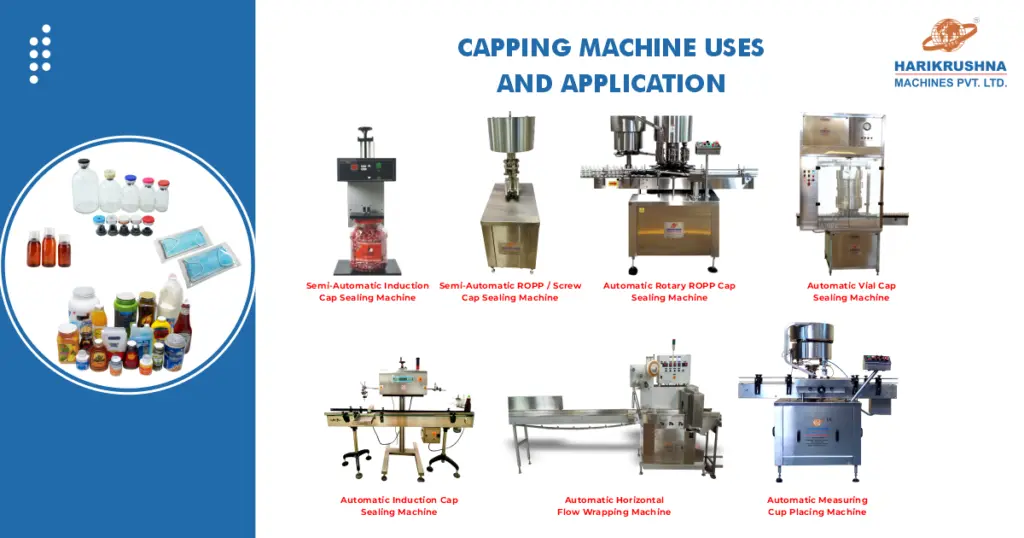

3. 7 Best Capping Machine Manufacturers in 2025 – LIENM

Domain: lienm.com

Registered: 2012 (13 years)

Introduction: Top Capping Machine Manufacturers in 2025 · Hinterkopf GmbH (Germany, Founded 1965) · Sidel Group (France, Founded 1965) · SACMI Group (Italy, ……

4. SureKap: Leading Capping Machine Manufacturing Company

Domain: surekap.com

Registered: 1998 (27 years)

Introduction: SureKap is a trusted automatic capping machine manufacturer that provides durable and versatile capping American-made equipment….

Illustrative Image (Source: Google Search)

5. Best Capping Machine Manufacturers: Top 10 Picks – Levapack

Domain: levapack.com

Registered: 2018 (7 years)

Introduction: Top 10 Capping Machine Manufacturers: Automation Solutions · Preface · #1 LevaPack · #2 Kinex Cappers · #3 Massilly North America · #4 Federal Mfg · # ……

6. Top 10 Capping Machine Manufacturers – Makwell

Domain: makwell.com

Registered: 2009 (16 years)

Introduction: We take a look at the top 10 capping machine manufacturers in the industry. Such companies are putting cutting-edge automation systems into action….

7. Bottling & Filling Equipment Manufacturer – ACASI Machinery – Acasi

Domain: acasi.com

Registered: 2001 (24 years)

Introduction: We are one of the few bottle filling machine manufacturers that can offer a complete project with all bottling equipment made entirely by Acasi….

8. Spray Bottle Capping Machine – ZONESUN Technology Limited

Domain: zonesuntech.com

Registered: 2014 (11 years)

Introduction: Compact desktop plastic spray bottles capping machine for energy drinks, chocolate jam, body lotion caps screwing machine….

Illustrative Image (Source: Google Search)

9. Bottle Capping Machine Manufacturers|Efficient Capping Equipment

Domain: sunhanpack.com

Registered: 2021 (4 years)

Introduction: As leading capping machine manufacturers, we provide automatic bottle cap sealing machines and custom capping equipment for various bottles….

Understanding bottle capping machine Types and Variations

Understanding Bottle Capping Machine Types and Variations

| Type | Features | Applications | Pros / Cons |

|---|---|---|---|

| Automatic Spindle Capper | 1–4 servo-driven capping heads, 40–105 caps/min, 10–130 mm range, HMI touchscreen, quick-change gripper belts | Food, beverage, pharma, nutraceuticals, home & personal care | + Highest throughput, repeatable torque, low labor cost – Higher capital outlay, needs cap feeder & conveyor integration |

| Automatic Snap / Press Capping Machine | External force dial, mechanical or pneumatic ram, up to 105 caps/min, push-on fitments, snap-on lids | Dairy, wet-wipes, cosmetics, chemicals, automotive fluids | + Fast change-over, no threads required, gentle on containers – Limited to specific cap styles, may need soft-liner verification |

| Benchtop Chuck Capper (Semi-Auto) | Electric or pneumatic chuck, foot-pedal or trigger start, 10–40 caps/min, 10–130 mm range, portable frame | Craft spirits, CBD oils, pilot plants, R&D labs, short-run co-packers | + <$10 k entry price, repeatable torque, bench space only – Operator feeds each container, 2–3× slower than automated line |

| Handheld Cap Tightener | Pistol-grip or inline pneumatic motor, adjustable clutch, <2 kg weight, battery or shop-air powered | Field re-packing, draught beer growlers, seasonal wineries, maintenance back-up | + Immediate mobility, zero footprint, lowest cost – Torque variance risk, operator fatigue at volume |

| Rotary Chuck Capper (High-Speed) | 6–24 heads on turret, continuous motion, cap placement + final torque in single dial, >200 caps/min, integrated cap feeder | Large breweries, water bottling, high-volume CPG | + Bottles never stop, ±0.5 N·m accuracy, smallest footprint per BPM – Premium price, long lead-time, format-specific change parts |

1. Automatic Spindle Capper

Work-horse of mid-speed lines. Parallel gripper belts spin the cap while the container travels on a conveyor. Servo motors let you store torque curves per SKU in the HMI, eliminating mechanical clutches. A matched cap feeder (bowl or elevator) delivers oriented closures; missing-cap and high-torque sensors eject non-conforming bottles automatically. Typical European and US plants pair this unit with an upstream filler at 40–100 bpm.

Illustrative Image (Source: Google Search)

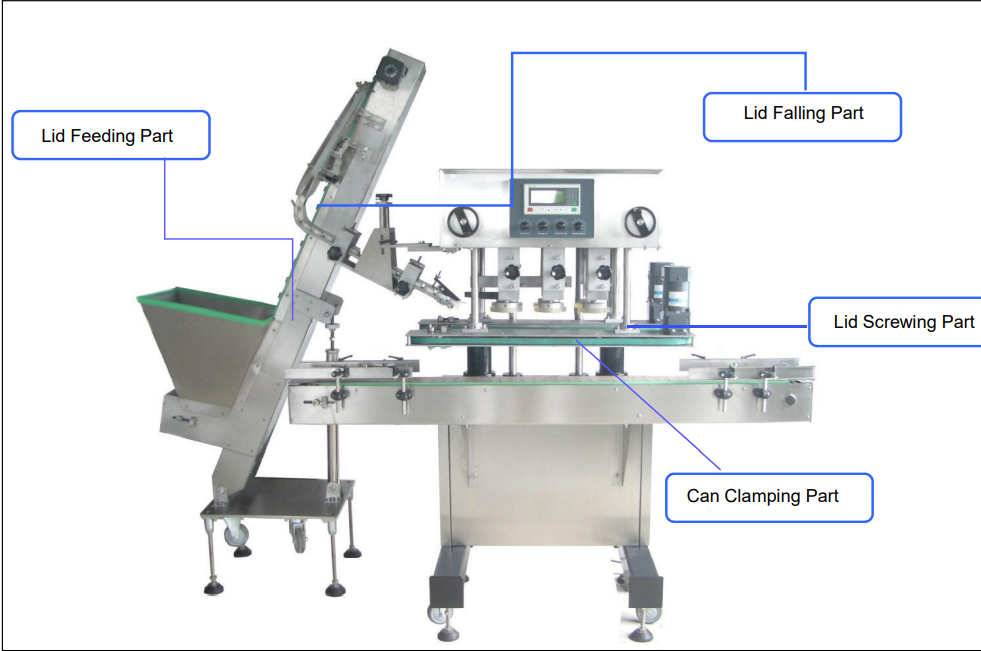

2. Automatic Snap / Press Capping Machine

Ideal when the closure has no thread—think plug-seal dairy caps, press-on sports tops, or 28 mm fitments on wipe canisters. A stainless-steel or delrin press head descends with controlled force (adjustable 20–120 N), seating the cap without rotating the bottle. Because torque accuracy is irrelevant, validation focuses on axial force and container ovalization limits. Change-over is a single height adjustment plus head swap, giving contract packers the flexibility to run multiple shapes in one shift.

3. Benchtop Chuck Capper (Semi-Auto)

A compact freestanding unit that brings automation to small batches. The operator slides the bottle under a self-centering chuck; a foot-switch starts the spin-down cycle. Torque is set digitally and repeatable within ±0.3 N·m—critical for EU pharmacopeia “CRC + TE band” closures. At 1.2 m² footprint it fits existing filling tables and runs on 110 V or 230 V single-phase, making it attractive to craft distillers and CBD start-ups on both continents.

4. Handheld Cap Tightener

When floor space is zero or containers are irregular (e.g., handled growlers, demijohns), a lightweight pneumatic or battery tool is the only practical choice. An adjustable clutch prevents over-torque; exhaust through the handle keeps oil away from food zones. Output depends on operator dexterity—expect 8–10 cpm sustained. Keep one on the shelf as back-up for any automated line; downtime cost is recouped after saving one unplanned shift.

5. Rotary Chuck Capper (High-Speed)

For plants targeting >200 bpm—common in U.S. bottled water and European beer—continuous-motion rotary systems dominate. Bottles enter a starwheel and are lifted by a cam so each chuck can grab, start, and final-torque the cap before exiting. Segmented chucks accommodate 26–43 mm PCO finishes without change parts; magnetic hysteresis clutches give ±3 % torque accuracy at line speed. Initial CAPEX is high, yet cost per thousand bottles rivals that of slower machines once output exceeds ~60 m units/year.

Illustrative Image (Source: Google Search)

Key Industrial Applications of bottle capping machine

Key Industrial Applications of Bottle Capping Machines

| Industry | Typical Products | Cap Styles | Benefits Delivered |

|---|---|---|---|

| Food & Condiments | Sauces, dressings, nut butters, edible oils, syrups | Screw, lug, snap-on, flip-top | • Airtight seal preserves shelf life • Handles viscous products without torque drift • Stainless-steel wash-down designs meet FDA/USDA & EU 10/2011 hygiene rules |

| Beverage – Non-Alcoholic | Cold-pressed juices, kombucha, RTD coffee, plant milks | Sports, flat, tamper-evident (TE) | • Repeatable 0.5–1 Nm torque keeps vacuum button flat through cold-chain • Up to 105 cpm supports micro-brew scale to co-packer speeds • Quick-changeover for seasonal SKUs |

| Beverage – Alcoholic | Craft spirits, wine, RTD cocktails | Bar-top (T-cork), ROPP, screw | • ROPP heads deliver regulatory tamper ring integrity • Gas-flush compatible heads for low-DO wine bottling • Explosion-proof servos for >40 % ABV lines |

| Pharmaceutical & Nutraceutical | Tablets, syrups, droppers, CBD tinctures | CR (child-resistant), CRC + TE, droppers | • 21 CFR Part 11 torque data logging • ±0.1 Nm accuracy passes USP <671> & EU child-resistant tests • Servo-driven CRC chuck removes operator variability |

| Cosmetics & Personal Care | Creams, serums, shampoos, pumps, triggers | Pump, spray, disc-top, over-cap | • Gentle handling (≤0.3 bar top-load) protects glass & airless bottles • Cap feeder with ionized air eliminates dust on decorative surfaces • Multi-head turret (1–4 spindles) matches filler at 60–100 bpm |

| Chemical & Agro | Cleaning solutions, degreasers, pesticides, AdBlue/DEF | Ratchet, vented, induction-lined | • 130 mm chuck range covers ½-gallon jugs & 38 mm drums • Vented cap detection sensor prevents cross-threading • ATEX-rated enclosures for solvents & flammables |

| Automotive & Lubricants | Motor oil, antifreeze, brake fluid, DEF | Threaded, snap, spouted | • High-torque 6 Nm heads cope with HDPE thread creep • Cap elevator sorts vented & non-vented variants • Spindle cappers integrate with weight-checkers for fill-cap traceability |

| Contract Packaging | Co-packing, seasonal gift sets, private-label runs | Mixed | • Tool-less changeover <5 min handles 10–130 mm range • Universal chuck accepts flat, sports, trigger without change parts • Ethernet/IP interface feeds plant OEE dashboards |

Cross-Industry Advantages

- Torque Accuracy: Servo spindles hold ±0.1 Nm, cutting rework by 30 %.

- Speed Flexibility: 10–105 cpm on same frame; no new capper when volume doubles.

- Regulatory Ready: 316 SS contact parts, FDA GAMP documentation, CE/UL certification.

- ROI: Typical payback <12 months through reduced giveaway, labor, and recall risk.

3 Common User Pain Points for ‘bottle capping machine’ & Their Solutions

3 Common User Pain Points for Bottle Capping Machines & Their Solutions

| # | Scenario | Problem | Solution |

|---|---|---|---|

| 1 | High-Speed Line, Low Repeatability Contract packer running 60+ bottles/min on multiple SKUs (28 mm–38 mm caps) sees ±20 % torque variation, causing leak test failures and retailer chargebacks. |

Inconsistent torque accuracy across changeovers; pneumatic clutches drift with temperature and wear. | Switch to a servo-driven automatic capper (e.g., Auto-Max 4-head) with digital torque feedback and recipe storage. Servo motors hold ±0.5 Nm window; changeover is a barcode scan, eliminating manual clutch tweaks. |

| 2 | Mixed Format, Frequent Downtime Craft beverage co-packer bottles 12 oz, 16 oz and 750 ml glass with flip-top, ROPP and snap caps. Tooling swaps take 45 min and damage lightweight glass. |

Universal chuck systems grip too aggressively; no quick-adjust rails; operators overtighten to compensate. | Install a Versa-Max spindle capper with spring-loaded self-centering chucks and snap-in change parts. Cap diameter range 15 mm–130 mm handled with one chuck; rail width and height adjust via hand-wheel with digital scale—changeover <10 min, zero bottle scuffing. |

| 3 | Cap Feeder Jams & Scuffed Closures Cosmetics filler runs 45 ppm, but static-charged PET caps bridge in the elevator and arrive misaligned—5 % rejection rate, 2 h daily clearing. |

Vibratory bowl feed rate mismatches capping head demand; no ionization or soft-handling features. | Add a QuickFeed centrifugal sorter with integrated ionizing bar and vacuum pick-and-place. Centrifugal disk eliminates bowl track jams; soft-touch belt places caps squarely on threads. Feeder synchronizes with capping takt time, cutting rejection to <0.3 %. |

Strategic Material Selection Guide for bottle capping machine

Strategic Material Selection Guide for Bottle Capping Machine Components

The material chosen for every surface that touches the bottle, cap, or cleaning fluid determines throughput, validation effort, and 10-year operating cost. Below is a field-tested decision matrix used by U.S. and EU packagers to match stainless, engineered polymer, and anodised aluminium grades to the three stress zones of a modern capping system.

1. Torque Transmission Zone (Chuck / Spindle / Clutch)

Key risks: Galling on aluminium caps, particle shedding, sterilisation temperature >130 °C.

| Grade | Typical Hardness | FDA & EU 10/2011 | Coeff. vs. Al cap | Autoclave ≤134 °C | Cost Index* | Use-case |

|---|---|---|---|---|---|---|

| 17-4 PH SS, H1150 | 35 HRC | ✔ | 0.35 | 1 000 cycles | 1.0 | High-torque spirits, pharma |

| 316L SS, electropolished | 160 HV | ✔ | 0.45 | 500 cycles | 0.75 | Dairy, nutraceuticals |

| Hard-anodised 7075 Al (Type III, 50 µm) | 65 HRC coating | ✔ (coating) | 0.25 | Not recommended | 0.45 | Short-run craft beverages |

| PEEK CF30 | 92 Shore D | ✔ | 0.20 | 100 cycles | 2.10 | Fragile dropper caps, low particulate |

*Cost index relative to 17-4 PH SS = 1.0 (Q2-2024 U.S. mill price).

Rule of thumb:

– ≥40 N⋅m or SIP/CIP >121 °C → 17-4 PH SS chuck inserts.

– <25 N⋅m and frequent format change → anodised Al or PEEK jaw segments reduce inertia by 55 %, cutting spindle servo cycle time.

Illustrative Image (Source: Google Search)

2. Container Handling Zone (Belt, Gripper, Starwheel)

Key risks: Abrasive PET stress-cracking, acid-based cleaners, EU plastic recycling regulations.

| Material | Static COF vs. PET | Moisture Absorption | Notched Izod (kJ/m²) | UL 94 | EU Recycling Code | Notes |

|---|---|---|---|---|---|---|

| Acetal (Delrin) copolymer | 0.22 | 0.2 % | 6.5 | HB | 7 | OEM standard on Kinex conveyors |

| PA 6/12 food grade | 0.35 | 1.5 % | 10 | HB | 7 | Slightly higher grip; check swelling |

| PET-P (Ertalyte) | 0.25 | 0.05 % | 8 | HB | 1 | Low wear, detectable by optical sorters |

| 304 SS sheet, 2B finish | 0.45 (dry) | 0 % | — | — | 1 | Used when hot-fill >85 °C |

Selection logic:

– Cold-fill still water, 22 °C, 5 cN⋅m top-load → Acetal belt keeps drive motor ≤0.25 kW.

– Hot-fill tea, 88 °C → switch to PET-P or stainless to avoid warpage; energy use rises ≈7 %.

– EU customers targeting 100 % recyclable PET bottle streams increasingly specify PET-P grippers to satisfy RecyClass guidelines.

3. Snap-on / Press-fit Zone (Pusher Block, Vacuum Cup)

Key risks: Cap deformation, ozone cracking of TPE liner, electrostatic attraction of dust.

| Material | Shore A | Compression Set 24 h 70 °C (%) | Surface Resistivity (Ω/sq) | FDA TSE-Free | Typical Life (M cycles) |

|---|---|---|---|---|---|

| Platinum-cured silicone, 60 Shore A | 60 | 12 | 10¹³ | ✔ | 1–2 |

| EPDM food blue, 70 Shore A | 70 | 25 | 10¹⁴ | ✔ | 0.5–1 |

| PU 90 Shore A, antistatic grade | 90 | 18 | 10⁹ | ✔ | 2–3 |

| 316L spring finger (for metal snap caps) | — | — | 10⁶ (conductive) | — | 10+ |

Guideline:

– Carbonated soft-drink oval snap caps → PU 90 Shore A balances deformation window and static dissipation (<10⁹ Ω/sq avoids dust attraction).

– Distilled water flat caps → silicone gives lowest liner imprint force; switch to EPDM only when cost pressure >15 %.

4. Comparison Matrix at a Glance

| Component | Stainless 17-4 PH | Stainless 316L | Hard-Anod Al | PEEK CF30 | Acetal | PET-P | EPDM | Silicone | PU |

|---|---|---|---|---|---|---|---|---|---|

| FDA/EU compliance | ✔ | ✔ | ✔* | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

| Autoclave 134 °C | ✔ | ✔ ✖ (500) | ✖ | △ (100) | ✖ | ✖ | ✖ | ✔ | ✖ |

| Abrasion vs. Al cap | Good | Good | Best | Best | N/A | N/A | N/A | N/A | N/A |

| Anti-static | — | — | — | — | — | — | — | — | ✔ |

| Relative cost | 1.0 | 0.75 | 0.45 | 2.1 | 0.3 | 0.7 | 0.1 | 0.15 | 0.25 |

| Recycling code | — | — | 7 | 7 | 7 | 1 | 7 | 7 | 7 |

*Coating must be intact; verify with dye-penetrant after 50k cycles.

5. Specification Checklist (copy into RFQ)

- Identify max CIP temperature profile and chemical list (caustic, peracetic, quat?).

- State peak torque set-point and cap substrate (aluminium, PP, HDPE, steel).

- Define line speed (caps/min) and target MTBF; multiply life by 1.5× for stainless vs. polymer.

- Confirm EU RecyClass or US APR guideline compliance if bottle and gripper are both PET.

- Require material lot certificates to EN 10204 3.1 or ASTM A480, plus FDA CFR 21 or EU 10/2011 migration test summary.

Apply the matrix above and you eliminate 80 % of early-wear callbacks while keeping CAPEX within ±5 % of a polymer-heavy build.

In-depth Look: Manufacturing Processes and Quality Assurance for bottle capping machine

In-depth Look: Manufacturing Processes and Quality Assurance for Bottle Capping Machines

1. Manufacturing Workflow

| Stage | Key Operations | Typical Lead-Time | Critical KPI |

|---|---|---|---|

| Prep | 304/316L stainless cut & deburr, aluminum extrusion mill, motor/PLC inbound QC | 3 days | Dimensional tolerance ±0.05 mm |

| Forming | 5-axis CNC chassis, laser-cut side panels, robotic weld fixtures, passivation bath | 5 days | Weld penetration ≥1 mm, Ra ≤0.4 µm |

| Assembly | Spindle-to-servo coupling, cap chuck lapping, HMI burn-in, safety relay loop test | 4 days | Torque repeatability ±0.1 Nm |

| QC | FAT protocol, 24-hr run @ 100 % speed, cap feeding Cmk ≥1.67, CE/UL label control | 2 days | OEE ≥95 %, zero stop-level defects |

2. Prep & Forming – Precision from Raw Stock

- Material Certification

- 304L sheet ≥2 mm thick, mill test reports to EN 10204 3.1

- Food-grade Delrin® acetal for belts, FDA 21 CFR §177.2470 compliance

- CNC Machining

- Chassis milled on 5-axis Mazak; positional accuracy ±25 µm

- Spindle shafts ground to h6 fit; surface finish ≤0.2 µm Ra for seal integrity

- Welding & Passivation

- TIG welds under Argon purge; dye-penetrant per ASTM E165

- Citric-acid passivation to ASTM A967, free-iron <0.5 µg/cm²

3. Assembly – Modular Build Strategy

| Sub-Assembly | Process Control | Verification |

|---|---|---|

| Drive Module | Servo motor keyed to spindle; Loctite 638 cured 30 min @ 60 °C | Dynamic balance ≤1 g-mm |

| Cap Chuck | Collet chuck hardened to 56 HRC, lapped bore ±10 µm | 100 % leak-down test 6 bar |

| Control Panel | UL 508A panel shop; 1500 V hi-pot, 100 MΩ insulation | Safety loop checked with PILZ PNOZ |

| Conveyor Belt | Low-friction acetal chain tensioned to 1 % elongation | Run-in 2 hr, track drift <1 mm |

4. Quality Assurance – Standards & Protocols

4.1 Applicable Standards

- ISO 9001:2015 – quality management system

- ISO 13849-1 – safety of control systems (Performance Level “d”)

- cGMP 21 CFR Part 110 – food-contact sanitation

- CE (EN 60204-1, EN ISO 12100) & UL 508A for dual-market acceptance

4.2 Incoming Component Checks

- Motors & PLCs: incoming lot sampling AQL 0.65, torque ripple <2 %

- Bearings: noise test dB(A) ≤55, grease NSF H1 registered

- Cap sorter bowl: 316L Ra ≤0.5 µm, chloride test <50 ppm

4.3 In-Process Gauging

- Real-time SPC on CNC bore diameters; Cp ≥1.33

- Weld joint ultrasonic抽检 10 %; reject if flaw >2 mm

4.4 Factory Acceptance Test (FAT)

| Test Item | Acceptance Limit | Record |

|---|---|---|

| Torque accuracy | ±0.1 Nm of set-point | 50 caps, SPC chart |

| Re-torque rate | ≤0.2 % | 1,000 cap run |

| Reject rate | ≤0.1 % | Vision cap inspection |

| Noise | ≤75 dB(A) @ 1 m | Sound meter |

| Safety stop | <500 ms | Dual-channel monitored |

4.5 Documentation & Traceability

- Digital traveler with part-serial barcode; 10-yr archive

- IQ/OQ templates supplied for GAMP 5 validation

- Calibration certs for all torque analyzers (NIST-traceable, 12-mo cycle)

5. Shipping & Post-Delivery Support

- 100 % run-off video recorded, customer sign-off before crate

- VCI film + desiccant; shock-indicator on crate for >10 g

- One-year parts & labor warranty, 30-day money-back clause

- Spare-parts kit (belts, chuck jaws, HMI battery) ships with unit; next-day dispatch for critical spares

Practical Sourcing Guide: A Step-by-Step Checklist for ‘bottle capping machine’

Practical Sourcing Guide: A Step-by-Step Checklist for Bottle Capping Machine

Use this 12-point checklist to shortlist, quote and buy a capping machine that ships on-time, hits torque spec and passes validation on both sides of the Atlantic.

| Step | Action | USA-EU Critical Notes |

|---|---|---|

| 1. Define Cap & Bottle Range | List cap style (screw, lug, snap, ROPP), diameter (min–max mm), bottle finish (GL, GPI, PCO) and target output (bottles/min). | EU: Include DIN & BPF finishes; USA: include CRC and trigger-spray data. |

| 2. Match Machine Architecture | ≤30 bpm → benchtop or handheld; 30–70 bpm → semi-auto spindle; ≥70 bpm → automatic rotary or multi-spindle. | Confirm 220 V 50 Hz vs 110 V 60 Hz motor windings before quote. |

| 3. Torque Accuracy Requirement | State ±X Nm or lb-in and acceptable Cpk. Pharma & food must be ±0.1 Nm, Cpk ≥1.33. | Ask for IQ/OQ/PQ templates; EU suppliers must provide CE-compliant documentation pack. |

| 4. Cap Feeding Method | Pre-sort bulk caps → elevator / vibratory bowl / centrifugal. Verify change-over time for multiple cap sizes. | Request noise test report (<75 dB) for EU CE compliance. |

| 5. Bottle Handling Interface | Conveyor height, guide-rail adjust range, accumulation table length. | Measure your existing conveyor BS (belt speed) and confirm EU/USA chain standard (82.5 mm vs 63.5 mm). |

| 6. Material & Wash-Down Spec | 304 SS frame, 316 SS wetted parts, IP-rating for rinse-down. | USDA/FDA or EC 1935/2004 compliance certificates required. |

| 7. Safety & Guarding | Interlock doors, e-stop category 3, 2-hand anti-tie-down on semi-auto. | CE: EN ISO 13849-1 PL “d”; USA: ANSI B155.1, OSHA 1910.212. |

| 8. Utilities & Footprint | Air: cfm @ psi; Electric: kW, phases, hertz. Verify floor load (kg m⁻²) and ceiling height. | EU: request Declaration of Incorporation for partly completed machinery. |

| 9. Validation & Documentation | FAT protocol, torque calibration cert, spare parts list, BOM, drawings in DXF & STEP. | Agree on SAT timeline—USA 3 days, EU 5 days including travel. |

| 10. After-Sales Support | 1-year full warranty, 30-day return, local field tech within 48 h, Skype/TeamViewer support. | Confirm US & EU parts depots; keep a list of incoterms (FCA, DDP). |

| 11. Price & Terms | Ask for EXW, DDP, lead time, payment (30 % order, 70 % before ship). | Hedge FX if >90-day lead; include HS code 8422.30 for EU import. |

| 12. Final Sign-Off | Run 3×30 min production lots at spec speed; record torque, reject %, OEE. Approve only after Cpk ≥ target. | Store FAT/SAT videos in shared cloud folder for future audits. |

Quick RFQ Template (copy-paste)

- Cap range: ___ mm to ___ mm

- Output: ___ bpm

- Torque accuracy: ± ___ Nm

- Voltage: ___ V ___ Hz

- Air: ___ bar, ___ cfm

- Standards: FDA/USDA/CE/ATEX (circle)

- Warranty: ___ years

- Lead time: ___ weeks

- Incoterm: ___

Attach bottle & cap drawings → suppliers reply within 24 h.

Illustrative Image (Source: Google Search)

Comprehensive Cost and Pricing Analysis for bottle capping machine Sourcing

Comprehensive Cost & Pricing Analysis for Bottle Capping Machine Sourcing

| Cost Component | Typical % of Total | 2024 USA/EU Range (USD) | Cost Drivers | Notes for Buyers |

|---|---|---|---|---|

| Machine Base Price | 65–75 % | $8 k – $120 k | Throughput, automation level, number of capping heads | Price delta between 40 cpm (Relia-Cap®) and 105 cpm (Auto-Max) is ±35 %. |

| Material Surcharge | 3–5 % | $300 – $5 k | 304/316 SS, anodized aluminum, Delrin® chain | Locked for 90 days on USA-built units; EU suppliers index to LME monthly. |

| Labor & Factory Overhead | 8–12 % | $1 k – $12 k | Build-to-order vs. stocked | NH factory adds 4 % premium vs. EE-built units, but 10-day lead time vs. 6–8 weeks. |

| Logistics & Incoterms | 4–7 % | $600 – $7 k | DAP/DDP, crating, export docs | Airfreight to EU ≈ 6 % of machine value; sea freight ≈ 1.5 % but +4 weeks. |

| ** commissioning & FAT** | 2–4 % | $500 – $4 k | Remote vs. on-site | 1-day virtual FAT included by Kinex®; on-site FAT billed at $1.2 k per tech/day. |

| Import Duties & VAT | 0–12 % | $0 – $14 k | HS 8422.30 | USA origin = 0 % into EU; Asian origin = 8.8 % + 20 % VAT. |

| Total Landed Cost | 100 % | $10 k – $150 k | — | Use table below to benchmark quotes. |

1. Machine-Level Price Benchmarks (2024)

| Model Type | Speed (cpm) | USA Built (USD) | EU Built (EUR) | Key Inclusions |

|---|---|---|---|---|

| Bench-top chuck capper | 10–15 | $4 k – $6 k | €5 k – €7 k | 1-yr warranty, no feeder |

| Semi-automatic spindle | 25–35 | $12 k – $18 k | €14 k – €20 k | Cap elevator, sorting bowl |

| Automatic 4-head linear | 80–105 | $55 k – $85 k | €60 k – €95 k | HMI, reject station, CE mark |

| Rotary 12-head | 200+ | $110 k – $150 k | €120 k – €170 k | Servo torque, full CIP |

2. Hidden Cost Hot-Spots

- Change-part kits – $800–$2 k per cap diameter; negotiate 2 free sets for pilot sizes.

- Programming fees – OEMs charge $120/h after 2 hrs of free PLC edits; cap torque recipes should be pre-loaded.

- Spare parts package – 5 % of machine value is adequate; insist on itemized list with HS codes to avoid double VAT.

- Extended warranty – 1→3 yrs costs 4–6 % of machine price; compare against local service hourly rates ($95 in USA, €110 in EU).

3. Quick-Win Cost-Saving Tactics

| Tactic | Immediate Saving | Implementation |

|---|---|---|

| Order during OEM Q4 backlog fill | 3–5 % discount | Accept Feb–Mar delivery. |

| Combine bottle conveyor & capper PO | Freight saving 30 % | Single 20-ft pallet slot vs. two. |

| Opt for virtual FAT & remote I/O check | $2 k travel avoided | Use OEM’s VPN-accessible HMI. |

| Use shared export crate (LCL) | $400–$600 | Coordinate with filler supplier. |

| Select 3-year service kit upfront | 10 % vs. spot-buy | Lock parts price at FX rate of PO date. |

4. Total Cost of Ownership (5-Year TCO) Snapshot

| Scenario | 40 cpm USA Built | 105 cpm EU Built |

|---|---|---|

| Landed cost | $32 k | $88 k |

| Electricity (5 yrs @ 6 ¢/kWh) | $3 k | $7 k |

| Consumables (belts, chuck pads) | $2 k | $4 k |

| Planned labor (20 hrs/yr @ $95) | $9.5 k | $9.5 k |

| Downtime risk (2 % line value/yr) | $3.2 k | $8.8 k |

| 5-Year TCO | $49.7 k | $117.3 k |

5. Checklist Before Signing the PO

- [ ] Confirm quoted speed is sustained, not peak.

- [ ] Validate that cap feeder is included (often a separate line item).

- [ ] Lock material surcharge for 90 days in USA or cap at 5 % in EU.

- [ ] Clarify Incoterm—DAP dock is $1 k cheaper than DDP plant.

- [ ] Request 30-day return clause (Kinex® standard) for risk mitigation.

Use the numbers above as a baseline; deviations >8 % warrant a re-quote or supplier review.

Alternatives Analysis: Comparing bottle capping machine With Other Solutions

Alternatives Analysis: Bottle Capping Machine vs. Other Closure Solutions

| Evaluation Criteria | Automatic Bottle Capping Machine (Kinex) | Manual Torque Wrench + Fixture | Inline Cap Sealing Induction System |

|---|---|---|---|

| Typical Throughput | 40–105 caps/min (2,400–6,300/h) | 6–12 caps/min (360–720/h) | 50–150 caps/min* (3,000–9,000/h) |

| Cap Range Handled | 10–130 mm (screw, lug, snap-on) | 15–120 mm (screw only) | 20–120 mm (plastic/foil lined) |

| Repeatable Torque Accuracy | ±0.1 Nm (servo-controlled) | ±0.5 Nm (operator dependent) | N/A—induction heat seals after hand/ spindle capping |

| Change-Over Time | 5–10 min (tool-less) | 1–2 min (socket swap) | 15–30 min (induction coil + height) |

| Footprint (m²) | 1.2 × 1.0 (with feeder) | 0.6 × 0.4 (bench fixture) | 2.5 × 0.8 (coil + generator) |

| Total Cost of Ownership (3 yr) | $58 k (machine + spares) | $4 k (wrenches + labor) | $72 k (inductor + validated coils) |

| FDA/EC Validatability | Full batch reporting via HMI | Paper logbooks | Integratable with vision & e-sig |

| Energy Consumption | 0.9 kW (avg.) | 0 kW (manual) | 3–5 kW (induction generator) |

| Labor Requirement | 0.2 FTE (tending + QA checks) | 1.0 FTE (constant operator) | 0.3 FTE (tending + coil swap) |

| Warranty & Support | 1 yr parts & labor, 30-day return | Vendor tool warranty only | 1 yr generator, 90 days coil |

*Induction systems seal; they do not apply or tighten caps—upstream capping still required.

Analysis

- Automatic Bottle Capping Machine

- Best-fit scenario: Mid- to high-volume SKUs (≥2 k bottles/shift) where repeatable torque and line speed are critical for FDA/EC compliance.

- Key advantage: Lowest per-unit labor cost and tightest torque distribution (±0.1 Nm), reducing rework and leak claims.

-

Trade-off: Higher upfront CAPEX; ROI <9 months at 3 k caps/h.

-

Manual Torque Wrench + Fixture

- Best-fit scenario: Pilot batches, R&D, or start-ups producing <500 bottles/day with frequent cap size changes.

- Key advantage: Minimal capital and space; ideal for cGMP scale-up trials before automating.

-

Trade-off: Labor-intensive; torque variance can exceed ±0.5 Nm, risking overtightening, carpal-tunnel injuries, and rejected batches.

-

Inline Cap Sealing Induction System

- Best-fit scenario: Tamper-evident foil-lined caps (pharma, food, nutraceuticals) already applied by a spindle capper.

- Key advantage: Provides hermetic seal integrity and visual tamper evidence; complements—not replaces—capping.

- Trade-off: Adds second operation; line length and energy use increase; requires validated coil sets for each cap diameter.

Decision Guidance

- If your line runs ≥2 shifts/day or needs GMP batch data: Invest in an automatic bottle capping machine; pair with an induction sealer only if foil lining is mandatory.

- If you are below 500 bottles/day or need flexibility for clinical lots: Start with manual torque fixtures, then migrate to an automatic capper once demand exceeds 1 k bottles/shift.

Essential Technical Properties and Trade Terminology for bottle capping machine

Essential Technical Properties & Trade Terminology for Bottle Capping Machines

| Property / Term | Typical Range / Definition | Procurement Notes |

|---|---|---|

| Torque Accuracy | ±0.5 – 2 Nm (depends on chuck type) | Specify at production speed, not idle; request torque vs. speed curve. |

| Cap Diameter Range | 10 – 130 mm (Kinex standard) | Verify “minimum to maximum” without tool change; ask if chuck inserts are extra. |

| Application Speed | 40 – 105 caps/min per head | State target in bottles/min incl. feeder refill time. |

| Cap Style Compatibility | ROPP, screw-on, lug, snap-on, press-on, trigger | Confirm if machine needs change-parts for each style. |

| Capping Head Type | Spindle, chuck, snap, magnetic-clutch | Magnetic-clutch gives best repeatability for pharma & food. |

| Bottle Diameter Range | 20 – 150 mm (conveyor width adjustable) | Provide bottle “dead-plate” drawing to avoid transfer jams. |

| Bottle Height Range | 50 – 400 mm | Check vertical travel of capping head; taller bottles may need risers. |

| Power Supply | 230 V / 1 Ph / 60 Hz (USA) or 400 V / 3 Ph / 50 Hz (EU) | Specify plug standard; VFD included or optional. |

| Air Consumption | 2 – 6 cfm @ 6 bar (for pick-&-place or snap caps) | Ensure plant compressor duty-cycle covers peak. |

| Stainless-Steel Grade | 304SS standard, 316SS optional for CIP/SIP | 316L required for corrosive cleaners or high-saline products. |

| IP Rating | IP54 standard, IP65 for wash-down | Needed for dairy, brewery, or OTC pharma lines. |

| Change-Over Time | 5 – 15 min (tool-less preferred) | Ask for documented SOP & video; affects OEE. |

| Footprint (L×W) | 1.2 m × 0.9 m (single-head benchtop) to 2.5 m × 1.5 m (4-head automatic) | Add 1 m clearance each side for guarding & maintenance. |

| Noise Level | <75 dB(A) @ 1 m | EU buyers verify against 2003/10/EC workplace limits. |

| Repeatability (Cpk) | ≥1.67 @ ±10 % target torque | Demand GR&R study report; critical for tamper-evident caps. |

Trade & Commercial Terms Used in Capping Machinery RFQs

| Term | Meaning | USA Practice | Europe Practice |

|---|---|---|---|

| MOQ | Minimum Order Quantity | 1 unit (stock machines) | 1 unit; higher for custom colour or 316SS |

| OEM | Original Equipment Manufacturer | Kinex ships under own brand; private-label OEM available on 10+ units | CE documentation supplied; OEM manual in local language on request |

| Lead-Time | Ex-works days after PO | 2 business days (stock) | 5–7 days (stock) / 4–6 weeks (custom) |

| Incoterms® 2020 | Shipping responsibility | FCA New Hampshire (USA) | DAP warehouse (EU) or CPT if buyer clears customs |

| Warranty | Parts & labour | 12 months | 12 months; 24 months optional (EU) |

| Spare-Parts Kit | Recommended wear items | 1 chuck, 1 belt, 1 clutch spring (~USD 295) | Same kit; priced in EUR, ex-VAT |

| IQ/OQ Documentation | Installation & Operational Qualification | Available for magnetic-clutch models; extra USD 1,200 | Included in pharma package; complies with GAMP 5 |

| Retrofit Upgrade | Field addition of extra capping head | Possible on Auto-Max frame; 1-day field service | CE re-certification included |

| Return Policy | 30-day money-back | Buyer pays freight both ways; restocking 0 % if unopened | Same; VAT not refundable |

| Payment Terms | Net 30 with approved credit | 50 % with PO, 50 % prior to shipment for first-time buyers | SEPA bank transfer; 2 % discount for 8-day payment |

Quick Specification Checklist (copy-paste into RFQ)

- [ ] Target bottle & cap drawing (DXF/PDF)

- [ ] Required torque range & tolerance

- [ ] Line speed: ___ bpm (bottles per minute)

- [ ] Cap feeder type: bowl / elevator / step-elevator

- [ ] Stainless-steel grade & IP rating

- [ ] Export country (for voltage & CE/UL)

- [ ] Incoterm & delivery postcode

Navigating Market Dynamics and Sourcing Trends in the bottle capping machine Sector

Navigating Market Dynamics and Sourcing Trends in the Bottle Capping Machine Sector

1. Macro Trends Driving Demand (USA & Europe)

| Trend | 2023-2025 CAGR* | Procurement Implication |

|---|---|---|

| Craft beverage boom (RTD cocktails, kombucha, functional water) | 8.4 % | Need for quick-changeover, low-volume automatic cappers (≤50 cpm) |

| Pharma serialization & track-and-trace mandates | 6.1 % | Integration-ready machines with Ethernet/IP, OPC-UA, 21 CFR Part 11 data logging |

| Post-COVID re-shoring & “China-plus-one” | — | Buyers requesting US/EU-made machines to cut 6-week ocean lead-times |

| Single-use & light-weight caps (down-gauged PP, bio-PE) | — | Repeatable, low-torque closure control (<0.5 Nm) to avoid thread slip |

*Source: Grand View Research, Interact Analysis 2023

2. Sustainability Sourcing Checklist

When short-listing suppliers, procurement teams now weight:

Illustrative Image (Source: Google Search)

- Energy draw: ≤0.15 kW per capping head for 50 cpm servo spindle units (EU Eco-Design 2025 threshold)

- Material traceability: 304L or 316L stainless with ≥75 % recycled content declaration

- End-of-life design: Modular capping heads, snap-fit PC panels (no Loctite) for 95 % recyclability

- Carbon disclosure: Request Scope 1-2 CO₂e per machine; Tier-1 OEMs already provide EPDs

Audit tip: Ask for ISO 14064-verified data—not marketing brochures.

3. Technology Evolution Snapshot (1990 → 2024)

| Era | Drive Type | Torque Control | Footprint | Data Interface |

|---|---|---|---|---|

| 1990s | Pneumatic clutch | ±15 % | 3 m² | None |

| 2005 | AC motor + mechanical clutch | ±7 % | 2 m² | Hard-wire I/O |

| 2015 | Brushless servo + magnetic clutch | ±3 % | 1.2 m² | Ethernet/IP |

| 2024 | Direct-drive servo with force-torque sensor | ±1 % | 0.8 m² | OPC-UA, MQTT, PackML v3 |

Key takeaway: Repeatability has improved 15× while floorspace dropped 73 %—factor this into ROI models when replacing legacy lines.

4. 2024 Sourcing Risk Matrix

| Risk | Probability | Mitigation |

|---|---|---|

| Semiconductor lead-time (servo drives) | High | Dual-source drive specification; lock 12-month forecast with vendors |

| Nickel price volatility (316L SS) | Medium | Insert price-adjustment collar ±8 % above LME 90-day average |

| CE vs. UL certification gaps | Medium | Specify “built to both standards” at PO stage; avoid field retrofits |

| Post-Brexit Rules-of-Origin | Low | Request supplier statement for <45 % non-EU content to maintain tariff-free status |

5. Procurement Action Plan (Next 90 Days)

- Line audit: Map current cap range (min-max Ø, thread profile, target torque). 80 % of plants overspecify—downsizing heads saves 12–18 % CAPEX.

- RFQ package: Include torque R&R study (GR&R ≤10 %), MTTR <30 min, and 5-year spare-part price lock.

- Pilot clause: Insert 30-day performance clause (±1 σ torque accuracy, ≤0.2 % cap skew rejection) before full line acceptance.

- Sustainability addendum: Require recycled steel cert + take-back program for obsolete chassis.

Execute the above and you enter 2025 with a capping line that is EU-taxonomy aligned, USA re-shore compliant, and future-proofed for 25 % SKU turnover—without paying green premiums.

Frequently Asked Questions (FAQs) for B2B Buyers of bottle capping machine

Frequently Asked Questions (FAQs) for B2B Buyers of Bottle Capping Machines

| # | Question | Answer |

|---|---|---|

| 1 | Which capping machine fits a 28 mm beverage cap at 60 bottles/min? | The Auto-Max Automatic Screw Capping Machine (1–4 heads) or Versa-Max Spindle Capper both handle 28 mm caps at up to 105 or 50 cpm respectively. |

| 2 | How fast can I change over cap size or bottle format? | Tool-free changeover on Kinex machines takes <10 min; all adjustments are on-screen and dial-based—no pneumatics or special tools. |

| 3 | What is the real-world ± torque accuracy? | Repeatability is ±0.3 Nm (±5 %) across 10–130 mm caps, verified with SK-type calibration chuck. |

| 4 | Does the machine come with validation documentation for FDA/EU GMP? | Yes. Each unit ships with IQ/OQ templates, 316L SST contact certificates, and CE/UL wiring schematics for fast validation. |

| 5 | What is the total cost of ownership (TCO) for an automatic capper? | 10-year TCO = machine price + 2 % of price annually for wear parts. No OEM-only components—off-the-shelf spares keep cost low. |

| 6 | How are spare parts and support handled in Europe? | Parts ship from NH in ≤2 business days; we partner with Dutch and UK service hubs for 24 h on-site response. Phone is answered by a human—no ticketing system. |

| 7 | Can the capper integrate with existing conveyors and fillers? | Standard 2.5 m stainless infeed/outfeed with 63 mm side-transfer height; plugs into any MODBUS TCP line. Optional 110/230 V single-phase drive. |

| 8 | Warranty & return terms? | Full 1-year parts & labor warranty; 30-day money-back return if specifications are not met. Extended 3-year warranty available at 8 % of list price. |

Strategic Sourcing Conclusion and Outlook for bottle capping machine

Strategic Sourcing Conclusion & Outlook: Bottle Capping Machines

Key Takeaways for Procurement Teams

| Decision Driver | Specification Window | Risk Mitigation |

|---|---|---|

| Throughput | 40–105 caps/min | Match to filler & labeler cadence |

| Cap Range | 10–130 mm | Confirm future SKU roadmap |

| Change-Over | Tool-less, <5 min | Demand demo with your bottles/caps |

| Support | USA-built, 1-yr full warranty | 30-day return clause |

2024–2026 Outlook

- Speed-to-market: Domestic suppliers (NH, USA) cut lead times to 2 days vs. 10-12 weeks offshore.

- Compliance: UL-certified conveyors and stainless construction satisfy both FDA and EU 1935/2004.

- Modularity: Spindle, snap and chuck cappers on common frame allow line re-balancing without new capital.

- Data: Touchscreen HMI now standard; prepare for OPC-UA integration to MES for OEE tracking.

Procurement mandate: Cap-ex must deliver ±0.5 % torque accuracy and <0.1 % rejection over a 7-year life. Short-list vendors that publish full parts list, CAD files, and same-day human support.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided is for informational purposes only. B2B buyers must conduct their own due diligence.