The global personal protective equipment (PPE) market, driven by increasing workplace safety regulations and industrial automation, is projected to expand at a CAGR of 6.4% from 2023 to 2028, according to Mordor Intelligence. Within this growing sector, flame-resistant and heat-resistant footwear remains a critical component for high-risk professions such as welding. With the welding equipment market itself expected to surpass $28 billion by 2030 (Grand View Research, 2023), the demand for specialized protective boots that meet ASTM F2413 standards for heat, electrical, and impact resistance has surged. This rising need has spurred innovation among manufacturers, leading to a competitive landscape of brands engineering boots specifically for welders—combining durability, comfort, and advanced protective features. Below, we spotlight the top 9 manufacturers leading this niche through performance-driven design and safety-certified innovation.

Top 9 Boots For Welders Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Work Boots

Domain Est. 1997

Website: whitesboots.com

Key Highlights: 6–7 day deliveryLoggers, miners, linemen, road workers, factory workers, and workers across the trades have been wearing our boots into the ground since 1853. As long as they ……

#2 Industrial Work Boots

Domain Est. 2003

Website: hexarmor.com

Key Highlights: Step into HexArmor®-grade safety boots – always field-inspired, and always engineered to the highest standard of comfort and performance….

#3 Honeywell Safety Boots

Domain Est. 1988

Website: automation.honeywell.com

Key Highlights: Mid-cut style safety shoe, made with flexible textile upper and EVA/rubber HRO outsole. Equipped with fast lacing system. Fiberglass 200J resistant toecap….

#4 USF89491 Welder Boots

Domain Est. 1993

#5 Men’s Work Boots

Domain Est. 1995

Website: danner.com

Key Highlights: $8 deliveryDanner boots are a mark of superior craftsmanship, Our hiking, hunting, work, military, and law enforcement boots are built with GORE-TEX waterproof liners, ……

#6 Men’s Boots and Footwear

Domain Est. 1999

Website: doublehboots.com

Key Highlights: Free delivery 30-day returnsFind traditional western and work boots with safety features at Double-H. Our men’s footwear is perfect for the ranch, job site, or everyday wear….

#7 Iron Age Footwear

Domain Est. 2010

Website: ironagefootwear.com

Key Highlights: Free delivery Free 30-day returnsOUR NEWEST WATERPROOF, COMPOSITE TOE WORK BOOT MADE FOR EXTREME JOB SITES. This men’s work boot is ready for wherever your job takes you. Its durab…

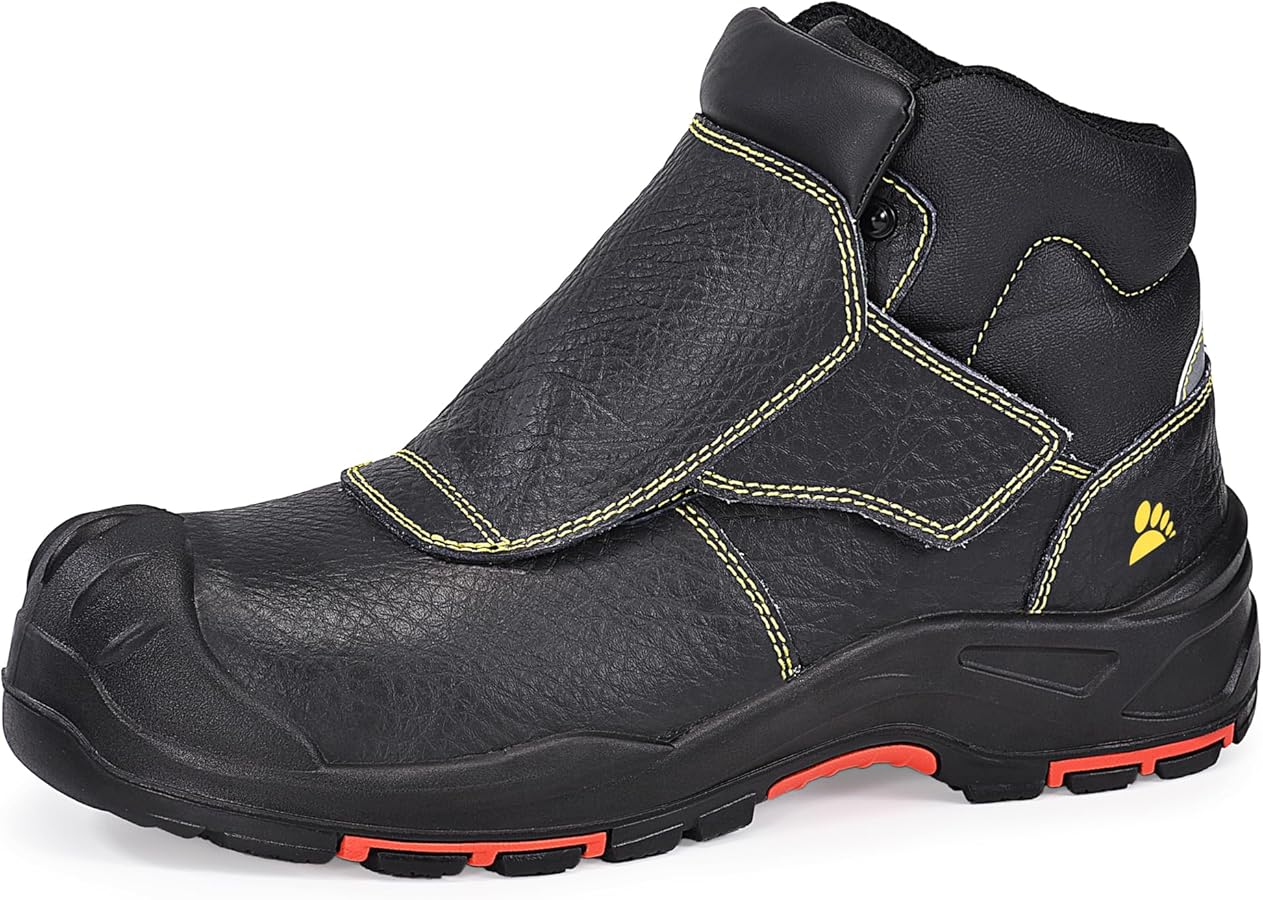

#8 Welding Boots

Domain Est. 2014

Website: overlookboots.com

Key Highlights: Free deliveryWelding boots are specialized footwear engineered to offer welders maximum protection, comfort, and durability in hazardous work environments….

#9 Mining & Welding Work boots

Domain Est. 2021

Website: aegisec.com

Key Highlights: The work boots is developed for the harsh working environment of mining and welding industries. With protective toecaps and midsoles….

Expert Sourcing Insights for Boots For Welders

H2: 2026 Market Trends for Boots for Welders

The market for specialized work boots, particularly those designed for welders, is poised for significant evolution by 2026. Driven by advancements in materials, increased safety regulations, and growing emphasis on worker well-being, the demand for high-performance welding boots is expected to rise globally. This analysis examines key trends shaping the Boots for Welders market in 2026 under the H2 header.

-

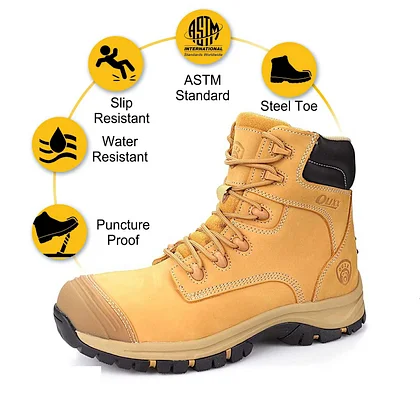

Enhanced Safety Standards and Regulatory Compliance

By 2026, stricter occupational safety regulations—especially in North America and Europe—are expected to mandate higher protective standards for personal protective equipment (PPE), including footwear. Welding boots will increasingly need to meet updated ISO, ASTM, and EN safety certifications, with a focus on improved heat resistance, electric arc protection (Category 2+), and molten metal splash resistance. Manufacturers will prioritize compliance to access regulated industrial markets. -

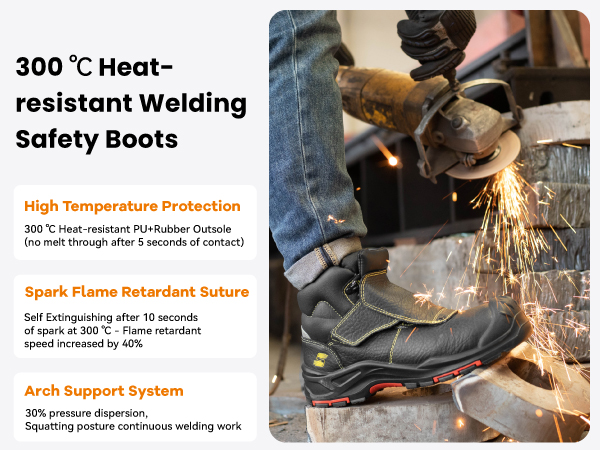

Innovations in Heat-Resistant and Flame-Retardant Materials

A major trend is the integration of advanced materials such as meta-aramid fibers (e.g., Nomex), carbonized leather, and proprietary heat-reflective linings. By 2026, expect wider adoption of boots featuring multi-layer thermal barriers capable of withstanding temperatures exceeding 1,000°C for short durations. These materials not only improve safety but also extend boot lifespan, appealing to cost-conscious industrial buyers. -

Lightweight and Ergonomic Designs

Welder fatigue remains a concern, leading to demand for lighter, more ergonomic boots. In 2026, manufacturers are expected to leverage composite safety toes (instead of steel), advanced midsole foams, and anatomical footbeds to reduce weight while maintaining protection. This trend supports productivity and long-term worker health, particularly in high-mobility welding environments. -

Smart Footwear Integration

The rise of Industry 4.0 and connected PPE is making inroads into safety footwear. By 2026, some premium welding boots may include embedded sensors to monitor environmental heat exposure, detect prolonged standing, or alert supervisors to potential hazards. While still niche, smart boots could become more common in high-risk industrial sectors, especially in automated fabrication plants. -

Sustainability and Eco-Friendly Manufacturing

Environmental concerns are influencing PPE production. Brands are increasingly adopting sustainable practices—such as using chrome-free tanned leathers, recycled outsoles, and low-emission manufacturing. By 2026, eco-certifications (e.g., OEKO-TEX, Bluesign) will likely become differentiators in competitive markets, especially among younger, environmentally conscious workers. -

Growth in Emerging Markets

Demand in Asia-Pacific, Latin America, and Africa is expected to surge due to expanding manufacturing, construction, and energy sectors. Countries like India, Vietnam, and Brazil will drive volume growth, with localized production and affordable, durable models becoming key market segments. This will encourage global brands to develop cost-effective yet compliant welding boots tailored to regional needs. -

E-Commerce and Direct-to-Consumer (DTC) Expansion

Online sales channels are reshaping how welding boots are purchased. By 2026, B2B e-commerce platforms and DTC models will allow welders and contractors to access specialty boots with detailed safety specs, customization, and fast delivery. Augmented reality (AR) try-ons and AI-driven size recommendations may enhance user experience. -

Customization and Personalization

As worker-centric design gains traction, customization options—such as personalized fit, color, and logo embroidery—will become more prevalent. This trend supports brand loyalty and meets the needs of corporate safety programs seeking identifiable, standardized PPE.

In conclusion, the 2026 market for boots for welders will be defined by a convergence of safety innovation, material science, digital integration, and sustainability. Brands that adapt to these H2 trends will lead in providing reliable, comfortable, and future-ready protective footwear for the modern welding workforce.

Common Pitfalls When Sourcing Welding Boots (Quality and IP)

Sourcing welding boots requires careful attention to both safety performance and intellectual property (IP) compliance. Overlooking key factors can lead to compromised worker safety, legal risks, and reputational damage. Below are common pitfalls to avoid:

Insufficient Heat and Spark Resistance

Many low-cost welding boots use materials that degrade quickly under intense heat or molten metal spatter. Sourcing boots without proper thermal insulation or flame-resistant uppers (such as full-grain leather with protective treatments) increases burn risk. Always verify that materials meet industry standards like ASTM F2413 for heat resistance.

Lack of Electrical Hazard (EH) Protection

Welders often work near live electrical circuits. Boots without certified EH protection can conduct electricity, leading to electrocution. Avoid sourcing generic “safety” boots that lack proper dielectric testing and certification—ensure compliance with ASTM F2413 EH ratings.

Poor Sole Durability and Slip Resistance

Welding environments are often slippery and littered with debris. Boots with low-quality rubber soles wear out quickly and offer inadequate grip. Prioritize soles made from high-density, oil-resistant rubber with aggressive tread patterns tested for slip resistance (e.g., SRC rating).

Inadequate Ankle Support and Fit

Ill-fitting or flimsy boots increase fatigue and injury risk during long shifts. Avoid one-size-fits-all designs or lightweight models without proper ankle support. Look for reinforced heel counters, padded collars, and ergonomic designs tailored to extended wear.

Misrepresentation of Safety Certifications

Some suppliers falsely claim compliance with safety standards like ASTM, ISO, or EN. Always demand verifiable test reports and certification documents from accredited labs. Avoid vendors who provide only self-declared conformity or vague claims like “industrial grade.”

Ignoring Intellectual Property (IP) Infringement Risks

Sourcing counterfeit or knockoff boots that mimic well-known brands (e.g., Red Wing, Dr. Martens, or Carhartt) can expose your company to legal liability. These copies often use trademarked logos, patented sole designs, or copyrighted branding illegally. Always vet suppliers for authenticity and request proof of authorized distribution.

Sourcing from Unverified Manufacturers

Dealing with unverified or third-party suppliers, especially on open marketplaces, increases the risk of receiving substandard or unsafe products. Conduct factory audits, request samples, and verify manufacturing credentials to ensure consistent quality and ethical production.

Overlooking Comfort and Breathability

While protection is critical, ignoring comfort leads to non-compliance as workers may remove or modify boots. Avoid sourcing boots without moisture-wicking linings or breathable materials, especially in hot environments. Heat buildup can cause discomfort and reduce productivity.

Failing to Consider Long-Term Total Cost of Ownership

Cheaper boots may cost less upfront but fail prematurely, increasing replacement frequency and downtime. Evaluate durability, warranty, and repair options to assess true cost-effectiveness over time.

Neglecting Compliance with Regional Safety Regulations

Safety standards vary by country (e.g., CE in Europe, ANSI in the U.S., AS/NZS in Australia). Sourcing boots that don’t meet local regulations can result in fines or work stoppages. Confirm that products are certified for the specific region of use.

By avoiding these common pitfalls, businesses can ensure they source high-quality, compliant, and safe welding boots while minimizing legal and operational risks.

Logistics & Compliance Guide for Boots for Welders

Product Specifications and Safety Standards

All boots supplied for welders must meet stringent safety standards to ensure protection against welding hazards. Key compliance requirements include:

- EN ISO 20345:2011 – Safety footwear standard with minimum impact resistance (200J) and compression resistance (15 kN).

- EN ISO 20345:2011 SRC – Includes slip resistance on ceramic tile and steel surfaces with glycerol and sodium lauryl sulfate.

- Heat Resistance (HRO) – Sole must withstand contact heat up to 300°C for 60 seconds without deformation.

- Electrical Insulation (A) – Basic insulation to reduce risk of electric shock in low-voltage environments.

- Metatarsal Protection (M) – Optional but recommended; protects the top of the foot from heavy impacts.

- Leather Construction – Full-grain leather or split leather with fire-retardant treatment; no synthetic materials near toe cap.

- No Metal Components – Avoid metal eyelets, laces, or zippers in high-risk welding zones to prevent electrical conduction or spark ignition.

Packaging and Labeling Requirements

Proper packaging ensures product integrity during transit and enables compliance with international trade regulations.

- Inner Packaging: Each pair must be individually wrapped in recyclable tissue or paper to prevent surface damage.

- Outer Packaging: Use sturdy corrugated cardboard boxes with internal dividers to prevent movement. Mark boxes clearly with:

- Product name: “Welders’ Safety Boots”

- Size range (e.g., EU 39–47)

- Batch/lot number

- Country of manufacture

- Safety standard certifications (e.g., “Certified to EN ISO 20345:2011”)

- Hazard symbols where applicable (e.g., heat warning)

- Labeling Compliance: Labels must be in the local language(s) of the destination country and include care instructions and manufacturer details.

Shipping and Transportation Logistics

Efficient and safe transportation is essential to deliver boots in optimal condition.

- Mode of Transport: Use temperature-controlled containers for sea freight if transporting through extreme climates. Air freight recommended for urgent orders.

- Palletization: Stack boxes on standard EUR/ISO pallets (1200mm x 800mm), secured with stretch wrap and corner boards. Max stack height: 1.8 meters.

- Weight Limits: Do not exceed 1,000 kg per pallet to ensure safe handling.

- Hazardous Materials Declaration: Not applicable unless treated with restricted flame retardants; verify chemical compliance (e.g., REACH, RoHS).

- Documentation: Include commercial invoice, packing list, bill of lading/air waybill, and certificate of conformity with each shipment.

Import/Export Compliance

Ensure all regulatory requirements are met for cross-border movement.

- HS Code Classification: Use HS Code 6403.91 (Footwear with outer soles and uppers of leather, protective) or 6403.99 (Other) depending on construction.

- Customs Declarations: Provide accurate valuation, country of origin, and end-use declaration (“Personal protective equipment for industrial welding applications”).

- Duty and Tax Rates: Verify preferential rates under trade agreements (e.g., EU-UK Trade and Cooperation Agreement); VAT/GST applicable based on destination.

- Prohibited Substances: Confirm compliance with:

- REACH (EU) – No SVHCs (Substances of Very High Concern) above threshold.

- Proposition 65 (California, USA) – No listed carcinogens or reproductive toxins.

- RoHS – If electronic components are present (rare in boots).

Quality Assurance and Inspection

Implement checks at production and pre-shipment stages.

- Factory Audits: Conduct bi-annual audits to verify ISO 9001 and ISO 14001 compliance.

- Pre-Shipment Inspection (PSI): Random sampling (AQL Level II) to check:

- Size accuracy

- Sole attachment strength

- Presence of safety labels inside each boot

- Absence of defects (stitching flaws, discoloration)

- Lab Testing: Annually test samples at accredited labs for:

- Heat resistance

- Electrical insulation

- Slip resistance

- Impact and compression protection

End-of-Life and Sustainability Compliance

Meet environmental obligations for product lifecycle management.

- WEEE/RoHS: Not applicable unless boots contain electronic elements.

- Recycling Guidelines: Provide end-user information on safe disposal and availability of take-back programs.

- Carbon Footprint: Measure and report logistics-related emissions using GHG Protocol standards.

- Sustainable Sourcing: Prefer suppliers with leather from tanneries certified by LWG ( Leather Working Group).

Recordkeeping and Traceability

Maintain documentation for audit readiness and recall preparedness.

- Batch Tracking: Assign unique lot numbers; retain records for minimum 10 years.

- Compliance Dossiers: Keep copies of test reports, certifications, and declarations of conformity.

- Incident Reporting: Establish a process for reporting safety issues; comply with EU RAPEX or U.S. CPSC regulations if applicable.

Training and Worker Compliance

Ensure end-users are informed on proper use and limitations.

- User Manuals: Include with each pair in local language, detailing:

- Proper donning and doffing procedures

- Inspection checklist before use

- Cleaning and maintenance instructions

- Limitations (e.g., not for molten metal splash unless rated)

- Safety Training Integration: Coordinate with client safety officers to include boot usage in PPE training programs.

By adhering to this logistics and compliance guide, Boots for Welders will meet global safety, regulatory, and operational standards, ensuring worker protection and supply chain efficiency.

In conclusion, sourcing boots for welders requires careful consideration of safety, durability, comfort, and compliance with industry standards. Welding environments pose significant hazards, including exposure to sparks, molten metal, electrical risks, and extreme heat, making it essential to select boots with features such as leather construction, metatarsal guards, heat-resistant soles, and electrical insulation. Prioritizing personal protective equipment (PPE) that meets or exceeds safety standards—such as ASTM F2413 or EN ISO 20345—ensures adequate protection for welders on the job.

Additionally, comfort and proper fit are critical to reduce fatigue and support long-term wear, especially in demanding work settings. Employers or procurement teams should evaluate reputable suppliers, compare quality versus cost, and consider user feedback when selecting appropriate footwear. Regular inspection and replacement of worn boots are also vital to maintain ongoing safety.

Ultimately, investing in high-quality, purpose-built welding boots not only protects workers from serious injury but also promotes productivity, compliance, and a strong safety culture within the workplace.