The global market for fastener machinery, including bolts making machines, has experienced robust growth, driven by rising demand from automotive, construction, and industrial manufacturing sectors. According to Grand View Research, the global fasteners market size was valued at USD 107.5 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. This growth directly fuels demand for high-precision, automated bolt manufacturing equipment capable of meeting stringent quality and volume requirements. Similarly, Mordor Intelligence reports that the increasing production of light and heavy commercial vehicles, coupled with infrastructure development in emerging economies, is accelerating investments in advanced cold forging and thread-rolling machines. As automation and production efficiency become critical differentiators, manufacturers are turning to leading machine builders offering reliability, speed, and integration with Industry 4.0 technologies. In this evolving landscape, identifying the top 10 bolt machine manufacturers provides key insights into innovation, global reach, and technological leadership shaping the future of fastener production.

Top 10 Bolts Machine Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Fastener Supplier for OEM, Distributors, and Industrial Applications

Domain Est. 2021

Website: gobigbolt.com

Key Highlights: We manufacture almost all bolt and nut types in the United States and around the world. Non-standard parts, gap buys, per-print orders, prototypes, low-volume ……

#2 OEM Speciality Nuts & Bolts Made in USA

Domain Est. 1995

Website: wyandotte.com

Key Highlights: Choose American-made nuts and bolts for unmatched strength and precision. Specialty fasteners and CNC parts built in the USA. Get a quote today!…

#3 Valley Forge & Bolt

Domain Est. 1997

Website: vfbolts.com

Key Highlights: We are a quality based, US fastener and bolt manufacturer that focuses on solving problems and doing it in a first class manner….

#4 Portland Bolt

Domain Est. 1998 | Founded: 1912

Website: portlandbolt.com

Key Highlights: Portland Bolt has manufactured and distributed the highest-quality anchor bolts and nonstandard construction fasteners since 1912….

#5 ASMC Industrial

Domain Est. 1998

Website: asmc.net

Key Highlights: Discover how ASMC will meet all your needs as a reliable industrial fastener supplier and distributor, offering quality products at competitive prices….

#6 U.S. Bolt, a WN Global Company

Domain Est. 1999

Website: usbolt.com

Key Highlights: US Bolt Manufacturing is a world-class producer of engineered bolting designed for use in hostile environments and safety-critical applications….

#7 Custom Fasteners Manufacturer

Domain Est. 1999

Website: nationalbolt.com

Key Highlights: National Bolt and Nut Corporation is a ISO Certified Nationwide custom fasteners manufacturer of nuts, washers, bolts and fasteners. Contact us today!…

#8 Copper State

Domain Est. 1996

Website: copperstate.com

Key Highlights: Our ISO 9001:2015 by TUV Rheinland of North America certified manufacturing facility specializes in large diameter bolts and custom fasteners. If you have ……

#9 PEM – PennEngineering

Domain Est. 1996

Website: pemnet.com

Key Highlights: PEM offers innovative fastening solutions for a variety of applications across industries like Automotive Electronics, Consumer Electronics, Datacom and more….

#10

Domain Est. 1997

Website: arp-bolts.com

Key Highlights: ARP was the first company to design and engineer fasteners specifically for racing. We developed many patented process for manufacturing high strength ……

Expert Sourcing Insights for Bolts Machine

H2: 2026 Market Trends for Bolt Manufacturing Machinery

The global bolt manufacturing machinery market is poised for significant transformation by 2026, driven by evolving industrial demands, technological innovation, and shifts in manufacturing practices. As industries such as automotive, construction, aerospace, and renewable energy continue to expand, the demand for high-precision, efficient, and automated fastening solutions is accelerating the evolution of bolt production machines. Below are key market trends expected to shape the bolt machine industry in 2026:

-

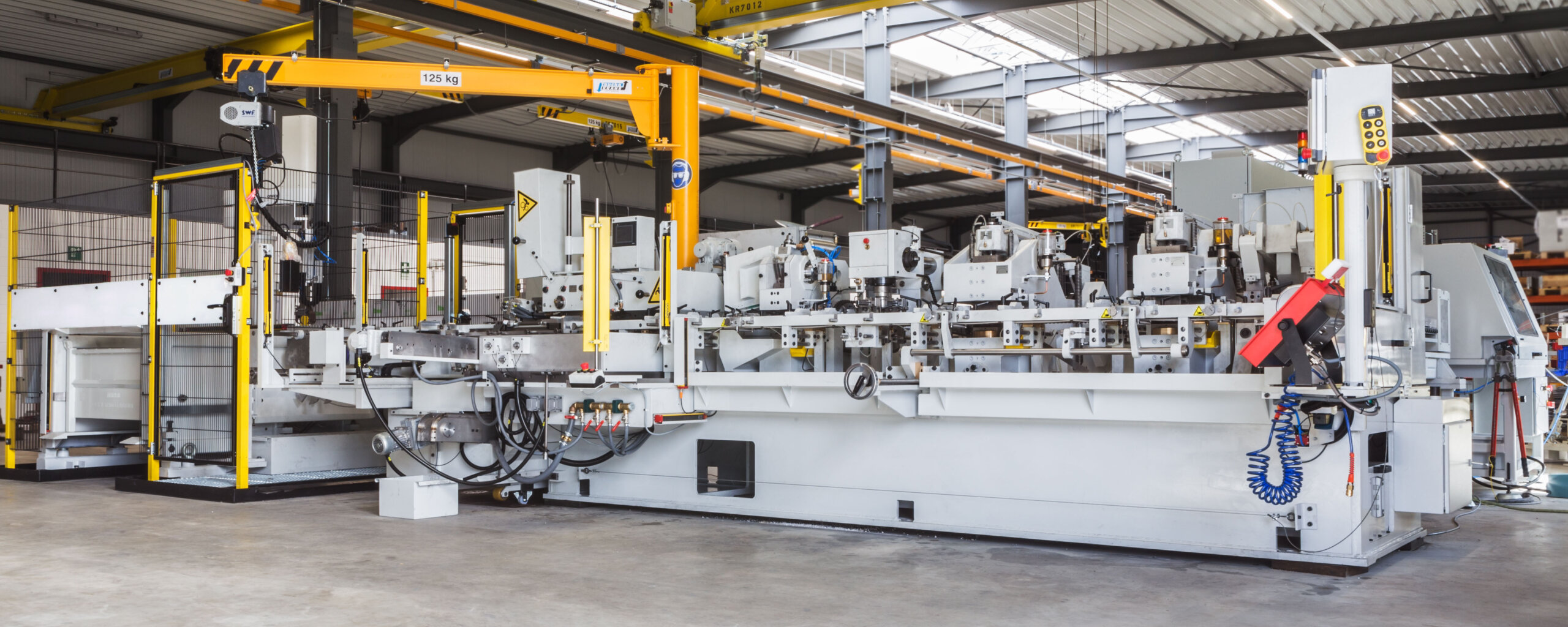

Increased Adoption of Automation and Smart Manufacturing

By 2026, automation will be a cornerstone of bolt machine operations. Manufacturers are integrating IoT-enabled sensors, AI-driven diagnostics, and real-time monitoring systems into bolt forming and threading machines. These technologies enhance predictive maintenance, reduce downtime, and improve production consistency. Smart factories utilizing Industry 4.0 principles will increasingly deploy robotic arms and closed-loop control systems for cold and hot forging processes, leading to higher throughput and lower labor costs. -

Demand for High-Strength and Specialty Fasteners

As automotive and aerospace sectors adopt lightweight materials (e.g., aluminum, carbon fiber), there is a growing need for high-strength, corrosion-resistant bolts. This drives demand for advanced bolt machines capable of precision forming of alloys like titanium, stainless steel, and heat-treated carbon steel. By 2026, bolt machine manufacturers will focus on flexible systems that support multi-material processing and tighter tolerance standards (e.g., ISO 898-1). -

Sustainability and Energy Efficiency

Environmental regulations and corporate ESG goals are pushing manufacturers to adopt energy-efficient bolt production systems. Machines with regenerative drives, reduced hydraulic usage, and optimized thermal processes will gain market share. Additionally, closed-loop recycling of metal scrap within bolt manufacturing lines is expected to become standard by 2026, aligning with circular economy principles. -

Regional Shifts in Manufacturing Hubs

Asia-Pacific, particularly China and India, will remain dominant in bolt machine demand due to booming infrastructure and automotive output. However, nearshoring trends in North America and Europe—driven by supply chain resilience concerns—will boost investments in local fastener production. This will increase demand for modular, scalable bolt machines that support agile manufacturing setups. -

Integration of Additive Manufacturing and Hybrid Processes

While traditional cold-heading remains dominant, hybrid systems combining additive manufacturing (e.g., 3D printing of bolt prototypes or custom tooling) with conventional forming are emerging. By 2026, bolt machine OEMs may offer hybrid solutions for low-volume, high-complexity fasteners used in medical or aerospace applications. -

Rise of Customization and On-Demand Production

Digital ordering platforms and cloud-based CAD integration will allow customers to customize bolt dimensions, thread types, and coatings with rapid turnaround. Bolt machines with quick-change tooling and AI-assisted setup optimization will be essential to support mass customization trends, especially in the industrial equipment and EV sectors. -

Consolidation and Technology Partnerships

The bolt machine market is expected to see increased M&A activity and strategic partnerships between machinery OEMs and software providers. By 2026, leading players will likely offer end-to-end digital solutions—from design to production analytics—positioning themselves as integrated industrial partners rather than equipment suppliers.

In conclusion, the 2026 bolt machine market will be defined by digitalization, sustainability, and adaptability. Companies that invest in smart, flexible, and eco-efficient machinery will be best positioned to capture growth amid rising global demand for advanced fastening solutions.

Common Pitfalls When Sourcing Bolt Making Machines (Quality and Intellectual Property)

Sourcing bolt making machines, especially from international or emerging market suppliers, can present significant challenges related to both machine quality and intellectual property (IP) risks. Being aware of these pitfalls is essential for ensuring long-term production efficiency and legal compliance.

Poor Build Quality and Substandard Components

One of the most frequent issues is receiving machines constructed with inferior materials and components. Low-cost suppliers may cut corners by using subpar steel, outdated electronics, or unreliable mechanical parts. This results in frequent breakdowns, inconsistent bolt quality, and higher maintenance costs. Buyers often discover that advertised specifications do not match actual performance, leading to production delays and safety hazards.

Lack of Precision and Repeatability

High-quality bolt production demands tight tolerances and consistent repeatability. Sourced machines may lack the precision engineering needed for uniform threading, head forming, or length cutting. Poor alignment, inadequate tooling, or weak control systems can produce defective fasteners, increasing scrap rates and damaging customer relationships.

Inadequate Technical Documentation and Support

Many suppliers, particularly from regions with less stringent manufacturing standards, provide incomplete or poorly translated technical manuals, maintenance guides, and schematics. This makes troubleshooting, training, and repairs difficult. Combined with limited after-sales service or unresponsive support teams, downtime can extend for weeks, severely impacting productivity.

Counterfeit or Reverse-Engineered Machines

A major IP concern is the sale of machines that are unauthorized copies of original designs. Some suppliers reverse-engineer patented technologies from reputable brands without licensing, offering “compatible” or “clone” models at lower prices. These machines may infringe on intellectual property rights, exposing the buyer to legal liability, especially when importing into countries with strong IP enforcement.

Use of Pirated or Unlicensed Software

Modern bolt making machines often rely on proprietary control software for automation and precision. Sourced machines may come with pirated or unlicensed versions of this software, which not only violates copyright laws but also poses cybersecurity risks and limits future upgrades or support. Detection of such software during customs or audits can lead to equipment seizure or fines.

Ambiguous Warranty and Liability Terms

Suppliers may offer warranties that appear comprehensive but are difficult to enforce internationally. Vague terms, exclusions for “normal wear,” or requirements to return the machine to the country of origin for repairs render warranties nearly useless. This lack of accountability shifts the risk entirely onto the buyer.

Hidden Costs from Non-Compliance

Machines that do not meet international safety or environmental standards (such as CE, ISO, or UL) can lead to regulatory issues, import restrictions, or workplace safety violations. Additionally, using IP-infringing equipment may result in legal claims from original equipment manufacturers, potentially leading to costly litigation or forced equipment replacement.

Recommendations to Mitigate Risks

To avoid these pitfalls, conduct thorough due diligence: verify supplier credentials, request references, inspect machines in person or via third-party audits, and consult legal experts to assess IP compliance. Prioritize transparency, service support, and long-term reliability over initial cost savings.

Logistics & Compliance Guide for Bolt’s Machine

This guide outlines the essential logistics and compliance considerations for the transportation, handling, and regulatory adherence related to Bolt’s Machine. Proper execution ensures timely delivery, regulatory compliance, and operational safety.

Shipping and Transportation

Coordinate with certified freight carriers experienced in handling industrial machinery. Bolt’s Machine must be securely crated and palletized to prevent damage during transit. Use shock sensors and GPS tracking for high-value or time-sensitive shipments. Ensure all transport documentation, including the bill of lading and packing list, accurately reflects the contents, weight, and dimensions.

Import/Export Compliance

Verify that Bolt’s Machine complies with destination country regulations, including CE, FCC, or other relevant certifications. Obtain necessary export licenses if shipping to restricted regions. Classify the machine under the correct HS (Harmonized System) code for accurate customs declarations. Maintain records of export control classifications (ECCN) as required by the U.S. Commerce Department or equivalent international bodies.

Packaging and Handling Standards

Follow ISO 22716 or equivalent standards for packaging industrial equipment. Use moisture barriers, anti-vibration materials, and secure strapping. Label all packages with handling instructions such as “Fragile,” “This Side Up,” and “Do Not Stack.” Include internal documentation with installation manuals, compliance certificates, and warranty information.

Regulatory Documentation

Provide a Declaration of Conformity (DoC) confirming compliance with applicable directives (e.g., Machinery Directive 2006/42/EC, Low Voltage Directive). Include technical files, risk assessments, and user manuals in the local language of the destination market. Retain all compliance records for a minimum of 10 years per regulatory requirements.

Customs Clearance Procedures

Submit complete customs documentation, including commercial invoice, certificate of origin, and packing list. Ensure duties and taxes are pre-calculated and paid promptly to avoid delays. Appoint a licensed customs broker in the destination country if required. Monitor changes in trade agreements or tariffs that may affect shipment costs or eligibility.

Safety and Environmental Compliance

Ensure Bolt’s Machine meets OSHA, REACH, RoHS, and WEEE directives where applicable. Confirm that no hazardous materials are included without proper labeling and documentation. Provide safety data sheets (SDS) for any accompanying consumables or lubricants. Comply with local electrical and operational safety codes upon installation.

Warranty and Post-Delivery Support

Include warranty terms in the shipping documentation and register the machine with the manufacturer’s support system upon delivery. Establish a logistics plan for spare parts distribution and technical service support. Train local personnel on compliance with operating and maintenance protocols.

Following this guide ensures that Bolt’s Machine is delivered efficiently, legally, and safely to its destination, minimizing risks and maximizing customer satisfaction.

Conclusion for Sourcing Bolts Machine:

In conclusion, sourcing a bolts manufacturing machine is a critical investment that directly impacts production efficiency, product quality, and long-term operational costs. After evaluating various suppliers, machine specifications, automation levels, and after-sales support, it is evident that selecting a machine aligned with production volume, bolt specifications, and future scalability is essential. Prioritizing reliability, precision, energy efficiency, and ease of maintenance will ensure optimal performance and return on investment. Additionally, establishing a strong relationship with a reputable supplier offering technical support and spare parts availability minimizes downtime and enhances productivity. With the right machine in place, the business can achieve consistent output, meet industry standards, and remain competitive in the fastener market.