The global market for precision measurement tools, including bolt thread gauges, is experiencing steady growth driven by increasing demand from automotive, aerospace, and industrial manufacturing sectors. According to Mordor Intelligence, the global thread gauge market is projected to grow at a CAGR of approximately 4.8% from 2023 to 2028, fueled by advancements in quality control standards and the rising need for dimensional accuracy in component manufacturing. As industries prioritize compliance with international standards such as ISO and ASME, the reliance on high-precision thread gauges has become critical. This underscores the importance of selecting reliable manufacturers capable of delivering consistent accuracy and durability. In this context, the following nine companies have emerged as leaders in innovation, quality, and market presence, setting the benchmark for bolt thread gauge manufacturing worldwide.

Top 9 Bolt Thread Gauge Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Gage Assembly

Domain Est. 2000

Website: gageassembly.com

Key Highlights: Gage Assembly is an industry leading custom thread gauge manufacturer. Metric and standard sizes available. Chrome plating available for ……

#2 Thread Gauge

Domain Est. 2001

Website: tn-testing.com.tw

Key Highlights: Standard thread gauge. The standard thread gauge consists of a set of thread ring gauges and thread plug gauges that are precisely matched with each other….

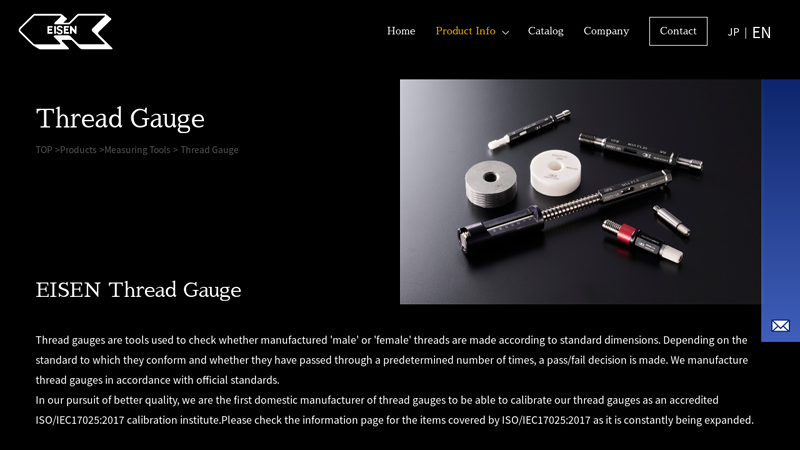

#3 EISEN Thread Gauge

Website: eisen.gr.jp

Key Highlights: We are the first domestic manufacturer of thread gauges to be able to calibrate our thread gauges as an accredited ISO/IEC17025:2017 calibration institute….

#4 Gauges Q&A

Website: kurodaprecision.com

Key Highlights: This is the Gauges Q&A information page for KURODA Precision Industries Ltd. KURODA Precision is a precision equipment manufacturer of precision Ball Screws …Missing: bolt manuf…

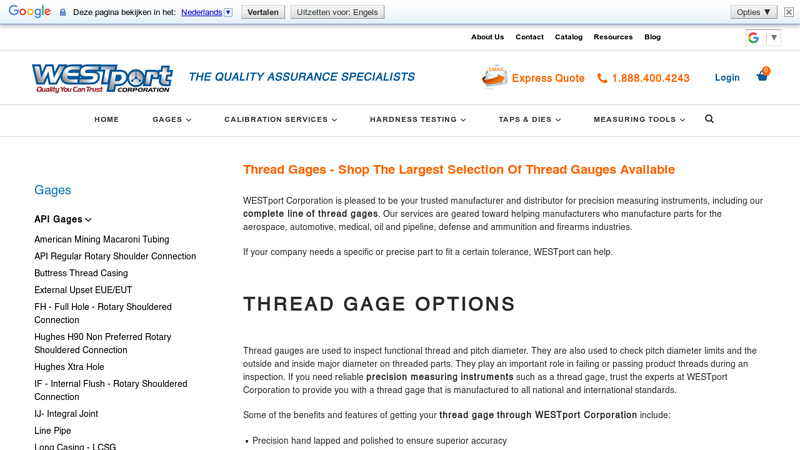

#5 Thread Gages

Domain Est. 1997

Website: westportcorp.com

Key Highlights: WESTport Corporation is the most trusted supplier of thread gauges, including our full line of thread plug gages and thread ring gages….

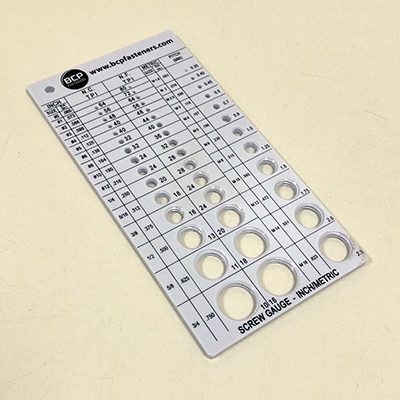

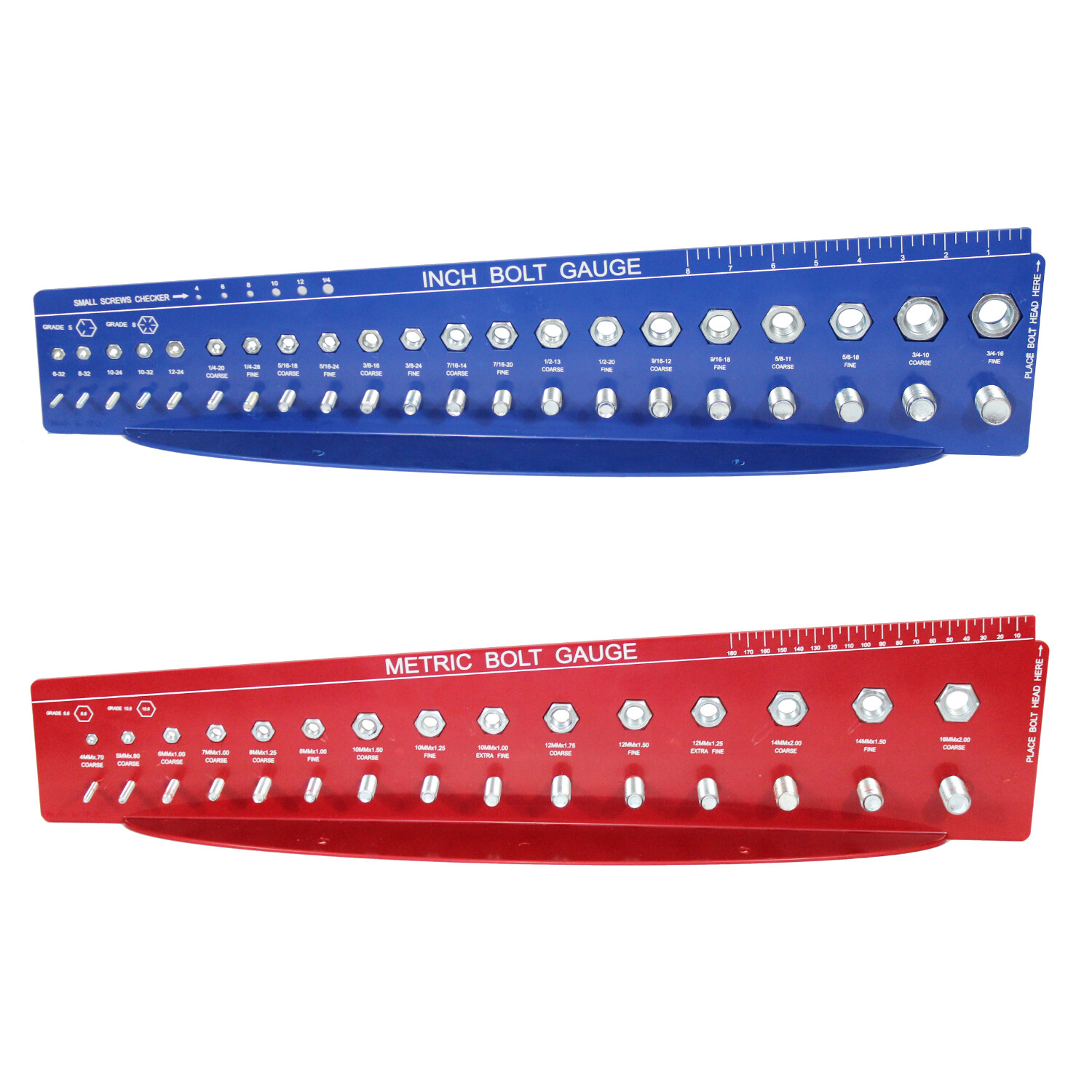

#6 Nut Bolt And Thread Gauge SAE And Metric

Domain Est. 1997

#7 Screw Thread Gauge

Domain Est. 1997

Website: generaltools.com

Key Highlights: The #714 Screw Thread Gauge quickly identifies thread pitch, tap size and drill bit size for machine and wood screws, bolts and common rivets and cotter pins….

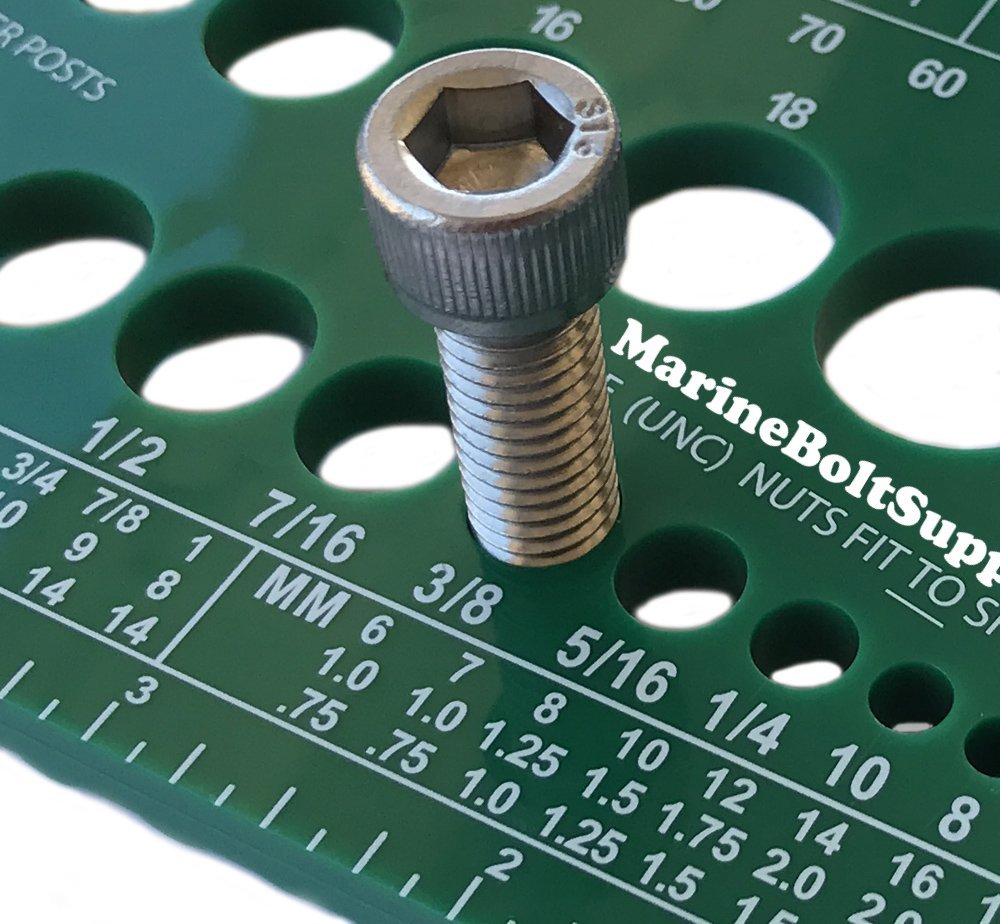

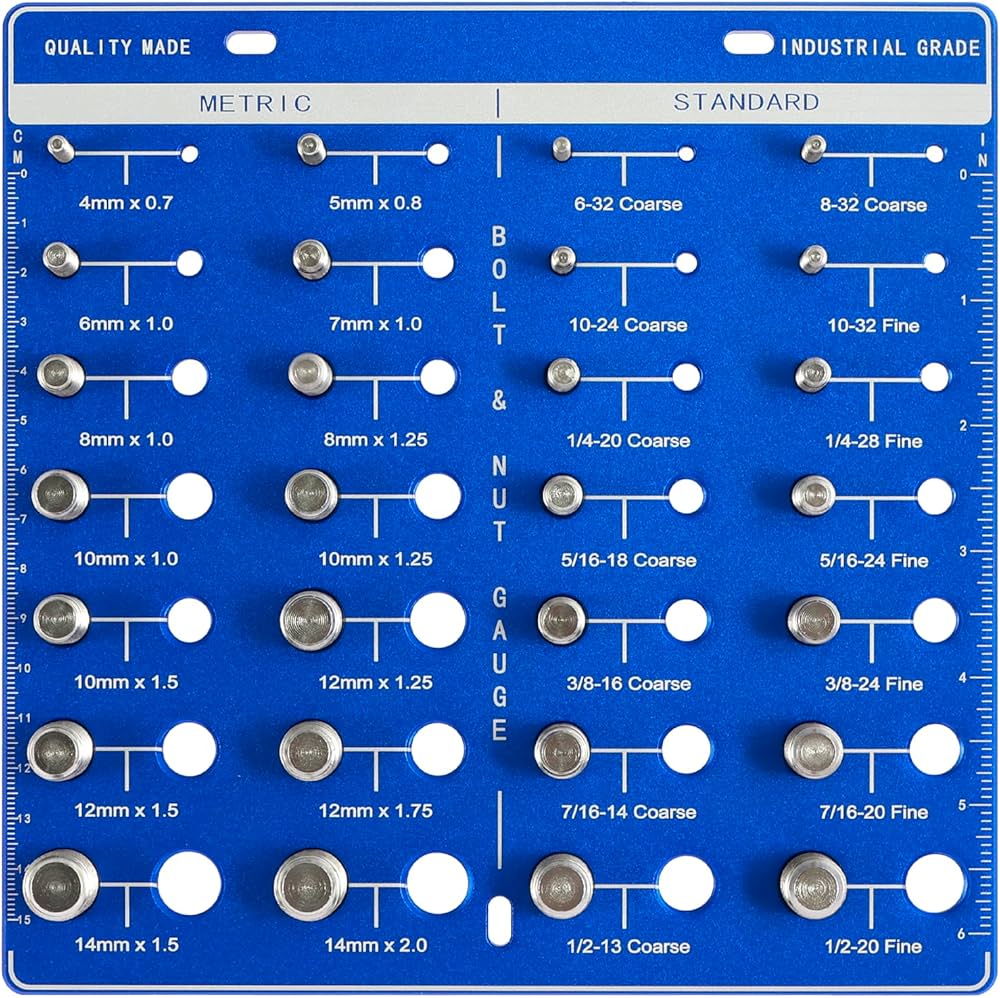

#8 Thread Gauge for Bolts & Screws

Domain Est. 2020

#9 Gauges

Website: osg.co.jp

Key Highlights: OSG offers thread gauge inspection via our web system as well as thread gauge calibration services….

Expert Sourcing Insights for Bolt Thread Gauge

H2: Projected 2026 Market Trends for Bolt Thread Gauge

The global market for bolt thread gauges is expected to experience steady growth by 2026, driven by increasing demand for precision measurement tools in manufacturing, automotive, aerospace, and construction industries. Several key trends are anticipated to shape the market landscape over the forecast period:

-

Rising Industrial Automation and Quality Control Standards

As industries adopt stricter quality control protocols and integrate smart manufacturing systems, the need for accurate thread measurement tools like bolt thread gauges is intensifying. Automated inspection processes increasingly rely on calibrated gauges to ensure consistency, reduce defects, and comply with international standards such as ISO 9001 and ASME B1.1. This shift is expected to fuel demand for high-precision, durable thread gauges. -

Growth in Automotive and Aerospace Sectors

The automotive industry, particularly with the expansion of electric vehicle (EV) production, requires tightly controlled fastening systems to ensure safety and performance. Similarly, the aerospace sector demands extreme precision in threaded components used in aircraft engines and fuselages. These applications will drive the need for advanced thread gauges capable of handling diverse thread types (e.g., metric, UNC, UNF, and NPT). -

Adoption of Digital and Smart Gauging Technologies

By 2026, digital thread gauges equipped with data output capabilities, Bluetooth connectivity, and integration with quality management software are projected to gain market share. These smart tools enable real-time data collection and analysis, supporting Industry 4.0 initiatives. Manufacturers are investing in digital calipers and electronic thread checkers that reduce human error and improve traceability. -

Expansion in Emerging Markets

Rapid industrialization in Asia-Pacific (particularly China, India, and Southeast Asia), along with infrastructure development in Latin America and the Middle East, is increasing the demand for fasteners and, by extension, thread inspection tools. Local production hubs are establishing in-situ quality control labs, boosting the need for affordable and reliable bolt thread gauges. -

Material and Design Innovations

To enhance durability and corrosion resistance, manufacturers are shifting toward advanced materials such as hardened stainless steel and ceramic-coated gauges. Ergonomic designs and modular gauge systems that support multiple thread sizes are also gaining traction, improving usability and reducing costs for end users. -

Stringent Regulatory Compliance and Standardization

Governments and industry bodies are enforcing tighter regulations on mechanical component safety, especially in critical applications. This regulatory push is increasing the adoption of certified thread gauges that meet international standards, driving market growth for calibrated, traceable measurement tools. -

Aftermarket and Calibration Services Growth

The lifecycle management of thread gauges—including recalibration, repair, and certification—is emerging as a significant service segment. By 2026, third-party calibration labs and OEM service networks are expected to expand, offering value-added services that ensure long-term accuracy and compliance.

In conclusion, the 2026 market for bolt thread gauges will be shaped by technological innovation, rising quality demands, and industrial expansion. Companies that invest in digital solutions, global standard compliance, and regional distribution networks are likely to gain a competitive edge in this evolving landscape.

Common Pitfalls When Sourcing Bolt Thread Gauge (Quality, IP)

1. Inadequate Attention to Material Quality

One of the most frequent issues in sourcing bolt thread gauges is overlooking the material composition. Low-quality materials, such as substandard steel or inadequate heat treatment, can lead to premature wear, deformation, or inaccurate measurements. This compromises the reliability of quality control processes. Always ensure gauges are made from hardened, wear-resistant materials like tool steel with proper surface finishing.

2. Lack of Traceable Calibration and Certification

Many suppliers offer thread gauges without proper calibration certificates or traceability to national or international standards (e.g., ISO, ASME). Without documented calibration (often required under ISO 9060 or ISO/IEC 17025), the accuracy of the gauge cannot be verified, leading to non-compliance in regulated industries.

3. Misunderstanding of Tolerance Classes (Go/No-Go Gauges)

Purchasers often fail to specify the correct tolerance class (e.g., 6H, 6g) required for their application. Using a gauge with incorrect tolerances can result in acceptance of defective parts or rejection of good ones. This is especially critical in high-precision industries like aerospace or automotive.

4. Ignoring International Standards Compliance

Thread standards vary by region (e.g., ISO metric, Unified National, Whitworth). Sourcing gauges that don’t conform to the required standard leads to incompatibility and quality failures. Always confirm that the gauge complies with the appropriate standard (e.g., ISO 1502, ASME B1.2) for your region and application.

5. Poor IP (Intellectual Property) and Counterfeit Risk

Low-cost suppliers, especially from unverified sources, may offer counterfeit or cloned versions of branded thread gauges. These may lack proper IP rights, reverse-engineer protected designs, or falsely claim compliance. This not only risks legal issues but also undermines quality assurance.

6. Insufficient Supplier Qualification and Audit

Sourcing from suppliers without proper quality management systems (e.g., ISO 9001 certification) increases the risk of receiving non-conforming products. Without on-site audits or supplier qualification processes, it’s difficult to verify manufacturing capabilities, inspection procedures, or consistency in production.

7. Overlooking Environmental and Usage Durability

Thread gauges are often used in harsh industrial environments. Sourcing gauges without considering corrosion resistance (e.g., chrome plating, stainless steel) or durability under repetitive use leads to shorter service life and increased calibration frequency.

8. Inadequate Documentation and Traceability (IP & Compliance)

Lack of proper documentation, including serial numbers, calibration history, material certifications, and compliance statements, can create issues during quality audits or regulatory inspections. This is particularly critical when intellectual property or compliance with industry-specific standards (e.g., automotive PPAP) is required.

9. Failure to Verify Actual vs. Advertised Specifications

Some suppliers exaggerate performance claims or provide incomplete specifications. Without independent verification or first-article inspections, buyers may receive gauges that do not meet stated accuracy, durability, or standard requirements.

10. Underestimating Total Cost of Ownership

Focusing only on initial purchase price rather than total cost (including recalibration, replacement frequency, downtime due to measurement errors) can lead to poor value over time. High-quality, properly sourced gauges typically offer better long-term ROI despite higher upfront cost.

Logistics & Compliance Guide for Bolt Thread Gauge

This guide outlines the logistics and compliance requirements for handling, shipping, storing, and using the Bolt Thread Gauge to ensure safety, accuracy, and regulatory adherence.

Product Overview

The Bolt Thread Gauge is a precision measurement tool used to verify the thread pitch and size of bolts and screws. It is typically made of hardened steel and designed for industrial, automotive, and mechanical applications.

Storage Requirements

Store the Bolt Thread Gauge in a dry, temperature-controlled environment to prevent rust and dimensional changes. Keep it in its protective case when not in use. Avoid exposure to moisture, corrosive chemicals, and extreme temperatures (storage range: 15°C to 30°C / 59°F to 86°F).

Handling & Use

Handle the gauge with clean, dry hands or gloves to prevent oil and debris transfer. Use only for its intended purpose—do not force it onto damaged or mismatched threads. Regularly inspect for wear, burrs, or deformation. Clean with a lint-free cloth and light machine oil if necessary.

Calibration & Maintenance

Calibrate the Bolt Thread Gauge annually or per organizational quality standards using certified reference standards. Document all calibration activities. Maintain a service log to track usage and maintenance history. Retire and replace if out of tolerance or physically damaged.

Shipping & Transportation

Package the gauge securely in its original case or equivalent protective container. Use shock-absorbent materials to prevent movement during transit. Label packages as “Fragile – Precision Instrument.” Ship via carriers that offer tracking and handling for sensitive equipment. Avoid prolonged exposure to temperature extremes during transport.

Regulatory Compliance

Ensure compliance with relevant industry standards, including:

– ISO 9001:2015 (Quality Management)

– ASME B1.1 (Unified Inch Screw Threads)

– ISO 1361 (Calibration of Screw Thread Gauges)

Verify that the product meets CE marking requirements if distributed in the European Economic Area. For U.S. shipments, comply with OSHA guidelines for tool safety and handling.

Export Controls

The Bolt Thread Gauge is generally not subject to export restrictions under EAR99 (U.S. Export Administration Regulations). However, confirm classification prior to international shipment, especially for destinations under trade sanctions. Maintain accurate records of export documentation when applicable.

Environmental & Safety Compliance

Dispose of damaged or obsolete gauges in accordance with local waste disposal regulations. Do not incinerate. The device contains metal components; recycle through approved metal recycling programs. No hazardous materials are present under normal use.

Training & Documentation

Provide user training on proper operation and care. Maintain accessible records of calibration certificates, safety data (if applicable), and compliance documentation. Ensure all users understand correct handling procedures to prevent injury and preserve measurement accuracy.

Contact Information

For compliance questions or support, contact:

Quality Assurance Department

Email: [email protected]

Phone: +1 (800) 555-0199

Conclusion:

Sourcing a bolt thread gauge is a critical step in ensuring accuracy, consistency, and quality in mechanical assembly, maintenance, and manufacturing processes. Selecting the right thread gauge—whether metric or imperial, internal or external—depends on specific application requirements, industry standards, and material compatibility. It is essential to source from reputable suppliers to guarantee gauge precision, durability, and compliance with relevant standards such as ISO, ANSI, or ASME. Investing in high-quality thread gauges not only enhances measurement reliability but also reduces the risk of assembly errors, equipment failure, and safety hazards. Proper calibration and maintenance further extend the tool’s lifespan and accuracy. In summary, a well-considered sourcing strategy for bolt thread gauges supports operational efficiency, product integrity, and long-term cost savings in any mechanical or industrial setting.