The global door hardware market, driven by rising construction activities and increasing demand for secure, durable, and aesthetically pleasing building components, is experiencing steady growth. According to Mordor Intelligence, the global door hardware market was valued at approximately USD 15.8 billion in 2023 and is projected to grow at a CAGR of over 6.2% from 2024 to 2029. A key component within this segment—bolt latches for doors—has seen increased demand due to their critical role in enhancing security and operational reliability across residential, commercial, and industrial applications. With technological advancements in materials and locking mechanisms, manufacturers are prioritizing innovation, durability, and compliance with safety standards. As the market expands, nine leading companies have emerged as dominant players, showcasing strong production capabilities, global distribution networks, and a consistent focus on R&D to meet evolving customer needs.

Top 9 Bolt Latch For Door Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Industrial Bolt Latches

Domain Est. 1997

Website: spep.com

Key Highlights: Explore SPEP’s extensive line of industrial bolt latches, all manufactured with quality and durability in mind. Contact us today to learn more….

#2 BOLT Lock: Breakthrough One

Domain Est. 2000

Website: boltlock.com

Key Highlights: We make Breakthrough One-Key Lock Technology, so you can set all your locks & keep everything conveniently secure with one key….

#3 Door bolt

Domain Est. 1996

Website: assaabloy.com

Key Highlights: Secure Your Wooden Doors With Our Elegant Door Bolt, Featuring A Charming Scroll Pattern. Designed Specifically For Timber Doors, This Antique-style Bolt Adds ……

#4 Baldwin Hardware

Domain Est. 1998

Website: baldwinhardware.com

Key Highlights: Baldwin Hardware is a leading provider of high-quality, stylish and durable door and cabinet hardware for both residential and commercial applications….

#5 Locks

Domain Est. 1998

Website: cisa.com

Key Highlights: A wide range of locks for all security and installation requirements. Mechanical, electric and electronic locks that can be installed on steel, aluminium and ……

#6 National Guard Products

Domain Est. 2000

Website: ngp.com

Key Highlights: 99% of NGP products are Made in the USA, and NGP’s broad portfolio includes smoke seals, automatic door bottoms, thresholds, fire-rated vision kits, fire and ……

#7 Spring Loaded Bolt Latch

Domain Est. 2006

Website: tsdistributors.com

Key Highlights: Aluminum Spring-Loaded Bolt Latch · HAP1181A · $7.67 ; Heavy Duty Uni-Latch · HAU101 · $39.95 ; Heavy-Duty Spring-Loaded Bolt Latch with Keeper….

#8 Ives Constant Latching Flush Bolt

Domain Est. 2007

Website: iveshinges.com

Key Highlights: Ives Constant Latching Flush Bolt, Top Bolt with Auxiliary Fire Latch and Retrofit Plate FB53 Metal Doors…

#9

Domain Est. 2023

Website: accentra-assaabloy.com

Key Highlights: ASSA ABLOY ACCENTRA provides a comprehensive range of high-performance door hardware and streamlined digital access control solutions….

Expert Sourcing Insights for Bolt Latch For Door

2026 Market Trends for Bolt Latch for Door

Rising Demand for Smart and Connected Locking Solutions

By 2026, the bolt latch for door market is expected to be significantly driven by the integration of smart technologies. Consumers and commercial property managers are increasingly favoring smart door locks that incorporate electronic bolt latches, enabling remote access, mobile app control, and integration with home automation systems like Google Home, Apple HomeKit, and Amazon Alexa. This trend is fueled by growing concerns for security, convenience, and the expanding Internet of Things (IoT) ecosystem. Manufacturers are responding by developing hybrid bolt latches that support both traditional mechanical operation and electronic actuation, ensuring backward compatibility while meeting future demands.

Enhanced Security and Anti-Snap/Bump Technologies

Security remains a paramount concern, pushing innovation in bolt latch design. By 2026, anti-snap, anti-bump, and anti-drill mechanisms are becoming standard rather than premium features. Regulations in regions like the UK (e.g., TS007 3-star rating) and increasing insurance requirements are mandating higher security standards. Bolt latches with reinforced materials such as hardened steel, dual locking points, and concealed strike plates are gaining traction. These advancements are particularly evident in residential markets where forced entry remains a persistent threat, leading to a shift from basic latches to high-security bolt systems.

Sustainable and Eco-Friendly Materials Adoption

Environmental sustainability is influencing material choices in the bolt latch industry. By 2026, there is a growing preference for recyclable metals, low-impact manufacturing processes, and finishes that minimize volatile organic compound (VOC) emissions. Zinc alloys with high recycled content and powder-coated finishes are being adopted to meet green building standards such as LEED and BREEAM. This trend is especially strong in commercial construction and eco-conscious residential developments, where sustainability certifications can enhance property value and appeal.

Growth in Retrofit and DIY-Friendly Solutions

The home improvement and renovation sector is a key driver for bolt latch adoption. With rising real estate prices limiting new construction, consumers are investing in upgrading existing doors. This has led to increased demand for retrofit-compatible bolt latches that can be easily installed without major door modifications. By 2026, manufacturers are focusing on modular designs, universal sizing, and clear installation guides to support DIY enthusiasts. Online retail growth further amplifies this trend, as users seek convenient, self-installable security upgrades.

Regional Regulatory and Standardization Shifts

Global variations in building codes and security standards are shaping product development. In Europe, compliance with EN 12209 and CE marking is essential, while North America sees growing adoption of ANSI/BHMA standards. By 2026, manufacturers are tailoring bolt latch designs to meet region-specific requirements, such as fire resistance ratings (e.g., 3-hour fire door compliance) or accessibility standards (e.g., ADA-compliant operation force). These regulatory pressures are leading to more diversified product lines and increased investment in certification testing.

Supply Chain Resilience and Localization

Ongoing geopolitical uncertainties and post-pandemic supply chain disruptions are prompting a shift toward localized production. By 2026, key players in the bolt latch market are investing in regional manufacturing hubs to reduce dependency on single-source suppliers, particularly from Asia. This trend supports faster delivery times, reduced carbon footprint, and better responsiveness to market fluctuations. Additionally, digital inventory management and just-in-time manufacturing are being adopted to enhance supply chain efficiency and reduce lead times.

In summary, the 2026 bolt latch for door market is characterized by technological integration, heightened security demands, sustainability, and adaptability to regional and logistical challenges. Companies that innovate across these dimensions will be best positioned to capture growth in an increasingly competitive and regulated landscape.

Common Pitfalls When Sourcing Bolt Latch for Door (Quality and IP Considerations)

Logistics & Compliance Guide for Bolt Latch For Door

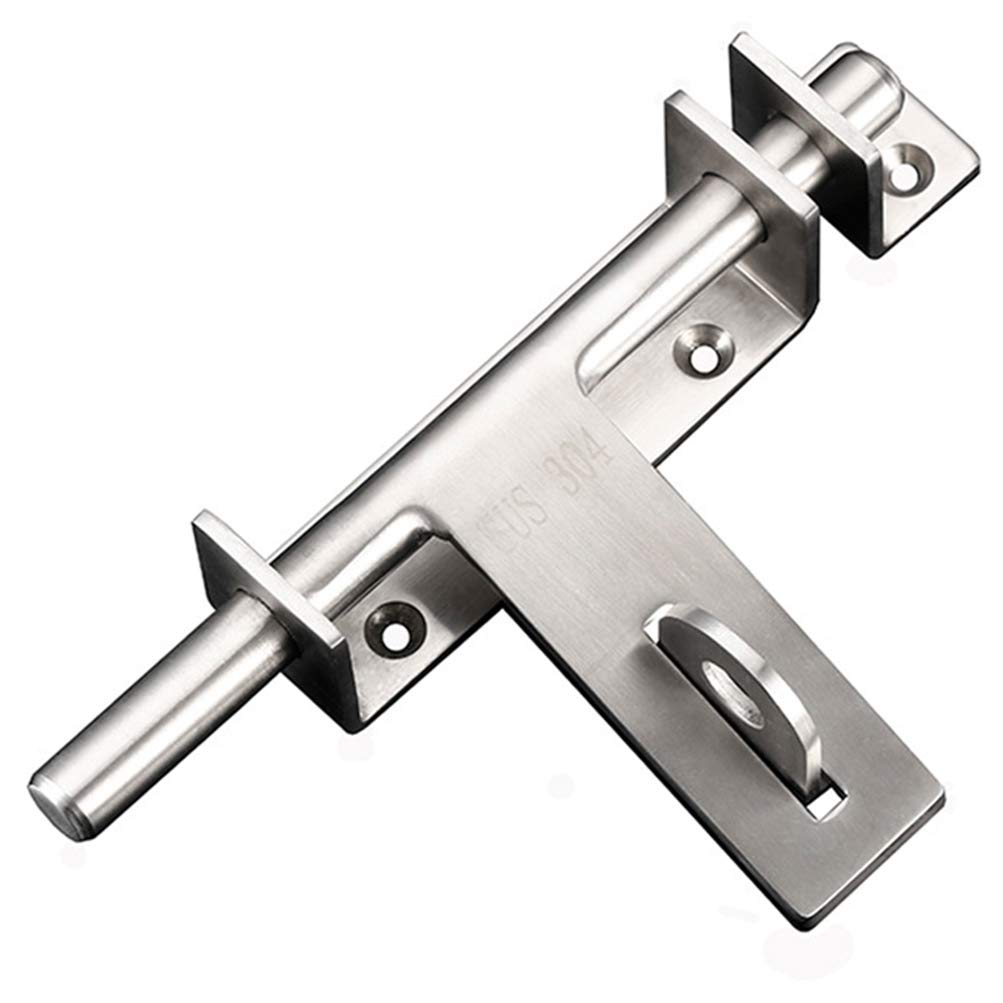

Product Overview and Classification

The Bolt Latch For Door is a mechanical hardware component designed for securing doors in residential, commercial, and industrial applications. It typically consists of a bolt mechanism operated via key, handle, or electronic trigger, and is used in conjunction with strike plates and door frames. This guide outlines the logistics handling procedures and regulatory compliance requirements for the safe and legal distribution of this product.

International Shipping and Packaging Requirements

Ensure the bolt latch is packaged in durable, moisture-resistant materials to prevent corrosion during transit. Individual units should be wrapped in anti-rust paper or vacuum-sealed if made from steel or iron. Use corrugated cardboard boxes with internal dividers to prevent movement. For bulk shipments, palletize securely using stretch wrap and corner boards. Label packages with:

– Product name and model number

– Net and gross weight

– “Fragile” and “Do Not Stack” markings as needed

– Harmonized System (HS) Code: 8302.41 (Door fittings of iron or steel)

Import/Export Regulations

Compliance with customs regulations is essential. Key requirements include:

– Export Controls: Verify if the product contains dual-use components (e.g., electronic access control) subject to export control regimes such as EAR (Export Administration Regulations). Most mechanical bolt latches are not controlled, but documentation should confirm non-applicability.

– Country-Specific Restrictions: Some countries restrict imports of certain metal hardware. Confirm with local customs authorities in destination markets (e.g., UAE, Australia, EU).

– Documentation: Provide commercial invoice, packing list, and bill of lading/air waybill. A certificate of origin may be required for preferential tariff treatment under trade agreements.

Safety and Product Compliance Standards

The bolt latch must meet relevant safety and performance standards in target markets:

– United States: Comply with ANSI/BHMA A156.5 for door locks and latches. Third-party certification (e.g., UL, Intertek) may be required.

– European Union: Conform to EN 12209 (Building hardware – Mechanical door locks, latches and striker plates). CE marking is mandatory, requiring a Declaration of Conformity and technical file.

– United Kingdom: UKCA marking required post-Brexit; follows similar standards to EU (BS EN 12209).

– Canada: Meets CAN/CGSB-146.1-M91 (Door Hardware) requirements. CSA certification may be needed.

Environmental and Material Compliance

Ensure materials used in manufacturing comply with environmental regulations:

– RoHS (EU/UK): Restricts use of lead, cadmium, mercury, and other hazardous substances in electrical/electronic components. Mechanical latches without electronics are typically exempt, but confirm material composition.

– REACH (EU): Registration, Evaluation, Authorization, and Restriction of Chemicals. Declare presence of Substances of Very High Concern (SVHCs) if above threshold.

– Conflict Minerals (U.S. Dodd-Frank Act): If applicable, disclose use of tin, tantalum, tungsten, or gold sourced from conflict-affected regions. Most latches use minimal quantities; perform supply chain due diligence.

Labeling and User Documentation

Each unit must include:

– Manufacturer name and contact information

– Model and part number

– Installation instructions in local language(s)

– Safety warnings (e.g., pinching hazard during installation)

– Compliance marks (e.g., CE, UKCA, ANSI/BHMA)

Warehousing and Inventory Management

Store in a dry, temperature-controlled environment to prevent rust or degradation. Use FIFO (First In, First Out) stock rotation. Maintain traceability via batch/lot numbering for recall preparedness. For hazardous material storage (e.g., lubricants used in pre-lubricated models), follow local chemical storage codes.

End-of-Life and Recycling

Design for disassembly and recyclability. Metal components (steel, brass, zinc) are recyclable. Provide disposal guidance in user manuals: “Dispose of at certified metal recycling facilities. Do not dispose of in household waste.” Comply with WEEE (EU) if electronic components are integrated.

Regulatory Updates and Monitoring

Assign a compliance officer to monitor changes in international trade policies, safety standards, and environmental regulations. Subscribe to alerts from regulatory bodies such as the U.S. CPSC, EU RAPEX, and ISO. Conduct annual compliance audits for continuous improvement.

By adhering to this logistics and compliance guide, manufacturers and distributors ensure the Bolt Latch For Door meets global standards for safety, environmental responsibility, and legal distribution.

Conclusion:

After evaluating various options for sourcing a bolt latch for a door, it is clear that the best approach depends on factors such as quality requirements, budget constraints, compatibility with existing hardware, and availability. Standard bolt latches can be efficiently sourced from local hardware stores or online retailers for immediate needs and cost-effective solutions. For specialized or higher security applications, direct sourcing from manufacturers or authorized suppliers ensures better durability, compliance with safety standards, and customization options.

Additionally, considering factors like material (stainless steel, zinc alloy, etc.), locking mechanism (deadbolt, spring bolt), and finish (to match door aesthetics) is essential in making a suitable choice. Establishing reliable supplier relationships and verifying product specifications prior to bulk purchasing can prevent installation issues and ensure long-term performance.

Ultimately, a balanced decision that weighs cost, quality, and reliability will lead to the successful integration of a bolt latch that enhances both the functionality and security of the door.