The global fasteners market, driven by sustained demand from the automotive, construction, and industrial equipment sectors, is projected to grow at a CAGR of 5.8% from 2023 to 2028, according to Mordor Intelligence. Within this expansive market, body bolts—critical components used to secure body panels and structural assemblies in vehicles and machinery—represent a high-precision niche with rising demand for corrosion-resistant and lightweight solutions. As automotive production volumes increase and electric vehicle platforms require more specialized fastening systems, the need for reliable body bolt manufacturers has intensified. Advancements in materials, including high-tensile steel and stainless alloys, coupled with stringent OEM quality standards, have reshaped supplier dynamics. Based on market presence, production capacity, innovation in coatings, and global supply chain reach, the following ten manufacturers have emerged as leaders in the body bolts segment.

Top 10 Body Bolts Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

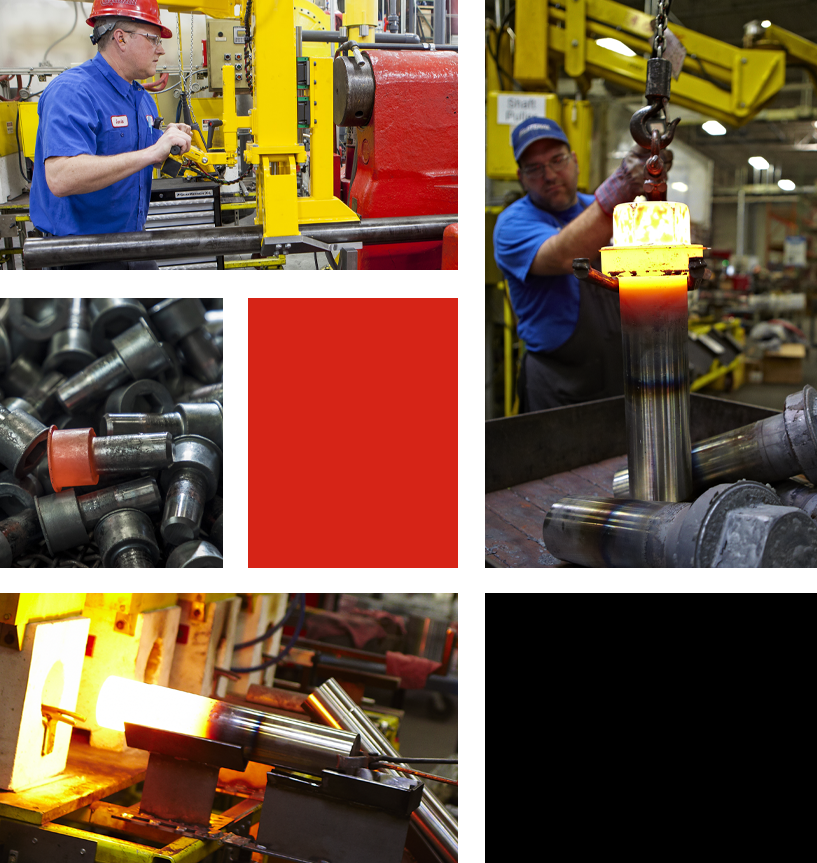

#1 Cardinal Fastener

Domain Est. 1997

Website: cardinalfastener.com

Key Highlights: Cardinal Fastener Inc. is one of the largest fastener manufacturers of large diameter, hot forged bolts in America….

#2 Haydon Bolts

Domain Est. 1998

Website: haydonbolts.com

Key Highlights: Haydon Bolts, Inc., an AISC Associate member company, is a family owned manufacturer specializing in domestic structural bolts and anchor rods, since 1864….

#3 Portland Bolt

Domain Est. 1998 | Founded: 1912

Website: portlandbolt.com

Key Highlights: Portland Bolt has manufactured and distributed the highest-quality anchor bolts and nonstandard construction fasteners since 1912….

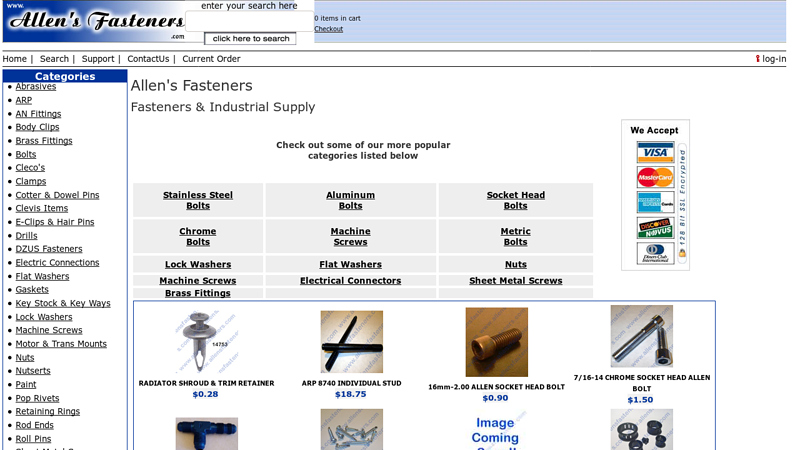

#4 Chrome Bolts, Stainless Steel Bolts, Metric Bolts, Socket Head Cap …

Domain Est. 2002

Website: allensfasteners.com

Key Highlights: 30-day returnsNut, Bolt, Fasteners & Industrial Supply. Online shopping, Low Prices, No Minimum, Fast shipping. Allen’s Fasteners, Fasteners & Industrial Supply….

#5 American Bolt

Domain Est. 2003

Website: americanboltcorp.com

Key Highlights: American Bolt Corp is a high quality industrial fastener supplier for a variety of different industries. We provide top fastener solutions to meet any need!…

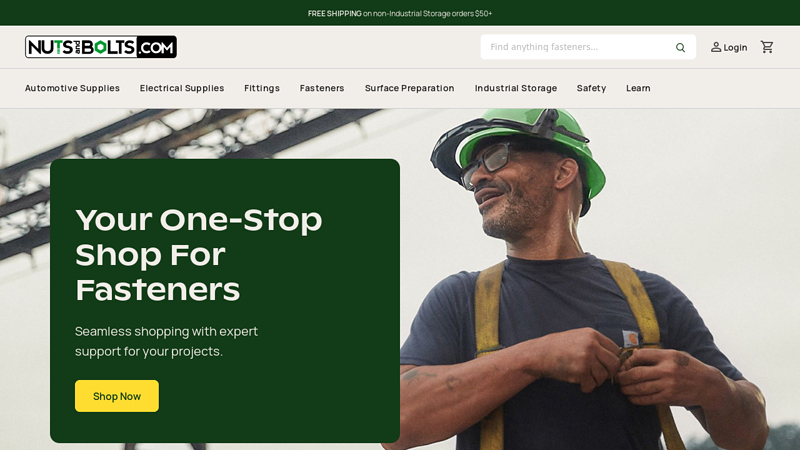

#6 NutsandBolts.com

Domain Est. 1996

Website: nutsandbolts.com

Key Highlights: Free delivery over $50 30-day returnsNuts, Bolts, Screws and Specialty Fastener Supplier. … Body Bolts · Clamps & Clips · Extension Springs · Grease Fittings · Grommets · License…

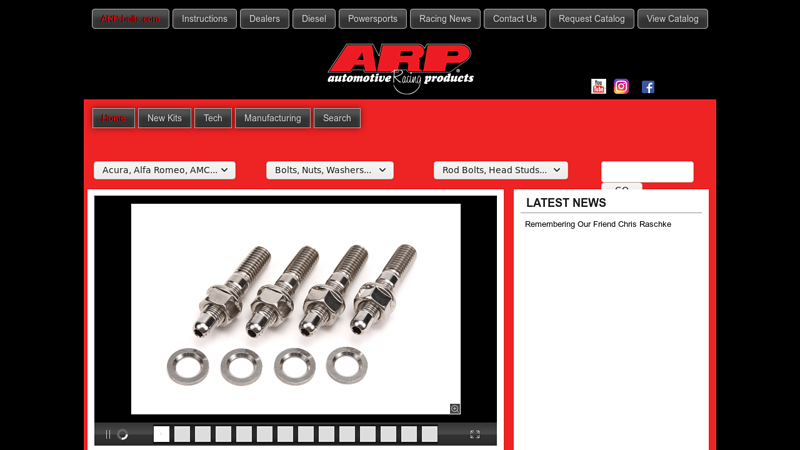

#7 ARP

Domain Est. 1997

Website: arp-bolts.com

Key Highlights: Fastener Tech • ARP Ultra-Torque • Find Your Kit Instructions • Fastener Installation Overview • Torque Value Lookup • Fastener Installation FAQs…

#8 Body Bolts & Nuts

Domain Est. 1997

Website: lawsonproducts.com

Key Highlights: Shop body bolts and nuts crafted for durability and secure fastening. Lawson Products delivers reliable solutions for every job. Discover quality and order ……

#9 Body Bolts & Nuts

Domain Est. 2001

Website: kent-automotive.com

Key Highlights: 90-day returnsShop body bolts and nuts crafted for durability and secure fastening. Lawson Products delivers reliable solutions for every job….

#10 ATC Bolts & Fasteners

Domain Est. 2021

Website: atcbolts.com

Key Highlights: ATC Bolts & Fasteners is a leading supplier of premium hardware, bolts, and fasteners engineered for performance, precision, and durability. We specialize in ……

Expert Sourcing Insights for Body Bolts

2026 Market Trends for Body Bolts

The body bolt market is poised for steady evolution by 2026, driven by advancements in automotive manufacturing, material science, and global sustainability initiatives. Body bolts—critical fasteners used to join structural components in vehicle frames and chassis—will experience shifts in demand, materials, and technological integration.

Rising Demand from Electrification and Lightweighting

The surge in electric vehicle (EV) production will significantly influence body bolt demand. As automakers prioritize weight reduction to extend battery range, there will be increased use of high-strength, lightweight materials such as advanced high-strength steel (AHSS), aluminum, and magnesium alloys. Body bolts must adapt to these materials, requiring enhanced tensile strength, corrosion resistance, and precision engineering. This trend will drive demand for specialized, high-performance fasteners capable of maintaining structural integrity in mixed-material assemblies.

Shift Toward High-Performance and Specialty Fasteners

By 2026, the market will see a growing preference for premium-grade body bolts, including those with multi-material compatibility, anti-vibration features, and integrated sealing functions. Innovations such as self-piercing rivets (SPRs) and flow-drill screws—often used alongside or in place of traditional bolts—will continue to gain traction, particularly in aluminum-intensive EV platforms. Additionally, smart fasteners with embedded sensors for structural health monitoring may begin limited adoption in high-end and commercial vehicle segments.

Regional Manufacturing and Supply Chain Resilience

Geopolitical factors and supply chain disruptions will push automakers and Tier 1 suppliers to localize production. This will benefit regional body bolt manufacturers in North America, Europe, and parts of Asia, especially India and Southeast Asia. Localization efforts will emphasize supply chain resilience, shorter lead times, and compliance with regional emissions and safety standards, influencing sourcing decisions and driving investments in local manufacturing capabilities.

Sustainability and Circular Economy Pressures

Environmental regulations and corporate ESG (Environmental, Social, Governance) goals will shape material choices and production processes. The industry will move toward recyclable fastener materials and energy-efficient manufacturing methods, such as cold forging and low-emission coatings. Reusability and disassembly considerations—important for end-of-life vehicle recycling—may influence bolt design, promoting innovations in reversible or easily removable fastening systems.

Consolidation and Technological Integration

Market consolidation among fastener suppliers is expected as companies seek economies of scale and R&D capabilities to meet evolving OEM requirements. Digitalization will also play a role, with increased use of IoT-enabled production lines, AI-driven quality control, and blockchain for traceability in high-criticality applications. These technologies will enhance precision and reliability, particularly for safety-critical body bolts.

In summary, the 2026 body bolt market will be defined by innovation in materials and design, alignment with EV production needs, regionalization of supply chains, and a stronger emphasis on sustainability and smart manufacturing. Suppliers who invest in advanced engineering and adaptive production will be best positioned to capture growth in this evolving landscape.

Common Pitfalls Sourcing Body Bolts (Quality, IP)

Sourcing body bolts—especially for critical structural or safety-related applications—requires careful attention to both quality and Intellectual Property (IP) considerations. Overlooking these factors can lead to performance failures, legal disputes, or reputational damage. Below are common pitfalls to avoid:

Poor Material and Manufacturing Quality

One of the most frequent issues when sourcing body bolts is receiving substandard products due to inadequate material specifications or poor manufacturing processes. Low-quality bolts may use inferior steel, incorrect heat treatment, or imprecise threading, leading to reduced tensile strength, fatigue failure, or stripping during installation. Always verify compliance with industry standards such as ISO, ASTM, or SAE, and request mill test certificates or third-party inspection reports.

Lack of Traceability and Certification

Many suppliers, particularly from less-regulated markets, fail to provide full traceability for sourced bolts. Without proper certification (e.g., EN 10204 3.1), it’s difficult to confirm that bolts meet required mechanical properties or chemical composition. This lack of documentation increases the risk of non-compliance in regulated industries like automotive, aerospace, or construction.

Counterfeit or Non-OEM Spec Parts

When replacing OEM body bolts, especially in automotive or industrial machinery, using counterfeit or look-alike fasteners is a major risk. These bolts may visually resemble the original but fail to meet dimensional tolerances, torque specs, or load-bearing requirements. Always source from authorized distributors or certified manufacturers to ensure authenticity and performance equivalence.

Intellectual Property Infringement

Design-specific body bolts—such as proprietary thread profiles, flange designs, or torque-to-yield configurations—may be protected by patents or design rights. Sourcing generic copies without proper licensing can lead to IP infringement claims, particularly if the bolt design is patented. Conduct due diligence to ensure that the supplier isn’t violating existing IP, especially when replicating OEM components.

Inadequate Corrosion Resistance

Body bolts are often exposed to harsh environments, making corrosion resistance critical. Sourcing bolts with insufficient plating (e.g., substandard zinc coating or missing passivation) leads to premature rust and joint failure. Ensure specified protection levels (e.g., ISO 9227 salt spray test compliance) match the application environment.

Misalignment of Thread Standards

Bolts sourced from international suppliers may adhere to regional standards (e.g., metric vs. imperial, fine vs. coarse threads) that don’t align with the original design. Even minor thread mismatches can cause galling, cross-threading, or reduced clamping force. Confirm thread standards and gauging requirements before procurement.

Overlooking Torque and Preload Requirements

High-performance body bolts—such as those used in engine or chassis assemblies—are often torque-to-yield (TTY) or require specific preload values. Generic replacements may not support the required elastic elongation or torque characteristics, compromising joint integrity. Always verify that sourced bolts are engineered for the intended preload and installation method.

Supplier Reliability and Long-Term Support

Choosing suppliers based solely on low cost can backfire if they lack consistent quality or go out of business. This is especially critical for maintenance and repair operations requiring long-term part availability. Evaluate supplier stability, quality management systems (e.g., ISO 9001), and service history before committing.

Avoiding these pitfalls requires a structured sourcing strategy that prioritizes certified quality, legal compliance, and technical suitability—ensuring body bolts perform safely and reliably over their service life.

Logistics & Compliance Guide for Body Bolts

This guide outlines the essential logistics and compliance considerations for the handling, transportation, and regulatory adherence related to body bolts—critical fasteners used in automotive, aerospace, and industrial applications.

Product Identification & Specifications

Ensure body bolts are clearly identified by part number, material grade (e.g., ASTM A325, ISO 898-1), size, thread type, and coating (e.g., zinc-plated, galvanized). Accurate specifications are vital for traceability and compliance with engineering requirements.

Packaging & Labeling Requirements

Package body bolts in moisture-resistant, anti-corrosive materials such as sealed plastic bags or vapor-corrosion inhibitor (VCI) packaging. Outer containers must include labels indicating contents, quantity, lot/batch numbers, handling instructions (e.g., “Fragile,” “Keep Dry”), and compliance marks (e.g., RoHS, REACH).

Storage Conditions

Store body bolts in a dry, temperature-controlled environment to prevent rust and degradation. Avoid exposure to chemicals, salt, or high humidity. Use FIFO (First In, First Out) inventory management to prevent aging of stock and ensure product integrity.

Transportation & Handling

Use secure, non-reactive pallets or containers during transit. Protect against vibration, impact, and environmental exposure. For international shipments, ensure packaging complies with ISPM 15 standards for wooden pallets. Handle with non-magnetic tools if required for specific material grades.

Regulatory Compliance

Verify that body bolts meet relevant regional and international standards:

– North America: DOT, ASTM, SAE, and FIM standards as applicable

– European Union: CE marking, EU Construction Products Regulation (CPR), REACH, and RoHS compliance

– Global: ISO 898-1 (mechanical properties), ISO 4042 (hexagon products), and IATF 16949 for automotive supply chains

Documentation & Traceability

Maintain complete documentation, including:

– Material Test Reports (MTRs)

– Certificates of Compliance (CoC)

– Batch and heat traceability records

– Customs documentation (e.g., commercial invoice, packing list, Bill of Lading)

Ensure digital and physical records are retained for a minimum of 10 years, or as required by industry standards.

Import/Export Controls

Check export classification (e.g., ECCN under EAR or USML under ITAR) for high-strength or specialty body bolts. Comply with destination country regulations—some may require import permits or product certification (e.g., INMETRO in Brazil, KC in South Korea).

Environmental & Safety Compliance

Dispose of packaging and non-conforming bolts in accordance with local environmental regulations. Provide Safety Data Sheets (SDS) for coated or chemically treated bolts. Ensure workplace handling follows OSHA or equivalent safety guidelines to prevent injury.

Audit & Quality Assurance

Conduct regular internal audits to verify compliance with ISO 9001, IATF 16949, or other quality management systems. Perform random sampling and mechanical testing to confirm bolt strength, hardness, and dimensional accuracy.

Adhering to this logistics and compliance framework ensures the safe, legal, and efficient distribution of body bolts across global supply chains.

Conclusion on Sourcing Body Bolts

In conclusion, sourcing body bolts requires a careful evaluation of quality, specifications, supplier reliability, and cost-effectiveness. It is essential to ensure that the bolts meet required industry standards (such as ISO, ASTM, or SAE) and are made from appropriate materials to withstand environmental and mechanical stresses. Establishing relationships with reputable suppliers, whether domestic or international, helps ensure consistent supply and product integrity. Additionally, considering factors such as lead time, scalability, and total cost of ownership—beyond unit price—contributes to long-term operational efficiency. By implementing a strategic sourcing approach that balances cost, quality, and reliability, organizations can secure high-performance body bolts that support the structural integrity and safety of their assemblies or end products.