The global nut processing equipment market is experiencing robust growth, driven by rising demand for convenience foods and increased consumption of tree nuts, including black walnuts. According to Mordor Intelligence, the global nut processing machinery market was valued at USD 9.8 billion in 2023 and is projected to grow at a CAGR of 6.2% through 2029. This expansion is fueled by advancements in automation, heightened food safety standards, and growing interest in value-added nut products. As black walnuts gain popularity for their rich flavor and nutritional profile, the need for efficient, high-throughput cracking machinery has intensified. Meeting this demand, a select group of manufacturers have emerged as leaders in designing and producing specialized black walnut cracking equipment—balancing shell fracture precision with kernel recovery rates. Based on market presence, technological innovation, and customer feedback, the following six companies represent the forefront of this niche but growing segment.

Top 6 Black Walnut Cracking Machine Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 China Walnut Cracking Machine Suppliers Factory

Domain Est. 2022

Website: lffoodmachine.com

Key Highlights: As one of the leading walnut cracking machine suppliers in China, we warmly welcome you to buy high-grade walnut cracking machine for sale here from our ……

#2 Products

Domain Est. 1998

Website: grimonut.com

Key Highlights: This heavily built machine can crack 600 pounds of black walnuts per hour. The steel surfaces are coated with a baked on food grade finish. The sealed 1 hp gear ……

#3 Unboxing the New U.S.A.

Domain Est. 2004

Website: grandpasgoodygetter.com

Key Highlights: They crack black walnuts and other tough nuts easily and very effectively. Yes, the U.S.A. machine costs more than the older model made overseas ……

#4 Black Walnut Cracker

Domain Est. 2011

Website: pecannutbusters.com

Key Highlights: In stockOur Large Black Walnut Nut Buster cracking machine can process aprox 480 lbs of nuts per hour. Other Highlights. Weights apx. 105 lbs….

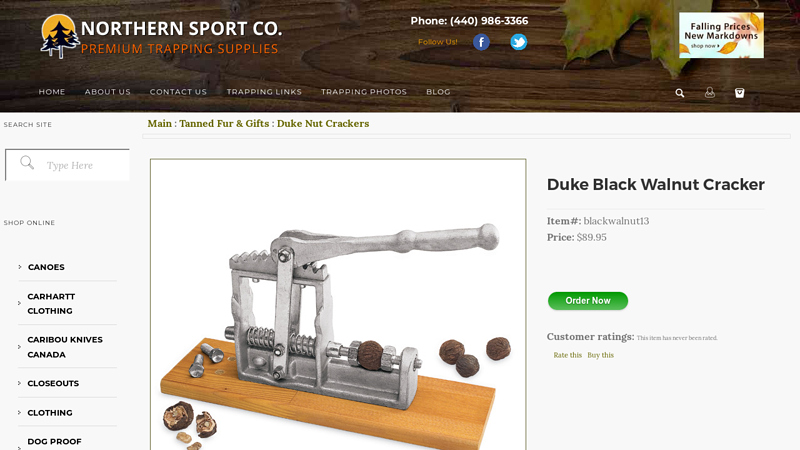

#5 Duke Black Walnut Cracker

Domain Est. 2011

Website: northerntrapping.com

Key Highlights: 30-day returnsDuke Black Walnut Cracker · Manufactured with a cast aluminum frame · Gear lever design · Hardened machine tool steel · Comes fully assembled….

#6 turcobazaar professional nut cracker machine full automatic walnut …

Domain Est. 2013

Website: turcobazaar.com

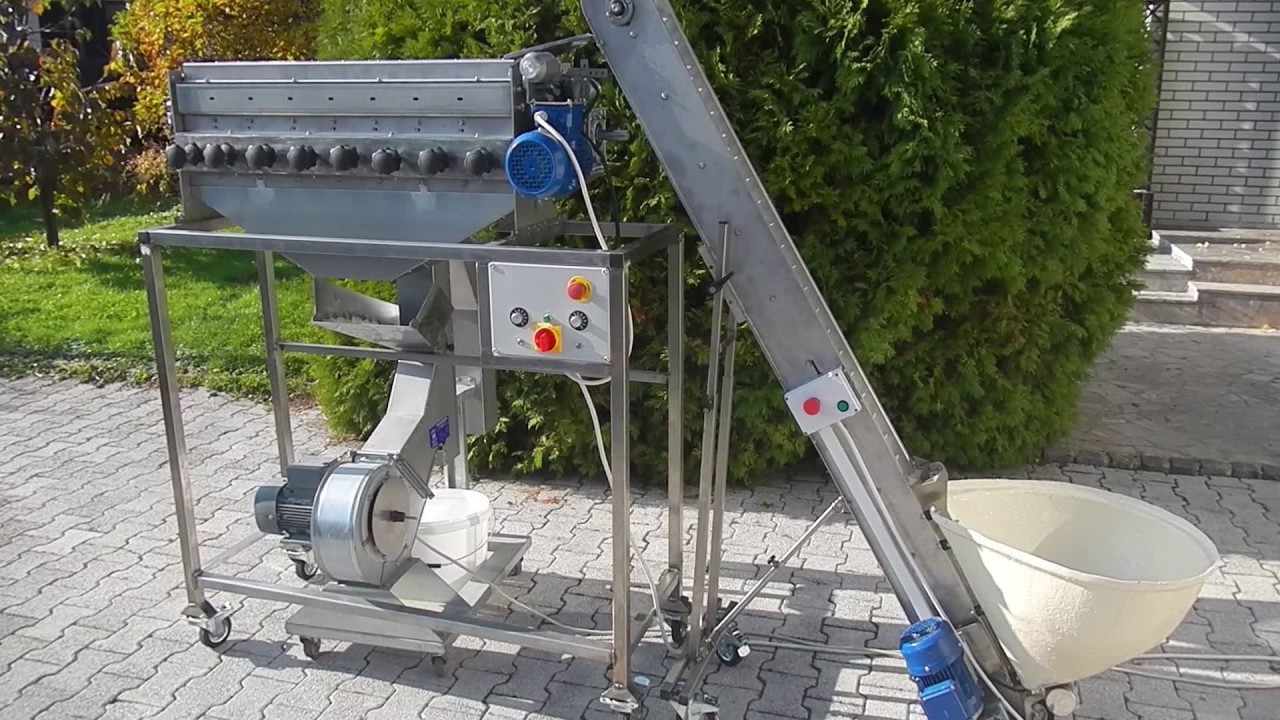

Key Highlights: In stock 2–6 day deliveryTHIS PRODUCT IS A COMPLETE HAZELNUT WALNUT ALMOND PROCESSING LINE. 2 MACHINES. 1- TB250B makes the sizing and categorizing the nuts according to their size…

Expert Sourcing Insights for Black Walnut Cracking Machine

H2: 2026 Market Trends for Black Walnut Cracking Machines

The global market for black walnut cracking machines is poised for notable shifts by 2026, driven by increasing demand for nut processing automation, rising health consciousness, and advancements in agricultural technology. Below is an analysis of key market trends expected to shape the industry in 2026.

1. Rising Demand for Mechanized Nut Processing

As the popularity of black walnuts grows due to their rich nutritional profile—high in omega-3 fatty acids, antioxidants, and protein—commercial nut processors are seeking efficient ways to scale production. Manual cracking is labor-intensive and inconsistent, prompting a shift toward automated black walnut cracking machines. By 2026, the demand for high-throughput, precision-based cracking systems is expected to surge, especially in North America, where black walnuts (Juglans nigra) are native.

2. Technological Advancements in Cracking Efficiency

Manufacturers are investing in R&D to improve cracking efficiency while minimizing kernel damage. In 2026, expect wider adoption of smart cracking machines equipped with AI-powered optical sorting, adjustable pressure controls, and real-time monitoring systems. These innovations enhance yield rates and reduce waste, making them attractive to mid- to large-scale processors.

3. Growth in Small-Scale and On-Farm Processing

There is a growing trend among small farmers and artisanal producers to vertically integrate their operations. Affordable, compact black walnut cracking machines designed for on-farm use are gaining traction. By 2026, this segment is projected to expand, supported by government grants for agricultural innovation and increasing consumer interest in locally sourced, sustainable products.

4. Sustainability and Energy Efficiency Focus

Environmental concerns are influencing machine design. In 2026, energy-efficient models with low power consumption and recyclable components will be preferred. Additionally, machines that minimize shell waste or facilitate byproduct utilization (e.g., shell mulch or biomass fuel) will gain competitive advantage.

5. Regional Market Expansion

While the U.S. remains the largest market due to black walnut availability, interest is growing in Europe and Asia as gourmet and functional food markets expand. By 2026, exporters of black walnut cracking machines are likely to target emerging markets in Eastern Europe and East Asia, adapting machines to local walnut varieties and processing needs.

6. Integration with Larger Processing Lines

Black walnut cracking machines are increasingly being integrated into end-to-end processing systems that include drying, sorting, shelling, and packaging. This trend toward turnkey solutions will accelerate by 2026, especially among commercial processors aiming to streamline operations and reduce labor costs.

7. Regulatory and Food Safety Standards

Stricter food safety regulations, including FDA and EU hygiene standards, will influence machine design. By 2026, manufacturers will need to ensure their equipment is made from food-grade materials, easy to clean, and compliant with international safety certifications to access global markets.

In conclusion, the 2026 market for black walnut cracking machines will be characterized by innovation, automation, and sustainability. Companies that prioritize efficiency, scalability, and regulatory compliance will be well-positioned to capitalize on expanding global demand for black walnut products.

Common Pitfalls When Sourcing a Black Walnut Cracking Machine: Quality and Intellectual Property Issues

Sourcing a black walnut cracking machine—especially from international suppliers—can present several challenges, particularly concerning product quality and intellectual property (IP) protection. Being aware of these pitfalls can help buyers make informed decisions and avoid costly mistakes.

Poor Build Quality and Material Standards

One of the most frequent issues when sourcing walnut cracking machines is receiving equipment made from substandard materials or with poor workmanship. Many low-cost suppliers use inferior steel, inadequate bearings, or undersized motors, leading to frequent breakdowns, reduced cracking efficiency, and shorter machine lifespan. Machines not designed specifically for the hardness of black walnuts may struggle with throughput and damage kernels.

Tip: Always request detailed specifications, material certifications (e.g., ASTM standards), and insist on third-party inspections before shipment.

Inadequate Performance Testing and Lack of Validation

Some suppliers provide untested or prototype machines without real-world performance data. Claims about cracking efficiency, throughput (kg/hour), and kernel recovery rates may be exaggerated or based on ideal lab conditions. Without independent verification, buyers risk investing in equipment that fails to meet operational needs.

Tip: Ask for video demonstrations with actual black walnuts and request trial units or on-site testing when possible.

Misleading or Outdated Technology Claims

Suppliers may market their machines as “patented” or “advanced” when the technology is actually outdated or based on expired designs. This can include copying older mechanical systems without innovation in efficiency or automation. Buyers may end up with equipment that underperforms compared to modern alternatives.

Tip: Conduct a patent search (e.g., via USPTO or WIPO) to verify claims and assess whether the technology is genuinely innovative or merely rebranded.

Intellectual Property Infringement Risks

Purchasing a machine that infringes on existing patents or designs can expose the buyer to legal liability, especially if the machine is imported and used commercially. Some manufacturers replicate designs protected by IP without authorization, offering lower prices but creating legal exposure for the end user.

Tip: Require suppliers to provide proof of legitimate IP ownership or licensing. Include indemnification clauses in purchase agreements.

Lack of After-Sales Support and Spare Parts Availability

Even if the initial machine quality is acceptable, many suppliers—particularly smaller or offshore ones—fail to provide reliable technical support, maintenance training, or spare parts. This can lead to extended downtime and increased operating costs.

Tip: Evaluate the supplier’s service network, response time, and inventory of spare parts before purchasing.

Inadequate Customization for Black Walnut Characteristics

Black walnuts are significantly harder and more irregular in shape than English walnuts. Machines designed for other nut types may not handle black walnuts effectively, leading to high kernel damage or low cracking rates.

Tip: Ensure the machine is specifically engineered or tested for black walnuts, and verify settings for adjustable cracking pressure and feed mechanisms.

By being vigilant about quality standards and IP integrity, buyers can avoid these common sourcing pitfalls and select a reliable, legally safe black walnut cracking machine that delivers long-term value.

Logistics & Compliance Guide for Black Walnut Cracking Machine

Overview

This guide outlines the essential logistics considerations and regulatory compliance requirements for the transportation, installation, operation, and maintenance of a Black Walnut Cracking Machine. Proper planning ensures efficient delivery, legal operation, and adherence to safety and environmental standards.

Shipping and Transportation

Coordinate with freight carriers experienced in handling agricultural machinery. The machine should be securely crated or palletized to prevent damage during transit. Verify weight, dimensions, and special handling requirements (e.g., forklift access, liftgate service) with the manufacturer. Ensure shipping documentation includes a detailed packing list, bill of lading, and insurance coverage.

Import/Export Compliance (if applicable)

If shipping internationally, comply with relevant customs regulations. Obtain necessary import/export licenses and ensure Harmonized System (HS) code 8437.80 (for agricultural processing machinery) is correctly applied. Verify compliance with USDA, FDA, or equivalent foreign agricultural authorities, especially if the machine will process food-grade walnuts.

Site Preparation and Installation

Prepare a level, stable foundation with adequate drainage. Ensure sufficient clearance around the machine for operation and maintenance. Confirm access to required utilities—typically 220V or 440V electrical supply and, if applicable, compressed air or water lines. Engage a qualified technician for assembly and commissioning per the manufacturer’s specifications.

Regulatory Compliance

Adhere to local, state, and federal regulations governing food processing equipment. In the U.S., comply with FDA Food Safety Modernization Act (FSMA) guidelines if producing walnuts for human consumption. Follow OSHA standards for workplace safety, including machine guarding, lockout/tagout procedures, and employee training. Machines must meet applicable electrical and mechanical safety codes (e.g., NEC, CSA, or UL standards).

Environmental and Waste Management

Plan for proper disposal of walnut shells and debris. Comply with local environmental regulations regarding waste handling and emissions. If operating at commercial scale, consider permits related to noise, air quality, or wastewater, depending on local jurisdiction.

Maintenance and Recordkeeping

Maintain a documented maintenance schedule to ensure machine performance and safety. Keep records of inspections, repairs, safety training, and compliance certifications. Retain proof of equipment origin, warranty, and conformity with industry standards for audit purposes.

Training and Operational Safety

Provide comprehensive training for all operators on machine operation, emergency shutdown procedures, and personal protective equipment (PPE) requirements. Display safety signage near the machine and enforce strict adherence to operational protocols to prevent accidents.

In conclusion, sourcing a black walnut cracking machine requires a thorough evaluation of several key factors including cracking efficiency, machine durability, throughput capacity, ease of maintenance, and cost-effectiveness. Given the exceptionally hard shell of black walnuts, it is crucial to select a machine specifically designed or adjustable for this purpose, ensuring high kernel recovery with minimal damage. Options range from small-scale manual or semi-automatic models for local producers to industrial-grade automated systems for commercial operations.

Suppliers should be vetted for reliability, technical support, and post-purchase service. Additionally, considering energy efficiency and adaptability to integrate into existing processing lines can enhance long-term productivity. By carefully aligning machine specifications with operational needs and volume requirements, producers can achieve consistent quality, reduce labor costs, and improve overall profitability in black walnut processing. Ultimately, investing in the right cracking machine is a strategic step toward efficient and sustainable production in the specialty nut market.