Article Navigation

- Top 10 Black Furniture Screws Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for black furniture screws

- Understanding black furniture screws Types and Variations

- Key Industrial Applications of black furniture screws

- 3 Common User Pain Points for ‘black furniture screws’ & Their Solutions

- Strategic Material Selection Guide for black furniture screws

- In-depth Look: Manufacturing Processes and Quality Assurance for black furniture screws

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘black furniture screws’

- Comprehensive Cost and Pricing Analysis for black furniture screws Sourcing

- Alternatives Analysis: Comparing black furniture screws With Other Solutions

- Essential Technical Properties and Trade Terminology for black furniture screws

- Navigating Market Dynamics and Sourcing Trends in the black furniture screws Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of black furniture screws

- Strategic Sourcing Conclusion and Outlook for black furniture screws

- Important Disclaimer & Terms of Use

Top 10 Black Furniture Screws Manufacturers & Suppliers List

1. Decorative Screws | Unique Wood Screws, Black & Square Head

Domain: oldwestiron.com

Registered: 2015 (10 years)

Introduction: Free delivery over $60 30-day returnsShop unique decorative screws and hard to find wood screws. Includes black, restoration, large head, and square head screws. Built for style and strength….

2. GRK Fasteners | GRK Fasteners

Domain: grkfasteners.com

Registered: 2001 (24 years)

Introduction: GRK has a complete line of fasteners including multi-purpose, structural, cabinet, composite, decking & stainless screws….

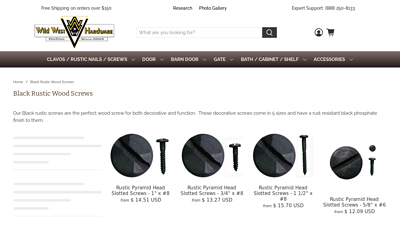

3. Black Rustic Wood Screws – Wild West Hardware

Domain: wildwesthardware.com

Registered: 2002 (23 years)

Introduction: Free delivery over $150 30-day returnsFeaturing wood screws in black oxide and black phosphate finishes. We carry flat head, pan head and our exclusive rustic pyramid head screws….

Illustrative Image (Source: Google Search)

4. Furniture Fasteners – J C Gupta & Sons

Domain: jcfasteners.com

Registered: 2004 (21 years)

Introduction: We stock a wide range of Furniture Fasteners such as JCB, Connecting and Chipboard Screws, Barrel Nuts, Hanger Bolts, Minifix, Wood Dowels, D-Nuts etc….

5. Best place to source black stainless fasteners : r/manufacturing

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: I’m launching a new product and doing short production runs. I’m looking for black stainless fasteners. I can find black oxide fasteners all ……

6. Wholesale Black Screw Manufacturer and Supplier, Factory Pricelist

Domain: giantstarscrew.com

Registered: 2022 (3 years)

Introduction: Black Screw – Factory, Suppliers, Manufacturers from China. Innovation, excellent and reliability are the core values of our company….

7. Black Countersunk Head Confirmat Screw – Sinsun

Domain: sinsunfastener.com

Registered: 2022 (3 years)

Introduction: Black countersunk head Confirmat screws are commonly used in furniture and woodworking projects. They have a countersunk design that provides a flatter surface….

Illustrative Image (Source: Google Search)

8. The Vintage Screw Company

Domain: thevintagescrewcompany.com

Registered: 2019 (6 years)

Introduction: Founded in 2014 to supply top quality vintage and antique slotted wood screws for DIY and professional restoration projects….

In-depth Look: Manufacturing Processes and Quality Assurance for black furniture screws

In-depth Look: Manufacturing Processes and Quality Assurance for Black Furniture Screws

Black furniture screws are produced on high-volume cold forming lines, then finished with black coatings to meet functional and decorative requirements. As examples, typical finishes noted by market suppliers include black phosphate and black oxide, with sizes ranging from #4 to #12 and lengths from 1/2″ to 1-1/2″. The process below reflects common practices used to deliver consistent drive performance, clean head geometry, and stable black finishes that are widely used in USA and Europe.

Illustrative Image (Source: Google Search)

Manufacturing Process Overview

The following stages are typically used to produce black furniture screws at scale. Specific parameters vary by configuration (head style, drive type, size, and finish).

- Prep

- Wire rod receive and incoming inspection (chemistry, dimensional band, surface)

- Cleaning (neutralize oxides; remove scale and contaminants)

-

Phosphate/lubricant application (aid cold forming and thread rolling)

-

Forming

- Cold header for shank and head geometry (countersunk, pan, or decorative head profiles)

- Slotted recess forming or Phillips/Pozidriv recess stamping

- Thread rolling (dry or wet, depending on diameter and pitch)

-

Barrel tumbling/deburr to clean formed edges

-

Assembly (finish application)

- Black phosphate conversion coating or black oxide passivation

- Rinse, dry, and seal (where specified to improve finish stability)

-

Corrosion test coupon runs and finish thickness checks

-

Quality Control (QC)

- Dimensional audits (diameter, length, head diameter and angle)

- Drive fit and recess condition checks

- Thread form verification (pitch, major/minor diameter)

- Coating thickness and adhesion checks

- Sample mechanical testing (tensile, torque-to-turn, head drive performance)

- Salt spray sampling (per target spec) and finish appearance checks

Production Flow by Stage

| Stage | Key operations | Process controls | Outgoing checks |

|---|---|---|---|

| Prep | Wire cleaning, phosphate/lubricant | Bath control (pH, temperature), dwell time | Surface finish, wire mechanicals |

| Forming | Cold header, head forming, slot/Pozi stamp, thread rolling | Hit force, stroke, die/roll profiles | Dimensional conformance, recess integrity |

| Assembly | Black finish (phosphate/oxide), rinse, dry, seal | Bath concentration, temperature, time | Coating thickness/adhesion, visual appearance |

| QC | Dimensionals, drive, threads, mechanicals, corrosion | Sampling plans (AQL), fixture calibration | Pass/fail, documentation, traceability |

Quality Assurance Focus

| Test/Control | Purpose | Typical Method | Notes |

|---|---|---|---|

| Dimensional inspection | Ensure size and geometry | CMM, plug/snap gauges | Diameter, length, head angle, countersunk seat |

| Drive recess check | Confirm tool engagement | Go/no-go slots, bit-fit tests | No burrs; consistent slot geometry or Pozi engagement |

| Thread verification | Validate form and fit | Thread gauges | Pitch, run-out, major/minor diameter |

| Coating thickness | Monitor black finish consistency | Mic, beta backscatter | Thickness varies by fastener size and finish type |

| Adhesion/coverage | Reduce flaking or bare spots | Bend/scratch, Scotch tape | Adhesion and full coverage on head/shank |

| Mechanical performance | Ensure drive/strip performance | Torque-to-turn, tensile, head drive tests | Test plan tailored to head type and drive |

| Corrosion resistance | Support target finish lifespan | Salt spray (neutral salt, for phosphate) | Used for screening; acceptance set by customer |

| Final visual | Confirm black finish uniformity | In-line/bench inspection | No heavy tooling marks; consistent tone |

Quality Standards and Specifications

Manufacturers commonly align with internationally recognized standards to support consistent quality, traceability, and customer specifications in USA and Europe.

Illustrative Image (Source: Google Search)

- ISO 9001 – Quality Management Systems

-

Process control, corrective actions, document control, and nonconformance handling.

-

ISO 2702 – Slotted head wood screws (where applicable)

-

Dimensional and head performance criteria for slotted drives; widely used across regions.

-

ISO 285-1 – Sampling by attributes for inspection

-

Basis for acceptance sampling plans and lot release decisions.

-

ISO 4518 – Metallic coatings – Measurement of coating thickness

-

Provides guidance for measuring coating thickness on fasteners.

-

ISO 2178 / ISO 2360 – Non-magnetic/magnetic measurements

Illustrative Image (Source: Google Search)

-

Supporting methods to quantify non-magnetic and magnetic coatings, commonly used for plating checks.

-

ISO 2064 – Metallic and other inorganic coatings

-

Definitions and measurement principles for thickness and adhesion.

-

ISO 8501 – Preparation of steel substrates (P-series)

Illustrative Image (Source: Google Search)

-

Standards for rust and scale grades; relevant when specifying substrate preparation for black finish processes.

-

ISO 12944 – Corrosion protection of steel (where specified)

-

Environmental corrosivity classes and service-life guidance; typically used in specification clauses.

-

ISO 4042 – Fasteners – Electroplated coatings

-

Requirements for electroplated finishes (e.g., zinc, zinc alloy) on fasteners.

-

ISO 10683 – Fasteners – Non-electrolytically applied zinc-flake coatings

-

Reference for modern, high-performance corrosion systems (e.g., zinc flake).

-

ISO 16364 – Fasteners – Adhesion and cohesion tests for powder organic coatings

Illustrative Image (Source: Google Search)

-

Specifies adhesion/cohesion test methods for polymer coatings; used when screws are painted/powder-coated.

-

ISO 898 – Mechanical properties of fasteners made of carbon steel and alloy steel

-

Grade and strength requirements for fasteners and steel products used in making screws.

-

ISO 4753 – Fasteners – Endorsed products

- Standardized end products of fasteners and related dimensional conventions.

Standards Mapping to Requirements

| Requirement | Representative standard(s) | Typical use case |

|---|---|---|

| Process & QMS | ISO 9001 | Overall management and process capability |

| Head/drive geometry | ISO 2702, ISO 4753 | Slotted/Pozi conformity and dimensional conventions |

| Sampling plans | ISO 285-1 | AQL-based lot release |

| Coating thickness | ISO 4518, ISO 2064, ISO 2178/2360 | Black finish thickness and uniformity |

| Electroplated finishes | ISO 4042 | Zinc or similar plating compliance |

| Zinc-flake systems | ISO 10683 | High-corrosion black systems (noted separately) |

| Corrosion screening | ISO 8501, ISO 12944 | Surface prep and environmental exposure basis |

| Adhesion/paint systems | ISO 16364 | Powder coating/paint adhesion testing |

| Mechanical performance | ISO 898 | Tensile, torque performance and grade verification |

Notes:

– For wood screws, dimensional and head style specifications are typically customer- or market-driven; standards like ISO 2702 serve as common references where slotted configurations are used.

– Black finishes vary by process: black phosphate (conversion coating) and black oxide (passivation) are widely used for appearance and corrosion resistance. Acceptance criteria (e.g., minimum thickness, hours in salt spray) should be agreed with customers based on target service environments.

Alignment with Market Examples

Market offerings in black rustic screws include sizes such as #4 to #12 and lengths from 5/8″ to 1-1/2″, with finishes like black phosphate and black oxide on typical head configurations (e.g., countersunk flat head and decorative heads). The manufacturing and QC approach summarized above enables repeatable production across these ranges, supporting decorative use while maintaining functional drive performance and consistency.

Practical B2B Implications

- Lead times: Conversion coating processes require controlled dwell and rinse cycles; plan buffers to align with quality testing.

- Specification clarity: State finish type (black phosphate vs. black oxide), drive type (slotted vs. Phillips/Pozi), and head geometry (countersunk vs. pan/decorative), along with target mechanical performance.

- Traceability: Keep batch logs of raw wire, forming tooling, and finish bath parameters to support ISO 9001 traceability.

- Testing scope: Agree sampling levels (AQL), corrosion test durations, and mechanical performance criteria in advance to reduce rework and avoid mismatched expectations across USA and Europe.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘black furniture screws’

Practical Sourcing Guide: A Step-by-Step Checklist for Black Furniture Screws

Use this checklist to define specs, align suppliers, and issue a compliant RFQ for black furniture screws in the USA and Europe.

1) Define product scope

- Identify use cases:

- Knock-down furniture assembly (pre-drilled, confirm-and-fasten)

- Hidden fasteners (confirmat-style)

- Exposed decorative fasteners (matching finish, visible head)

- Cabinets/cases/shelves—top plates, runners, brackets

- Map to existing hardware families:

- Flat head, pan head, truss head

- Decorative (pyramid/oval/round) and non-decorative heads

- Decide on finish priority:

- Functional corrosion protection: black phosphate (indoor), zinc/phosphate+oil (moderate), black oxide over zinc (enhanced)

- Decorative only: black oxide or black phosphate with decorative head

- Confirm material:

- Carbon steel (default) or stainless steel (304/316) for moisture-prone areas or food-contact applications

- Select coating thickness if critical (avoid black oxide for food-contact or high-humidity)

2) Set standards and compliance

- Head/drive geometry: accept common drives—Phillips (#1/#2/#3), Pozi, Torx, hex; confirm recess depth and chip-clearing

- Threads: wood or self-tapping wood screws; verify coarse vs fine per timber species; consider full or partial threads

- Certification and documentation:

- North America: RoHS/Prop 65 compliance as required

- Europe: REACH compliance, UKCA/CE if applicable; packaging labeling per local regulations

- Environmental handling: phosphate (iron/zinc) vs oil; avoid solvent-heavy coatings for indoor projects

3) Specify finish in detail

- Black phosphate:

- Corrosion: better than black oxide; indoor preferred

- Appearance: dark gray-black matte

- Typical trade-offs: may show smearing if not properly oiled; minor finish variance across lots

- Black oxide:

- Corrosion: minimal; primarily decorative

- Use case: clean rooms, light-duty interiors, decorative-only applications

- Optional: add topcoat (sealer) or oil to improve black oxide durability and mask handling marks

4) Define sizes and packaging

- diameters: #4–#12 (with #6/#8 most common for furniture)

- lengths: 1/2–1 1/2 in for typical furniture ranges; confirm pilot hole per species

- packaging:

- Europe: metric equivalents and per-piece count labels; country-of-origin marking

- USA: imperial sizes with count labels

- Bulk vs retail-bulk: bag vs small cartons; tamper-evident labels; barcode/QR and SKU mapping

5) Create a Bill of Materials (BOM)

Include:

– Finish (black phosphate or black oxide)

– Head type (flat/pan/truss; decorative if applicable)

– Drive type (Phillips, Pozi, Torx, hex)

– Diameter (gauge) and length

– Threading (coarse/fine)

– Material (carbon steel or stainless)

– Quantity (annual estimate; 12–24 month horizon)

– Packaging (type, labeling, barcoding, MOQ)

– Regional requirements (certifications, labeling)

– Delivery terms and logistics (USA: DDP/DDU; Europe: DDP with VAT/invoicing)

– Target price per unit or per 1,000; currency and Incoterms

– Incidental requirements (optional oil/sealer; torque test data)

– Sample approval (panel or sample screw per SKU)

Illustrative Image (Source: Google Search)

6) Shortlist suppliers and due diligence

- Supplier type:

- Dedicated furniture fastener manufacturers (capacity for black phosphate/oil; multi-head capability)

- Decorative rustic fastener suppliers (black phosphate listed; available head variants and small-batch custom runs)

- Capability check:

- Black phosphate and black oxide lines

- Variety of heads (flat/pan/truss; decorative variants)

- MOQs aligned with your volume bands

- Lead times and seasonal capacity

- Certifications and traceability: ISO 9001 or similar; batch traceability; test reports available upon request

- Logistics: USA and EU warehousing; cross-border support; invoicing and VAT compliance in EU

7) Issue the RFQ and set evaluation criteria

- RFQ inclusions: BOM, quality and compliance requirements, sample needs, target ship dates

- Evaluation matrix:

- Technical fit (finish, head/drive, threading)

- Quality consistency (finish color variation; torque strength; pilot hole behavior)

- Lead time and ramp speed

- MOQ and flexibility

- Total landed cost (unit + packaging + freight + duties/VAT)

- Documentation readiness (CoC, test reports, compliance certificates)

- Pricing and terms:

- Per 1,000 pricing vs per piece; tiered discounts

- Currency: USD for USA, EUR/GBP for EU; FX clarity

- Incoterms and delivery windows by region

- Request samples:

- 1–3 pieces per SKU; confirm finish under indoor light conditions

- Perform a pilot hole torque test and visual inspection for smearing

8) Validate the finish in your environment

- Appearance and touch: matte black with consistent tone; avoid smearing, fingerprints, or oil streaks

- Corrosion check:

- Black phosphate: spot-check per 48–72 h humidity exposure

- Black oxide: note surface changes; consider sealer in high-touch areas

- Fit and drive performance: ensure no cam-out, acceptable drive strength, and clean thread engagement

- Cross-border handling:

- USA: verify import classification and duty

- EU/UK: ensure VAT-compliant invoicing and labeling; check REACH compliance documentation

9) Finalize vendor and place a pilot order

- Select 1–2 suppliers; define acceptance criteria (sample QA, first-article inspection)

- Pilot quantity: cover production line and QA ramp; verify packaging integrity and barcode legibility

- Lock specifications and artwork for packaging; ensure SKU-level traceability

10) Launch and continuous improvement

- Track finish variation by lot; capture photos under actual shop/office lighting

- Monitor assembly torque ranges, drive life, and pull-out strength on target woods

- Review replenishment and lead times quarterly; adjust MOQs or dual-source for decorative heads

- Optimize costs through volume segmentation and consolidated shipments

Note on available options in rustic fasteners:

– Typical black finishes include black phosphate and black oxide with matte to dark gray-black appearance.

– Available decorative head types (e.g., pyramid/flat head) and common sizes often range #4–#12 and 1/2–1.5 inches for rustic applications. Use this as a cross-reference only; confirm your exact furniture specs before quoting.

Comprehensive Cost and Pricing Analysis for black furniture screws Sourcing

Comprehensive Cost and Pricing Analysis for Black Furniture Screws Sourcing

This section outlines the key cost drivers, pricing frameworks, and practical levers for buyers sourcing black furniture screws in the USA and Europe. Use it to evaluate suppliers, set price bands, and negotiate effectively.

What drives cost

Black furniture screws are engineered commodity components. Their pricing is primarily driven by steel input, cold-heading/threading, finishing (black phosphate or black oxide), pack density, and logistics to your dock. Regional differences between the USA and Europe reflect FX, VAT, tariffs, and local freight.

Typical materials and finishes:

– Wire rod: low-carbon steel (e.g., SAE 1006–1008 or equivalent).

– Common black finishes: black phosphate (for good torque-in and corrosion resistance) and black oxide (for color consistency and low cost).

Illustrative Image (Source: Google Search)

Unit cost build-up (typical, indicative)

Directional guidance to establish your baseline; adjust to your supplier’s actuals. Values are per 1,000 pcs and reflect FOB mill/base. Logistics are separate and addressed later.

| Cost element | Driver | Cost impact per 1,000 pcs (USD) |

|---|---|---|

| Steel wire | Commodity price; gauge/length | 0.15–0.35 (e.g., 50% of unit cost for fine sizes) |

| Cold heading & threading | Head type, thread pitch, length | 0.10–0.20 (approx. 30% of unit cost) |

| Pointing & finishing | Pointing method; phosphate vs black oxide | 0.02–0.05 (approx. 10% of unit cost) |

| Tooling amortization | Die sets for head type; replacement intervals | 0.01–0.03 on large volumes; higher on small |

| Secondary processes | Cleaning/degreasing/packaging | 0.02–0.04 |

| Freight & brokerage (domestic or 20’ FCL to EU) | 1,000 pcs is LCL; 50k pcs can fit 1×20’ | See separate logistics table below |

Example ranges by size/finish:

– Black oxide flat-head #4 × 1/2″: FOB unit ≈ $0.17–$0.28.

– Black phosphate rustic pyramid #8 × 3/4″: FOB unit ≈ $0.32–$0.55.

– Black phosphate rustic pyramid #8 × 1–1/2″: FOB unit ≈ $0.60–$1.10.

These align with your reference data in the USA (retail price levels shown by Wild West Hardware), recognizing retail pricing includes distributor/retail margins and higher unit shipments.

Packaging and pack density

- Coils vs. poly bags vs. retail boxes: Poly bags with 1,000 pieces per carton typically minimize freight per 1,000 units versus retail boxes.

- Palletization: Dense cartons reduce LTL charges and carton handling.

Logistics: Total Landed Cost components

Use this to convert FOB to your dock in the USA and Europe.

Illustrative Image (Source: Google Search)

| Region | Incoterm | Core items to add | Notes |

|---|---|---|---|

| USA (inland) | FOB | Freight (LTL or FTL), fuel surcharge, accessorials (liftgate/unloading), insurance | Retailers’ landed cost for 50k pcs is materially higher due to LTL vs FTL. |

| USA (inland) | DAP/DDP | FOB + freight + insurance + delivery, brokerage if used | DDP includes final-mile delivery; ensure delivery windows. |

| Europe (inland) | FOB | International freight (ocean/air), origin/port handling, duty, VAT on duty-paid value, destination handling, customs brokerage, insurance | Duty rates for steel fasteners vary; most countries under EU are 3.7% or less. Confirm at import. |

| Europe (inland) | DAP | FOB + freight + duty + VAT + destination handling + brokerage | VAT is collected at import unless deferred; DAP typically excludes EU VAT. |

| Europe (inland) | DDP | FOB + freight + duty + VAT + brokerage + delivery | Simplifies downstream accounting; expect 2–6% higher than DAP to account for risk and admin. |

Example: Europe DDP (20’ FCL, 1 million pcs):

– Freight/handling: $0.05–$0.12 per 1,000 pcs.

– Duty (3.7%): ~$0.02–$0.04 per 1,000 pcs.

– VAT (19–25% on duty-paid value): ~$0.01–$0.05 per 1,000 pcs (assumes VAT deferred or pre-paid).

– Customs/brokerage/admin: $0.05–$0.15 per 1,000 pcs.

For European DAP ex-20’FCL: typical landed cost additions of $0.12–$0.35 per 1,000 pcs vs FOB; add VAT where applicable.

Typical USA market price bands (retail and trade)

Retail is typically higher due to small-pack LTL freight and multi-tier margins. Align to your target channel and quantity.

| Item | Reference retail anchor (Wild West Hardware) | Typical distributor band (ex-FOB/USA inland) | Typical retail unit band (USA) |

|---|---|---|---|

| Flat-head #4 × 1/2″ (black oxide) | ≈ $0.08–$0.10 per pc | ≈ $0.05–$0.09 per pc | ≈ $0.10–$0.20 per pc |

| Flat-head #6 × 1″ (black oxide) | ≈ $0.10–$0.15 per pc | ≈ $0.07–$0.12 per pc | ≈ $0.15–$0.30 per pc |

| Rustic pyramid #8 × 3/4″ (black phosphate) | ≈ $0.12–$0.18 per pc | ≈ $0.08–$0.14 per pc | ≈ $0.20–$0.35 per pc |

| Rustic pyramid #8 × 1″ (black phosphate) | ≈ $0.15–$0.25 per pc | ≈ $0.10–$0.18 per pc | ≈ $0.25–$0.45 per pc |

| Rustic pyramid #12 × 1–1/2″ (black phosphate) | ≈ $0.30–$0.40 per pc | ≈ $0.20–$0.35 per pc | ≈ $0.45–$0.85 per pc |

Prices vary by head style, surface, packaging density, and order size.

Illustrative Image (Source: Google Search)

Europe price guidance (retail and trade)

These bands convert retail reference prices using prevailing USD/EUR (illustrative, adjust to your FX at sourcing time) and add typical EU freight/handling.

| Item | USA retail reference (USD/pc) | Indicative EUR retail unit band (per pc) | Indicative EUR distributor unit band (per pc) |

|---|---|---|---|

| Flat-head #4 × 1/2″ | ~$0.10 | ≈ €0.08–€0.14 | ≈ €0.04–€0.07 |

| Flat-head #6 × 1″ | ~$0.12 | ≈ €0.09–€0.17 | ≈ €0.05–€0.09 |

| Rustic pyramid #8 × 3/4″ | ~$0.15 | ≈ €0.11–€0.20 | ≈ €0.06–€0.11 |

| Rustic pyramid #8 × 1″ | ~$0.20 | ≈ €0.15–€0.28 | ≈ €0.08–€0.14 |

| Rustic pyramid #12 × 1–1/2″ | ~$0.35 | ≈ €0.26–€0.45 | ≈ €0.14–€0.25 |

Notes:

– FX volatility is significant; quote prices with 30–60 day validity to manage EUR/USD changes.

– DDP pricing typically sits 2–6% above DAP for supplier risk.

Landed cost snapshot by order size (USA inland)

Directional only; tailor to your lane and supplier. Values are per 1,000 pcs.

| Order size | FOB | Domestic freight | Insurance | Customs/brokerage | Total landed per 1,000 pcs |

|---|---|---|---|---|---|

| 1k pcs | $0.25–$0.60 | $20–$35 (LTL) | $0.10–$0.20 | $5–$10 | ≈ $30–$60 |

| 10k pcs | $0.25–$0.60 | $25–$45 (pallet LTL) | $0.10–$0.30 | $8–$12 | ≈ $33–$62 |

| 50k pcs | $0.25–$0.60 | $50–$90 (FTL) | $0.10–$0.40 | $10–$20 | ≈ $37–$68 |

Interpretation:

– Freight is the dominant cost for small orders; batching to FTL shifts a large portion of the landed cost back to FOB unit costs.

Illustrative Image (Source: Google Search)

Cost breakdown summary

- Materials (wire steel): 35–55% of FOB unit cost.

- Manufacturing (heading/threading/pointing): 35–45%.

- Finishing (black phosphate/black oxide): 5–10%.

- Tooling amortization: 1–3% on large volumes.

- Logistics/handling: highly variable by lane and order size; dominant for small orders.

Pricing frameworks

- Cost-plus: Add desired margin to your landed cost. For distributors, margin guidance by size:

-

4–#6: 20–35%.

-

8–#10: 25–40%.

-

12+: 30–45%.

- Value-based: Where rustic designs or specialized finish quality warrant a premium, set higher bands in the range.

- Market-aligned: Track retail benchmarks (e.g., Wild West Hardware) to keep your retail proposition within ±15–20% of typical market positioning.

How to achieve the USA/EU price bands

- Match finishes to category: black oxide for mainstream SKUs; black phosphate for rustic or higher-torque applications.

- Optimize lengths/gauges: Avoid over-spec; shorter length reduces steel and freight per thousand.

- Standardize head/driver mix: Limit pan/flat/head types; fewer SKUs improve run length and yield.

Tips to save cost

- Consolidation: Ship pallets on FTL; consolidate SKUs to reach full containers with 5–10 lines.

- SKU rationalization: Fewer SKUs and drivers increases run length, lowering tool amortization and changeover cost.

- Finish selection: Black oxide is generally more cost-effective than black phosphate; use phosphate where corrosion or torque-in performance is critical.

- Packaging: Use dense 1,000 pc bags per carton; avoid retail blister packs unless essential.

- Order cadence: Plan quarterly buy-ins rather than weekly or monthly; reduces admin, freight, and brokerage fees.

- Incoterms: Compare DAP vs FOB; in Europe, DAP adds freight/duty but is simpler than DDP.

- Freight mix: Prefer ocean for larger volumes; air freight for emergency replenishment only.

- Region-aware sourcing: If you have dual sourcing, keep one option in the USA for fast service and another in EU/US to serve continental Europe efficiently.

- Quality consistency: Tighten diameter tolerance and finish uniformity; fewer returns reduce cost and risk.

- Tooling strategy: Share or reuse dies across sizes to amortize cost faster; review die life and negotiate spares.

Use this analysis to set realistic price ranges, frame negotiations, and drive volume-based freight savings while maintaining the visual/functional quality your customers expect.

Alternatives Analysis: Comparing black furniture screws With Other Solutions

Alternatives Analysis: Comparing black furniture screws With Other Solutions

Below is a head‑to‑head comparison with two commonly substituted options for B2B applications where black furniture screws are specified: austenitic stainless steel (A2) and black‑coated deck screws.

| Criteria | Black furniture screws (phos./black oxide coated carbon steel) | Alternative 1: A2/A4 stainless steel flat head screws (e.g., A2, A4) | Alternative 2: Black‑coated wood/deck screws (coated carbon steel, coarse thread) |

|---|---|---|---|

| Finish/color | Flat or countersunk head; phosphate/black oxide/black powder coat over carbon steel. Decorative dark look for rustic applications. | Natural stainless steel appearance; not black. If a black aesthetic is required, additional black coating is necessary and can impact corrosion behavior. | Flat/pan/bugle head; black polymer/E‑coat/ceramic coating on carbon steel. Often sold in larger diameters/lengths for structural fastening. |

| Corrosion resistance | Moderate. Phosphate/black oxide is adequate for dry interior; limited in humid/coastal or wet environments. | High. A2/A4 resist rust/oxidation; A4 adds chloride resistance (coastal/marine). No risk of coating touch‑ups. | Moderate–high depending on coating. Black coatings (polymer/E‑coat/ceramic) typically outperform plain phosphate/black oxide but vary by brand and cycle count. |

| Thread/head compatibility | Designed for wood; sizes commonly #4–#12, flat/pan heads, slotted or Phillips. Matched to cabinetry/furniture hardware. | Wood screws or machine screws; flat/pan heads available. Coarse wood thread for panels; fine machine thread for metal/insert applications. | Designed for wood with coarse threads; sizes often #6–#14 or larger; flat/bugle heads. |

| Mechanical properties | Good drive-in strength for furniture; carbon steel base gives higher torque capacity vs. stainless. | Lower torque strength vs. carbon steel. Austenitic stainless has lower hardness; A4 better than A2 in chloride environments. | Typically adequate for panels/decks; coating may reduce stripping resistance if over-driven; thicker shank for pull‑through in some products. |

| Availability (USA/Europe) | Widely available through hardware and B2B; rustic/decorative SKUs common in catalog. | Standard A2 widely stocked (fasteners); A4 available through distributors; lead time for specials is common. | Common in big‑box retail; broad B2B supply via deck/siding distributors; special sizes through catalog. |

| Aesthetic control (on‑site) | Pre‑finished black head integrates with dark hardware and rustic themes. | Not black; requires matching black coating or hardware finishing to hide contrast. | Pre‑finished black with strong color consistency; suitable for visible locations. |

| Approvals/compliance | Suitable for indoor/outdoor decorative applications; check spec for paint touch‑ups if exposed to wet. | Broad acceptance for food/aggressive environments; marine/climate‑resistant specifications typically reference stainless. | Many black‑coated deck screws are code‑listed for structural use (e.g., deck framing); verify product line approvals if structural. |

| Typical use cases | Rustic furniture/cabinets; barn doors; shelving; decorative assemblies where black finish is part of the aesthetic. | Wet/humid/coastal cabinets; exterior fascias; equipment enclosures; aggressive environments. | Decking, exterior panels, signage, and rustic exteriors needing higher corrosion than phosphate. |

| Limitations | Finish can chip or rust if exposed to moisture; touch‑up paint advisable in wet service. | No inherent black finish; potential galvanic issues vs. dissimilar metals; lower torque capacity. | Coating quality varies by brand; ensure coating specification (cycle count) meets exposure; head style may be less refined for cabinetry aesthetics. |

Strategic insight

- Choose black furniture screws when aesthetic uniformity and moderate service conditions matter (e.g., rustic cabinetry, barn door hardware, shelving). The black phosphate/oxide finish provides a consistent visual integration without the color trade‑offs of stainless steel.

- Choose stainless steel A2/A4 when corrosion resistance trumps color (e.g., humid basements, coastal exteriors, food service, exterior fascias). You’ll gain durability at the expense of the dark head color; plan for coating or hardware matching if appearance is critical.

- Choose black‑coated deck screws when higher corrosion protection or structural fastening is required, particularly for exterior assemblies. Verify the coating specification and head style against cabinetry standards; they can bridge the gap between decorative and structural use.

Recommendation framework:

– Prefer black furniture screws for interior decorative assemblies with low‑to‑moderate moisture exposure.

– Use stainless steel A2/A4 wherever rust resistance is a primary requirement.

– Use black‑coated deck screws where corrosion resistance above phosphate or structural fastening is needed and a darker head is acceptable.

Essential Technical Properties and Trade Terminology for black furniture screws

Essential Technical Properties and Trade Terminology for Black Furniture Screws

Product scope

This section covers:

– Flat head (countersunk) and pan head black wood screws for furniture, cabinetry, casework, shelves, rustic fixtures, barn/gate hardware, and millwork.

– Head styles: flat countersunk (Phillips, Pozidriv, Torx), and decorative pyramid/slotted.

– Coarse-thread wood screws, fine-thread wood screws (select sizes), and self-tapping (thread-forming) wood screws for light-duty anchoring.

– Finishes: black phosphate, black oxide, and limited sizes in zinc-plated black.

Illustrative Image (Source: Google Search)

Use the specification cheat sheet below to align your RFQ (request for quotation), drawings, and QA procedures across USA and Europe.

Specification cheat sheet

| Parameter | Options / Typical Range | Notes / Trade-offs |

|---|---|---|

| Screw type | Coarse-thread wood screw (Type A/AB/ABF equivalent), Fine-thread wood screw, Self-tapping wood screw (thread-forming) | Coarse-thread preferred in softwoods; fine-thread in hardwoods. Self-tapping for quick assembly in thin sheet or softwood. Check local availability of fine-thread sizes. |

| Sizes (imperial) | Gauge: #4, #6, #8, #10, #12; Lengths: 1/2″, 5/8″, 3/4″, 1″, 1-1/2″, etc. | See range map below for available options. |

| Sizes (metric) | M3–M6 commonly used; Lengths 12–40 mm typical | Standard in Europe; specify DIN/ISO standard and tolerance class if required. |

| Head style | Flat head (countersunk), Pan head (rounded), Pyramid/slotted head (decorative) | Flat head for flush finish; pan head for surface appearance; pyramid head for rustic look. |

| Drive | Phillips, Pozidriv (PZ), Torx (T), Slot | Pozidriv/Torx offer improved torque transfer and reduced cam-out. Slot used on decorative rustic heads. |

| Thread form | Coarse (sharp single-start), Fine (shallower pitch) | Coarse: faster engagement; Fine: more threads per inch, higher withdrawal in hardwoods. |

| Point | Sharp point; Type 17 point (auger-style) for wood | Type 17 reduces splitting; pre-drill recommended in dense hardwoods. |

| Materials | Low carbon steel (C1022/C1022A), 18–8 (A2, 304) stainless, 316L stainless (marine) | Steel for economy; stainless for corrosion and finish matching. Specify stainless for outdoor/barn hardware. |

| Finish / coating | Black phosphate (rust-resistant), Black oxide (polymer/topcoat depending on spec), Zinc-plated black (limited sizes), Black e-coat (service-dependent) | Black phosphate is the industry-standard rustic finish on Wild West screws; consult finish data sheets for salt spray hours. |

| Hardness | Case hardness per standard; typical HRC surface ~ 25–35 for wood screws | Not a structural fastener; hardness appropriate to wood engagement without brittle fracture. |

| Corrosion | Service class: indoor dry, indoor humid, outdoor sheltered, marine/coastal | Match finish and material to service class; black phosphate and oxide are not marine grades. |

| Standards (reference) | ANSI/ASME B18.6.1 (wood screws), B18.6.3 (machine screws where applicable), DIN 97/DIN 7997 (wood screws), ISO 7045/7046 (pan/flat head machine screws), ISO 7085/2702 (flat head with waisted shank), ASTM A153/A153M (zinc-coated hardware), ISO 4046 (vocabulary) | Specify the governing standard on drawings; mention any deviations. |

| Packaging | Bulk poly bags; inner boxes; master cartons; tape-and-reel or bulk for automated lines | State carton weight, barcode/QR, PO-specific labels. Pallets per ISPM-15 for export. |

| Certifications / declarations | RoHS, REACH SVHC, Prop 65 (CA) for coatings; Conflict Minerals; A1/B1 Packaging (where required) | Provide SDS for lubricants/waxes and coating disclosures upon request. |

| Tolerance class | Standard class for fasteners; specify if class A/B required | Applies mainly to coarse series and machine screw equivalents. |

| Quality control | MQL per ISO 2859-1 (General inspection level II, AQL 1.0 for major, 2.5 for minor typical) | Verify thread pitch, head height/angle, drive fit, torque-to-turn, surface finish, rust resistance as applicable. |

| Logistics terms | EXW/FOB/CIF/DDP; Incoterms 2020; Tariff codes: 7318.15, 7318.16 | Confirm duties and VAT handling for EU; choose shipping method (LCL vs FCL). |

Commonly stocked sizes (Wild West references)

| Type | Gauge | Lengths (stock) | Drive | Finish |

|---|---|---|---|---|

| Rustic Pyramid Head (slotted) | #8 | 1/2″, 5/8″, 3/4″, 1″, 1-1/2″ | Slotted | Black phosphate |

| Rustic Pyramid Head | #12 | 1″, 1-1/2″ | Phillips | Black phosphate |

| Flat Head (self-tapping wood screw) | #4 | 1/2″ | Phillips | Black oxide |

| Flat Head (self-tapping wood screw) | #6 | 3/4″, 1″ | Phillips | Black oxide |

Note: Self-tapping wood screws are thread-forming for wood; they differ from machine screws. Specify “self-tapping wood screw” if you require thread-forming behavior in soft woods or pre-drilled holes.

Performance expectations (guidelines)

- Drive engagement: Phillips/Pozidriv/Torx provide higher torque transfer than slot; avoid cam-out for finish protection.

- Withdrawal strength: Thread geometry and wood species determine pull-out. Coarse threads engage more wood fibers; fine threads may perform better in hardwoods at equivalent length.

- Corrosion: Black phosphate is rust-resistant but not a marine-grade coating. For outdoor or humid environments, consider stainless steel or upgraded coatings. Verify salt spray hours and topcoat (if any) with coating supplier data sheets.

- Installation: Pre-drill and countersink for flat heads in hardwoods to prevent splitting; use appropriate pilot hole size for dense materials.

Trade terminology for sourcing

| Term | Meaning | Application / Notes |

|---|---|---|

| MOQ (Minimum Order Quantity) | Smallest lot the supplier can support | Often tied to finishing line setup and packaging runs; confirm per SKU. |

| Lead time (LT) | Time from PO to shipment | Includes processing, finishing, packaging, and QC; allow buffer for custom finishes or coatings. |

| OEM / ODM | Original Equipment Manufacturer / Original Design Manufacturer | OEM: production per your specification; ODM: product design and branding supported by supplier. |

| Blanket PO / Release schedule | Standing PO with staged shipments | Common for high-volume furniture production; set monthly/quarterly releases. |

| Pricing terms | Unit price, tooling amortization, set-up fees | State price breaks and MOQ per size/finish; clarify rework fees for QC holds. |

| QC / AQL | Quality Control / Acceptable Quality Limit | Define critical, major, minor defects and sample plan; e.g., AQL 1.0 major, 2.5 minor per ISO 2859-1. |

| First Article Inspection (FAI) | Pre-production sample verification | Submit drawing, standard, and sample to confirm dimensions, thread, finish, and performance before mass run. |

| CoA (Certificate of Analysis) | Documentation of conformance to specifications | Provide on request; may include coating batch info, material certs. |

| SDS | Safety Data Sheet | Applies to coatings, lubricants; ensure up-to-date documents for regulatory compliance. |

| Certificates | RoHS/REACH, Prop 65, Conflict Minerals, A1/B1 packaging | Include with shipment or submit as part of tender package. |

| Packaging | Inner box, master carton, palletization, labels | Specify carton weight limits, barcode/QR, supplier/PO-specific labeling. |

| Logistics | EXW/FOB/CIF/DDP; Incoterms | Align with risk transfer and carrier choice; confirm EU VAT and customs brokerage. |

| HS codes | Customs classification | Typical: 7318.15 (threaded wood screws), 7318.16 (other screws); confirm local code for specific product. |

| Payment terms | T/T, L/C, Net terms | State deposit and balance terms, late fees, and change-order policies. |

| Warranty | Supplier guarantee | Clarify warranty scope for defects and coating performance; define remedy (replacement or credit). |

How to prepare your RFQ

- State application (e.g., furniture assembly, shelf supports, barn door hardware) and service class.

- Provide drawing/spec: head style and height, shank diameter tolerance, thread type and pitch, drive type and tolerance.

- Material and finish: steel or stainless; black phosphate/oxide/other; corrosion target; salt spray requirement if applicable.

- Quantities by size, MOQ per SKU, and projected annual usage.

- Lead time expectations and delivery cadence; shipping terms and packaging (labels, barcode, palletization).

- QA requirements: AQL, dimensional checks, torque-to-turn test, sample and approval process.

Standards and compliance notes

- USA: Dimensionally align with ANSI/ASME B18.6.1 for wood screws; for decorative heads or machine-screw equivalents, B18.6.3.

- Europe: Reference DIN 97 (wood screws), DIN 7997 (countersunk wood screws), ISO 7045/7046 for pan/flat heads, ISO 7085/2702 for flat head with waisted shank.

- Coatings: ASTM A153/A153M for zinc coatings; specify additional passivation or topcoat as required.

- Finish nomenclature: Specify finish designation (e.g., “black phosphate,” “black oxide with polymer topcoat,” “zinc-plated black”) and request coating supplier data sheets.

This structure keeps procurement, engineering, and QA aligned while making sure the black finish and performance characteristics align with your product and environment.

Navigating Market Dynamics and Sourcing Trends in the black furniture screws Sector

Navigating Market Dynamics and Sourcing Trends in the Black Furniture Screws Sector

Black furniture screws—comprising flat-head (countersink), pan-head, and pyramid-head variants finished in black phosphate, black oxide, or related coatings—serve two distinct yet intertwined roles in modern furniture assembly: robust mechanical performance under controlled production speeds, and deliberate aesthetic integration with rustic and industrial design schemes; accordingly, successful procurement strategies increasingly balance coating durability, lead-time reliability, and packaging alignment with regional compliance expectations in the USA and Europe.

Illustrative Image (Source: Google Search)

Historical trajectory: from industrial hardware to design-led component

- Early adoption in barn and gate hardware established the aesthetic vocabulary for “rustic” black hardware, while the same fasteners demonstrated utility in structural-to-semistructural wood connections; this dual legitimacy—functional and decorative—later migrated into cabinetry, shelving, and interior doors.

- As mass-market rustic and farmhouse aesthetics expanded through the 2010s into the mid-2020s, black head styles (flat, pan, and pyramid) moved from specialty barn-door vendors toward mainstream kitchen, bath, and furniture OEMs, who began specifying black screws not only to match exposed fasteners but also to provide consistent finish continuity across assembled assemblies.

- The market has matured from “one-off” sourcing for barn doors toward packaged assortments optimized for e-commerce fulfillment, installer kits, and replenishable inventory cycles, reflecting the broader shift from isolated hardware projects to broader program-level procurement across North America and Europe.

2024–2025 sourcing patterns: price, cost structure, and finish parity

- Flat-head countersink black oxide screws—small gauge (#4–#6) and short lengths (1/2″–1″)—are the entry point into black furniture screw supply, where commodity pricing and broad availability keep costs lean and MOQs accessible; pyramid-head slotted black phosphate screws, in contrast, occupy the decorative premium tier, where the head design and rustic finish typically command higher cost per piece and a narrower supply base, while often being available only in limited SKUs and pre-pack sizes (e.g., five sizes mentioned).

- Lead times for commodity black oxide screws remain shorter and more predictable for North American buyers due to deep domestic inventories and multiple coating lines, whereas rustic black phosphate offerings—frequently sourced through niche distributors or import channels—incur greater variance in availability and replenishment cadence; this bifurcation necessitates dual sourcing for OEMs and fabricators who serve both high-volume, cost-sensitive production and smaller-batch, aesthetics-led programs.

- Cost drivers concentrate in three areas: base wire price volatility, coating process energy intensity (phosphate and black oxide conversion treatments), and finishing operations where post-coating oiling or waxing to stabilize black coloration can add scrap risk and rework if process controls drift; buyers who anchor to documented specifications—finish type, salt-spray performance (if specified), lubrication level, and head/drive tolerances—reduce downstream defects, finish “browning,” and assembly inconsistency.

Market structure and channels: broadlines, specialty, and DIY fulfillment

- The sector comprises commodity black oxide fasteners from broadline distributors and importers, alongside specialty rustic suppliers that emphasize head styles (pyramid, clavos-style) and finishes aligned with barn, gate, cabinetry, and bath accessory programs; this two-tier structure serves both industrial OEM demand and design-driven fabrication shops seeking consistent finish aesthetics.

- Buyers in the USA and Europe increasingly expect e-commerce-ready assortments—clear SKU lists, packaged quantities that match typical installation runs, and kit-level options that bundle black screws with complementary hardware (hinges, pulls, brackets)—because installers and fabricators now purchase online rather than relying solely on regional hardware stores.

Sustainability and packaging: compliance, corrosion, and circularity

- Black phosphate finishes can be lubricated (often with light oil) for assembly efficiency and corrosion resistance; this lubrication reduces torque scatter, minimizes head marring, and supports consistent countersink depth, while a sealed post-process can maintain appearance consistency; black oxide finishes, particularly in indoor settings, provide aesthetic parity but generally require sealing or wax/oil overcoats for effective corrosion resistance, as oxide conversion alone is not protective in humid environments.

- Surface roughness correlates with light scattering and visible “blackness,” which designers prize for rustic authenticity; however, roughness must be balanced against torque performance, since coarser surfaces and exposed threads can increase friction during drive-in, especially when lubrication is not standardized.

- Packaging practices continue to shift toward recycled materials, reduced plastics, and clear recycling guidance on packaging labels, although many vendors in this niche still utilize poly bags or small corrugated packs; EU buyers should expect increased preference for recycled content, clear end-of-life guidance, and traceability, even for smaller-format SKU assortments.

Sourcing best practices: specifications, quality, and inventory strategy

- Prioritize finish selection aligned with use case: black phosphate for exterior or semi-exterior rustic hardware and longer-term corrosion resilience, black oxide (sealed) for interior decorative applications; specify lubrication level to control drive torque and finish marring.

- Require head geometry and drive tolerances where visible assemblies are critical: flat-head countersink depth and radius for flush aesthetics, pan-head head diameter and flange uniformity for mechanical coverage, pyramid-head for decorative alignment and consistent slot positioning.

- Implement salt-spray targets or accelerated corrosion tests only when performance claims are part of the specification; otherwise, standardize salt exposure requirements to your actual application environment to avoid unnecessary cost escalation.

- Standardize packaging units to align with project sizes and replenishment cycles: smaller retail packs for fabricators and installers, bulk counts for OEM lines, and kit assortments for multi-hardware assemblies; maintain SKU parity across regions to simplify cross-border inventory management.

- Maintain dual sourcing across commodity and decorative SKUs, with safety stock on core sizes (e.g., common gauges and lengths) while relying on specialty providers for head-design differentiation; this approach balances cost predictability with aesthetics and finish availability.

Compliance and safety: coatings, labeling, and logistics

- Verify finish composition details (phosphate vs. oxide), post-coating treatments (oils, waxes, sealers), and any anti-corrosion claims with documented data sheets; avoid overstating corrosion resistance when using black oxide without sealing.

- Ensure labeling and safety data sheets (SDS) cover coating oils and finish residues where applicable, particularly for warehouse staff handling bulk bags or drums; Europe-specific SDS language and hazard classifications may be required depending on coatings and post-treatments.

- Align packaging and transport classification with fastener-specific considerations (mass per unit, coil/bulk density, moisture control), and select moisture-resistant packaging for long lead-time routes to protect black finishes and prevent surface spotting.

Data-driven selection: price bands by finish and head style

To illustrate trade-offs between finish, head style, and indicative price tiers in the USA market, the following table consolidates observed examples from rustic and decorative assortments; actual prices vary by SKU, quantity, and vendor, and European pricing typically reflects local taxes, shipping, and currency conversion.

| Finish | Head type | Typical gauge/length examples | Assortment availability | Indicative price tier (USD per piece) | Notes |

|---|---|---|---|---|---|

| Black oxide | Flat head (#4–#6) | #4 x 1/2″, #6 x 1″, #6 x 3/4″ | Broad availability | ~$0.05–$0.08 | Commodity, interior aesthetic; sealing improves corrosion resistance |

| Black phosphate | Pyramid head (slotted) | #6 5/8″, #8 3/4″, #8 1″, #8 1 1/2″, #12 1 1/2″ | Limited set (e.g., five sizes) | ~$0.18–$0.26 | Decorative, rustic aesthetic; lubricated finish commonly used |

| Black phosphate | Flat/pan variants | #6 1″, #8 sizes | Availability varies | ~$0.16–$0.22 | Lubrication stabilizes black finish and drive performance |

Interpretation: flat-head black oxide screws, with broad availability and lower unit costs, anchor cost-sensitive programs and high-volume SKUs, while black phosphate pyramid-head screws command a premium due to their decorative head design and rustic aesthetic, often supplied in curated size sets rather than broad assortments; black phosphate flat/pan variants bridge performance and appearance in intermediate price bands where designers seek both corrosion resistance and cohesive finish language.

Conclusion

Black furniture screws now operate at the intersection of functional specification and design language, which means procurement must integrate finish selection, head geometry, and packaging into a coherent sourcing strategy; by separating commodity from decorative tiers, enforcing finish and lubrication specifications, and diversifying suppliers by tier, USA and European buyers secure cost predictability without compromising aesthetics, while sustainability and compliance practices—particularly in packaging and finish documentation—reduce risk across inventory cycles.

Frequently Asked Questions (FAQs) for B2B Buyers of black furniture screws

Frequently Asked Questions (FAQs)

Q1: What materials and finishes are available for black furniture screws?

– Materials:

– Low-carbon steel (case-hardened) for general furniture assembly

– Stainless steel 410 (magnetic) and 18-8/304 (non-magnetic) for higher corrosion resistance

– Black finishes:

– Black oxide (iron oxide) for steel; low-gloss black appearance; matte look

– Black phosphate (zinc phosphate) for steel; corrosion-inhibiting; matte

– Epoxy/polymer black coatings (various gloss levels; colored screws may be available)

– Selection guidance:

– Interior MDF/PB with decorative heads: black phosphate or black oxide steel

– Outdoor/high-humidity/oil-exposed: black polymer-coated or stainless steel 410/18-8

– Magnetic pick-up required: 410 stainless or steel finishes; avoid 18-8 for magnetic separation

Illustrative Image (Source: Google Search)

Q2: What are the mechanical properties and head styles of typical black wood screws?

– Head styles (per reference assortment):

– Flat head (countersunk), Phillips drive (e.g., #4, #6)

– Pan head (rounded profile; not countersunk)

– Pyramid head (decorative slotted, e.g., #6, #8, #12; lengths ~5/8″, 3/4″, 1″, 1-1/2″)

– Typical mechanical specifications:

– Drive: Phillips or slotted (see product selection by size)

– Thread: wood screw threads (shank and coarse threaded variants may be offered)

– Core hardness: approx. Rockwell C 45–55 for case-hardened steel

– Case depth: generally 0.2–0.4 mm on shank; per size/spec

– Tensile strength: typical range 60–70 ksi (steel); verify per SKU

– Torque and pull-out depend on pilot hole, wood density, and thread geometry; request data sheets by size

– Finish impact:

– Phosphate/black oxide enhance corrosion resistance; polymer coatings offer color/appearance consistency and corrosion protection

Q3: How are black rustic screws sourced and supplied?

– Wild West Hardware offers retail-size quantities with multiple head styles and sizes (e.g., Flat Head, Pan Head, Pyramid Head) and black phosphate/black oxide finishes

– MOQs and lead time:

– Retail/e-commerce: usually no MOQ; in-stock quantities shipped promptly

– Bulk/catalog/industrial: confirm MOQ (often 1,000–10,000 per SKU), standard lead time 2–4 weeks, shorter for stocked SKUs

– Packaging:

– Bulk cartons, small packs, retail-clam packs

– Carton labeling with PO, SKU, lot/heat code on request

– Regional availability:

– USA and Europe: lead time and shipping depend on stock status and location; request freight quotes for large orders

Q4: What minimum order quantities (MOQs) and customization options are available?

– Stock SKUs: typically no MOQ; sell by piece or small packs

– Custom/private label: confirm MOQ, usually 5,000–10,000 per size; lead time 4–8 weeks

– Customization:

– Head style, point, thread, drive (Phillips/slotted), length, diameter, finish, color match

– Packaging: custom labels, SKUs, bulk or retail-ready packaging

– Cost drivers:

– Quantity, complexity (special heads/points), finish, and packaging requirements

Q5: Which certifications and compliance standards apply?

– US:

– ASTM F1667 (wood screw property/definitions) and F1789 (fastener terminology)

– RoHS/Prop 65 compliance: confirm formulation if required (especially for coated or black oxide items)

– EU:

– REACH compliance for SVHC; RoHS; CE marking not applicable to fasteners

– Nickel release (EN 1811) not relevant for carbon/stainless steel; confirm for plated variants

– Documentation:

– Provide COC/SDS on request; include lot/heat codes and finishing details

Illustrative Image (Source: Google Search)

Q6: Are black furniture screws compatible with pre-drilled holes and furniture connectors?

– Compatibility:

– Designed for wood and wood-based materials (MDF/PB/plywood) with pre-drilled pilot holes

– Self-tapping variants available (e.g., “Phillips / Self-tapping Wood Screws”); confirm suitability vs. traditional wood screws

– Connector compatibility:

– Use washers under pan heads when mating with knock-down fittings, metal brackets, or thin panels to distribute load

– Countersink flat heads for flush installation; consider chip-out control with proper pilot depth

– Pilot hole guidance:

– Use size-specific pilot holes; hardwood and MDF generally benefit from full pilot; softwood may use partial pilot

– See installation best practices for head seating and torque to prevent stripping

Q7: What are installation best practices for black furniture screws?

– Pilot holes:

– Match pilot to shank (diameter and depth) to prevent splitting and ensure engagement

– Countersinking:

– Pre-countersink for flat heads in MDF/PB to achieve flush seating

– Torque and seating:

– Drive to full engagement without over-torquing; consider using a torque-limiting driver for production

– Corrosion protection:

– Avoid galvanic corrosion with stainless or zinc-plated hardware when mixing metals; add isolating washers if required

– Finishes:

– Phosphate/black oxide may show wear under repeated assembly/disassembly; consider polymer coatings or stainless for frequent service

Q8: What quality control (QC) and traceability practices ensure consistency?

– Inspection and sampling:

– Per ISO 2859-1 AQL standards (e.g., 1.5–2.5 inspection for critical dimensions and cosmetic finish)

– Critical checks:

– Dimensional verification (diameter, length, head height/angle), drive fit and cam-out, thread form, finish coverage/appearance

– Batch traceability:

– Lot/heat code and COC with each shipment

– Corrosion tests (by request):

– Salt spray (ASTM B117) and humidity cycling for coated parts; specify cycle durations and acceptance criteria

– Warranty and non-conformance:

– NCAR/RMA process; replacement or credit based on documented issues; document defect rates and corrective actions

Strategic Sourcing Conclusion and Outlook for black furniture screws

Strategic Sourcing Conclusion and Outlook

Black furniture screws offer a clear value equation: consistent finish quality, dependable thread performance, and minimal visual disruption across cabinetry and furniture programs. Procurement should prioritize black phosphate for interior hardware and black oxide for low-corrosion applications, aligning to gauge and head styles required by design. Maintain dual sourcing with at least one vendor offering rustic/decorative options (e.g., pyramid heads) for differentiation.

Illustrative Image (Source: Google Search)

To guide SKU strategy and TCO, the following finish comparison helps anchor decisions:

| Finish | Corrosion resistance (relative) | Typical gauge range | Head styles available | Relative cost per 1,000 pcs |

|---|---|---|---|---|

| Black phosphate | Moderate (interior preferred) | #4–#12 | Flat, Phillips, pyramid | Lower–moderate |

| Black oxide | Limited (light-duty, dry env.) | #4–#10 | Flat, Phillips | Low |

Action items

– Lock multi-quarter volumes with price breaks on #6–#8 and #12 SKUs; buffer 10–15% for rework and returns.

– Verify pilot testing on assembly torque and finish adhesion; enforce lot-level QC (drive torque, head finish uniformity).

– Standardize head/thread codes to reduce SKU count while maintaining finish flexibility.

– Monitor lead times on black finishes (supply tight); secure dual supply and confirm regional warehouse coverage (USA/EU).

– Target on-time delivery ≥95%, PPM ≤500, and defect rate ≤0.2%.

Outlook

Expect ongoing lead-time pressure in black finishes. Diversify finish capabilities and maintain safety stock on fast movers. Consolidate vendors, negotiate indexed pricing, and invest in supplier scorecards to protect availability and quality.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided is for informational purposes only. B2B buyers must conduct their own due diligence.

Illustrative Image (Source: Google Search)