The global biomass pellet machine market is experiencing robust growth, driven by rising demand for renewable energy and increasing adoption of biomass as a sustainable alternative to fossil fuels. According to a report by Mordor Intelligence, the biomass pellet market was valued at USD 8.9 billion in 2023 and is projected to grow at a CAGR of over 8.5% from 2024 to 2029, with pellet machine manufacturers playing a pivotal role in enabling this expansion. Similarly, Grand View Research estimates that the global biomass pellets market size reached USD 12.3 billion in 2022 and is expected to expand at a CAGR of 7.6% from 2023 to 2030, further underscoring the critical need for efficient and scalable pelletizing equipment. As governments and industries worldwide prioritize decarbonization and energy security, the demand for high-performance biomass pellet machines continues to surge. In response, leading manufacturers are innovating with advanced technology, improved energy efficiency, and automated systems to meet evolving market needs. This list highlights the top 10 biomass pellet machine manufacturers shaping the industry through technological leadership, global reach, and consistent product performance.

Top 10 Biomass Pellet Machine Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

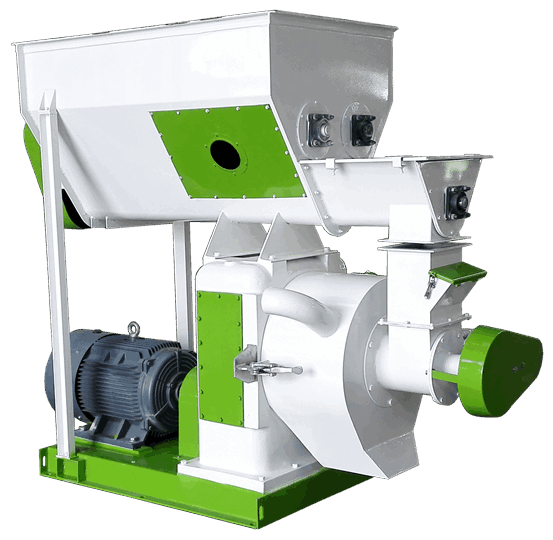

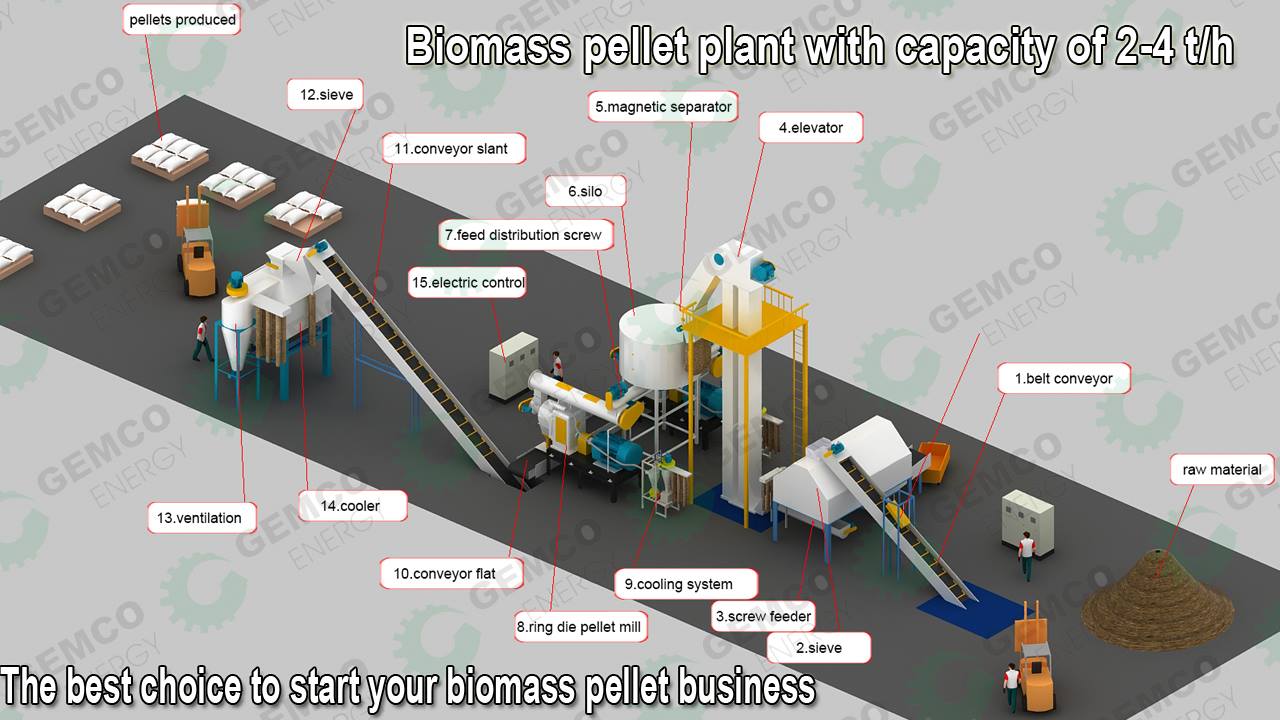

#1

Domain Est. 2013

Website: gemco-energy.com

Key Highlights: Anyang GEMCO Energy Machinery Co., Ltd, the leader of biomass pellet mill / briquette machine manufacturer in China, is one of the members of the first batch ……

#2 Proveg Engineering

Domain Est. 2017

Website: provegengineering.in

Key Highlights: As a leading Industrial Biomass Pellet Manufacturer India, we specialize in designing and manufacturing biomass pellet machines, Yulong pellet machines, pellet ……

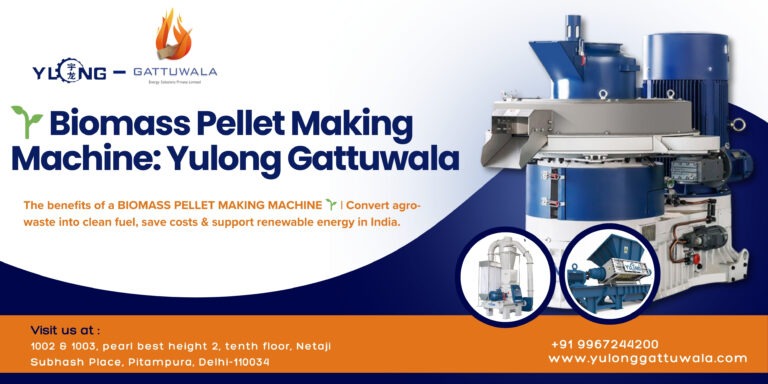

#3 Yulong-Gattuwala

Website: yulonggattuwala.com

Key Highlights: We specialize in offering customized biomass pellet machines that cater to various needs, whether for small-scale production or large industrial applications….

#4 Manufacturer And Exporter

Website: radherico.com

Key Highlights: From behind-the-scenes factory footage to live machine demos, this page brings you closer to the precision, quality, and reliability that define our brand….

#5 Enviva Biomass

Domain Est. 2010

Website: envivabiomass.com

Key Highlights: Our wood pellets provide biogenic carbon solutions for power and heat generation, industrial processes, chemicals, and advanced biofuels worldwide….

#6 Pellet Mill & Pelleting Plant Manufacturer

Domain Est. 2012

Website: akahl.com

Key Highlights: PELLET MILL MANUFACTURER: Your expert in the field of flat die pellet mills for feed mills, wood pelleting plants, recycling plants and much more | AMANDUS ……

#7 Pellet Mills

Domain Est. 2013

Website: onecpm.com

Key Highlights: As the world’s largest manufacturer of pellet mills, CPM has led the way in developing specialized pellet mills and dies to produce pellets both efficiently and ……

#8 Pellet mills, biomass

Domain Est. 1995

Website: andritz.com

Key Highlights: Pellet mills for biomass production · The ANDRITZ range of pellet mills offers reliability and high output for conversion of biomass into biomass pellets….

#9 Buskirk Engineering Pellet Mills

Domain Est. 2005

Website: buskirkeng.com

Key Highlights: Buskirk Engineering has been a leader in the biomass densification industry for over a decade. We pride ourselves on building high quality flat die pellet mills ……

#10 Biomass Pellet Machine & Wood Pellet Plants Manufactures. One …

Domain Est. 2013

Website: biopelletmachine.com

Key Highlights: We specialize in providing reliable, efficient, and eco-friendly biomass pellet machines and complete biomass pellet plant solutions to customers worldwide….

Expert Sourcing Insights for Biomass Pellet Machine

H2: 2026 Market Trends for Biomass Pellet Machines

The global biomass pellet machine market is poised for significant transformation by 2026, driven by increasing demand for renewable energy, supportive government policies, and technological advancements. Below are key trends shaping the industry:

-

Rising Demand for Renewable Energy

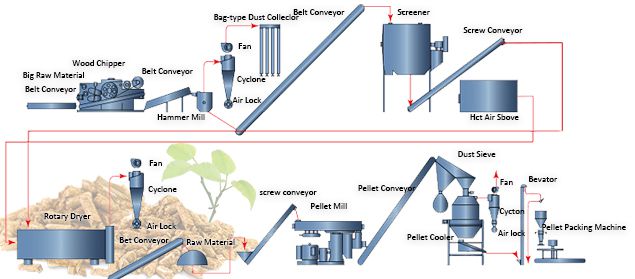

As countries intensify efforts to meet climate targets under the Paris Agreement, biomass energy is gaining traction as a carbon-neutral alternative to fossil fuels. Biomass pellet machines are critical in converting organic waste—such as wood residues, agricultural byproducts, and energy crops—into high-density fuel pellets. The expansion of bioenergy in power generation, heating systems, and industrial boilers is fueling demand for efficient pelletizing equipment. -

Government Incentives and Regulatory Support

Many governments are implementing subsidies, tax credits, and renewable energy mandates to promote biomass utilization. For instance, the European Union’s Renewable Energy Directive (RED III) and the U.S. Inflation Reduction Act (IRA) include provisions supporting biomass energy adoption. These policies are encouraging investments in pellet production infrastructure, directly benefiting the biomass pellet machine sector. -

Technological Advancements and Automation

By 2026, biomass pellet machines are expected to feature enhanced automation, IoT integration, and real-time monitoring systems. Smart pellet mills with predictive maintenance capabilities, energy-efficient motors, and improved die designs will improve productivity and reduce operational costs. These innovations are particularly appealing to large-scale producers seeking consistent pellet quality and lower downtime. -

Growth in Emerging Markets

Asia-Pacific, Latin America, and parts of Africa are emerging as high-growth regions due to increasing energy demand, abundant biomass resources, and rural electrification programs. Countries like India, Indonesia, and Brazil are investing in decentralized biomass energy solutions, creating new opportunities for pellet machine manufacturers. -

Focus on Sustainability and Feedstock Diversification

There is a growing emphasis on using non-wood biomass sources such as rice husks, sugarcane bagasse, and municipal green waste. This shift is driving the development of multi-feedstock compatible pellet machines capable of handling diverse raw materials with varying moisture and fiber content. -

Consolidation and Competitive Landscape

The market is witnessing increased consolidation, with key players expanding through mergers, acquisitions, and partnerships. Companies are also investing in R&D to differentiate their products through energy efficiency, durability, and ease of maintenance. Chinese, German, and American manufacturers continue to dominate, but local players in developing regions are gaining market share. -

Challenges and Constraints

Despite growth, the sector faces challenges such as fluctuating raw material prices, logistical hurdles in biomass collection, and stringent emissions standards for pellet combustion. Additionally, competition from other renewable sources like solar and wind may impact investment flows.

In conclusion, the 2026 biomass pellet machine market is set for steady growth, supported by environmental imperatives, energy security concerns, and technological innovation. Manufacturers who prioritize efficiency, adaptability, and sustainability are likely to lead the market in this evolving landscape.

Common Pitfalls When Sourcing Biomass Pellet Machines: Quality and Intellectual Property Risks

Sourcing biomass pellet machines, especially from international suppliers, involves significant risks related to both product quality and intellectual property (IP) protection. Being aware of these pitfalls is crucial for ensuring a successful investment and long-term operational efficiency.

Poor Machine Quality and Substandard Components

One of the most frequent issues encountered is receiving machines that fail to meet promised performance standards. Many suppliers, particularly in competitive low-cost markets, use inferior materials and cut corners in manufacturing. This includes using low-grade steel for critical components like the die and rollers, which leads to rapid wear, frequent breakdowns, and inconsistent pellet quality. Buyers may find that the actual production capacity is far below advertised levels, and energy consumption is significantly higher, increasing operational costs. Without rigorous third-party inspections or clear performance guarantees, buyers risk investing in equipment that requires constant maintenance or fails prematurely.

Lack of Genuine Technical Innovation and IP Infringement

A major but often overlooked pitfall is the risk of purchasing machines that infringe on existing intellectual property. Some suppliers replicate patented designs, gearboxes, or automation systems from established manufacturers without licensing. While these machines may appear identical and cost less, they expose the buyer to legal and reputational risks—especially if the equipment is imported into jurisdictions with strong IP enforcement. Furthermore, counterfeit or copied machines often lack the engineering refinements that ensure reliability and efficiency, resulting in poor performance and safety hazards. Buyers may also find that technical support and spare parts are unreliable due to the absence of legitimate manufacturer backing.

Inadequate After-Sales Support and Spare Parts Availability

Even if a machine initially performs well, sourcing from suppliers with weak IP practices often correlates with poor after-sales service. Because the design may be a copy, original spare parts are unavailable, and technical support is limited or nonexistent. This leads to extended downtime when components fail, undermining production schedules. Buyers may struggle to find compatible replacements, and local technicians may lack documentation or training to maintain the machine properly.

Misleading Certifications and Compliance Claims

Some suppliers falsely claim international certifications (such as CE or ISO) or assert compliance with environmental and safety standards. These misrepresentations can be difficult to verify without independent audits. Using non-compliant equipment may result in regulatory penalties, insurance issues, or workplace safety incidents. It’s essential to request verifiable certification documents and conduct factory audits before finalizing procurement.

How to Mitigate These Risks

To avoid these pitfalls, conduct thorough due diligence: verify supplier credentials, request machine testing under real conditions, and insist on clear contractual warranties. Engage third-party inspection services and consult IP databases to ensure the technology does not infringe on existing patents. Prioritize suppliers with transparent manufacturing processes, proven track records, and robust after-sales networks to protect your investment and ensure long-term operational success.

Logistics & Compliance Guide for Biomass Pellet Machine

This guide outlines key considerations for the transportation, import/export, and regulatory compliance associated with biomass pellet machines. Proper planning ensures smooth delivery and adherence to local and international standards.

Transportation and Handling

- Secure Packaging: Ensure the machine is packed in robust wooden crates with waterproof wrapping to protect against moisture and physical damage during transit.

- Weight and Dimensions: Confirm the machine’s weight, dimensions, and center of gravity to select appropriate transport (e.g., flatbed truck, containerized shipping). Oversized loads may require special permits.

- Lifting Points: Use designated lifting points and certified rigging equipment when loading/unloading to prevent structural damage.

- Climate Protection: Shield electrical components and bearings from rain, snow, and extreme temperatures during transport and temporary storage.

International Shipping Requirements

- Export Documentation: Prepare commercial invoice, packing list, bill of lading, and certificate of origin. Include HS code 8439.89 (machinery for making pulp or fiberboard) for customs classification.

- Import Regulations: Verify the destination country’s import duties, restrictions, and certification requirements (e.g., CE, UL, or local safety marks).

- Incoterms: Clearly define responsibilities using standard Incoterms (e.g., FOB, CIF, DDP) to avoid disputes over freight, insurance, and customs clearance.

Regulatory Compliance

- Safety Standards: Machines must comply with relevant safety regulations such as:

- CE Marking (EU): Complies with Machinery Directive 2006/42/EC, EMC Directive, and Low Voltage Directive.

- UL/CSA (North America): Meets applicable OSHA and ANSI/ISA safety standards.

- GB Standards (China): Follows GB/T 15777 and other national safety regulations.

- Electrical Compliance: Voltage and frequency must match the destination’s grid specifications. Include appropriate plug types and transformers if necessary.

- Environmental Regulations: Ensure the machine meets emissions and noise standards in the operating region (e.g., EU Ecodesign Directive).

Installation and Operational Compliance

- Site Preparation: Verify foundation strength, ventilation, and clearance around the machine per manufacturer specifications.

- Operator Training: Provide certified training on safe operation, maintenance, and emergency shutdown procedures.

- Permits and Inspections: Obtain required local permits for industrial machinery installation. Schedule inspections by authorized bodies if mandated.

After-Sales and Warranty Considerations

- Spare Parts Logistics: Maintain an inventory of critical spare parts (e.g., dies, rollers) and ensure supply chain reliability.

- Service Accessibility: Confirm availability of qualified technicians or remote support for troubleshooting and maintenance.

- Warranty Terms: Clearly document warranty coverage, including conditions related to transportation damage, improper installation, or non-compliant operation.

Adhering to this guide ensures timely delivery, legal operation, and long-term reliability of your biomass pellet machine. Always consult local authorities and the machine manufacturer for region-specific requirements.

Conclusion:

Sourcing a biomass pellet machine is a strategic and sustainable investment that supports renewable energy production, waste utilization, and environmental conservation. With the growing global emphasis on reducing carbon emissions and transitioning to clean energy sources, biomass pellets have emerged as a reliable and eco-friendly alternative to fossil fuels. Selecting the right pellet machine requires careful consideration of several factors, including raw material type, production capacity, energy efficiency, durability, and after-sales support.

After evaluating various suppliers, machine types (such as flat die and ring die models), and cost-benefit ratios, it is evident that investing in a high-quality, well-maintained pellet machine can yield significant long-term economic and environmental returns. Additionally, partnering with reputable manufacturers who offer technical guidance, spare parts availability, and installation assistance ensures smooth operations and minimizes downtime.

In conclusion, sourcing a biomass pellet machine is not only a step toward energy self-sufficiency and cost savings but also a contribution to a greener, more sustainable future. As technology advances and demand for renewable energy grows, businesses and individuals alike can benefit from integrating biomass pellet production into their energy or manufacturing strategies.