The global marine hardware market, including critical components such as Bimini top fittings and mounting systems, is experiencing steady growth driven by rising recreational boating activities and increased demand for aftermarket marine accessories. According to a 2023 report by Mordor Intelligence, the global marine equipment market is projected to grow at a CAGR of 4.8% from 2023 to 2028, with expanding production of powerboats and sailboats directly boosting the need for durable, corrosion-resistant hardware. Bimini tops—essential for sun protection on recreational vessels—rely on high-performance hardware such as hinges, brackets, clamps, and bases, creating sustained demand among OEMs and replacement part consumers. As marine manufacturers focus on lightweight, marine-grade stainless steel and aluminum components, the competitive landscape for Bimini hardware suppliers has intensified. Based on market presence, product range, material quality, and distribution networks, the following ten manufacturers have emerged as leaders in producing reliable, marine-certified hardware parts for Bimini tops worldwide.

Top 10 Bimini Hardware Parts Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Marine Town

Domain Est. 2001

Website: marinetown.com

Key Highlights: BIMINI HARDWARE · TRAILER · VENTILATION · WATER SPORTS · SAILBOAT HARDWARE … Marine Town is a professional manufacturer of stainless steel marine hardware ……

#2 Frame & hardware options

Domain Est. 2005

Website: anp.ca

Key Highlights: Bimini boat top specifications. What makes a quality boat top or boat cover? The frame, the hardware, the construction, and most of all the fabric….

#3 Bimini Tops

Domain Est. 2006

Website: dowcomarine.com

Key Highlights: 3-day deliveryDowco Marine is the premier manufacturer of replacement bimini tops for pontoon boats, fishing, and runabout boats….

#4 Bimini Top Hardware and Accessories

Domain Est. 1996

#5 Bimini Hardware & Parts

Domain Est. 1996

Website: westmarine.com

Key Highlights: Free delivery over $99Shop the best selection of Bimini Hardware & Parts from West Marine. Visit for products, prices, deals and more!…

#6 Attwood Marine

Domain Est. 1999

Website: new.attwoodmarine.com

Key Highlights: Attwood has been a proven marine industry leader for over 100 years. Our wide range of products, including general marine accessories, seat & table hardware ……

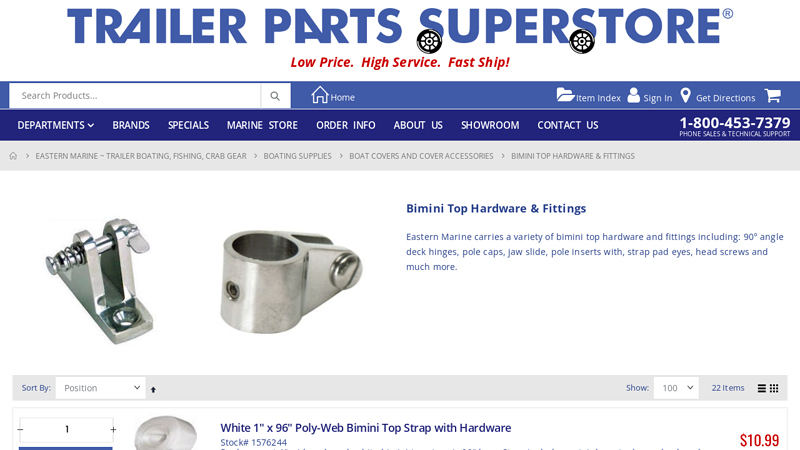

#7 Bimini Top Hardware & Fittings at Eastern Marine

Domain Est. 1999

#8 Bimini Boatops®

Domain Est. 2001

Website: taylormadeproducts.com

Key Highlights: Manufactured with superior features, these boat bimini tops are sold with the frame, fabric tops and storage boots packaged separately….

#9 Bimini Top Hardware

Domain Est. 2002

Website: boatoutfitters.com

Key Highlights: Free delivery over $150Bimini top hardware refers to all the fittings, hinges, eyelets, clips, and straps that hold a Bimini top and its frame in place….

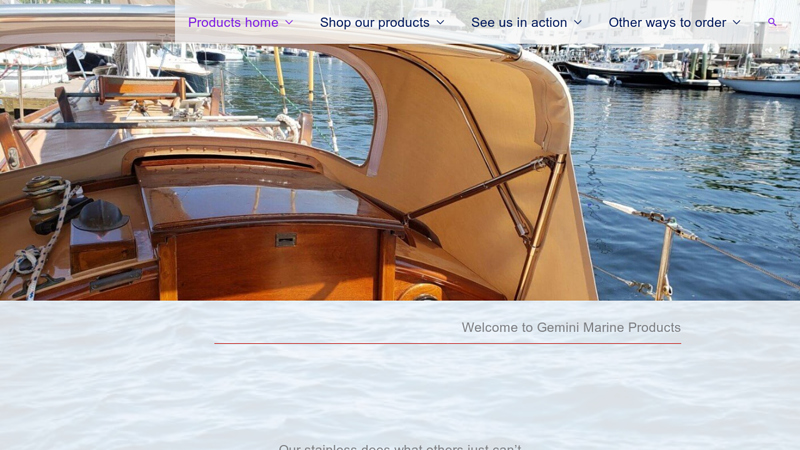

#10 Gemini Marine Products

Domain Est. 2009

Website: geminiproducts.net

Key Highlights: Our 316 stainless steel fittings, including our exclusive, patented hinges and struts, set new standards in marine canvas hardware….

Expert Sourcing Insights for Bimini Hardware Parts

H2: 2026 Market Trends for Bimini Hardware Parts

The global market for Bimini hardware parts—components such as hinges, brackets, support tubes, clamps, and mounting fittings used in marine Bimini tops and boat canopies—is expected to undergo significant transformation by 2026. Driven by advancements in marine leisure activities, evolving consumer preferences, and innovations in materials and manufacturing, the sector is poised for moderate but steady growth. Below is an analysis of the key trends shaping the Bimini hardware parts market in 2026:

-

Increased Demand from Recreational Boating Sector

The recreational boating industry continues to expand, particularly in North America, Europe, and parts of Asia-Pacific. As more consumers invest in personal watercraft and yachts, demand for durable, stylish, and functional Bimini tops—and by extension, high-quality hardware parts—rises. The post-pandemic surge in outdoor leisure activities has sustained interest in marine lifestyles, further boosting aftermarket and OEM demand. -

Shift Toward Corrosion-Resistant and Lightweight Materials

By 2026, manufacturers are increasingly adopting marine-grade stainless steel (e.g., 316L), anodized aluminum, and composite polymers to enhance durability and reduce weight. These materials resist saltwater corrosion—critical for longevity in marine environments—and improve ease of installation and handling. Innovations in powder-coated finishes also offer enhanced UV and weather resistance, aligning with consumer demand for low-maintenance hardware. -

Growth in Customization and Modular Design

Boaters are seeking customizable Bimini systems that fit diverse vessel configurations. As a result, hardware suppliers are focusing on modular, adjustable, and universal-fit components. This trend supports both DIY enthusiasts and marine outfitters, enabling flexible installations across different boat models and sizes. Interchangeable hinge systems and quick-release clamps are expected to gain market share. -

Expansion of E-Commerce and Direct-to-Consumer Sales

Online marketplaces and specialized marine parts retailers are becoming primary channels for Bimini hardware distribution. By 2026, a growing number of consumers are purchasing components directly online, attracted by competitive pricing, product reviews, and easy access to technical specs. This shift pressures traditional distributors to enhance digital presence and streamline logistics. -

Sustainability and Eco-Friendly Manufacturing

Environmental concerns are influencing product development. Manufacturers are adopting sustainable practices such as recycling scrap metal, reducing energy consumption in production, and minimizing packaging waste. Some brands are beginning to offer hardware with recycled content or biodegradable packaging, appealing to eco-conscious marine consumers. -

Integration with Smart Marine Accessories

While still in early stages, there is emerging interest in integrating Bimini hardware with smart marine systems—such as automated retractable canopies or sensor-equipped mounting brackets that detect stress or misalignment. Though not yet mainstream, R&D in this area may position certain hardware parts as part of broader smart boat ecosystems by the late 2020s. -

Regional Market Dynamics

North America remains the largest market due to high boat ownership rates and a mature marine aftermarket. Europe shows steady growth, particularly in the Mediterranean region, while Asia-Pacific is an emerging market fueled by rising disposable incomes and expanding marina infrastructure in countries like China, Thailand, and Australia.

In summary, the 2026 Bimini hardware parts market is characterized by innovation in materials, increasing demand for customization, and digital transformation in distribution. Companies that prioritize durability, ease of use, and sustainability are likely to lead in this evolving landscape.

Common Pitfalls Sourcing Bimini Hardware Parts (Quality, IP)

Sourcing Bimini top hardware—such as hinges, clamps, brackets, and mounting fittings—can be fraught with risks, especially when balancing cost, durability, and legal compliance. Overlooking key factors can lead to product failure, customer dissatisfaction, or even intellectual property (IP) disputes. Below are the most common pitfalls to avoid.

Poor Material Quality and Corrosion Resistance

One of the most frequent issues is receiving hardware made from substandard materials. Bimini tops are constantly exposed to saltwater, UV radiation, and high humidity, making corrosion resistance critical. Sourcing parts made from low-grade stainless steel (e.g., non-marine grade 304 or 316) or poorly coated metals often leads to premature rusting, weakening structural integrity, and unsightly appearance. Always verify material specifications and request salt-spray test reports to ensure longevity.

Inconsistent Manufacturing Tolerances

Low-cost suppliers, particularly those without strict quality control processes, may produce hardware with inconsistent dimensions or poor welds. This inconsistency can result in misaligned fittings, difficulty during installation, or weak load-bearing performance. Request samples and inspect for dimensional accuracy and finish quality before placing bulk orders.

Lack of Load and Stress Testing

Many sourced hardware components are not properly tested for marine environmental stresses. Without adequate load ratings or fatigue testing data, parts may fail under real-world conditions—especially on larger boats or in rough waters. Ensure the supplier provides performance certifications or engineering data to validate the hardware’s suitability.

Non-Compliance with Marine Industry Standards

Marine hardware should adhere to standards such as ISO, ABYC (American Boat & Yacht Council), or NMMA (National Marine Manufacturers Association). Sourcing parts without these certifications can compromise safety and make it difficult to meet regulatory requirements for boat manufacturers. Always confirm compliance during the sourcing process.

Intellectual Property (IP) Infringement Risks

Copying or sourcing look-alike hardware that replicates patented designs (e.g., proprietary hinge mechanisms or clamp configurations) can lead to legal action. Many established marine hardware brands hold design and utility patents. Sourcing unlicensed replicas—even if supplied by third-party manufacturers—exposes your business to IP litigation, product recalls, and reputational damage. Conduct due diligence to ensure designs are either licensed, in the public domain, or original.

Misrepresentation of Supplier Capabilities

Some suppliers claim to manufacture parts in-house but actually outsource to unqualified subcontractors. This lack of control often results in inconsistent quality and difficulty tracing defects. Vet suppliers thoroughly, ideally with on-site audits, and require transparency about their production chain.

Inadequate Packaging and Logistics Damage

Poor packaging can lead to scratched, bent, or corroded hardware upon arrival. Marine-grade hardware should be individually wrapped or protected against moisture and impact during shipping. Confirm packaging standards with suppliers to prevent in-transit damage.

Avoiding these pitfalls requires due diligence, clear specifications, and strong supplier relationships. Prioritize quality assurance and IP compliance over initial cost savings to ensure reliable, durable, and legally safe Bimini hardware sourcing.

Logistics & Compliance Guide for Bimini Hardware Parts

Overview

This guide outlines the logistics and compliance requirements for the import, export, storage, and distribution of Bimini hardware parts. These components—such as stainless steel brackets, hinges, tubing clamps, and mounting hardware—are used in marine bimini top assemblies and must meet stringent quality, safety, and regulatory standards. Adherence to this guide ensures smooth operations, minimizes delays, and maintains regulatory compliance.

International Shipping & Export Compliance

All shipments of Bimini hardware parts across international borders must comply with export control regulations, including:

– Export Classification: Determine if parts fall under ECCN (Export Control Classification Number) under the U.S. Commerce Control List (CCL). Most standard marine hardware typically falls under EAR99, but verify for stainless steel alloys or specialized designs.

– Destination Restrictions: Screen end-users and countries against denied party lists (e.g., OFAC, BIS). Avoid shipping to embargoed nations without proper licensing.

– Documentation: Prepare commercial invoices, packing lists, and bills of lading with accurate product descriptions, HTS codes, and country of origin (typically USA, China, or Mexico).

– Trade Agreements: Leverage preferential treatment under USMCA or other free trade agreements where applicable, provided rules of origin are met.

Import Regulations & Customs Clearance

Upon entry into a destination country, Bimini hardware parts are subject to customs scrutiny:

– Harmonized Tariff Schedule (HTS) Codes: Use correct HTS codes—for example, 7326.90 (other articles of iron or steel) or 8302.41 (stainless steel mountings). Misclassification can result in fines or delays.

– Duties & Tariffs: Monitor applicable tariffs based on origin and trade agreements. Apply for duty drawback or bonded warehouse programs where eligible.

– Country of Origin Labeling: Clearly mark parts with the country of manufacture per FTC and customs requirements (e.g., “Made in China”).

– Importer of Record (IOR): Designate a compliant IOR responsible for ensuring duties are paid and documentation is accurate.

Product Compliance & Safety Standards

Bimini hardware must meet relevant industry and safety standards:

– Marine Industry Standards: Comply with ABYC (American Boat & Yacht Council) standards where applicable, particularly for corrosion resistance and structural integrity.

– Material Specifications: Use marine-grade stainless steel (e.g., 316/L) that meets ASTM A276 or equivalent. Provide mill test reports upon request.

– RoHS & REACH: Confirm parts are free from restricted substances (e.g., lead, cadmium) if sold in the EU or other regulated markets.

– Certifications: Maintain records of ISO 9001 (quality management) and ISO 3506 (mechanical properties of corrosion-resistant fasteners) if applicable.

Packaging & Labeling Requirements

Proper packaging ensures product integrity and regulatory compliance:

– Protective Packaging: Use rust-inhibitive materials, vacuum sealing, or VCI (Vapor Corrosion Inhibitor) packaging for stainless components to prevent corrosion during transit.

– Labeling: Include SKU, part description, quantity, lot number, country of origin, and handling instructions (e.g., “Fragile,” “Keep Dry”).

– Barcoding & Traceability: Implement serialized or batch-level tracking for recall readiness and inventory accuracy.

Storage & Inventory Management

- Warehouse Conditions: Store parts in dry, climate-controlled environments to prevent oxidation and contamination.

- Inventory Rotation: Use FIFO (First In, First Out) to minimize obsolescence and maintain material quality.

- Bonded Warehousing: Consider for deferred duty payments in multi-destination distribution networks.

Transportation & Carrier Requirements

- Mode Selection: Choose reliable carriers experienced in handling industrial hardware—air freight for urgent orders, ocean freight for bulk shipments.

- Incoterms: Clearly define responsibilities using standard Incoterms (e.g., FOB, EXW, DDP) in all sales contracts.

- Insurance: Ensure cargo is fully insured against loss, damage, or delay during transit.

Recordkeeping & Audit Preparedness

Maintain records for a minimum of five years, including:

– Export license applications (if required)

– Customs declarations and duty payment records

– Certificates of origin and compliance

– Supplier quality assurance documentation

– Shipping and receiving logs

Regular internal audits should verify compliance with all logistics and regulatory requirements.

Contact & Support

For questions regarding logistics or compliance:

– Compliance Officer: [email protected]

– Logistics Manager: [email protected]

– Emergency After-Hours Support: +1 (800) 555-0199

Ensure all staff involved in shipping, receiving, or compliance are trained annually on updates to regulations and internal procedures.

Conclusion for Sourcing Bimini Hardware Parts:

Sourcing Bimini top hardware parts requires a careful balance between quality, durability, compatibility, and cost. Stainless steel components, particularly grade 316, are highly recommended due to their superior resistance to corrosion in marine environments. When selecting suppliers, it is essential to prioritize reputable manufacturers or distributors that offer marine-grade materials and provide specifications to ensure long-term performance. Compatibility with existing Bimini frame dimensions and boat configurations must be verified to ensure a proper fit and secure installation. Additionally, considering factors such as ease of availability, lead times, and warranty can contribute to a smoother procurement process. Ultimately, investing in high-quality hardware not only enhances the structural integrity and functionality of the Bimini top but also reduces maintenance and replacement costs over time, ensuring reliable protection and comfort during marine activities.