Introduction: Navigating the Global Market for the Best Screws for Outdoor Use

Corrosion is a leading cause of callbacks, rework, and warranty costs in exterior assemblies. To reliably serve USA and Europe markets, procurement, construction, and engineering teams must align screw selection with environment, substrate, and assembly risk—without overpaying where performance isn’t needed.

This guide delivers a practical, vendor-neutral decision framework:

– Materials overview: stainless steel vs coated carbon steel vs deck screws

– Coatings and performance trade-offs (galvanic protection, coating durability)

– Environment mapping (coastal/marine, treated lumber, frequent wetting)

– Torque and installation practices to preserve coatings and avoid cam-out

– Compliance, certifications, and sourcing considerations across regions

Use the table below to frame the options you’ll evaluate in the guide.

| Screw type | Corrosion resistance | Strength/torque | Cost (relative) | Best use cases | Installation notes |

|—|—|—|—|—|—|

| Stainless steel | Highest; resistant through thickness | Softer; more torque-sensitive | Highest | Coastal, wet zones, assemblies requiring serviceability | Use lower torque; avoid cam-out to preserve coating |

| Coated/galvanized steel | Good when coating intact; zinc sacrificial | Stronger; higher torque tolerance | Lower | General outdoor; budget-constrained projects | Handle carefully; drive-bite can breach coating |

| “Deck” screw (coated carbon) | Good; depends on coating type | Stronger; designed for wood | Lower | Wood decking and outdoor structures | Pre-drill in hard woods; manage drive-bite to avoid cracks |

From material choice to installation method, every decision has an outsized effect on total installed cost. The following sections translate these trade-offs into actionable selection criteria, checklists, and sourcing guidance for global buyers.

Illustrative Image (Source: Google Search)

Article Navigation

- Top 10 Best Screws For Outdoor Use Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for best screws for outdoor use

- Understanding best screws for outdoor use Types and Variations

- Key Industrial Applications of best screws for outdoor use

- 3 Common User Pain Points for ‘best screws for outdoor use’ & Their Solutions

- Strategic Material Selection Guide for best screws for outdoor use

- In-depth Look: Manufacturing Processes and Quality Assurance for best screws for outdoor use

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘best screws for outdoor use’

- Comprehensive Cost and Pricing Analysis for best screws for outdoor use Sourcing

- Alternatives Analysis: Comparing best screws for outdoor use With Other Solutions

- Essential Technical Properties and Trade Terminology for best screws for outdoor use

- Navigating Market Dynamics and Sourcing Trends in the best screws for outdoor use Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of best screws for outdoor use

- Strategic Sourcing Conclusion and Outlook for best screws for outdoor use

- Important Disclaimer & Terms of Use

Top 10 Best Screws For Outdoor Use Manufacturers & Suppliers List

1. Exterior Screws with PrimeGuard Plus® | Grip-Rite®

Domain: grip-rite.com

Registered: 2002 (23 years)

Introduction: Grip-Rite Exterior Screws are the perfect fastener for most non-structural outdoor building projects. Protected from corrosion and rust by our exclusive ……

2. GRK Fasteners | GRK Fasteners

Domain: grkfasteners.com

Registered: 2001 (24 years)

Introduction: Top Star™ Adjustable Shim Screws … GRK fasteners are corrosion resistant, approved for use in treated lumber & designed for both interior & exterior use….

3. Outdoor Screws & Fasteners – Intercorp

Domain: intercorpusa.com

Registered: 1997 (28 years)

Introduction: Corrosion-resistant outdoor screws for decking, fencing, and patio projects. Intercorp offers high-strength fasteners for durable, weatherproof connections….

4. Best Type of Screws for Outdoor Use – Fastener USA

Domain: fastenerusa.com

Registered: 2003 (22 years)

Introduction: Best Type of Screws for Outdoor Use · Deck Screws and Coated Screws · Silicon Bronze Screws · Stainless Steel Screws · W.A.R. Coated Screws….

Illustrative Image (Source: Google Search)

5. What type of screw or brand should I use for building a dock and …

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: Science: Hot-dipped galvanized screws are the most rust-resistant and best suited for outdoor applications. IF rust is a strong concern …Missing: manufacturers suppliers…

6. What Are The Best Structural Wood Screws?

Domain: allenstrading.com

Registered: 2011 (14 years)

Introduction: Simpson Strong-Tie manufacture some of the best structural and construction screws. Designed for builders who rely on top quality screws and ……

Understanding best screws for outdoor use Types and Variations

Understanding best screws for outdoor use: Types and Variations

Outdoor performance depends primarily on corrosion resistance and material composition, not just coatings. Below is a concise comparison of the main screw types used in North America and Europe for exterior applications.

| Type | Key Features | Typical Applications (USA/EU) | Pros | Cons |

|---|---|---|---|---|

| Stainless steel screws | 304/18-8 or 316/A4 grades; inherent corrosion resistance through the full cross-section | Decks, cladding, fences, landscaping, coastal structures, exterior wood-to-wood and wood-to-metal; railing and architectural hardware | Highest rust and corrosion resistance; no coating to wear off; low magnetic permeability (especially 304) | Softer; more prone to cam-out and head damage if over-torqued or used with worn drivers; higher cost |

| Hot‑dip galvanized (HDG) steel screws | Zinc coating applied by dipping; thicker, more durable zinc layer than electroplating | Structural framing, decks (where cost or torque needs favor steel), fences, general exterior carpentry in non-coastal environments | Stronger than stainless; excellent corrosion resistance for the price; handles higher torque | Bulkier zinc surface can interfere with close-fit joints; slower driving; cost varies with zinc layer thickness |

| Coated carbon steel “deck” screws | Hardened carbon steel with corrosion-resistant polymer/ceramic or zinc-based coatings; ACQ/CA compatible | Pressure-treated lumber decks, exterior framing, fences, landscaping, general-purpose outdoor wood assembly | High driving speed; strong torque transfer; good corrosion resistance when properly coated; cost-effective | Coating integrity is critical; coating damage during installation reduces service life; variable quality between brands |

| Ceramic/polymer‑coated screws (exterior-grade) | Multi-layer coatings with ceramic or polymer topcoats over zinc or zinc-alloy underlayers | Outdoor furniture, cladding, trim, decking where moderate corrosion resistance and fast installation are desired | Aesthetics (often colored); good chip and wear resistance; decent corrosion performance | Coating can chip if driven too fast or with misaligned drivers; service life is coating-dependent; not for marine/coastal use |

| Brass screws (solid brass) | Non-magnetic, naturally corrosion-resistant; softer and more ductile | Marine, decorative hardware, nautical fittings, brass-to-brass assemblies in mildly corrosive environments | Excellent corrosion resistance in marine and outdoor settings; attractive finish | Low strength and ductility; prone to thread stripping and head damage; limited load-bearing use |

Details and selection guidance by type

- Stainless steel screws

-

Use 304 (18-8) for most outdoor applications; choose 316 (A4) for high-chloride/coastal or immersion zones. Stainless resists corrosion through the material, not just a surface layer, which eliminates rust undercutting if the surface is scratched. Drive carefully (prefer T-STAR/Torx or square drives) and avoid over-torqueing to reduce cam-out and head fractures. Ideal where longevity and disassembly matter (decks, cladding, fences, railing).

-

Hot‑dip galvanized (HDG) steel screws

-

Provide steel strength with robust zinc protection, especially for structural and high-torque connections. The heavy zinc layer sacrifices speed and may create bulky thread geometry; however, HDG is a cost-effective choice for non-coastal framing, deck substructures, and fencing. For coastal or wet-marine applications, HDG often underperforms relative to 316 stainless.

-

Coated carbon steel “deck” screws

-

Engineered for pressure-treated lumber and exterior carpentry. They combine hardened steel for strength with exterior-grade coatings to resist corrosion from ACQ/CA preservatives. When the coating remains intact, performance is excellent; if coating is chipped by cam-out or misaligned driving, local rust can initiate. Select drive systems that minimize cam-out (e.g., Torx, square) and pre-drill hard woods as needed.

-

Ceramic/polymer‑coated screws (exterior-grade)

-

Often used for outdoor furniture, cladding, and trim where speed and appearance are important. The topcoat improves wear and corrosion resistance, but installation technique matters—high-speed driving or worn drivers can chip the finish. These screws are not recommended for coastal/marine or fully immersed service.

-

Brass screws

- Solid brass offers superior corrosion resistance in marine and decorative contexts and a premium look. Their softness makes them susceptible to thread stripping and head damage under load; they are best for low-stress, aesthetic assemblies or brass-to-brass hardware where corrosion resistance is the primary requirement.

Key Industrial Applications of best screws for outdoor use

Key Industrial Applications of Outdoor Screws

Choosing the right fastener for outdoor exposure directly impacts service life, safety, and lifecycle cost. The table below maps common B2B industrial applications to the most effective screw types, highlighting material choices, performance benefits, and practical considerations.

| Industry / Application | Recommended Screw Material (Grade) | Detailed Benefits | Typical Outdoor Environment | Key Considerations |

|---|---|---|---|---|

| Marine & Coastal Infrastructure (piers, docks, seawalls) | 316 stainless steel (marine grade) | • Excellent resistance to saltwater & chlorides • No coating wear‑off risk • Long service life with minimal maintenance |

Salt spray, tidal zones, high humidity | Use torque‑controlled drivers to avoid head deformation; isolate from dissimilar metals to prevent galvanic corrosion |

| Building Envelope & Exterior Cladding | Hot‑dip galvanized steel (ASTM A153) or 304 SS for premium projects | • High tensile strength for structural load transfer • Cost‑effective corrosion protection in urban rain • Durable coating for 10‑20 yr service |

Moderate to high humidity, rain, industrial pollution | Verify coating thickness; 304 SS offers better aesthetics & longevity |

| Renewable Energy – Solar Panel Mounting | 304/316 SS, or epoxy‑coated alloy steel for budget projects | • Superior corrosion resistance across climates • Consistent torque ensures structural integrity • Reduces warranty risk |

Rooftops, ground‑mount arrays, variable precipitation | Use isolating washers when fastening aluminum rails; avoid over‑torquing stainless heads |

| Agricultural & Greenhouse Structures | Hot‑dip galvanized steel (optional polymer topcoat) | • Good rust protection in humid, fertilizer‑rich air • Cost‑effective for large‑scale installations • Polymer topcoat resists ammonia & chemicals |

High humidity, fertilizer chemicals, frequent washdowns | Select polymer‑coated screws where ammonia exposure is high |

| Transportation & Road Signage | Galvanized steel; 304 SS for coastal/high‑value signage | • High shear strength for vibration resistance • Fast installation with self‑drilling options • Durable finish against de‑icing salts |

Roadside exposure, salt, rain, temperature cycles | Verify coating integrity after installation; consider self‑drilling screws for metal sign panels |

| Outdoor Furniture, Street Furniture & Signage | 304 SS (optional epoxy/powder coating for color) | • Aesthetic finish that retains appearance • Corrosion resistance for low‑maintenance cycles • No rust bleed onto adjacent surfaces |

Parks, streetscapes, public plazas | Ensure galvanic isolation from aluminum frames; avoid abrasive cleaning agents |

| Utilities & Pipeline Supports | Hot‑dip galvanized steel (ASTM A153) or 316 SS in aggressive soils | • Strong clamping force for pipe brackets • Corrosion resistance to moisture & chemicals • Long‑term reliability in buried or exposed service |

Wet ground, chloride‑rich soils, chemical exposure | Use 316 SS where soil chloride > 500 ppm; comply with EN 10088 for stainless |

| Telecommunications Towers & Antennae | 316 SS (or duplex 2205 for extreme conditions) | • Maximum corrosion resistance in harsh outdoor climates • High mechanical strength for heavy antenna loads • Preserves RF performance by eliminating rust debris |

High‑altitude, rain, wind, temperature swings | Verify torque specs; isolate from aluminum tower sections to avoid galvanic couples |

| Oil & Gas – Offshore Platforms & Pipelines | Duplex stainless steel (e.g., 2205) or 316 SS | • Superior resistance to seawater, sour gas, & CO₂ • High yield strength for structural fasteners • Extended inspection intervals |

Marine environment |

3 Common User Pain Points for ‘best screws for outdoor use’ & Their Solutions

3 Common User Pain Points for ‘Best Screws for Outdoor Use’ & Their Solutions

Pain Point 1: Premature corrosion and rust in wet/coastal environments

- Scenario: A multi-family deck project in a humid or coastal region experiences corrosion within 12–24 months. Screws show pitting at the head recess and along threads; some fasteners seize during maintenance, forcing costly rework.

- Problem: Corrosion resistance differences between stainless steel, hot-dip galvanized, and coated deck screws are large. Coatings can micro-fail during installation (e.g., Phillips cam-out), exposing steel to moisture and salts. Stainless steel offers full-body corrosion resistance but is softer and slightly more expensive.

- Solution:

- Use marine-grade stainless steel (A2/A4/316) for high-humidity/coastal zones; stainless resists rust through and through.

- Favor hot-dip galvanized (ASTM A153 or EN ISO 1461) when cost is critical but stainless is impractical.

- For coated screws, ensure a robust anti-corrosion layer and select a drive that reduces cam-out (e.g., Star/Torx or Pozidriv); avoid soft Phillips drives.

- Avoid using stainless screws in direct contact with CCA/ACQ-treated lumber unless isolated with rubber or nylon washers; use stainless- or ACQ-rated compatible fasteners per manufacturer specs.

Quick comparison: Corrosion resistance and trade-offs

| Screw type | Rust/corrosion resistance | Key caveats | Recommended zones |

|——————————–|—————————|————————————–|——————————————|

| Stainless steel (316/A4) | Very high (marine/coastal) | Softer; lower stripping torque | Coastal, high humidity, high salt |

| Stainless steel (304/A2) | High | Soft; best for mild-moderate climates | Suburban/urban exteriors |

| Hot-dip galvanized (zinc) | High (surface protection) | Zinc coating wear at install affects life | Rural/industrial where cost matters |

| Electro-galvanized (zinc) | Low–moderate | Thin coating; poor in wet/coastal | Indoor/outdoor dry, limited exposure |

| Coated deck screws | Moderate–high | Dependent on coating integrity; drive wear matters | Budget projects, dry inland climates |

Pain Point 2: Drive stripping, torque control, and installation damage

- Scenario: A production crew experiences frequent stripping of stainless head recesses and inconsistent torque during fastening, leading to callbacks and slower schedules.

- Problem: Stainless steel is softer than hardened carbon steel; Phillips and slotted drives cam-out easily, damaging coatings and increasing torque scatter. Coated screws can also suffer coating wear at the head recess, accelerating corrosion at that weak point.

- Solution:

- Specify Star (Torx) or Pozidriv drives; they reduce cam-out and maintain stripping torque, improving production consistency.

- Implement controlled clutch/ratcheting drivers and reduce RPM for stainless fasteners; avoid over-torqueing.

- Pre-bore pilot holes where hardwoods or dense composites are used to minimize driving torque and preserve coating integrity.

- Separate fastener lines (stainless vs. coated) and use color-coded bins to prevent cross-contamination of drive systems that are tuned for different materials.

Screw drive comparison (installation outcomes)

| Drive type | Strip risk | Cam-out tendency | Torque control | Best use |

|——————-|————|——————|—————-|———————————————–|

| Phillips | High | High | Low | General DIY; avoid for stainless/coated |

| Slot | High | Medium | Low | Low-speed manual use; avoid in production |

| Pozidriv | Low | Low–moderate | Medium | Good compromise for coated fasteners |

| Star (Torx) | Very low | Very low | High | Production lines; stainless and coated screws |

Pain Point 3: Budget constraints vs. total installed cost

- Scenario: A commercial exterior siding project uses the cheapest coated screws to meet upfront cost targets. Early corrosion and fastener failures require service calls within 18 months, eroding savings and increasing lifecycle cost.

- Problem: Lower upfront cost can inflate lifecycle costs through accelerated corrosion, warranty claims, re-fasts, and labor. Material softness and coating integrity affect performance more than price alone.

- Solution:

- Align screw selection with exposure class and end-of-life expectations:

- Coastal/high humidity: stainless 316/A4.

- Inland/dry: hot-dip galvanized or quality coated screws.

- Calculate total installed cost (TIC): fastener + labor + expected maintenance per year × years. Account for corrosion downtime, schedule risk, and warranty terms.

- Consolidate SKU count: standardize on two grades (e.g., A4 for exposed coastal and hot-dip for inland), with common thread/drive to minimize supply complexity.

TIC calculator template

| Metric | Stainless (316) | Hot-dip galvanized | Coated deck screw |

|————————————–|————————–|————————-|————————–|

| Fastener unit cost | High | Moderate | Low |

| Installed labor per 1,000 screws | Moderate (controlled torque) | Low–moderate | Low–moderate |

| Expected service life (years) | 10–25 (coastal) / 20–40 (inland) | 7–15 (inland) / 5–10 (coastal) | 5–10 inland / <5 coastal |

| Maintenance visits per 5 years | 0–1 | 1–2 | 2–3+ |

| Total cost per 1,000 screws (5 years)| Moderate | Low–moderate | High (due to rework) |

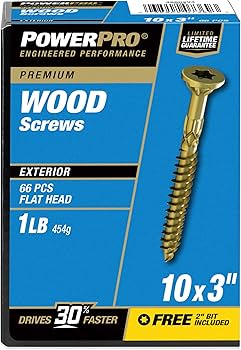

Illustrative Image (Source: Google Search)

Cross-cutting recommendations

- Specify grade clearly: A2 (304/A2-70/80), A4 (316/A4-70/80), or hot-dip galvanized per ASTM A153 or EN ISO 1461.

- Document fastener compatibility for pressure-treated lumber (e.g., ACQ/CCA); use stainless or rated steel with compatible coatings.

- Select drive geometry based on material: Torx/Pozidriv for stainless/coated, Phillips only where unavoidable and for dry, low-exposure use.

- Pilot holes in dense hardwoods/composites to reduce torque and preserve coatings/stainless performance.

- Apply isolation when stainless contacts non-stainless metals or dissimilar alloys; use nylon/rubber washers or non-conductive bushings to mitigate galvanic coupling.

References and standards to cite in B2B specs

- ASTM A153: Zinc Coating (Hot-Dip) on Iron and Steel Hardware

- EN ISO 1461: Hot dip galvanized coatings on fabricated iron and steel articles

- ASTM F3125: Standard Specification for Structural Bolts, Steel, Heat Treated, 830/1050 MPa Minimum Tensile Strength (scope reference for fastener performance framework)

- A2 (304/A2) and A4 (316/A4) stainless steel specifications per relevant materials standards

These pain points and solutions give procurement, engineering, and construction teams a clear framework for selecting the best screws for outdoor use while controlling installed cost, installation risk, and long-term reliability in both USA and Europe markets.

Strategic Material Selection Guide for best screws for outdoor use

Strategic Material Selection Guide for Best Screws for Outdoor Use

Purpose: Align material selection with real-world exposure, performance expectations, and cost-to-serve for USA/Europe audiences. Emphasis is on corrosion resistance, driving behavior, and lifecycle cost.

Key material classes:

– Austenitic stainless steel (304/316/316L)

– Carbon steel with protective coatings (polymer/ceramic/oxide; sometimes marketed as “deck screws”)

– Zinc-coated carbon steel (electroplated/Zn-plated; hot-dip galvanized/HDG)

Material behavior in outdoor service:

– Stainless steel is inherently corrosion-resistant across its cross-section; it does not rely on a surface coating that can wear away. In wet or coastal exposures, stainless outperforms coated/galvanized options. Trade-offs: lower hardness, greater susceptibility to cam-out and head damage if over-torqued, higher unit cost.

– Coated carbon steel (“deck screws”) offers good corrosion protection while driving—often superior to thin electroplating—via thicker organic/ceramic layers,lubrication, and sealed drill points. The core is still mild/carbon steel; once the coating is breached (e.g., from driver slippage), corrosion risk rises quickly. Cost is moderate; driving performance is strong.

– Galvanized coatings (especially hot-dip) provide sacrificial zinc protection but are surface-limited. Electroplated/zinc-plated has a thin layer that wears easily and offers the lowest outdoor durability among the three. Hot-dip is better than electroplated but still inferior to stainless in wet or marine contexts. Cost is lower, but lifecycle risk is higher in harsh exposures.

Illustrative Image (Source: Google Search)

Compatibility and use considerations:

– Pressure-treated lumber (CCA/ACQ/CA): Preferred materials are HDG (preferably G90 or thicker) or stainless (304/316) to mitigate zinc and copper interactions. Coated carbon deck screws are often acceptable but verify coating compatibility with the specific PT preservative and manufacturer listings.

– Coastal/marine atmospheres: Favor 316/316L stainless for high chloride exposure. Duplex/super-duplex stainless can further increase resistance but at higher cost and stricter installation control.

– Dissimilar metals: Pair stainless screws with stainless or compatible fasteners when used with aluminum, galvanized steel, or copper alloys to limit galvanic corrosion; isolate with non-conductive washers/gaskets where appropriate.

– Concrete/masonry: Adhesive or mechanical anchors in stainless or HDG are recommended; many threaded screws are case-hardened carbon with proprietary coatings and require manufacturer-specific approvals.

Installation notes (performance-critical):

– Minimize driver cam-out. Use bits matched to head geometry, control torque, and avoid aggressive impact drivers with stainless screws.

– Pre-drill hard/dense woods to reduce torque and prevent coating damage at the entry point.

– Do not re-drive or over-tighten; this compromises protective coatings and increases corrosion initiation sites.

Regulatory/standard context (high-level):

– Hot-dip galvanized hardware commonly references ASTM A153/A153M; stainless bolts/screws often reference ASTM F593 (stainless steel fasteners). Selection should be supported by manufacturer data sheets, ASTM/EN compliance, and corrosion test reports (e.g., ASTM B117 neutral salt spray) with specified hours to failure.

Lifecycle cost perspective:

– Stainless offers the longest service life in wet/coastal exposures and reduces rework risk for disassembly. Coated carbon is cost-effective for general exteriors with moderate corrosion demand. Galvanized is budget-oriented and best for low-to-moderate exposure, recognizing earlier replacement risk in severe environments.

Illustrative Image (Source: Google Search)

Practical selection guidance:

– General exterior wood-to-wood (decking, fencing, siding, pergolas): Coated carbon (“deck screws”) or 304 stainless. Prefer 304 stainless when rework is anticipated or exposure is wet/shaded.

– Pressure-treated lumber: HDG or stainless (304/316). Confirm PT preservative compatibility with the coating/system.

– Coastal/marine and severe industrial atmospheres: 316/316L stainless.

– Interior non-condensing: Zinc-plated is acceptable; exterior wet requires at least coated carbon or HDG.

Note: Manufacturer-specific formulations (e.g., proprietary deck-screw coatings) vary. Use data sheets, coating thickness specifications, and corrosion test results to validate selection.

Comparison: Outdoor Screw Materials

| Material class | Corrosion resistance (relative) | Core vs. coating | Typical cost tier (USA/EU) | Strength/hardness | Driving performance | Ideal exposure | Key notes |

|---|---|---|---|---|---|---|---|

| Austenitic stainless (304/304L) | High | Homogeneous stainless | High | Lower hardness vs. case-hardened carbon | Moderate; control torque; cam-out risk | General exterior, some coastal | Good for rework; not marine-grade |

| Austenitic stainless (316/316L) | Highest | Homogeneous stainless | Highest | Lower hardness vs. case-hardened carbon | Moderate; control torque; cam-out risk | Coastal, marine, severe industrial | Best in chloride-rich atmospheres |

| Coated carbon steel (“deck screw”) | Medium–High (depends on coating) | Carbon steel core + protective organic/ceramic coating + lubrication | Moderate | High (case-hardened core) | Excellent drive; strong cam-out resistance | General exterior; dry-to-wet | Coating breach leads to rust; validate PT compatibility |

| Hot-dip galvanized (HDG) carbon steel | Medium (sacrificial zinc) | Zinc layer on carbon steel | Low–Moderate | High | Good | Light exterior; PT lumber; agricultural | Thicker zinc vs. plating; still surface-limited |

| Electroplated/zinc-plated carbon steel | Low | Thin zinc layer | Lowest | High | Good | Interior, limited exterior | Coating wears easily; avoid in wet/coastal |

Implementation checklist

- Define exposure category (general exterior vs. coastal/industrial vs. PT lumber).

- Set performance target (service life, disassembly need).

- Select material per comparison table and compatibility notes.

- Verify standards compliance (ASTM/EN) and test data.

- Train installers on torque control and bit selection for stainless; pre-drill dense woods.

- Document substitution approvals when switching between coated carbon, HDG, and stainless.

In-depth Look: Manufacturing Processes and Quality Assurance for best screws for outdoor use

In‑depth Look: Manufacturing Processes and Quality Assurance for best screws for outdoor use

How the right process turns raw materials into corrosion‑resistant outdoor fasteners

Outdoor screws face moisture, UV, thermal cycling, and chemical exposure. The best long‑term outcomes come from pairing suitable materials with disciplined manufacturing, surface protection, and verification. Stainless steel resists rust throughout the material; coated or galvanized carbon steel depends on an intact protective layer. Two practical trade‑offs shape the choice: (1) installation care and (2) total cost.

Manufacturing pathway at a glance

| Step | Key operations (stainless) | Key operations (coated carbon) | Critical checks (typical) |

|---|---|---|---|

| Prep | Verify bar/rod grade (e.g., A2=304, A4=316 per ISO 3506). Inspect surface. | Select low‑carbon steel (e.g., AISI 10B21/10B22/1008–1018). Verify chemistry. | Mill certs, traceability, incoming inspection per ISO 9001; grade verification (XRF/spectro). |

| Forming | Cold heading to form head/shank; optional point rolling. | Cold heading or upset forging; thread rolling preferred over cutting. | Dimensional: head height/diameter, shank, point geometry; surface defects via eddy current/visual. |

| Heat treatment (if applicable) | Solution anneal for austenitic grades when required; avoid sensitization. | Quench/temper for required property class; temper embrittlement control. | Hardness (ISO 6506 Rockwell/Vickers), microstructure, decarburization (ISO 3888). |

| Threading | Thread rolling for roll‑formed threads; or cutting for some coarse/coach screws. | Thread rolling produces strong threads and better fatigue; cutting as specified. | Pitch diameter (ISO 965‑1/2), thread tolerance class, surface roughness. |

| Surface finishing | Passivation (ASTM A967/ISO 17668) to remove free iron and restore oxide layer; electropolish for premium fittings. | Hot‑dip galvanized (ASTM A153/ISO 1461), mechanical plating (ASTM B695), zinc electroplate (ASTM F1941) + clear seal. | Coating thickness (ASTM B499/ISO 2178/2360), coating adhesion (ASTM D3359), uniformity. |

| Assembly (if applicable) | Pre‑assembled washers/bolts; torque‑controlled crimping. | Same; ensure washer compatibility to avoid coating damage. | Fastener fit/clearance, cam‑out damage risk (Phillips vs torx), contamination checks. |

| Final QC & release | Dimensional, mechanical, magnetic test (austenitic may show slight magnetism post‑cold work), passivation verification. | Dimensional, torque‑tension, pull‑out/withdrawal, coating continuity, salt‑spray or cyclic corrosion testing. | C of A against ISO 898‑1 (carbon) or ISO 3506 (stainless), coating spec compliance, lot traceability. |

Corrosion resistance: how materials and finishes compare

| Material/finish | Typical corrosion resistance outdoors | Notes (installation) | Applicable standards (typical) |

|---|---|---|---|

| Austenitic stainless (A2=304/304L; A4=316/316L) | Very high; 316/A4 preferred near coasts/chemicals | Softer than hardened carbon; reduce torque, use T‑drive to avoid cam‑out | ISO 3506‑1/2/4 (mechanical/property), ISO 4955 (steels), ASTM A240 (plate), ASTM A276 (bars), ASTM A967/ISO 17668 (passivation) |

| Duplex stainless (e.g., 22Cr/5Ni) | High strength with very good corrosion resistance; specialized use | Requires strict process control; check for chloride‑stress corrosion risk in some conditions | ASTM A240/A479; ISO 3506 series (where applicable) |

| Martensitic stainless (410/420) | Moderate; hardened, but less corrosion‑resistant than austenitic | Good where high hardness/strength is needed | ISO 3506 series; ASTM A276/A240 |

| Hot‑dip galvanized carbon steel (zinc) | High protection if thick, uniform coating; sacrificial cathodic protection | Watch for coating damage during installation; avoid over‑torque | ASTM A153/ISO 1461 (galvanizing), ASTM A153 (thread engagement notes), ISO 2064 (coating thickness), ISO 898‑1 (mechanical) |

| Mechanically plated zinc carbon steel | Good; thin, uniform coatings; no hydrogen embrittlement risk | Sensitive to handling; avoid nicks | ASTM B695, ISO 2064, ISO 898‑1 |

| Electroplated zinc carbon steel (with seal) | Good for mild exposure; thinner than HDG | Common for indoor‑outdoor; ensure seal for durability | ASTM F1941 (electroplating), ASTM B633 (zinc), ISO 898‑1, ISO 2064 |

| Brass/Bronze | Good in many outdoor settings; can dezincify in some waters | Non‑magnetic; soft | ASTM B455 (brass), ASTM B139 (bronze) |

Quality assurance: standards, tests, and acceptance

| Test/attribute | Purpose | Typical standards (USA/EU) | Typical acceptance (example) |

|---|---|---|---|

| Dimensional compliance | Fit, driving, engagement | ISO 68/261/965 (thread geometry), ISO 261 (M‑series) | Within specified tolerance (e.g., coarse/fine thread class per ISO 965) |

| Mechanical properties | Strength, hardness, ductility | Carbon: ISO 898‑1, ASTM F568; Stainless: ISO 3506‑1/2/4; Hardness: ISO 6506/6507, ASTM E18 | Property class verified; hardness within spec; torque‑tension performance met |

| Thread tolerance verification | Ensure engagement and strength | ISO 965‑1/2/3 | Threads within specified tolerance grade |

| Corrosion resistance (salt spray) | Compare coatings/corrosion performance | ASTM B117 (neutral salt spray) | Meets customer‑specified hours for finish (e.g., ≥72–720 h depending on spec) |

| Coating thickness | Confirm corrosion protection | ISO 2064, ISO 2178/2360, ASTM B499 | Meets minimum thickness for finish class |

| Coating adhesion/continuity | Detect damage/peeling | ASTM D3359 (tape), ASTM B571 (bend), ISO 2064 (local mass), ASTM B117 (post‑exposure) | No flaking beyond defined criteria; continuity coverage of ≥~95% of surface (per customer spec) |

| Hydrogen embrittlement (if applicable) | Prevent brittle failure (plated steels) | ASTM F519 (electroplated), ISO 15330; test methods vary by application | No cracks under sustained load test; stress‑relief baked per process |

| Passivation verification | Ensure stainless surface is clean/passive | ASTM A967, ISO 17668; ferroxyl test (ASTM A380 Annex) | No free iron contamination; specified surface finish maintained |

| Packaging & shelf life | Preserve finish until use | ISO 9001 packaging controls; avoid mixed metals in humid storage | Dry, ventilated packaging; VCI where needed; inventory rotation |

Why material/process choice matters for outdoor life

- Stainless steel is resistant through the entire section. Coatings (zinc, polymer) are surface‑only; any damage during assembly or service can expose carbon steel to corrosion. This is why installation technique matters: over‑torque or Phillips cam‑out can gouge coatings, increasing rust initiation points.

- For aggressive environments (coastal, de‑icing salts, pool chemicals), stainless steel grades A4 (316/316L) or duplex grades typically outperform coated carbon steel.

- Coated carbon remains cost‑effective and strong. When used, choose hot‑dip galvanizing for thicker, durable zinc or ensure robust mechanical/electroplating plus sealers. Minimize coating damage by using appropriate drivers (e.g., Torx/Pozi) and controlled torque.

Practical specification checklist for USA and EU buyers

| Clause | What to request | Reference standards |

|---|---|---|

| Material grade | Austenitic stainless: A2 (304/304L) or A4 (316/316L); coated carbon: low‑carbon steel with specified property class | ISO 3506‑1/2/4; ISO 898‑1 |

| Mechanical class | Specify property class and hardness range | ISO 3506 (stainless), ISO 898‑1 (carbon) |

| Corrosion protection | Finish type (HDG per ASTM A153/ISO 1461; mechanical plating ASTM B695; electroplate ASTM F1941); required salt‑spray hours or cyclic corrosion | ASTM B117; ISO 1461; ASTM F1941; ASTM B695 |

| Coating verification | Thickness by ISO 2064; adhesion by ASTM D3359; uniformity/contamination checks | ASTM B499/ISO 2178; ASTM D3359 |

| Surface treatment (stainless) | Passivation to ASTM A967/ISO 17668; electropolish if specified | ASTM A967; ISO 17668 |

| Packaging & traceability | Lot/heat‑number traceability, dry packaging, shelf‑life controls | ISO 9001 |

| Test regime | Dimensional, hardness/tensile, salt spray or equivalent, thread verification, torque‑tension, and packaging inspection with acceptance criteria | ISO 3506, ISO 898, ISO 2064, ISO 965, ASTM standards noted above |

Final note

Installation is the last step of manufacturing. For coated carbon screws, keep torque and driver selection under control to preserve the protective layer. For stainless screws, moderate torque and proper drive (e.g., Torx) avoid head damage and maintain corrosion integrity. Selecting the right material/finish, then executing a disciplined process chain with ISO‑based verification, is what separates long‑life outdoor fasteners from short‑term fixes.

Illustrative Image (Source: Google Search)

Practical Sourcing Guide: A Step-by-Step Checklist for ‘best screws for outdoor use’

Practical Sourcing Guide: A Step-by-Step Checklist for Best Screws for Outdoor Use

Use this checklist to standardize purchasing decisions across USA and Europe. It focuses on outdoor corrosion resistance, drive/driveability, environmental compatibility, and supply availability. It excludes fluff and stays vendor-neutral.

Quick Compare: Common Outdoor Screws

| Material | Corrosion resistance | Fastener hardness | Head durability / driveability | Price tier | Typical outdoor use | Notes |

|---|---|---|---|---|---|---|

| Stainless steel (304/316, marine/coastal recommended) | Highest; resistant throughout the cross-section | Softer than carbon/case-hardened steel | Prone to cam-out/head chipping if over-torqued; use Torx/Pozidriv; better drive control needed | High | Decks, fences, shutters, outdoor furniture; coastal/marine; anywhere disassembly is expected | Excellent long-term corrosion resistance in wet settings |

| Galvanized (hot-dip or mechanical) | High (zinc sacrificial protection) | Harder | Good; less prone to cam-out | Medium | Structural wood framing, fencing, general outdoor build | Coating protects the surface; damage during install reduces protection |

| Coated deck screws (carbon steel with organic or ceramic coating) | High for common climates | Harder | Very good | Medium–High | Decks, cladding, general exterior wood | Coatings can wear or chip during install; performance varies by climate |

| Treated-lumber-compatible screws (e.g., coated carbon or 410 SS) | High; formulated for PTL chemicals | Hard/Medium | Good | Medium–High | Pressure-treated lumber connections | Verify ACQ/CA compatibility; 410 SS can be better for very aggressive treatments |

- Material selection trade-off: stainless steel = best corrosion but higher cost and more careful driving; galvanized/coated = cost-effective but surface protection only.

Step-by-Step Sourcing Checklist

1) Define service environment and performance goals

– Document exposure: coastal/marine, high humidity, salt exposure, UV, thermal cycling, chemical contact (e.g., ACQ/CA-treated lumber).

– Set design life targets and rework expectations.

– Confirm inspection frequency and corrosion failure tolerances.

2) Identify substrates and joint geometry

– Wood species/density; engineered lumber; metal fasteners-to-wood; wood-to-wood.

– Determine if pre-drilling is required by spec/manufacturer for high-density woods.

– Decide on self-drilling vs point-type (Type 17 auger) for wood.

3) Choose material and coating by exposure and budget

– Coastal/marine: stainless steel 316 (or 304); for treated lumber close to saltwater, 410 stainless can be considered for higher hardness with good corrosion resistance.

– High humidity/rain: stainless steel 304/316 or hot-dip galvanized/coated deck screws.

– General exterior: coated deck screws or hot-dip galvanized; stainless for critical joints or frequent disassembly.

– Pressure-treated lumber: use fasteners compatible with ACQ/CA; verify testing to AWPA standards and manufacturer approval.

Illustrative Image (Source: Google Search)

4) Select head and drive system for durability and installability

– Preferred drives: Torx (best torque transfer and reduced cam-out) or Pozidriv; avoid Phillips where possible.

– Specify recess quality (e.g., ISO 4757 for Pozidriv) and head geometry for countersinking or flushness.

5) Set technical specs and inspection criteria

– Thread form/pattern and point type suitable for substrate.

– Surface finish/coating details (e.g., mechanical galvanized thickness; organic/ceramic coating system; stainless passivation).

– Mechanical properties and case/hardness limits (e.g., minimum tensile, proof load; for stainless, follow ASTM F738M or ISO 3506-1 torque guidance).

– Driveability: specify recommended torque range or installation speed for stainless to reduce head damage.

6) Align standards and certifications

– USA: ASTM F738M (stainless metric), ASTM F1591 (stainless imperial), AISI standards, AWPA (treated lumber compatibility), building codes for structural use.

– Europe: ISO 3506-1 (stainless), ISO 4757 (Pozidriv), EN standards, REACH compliance, RoHS where applicable to coated systems.

– Documentation: certificates of compliance, material test reports (MTR), and coating thickness/performance data.

7) Build the RFQ and qualify suppliers

– Include environment, substrate, performance requirements, and standards in the RFQ.

– Validate vendor capabilities for stainless passivation, mechanical/galvanized finishing, and treated-lumber-compatible coatings.

– Request samples for field installation testing (driveability in your substrates).

Illustrative Image (Source: Google Search)

8) Run a controlled pilot and field validation

– Test torque settings, drill speed, and driver bit selection; track head integrity and drive time.

– Verify corrosion exposure in pilot assemblies (salt spray/humidity per agreed test method; e.g., ASTM B117 if applicable).

– Confirm compatibility with treated lumber and adhesives/sealants where used.

9) Finalize spec and award

– Lock approved vendors and part numbers with clear coating/material specs.

– Include packaging, marking, and QC requirements (lot traceability, thickness measurements).

– Establish QA inspection points at receiving (visual, dimensional, coating checks, documentation review).

10) Plan maintenance and re-qualification

– Define cleaning and inspection intervals for outdoor assemblies.

– Set re-qualification cadence for fastener performance (e.g., after major climate shifts or supplier changes).

– Monitor failure rates and rework to refine torque settings/material choices.

Practical Notes for USA/Europe Sourcing

- Driveability and torque: stainless fasteners require slower speeds and controlled torque to avoid cam-out and head chipping; Torx/Pozidriv significantly reduce cam-out vs Phillips.

- Coatings and chemicals: ensure coated screws are tested for compatibility with modern pressure treatments (ACQ/CA) and any site-applied finishes/sealants.

- Logistics and lead times: stainless availability varies; mechanical galvanized and certain coated systems often have faster throughput; hold safety stock for critical exterior schedules.

- Documentation and compliance: collect REACH/RoHS declarations and RoHS exemptions where applicable for coated systems; request AWPA compliance for PTL products in USA.

Use stainless steel where long-term rust resistance and reusability are critical; choose hot-dip galvanized/coated systems for budget-sensitive applications with appropriate drive control and install QC.

Comprehensive Cost and Pricing Analysis for best screws for outdoor use Sourcing

Comprehensive Cost and Pricing Analysis for Sourcing Best Screws for Outdoor Use

1) Outdoor Screw Families: Price, Performance, and Where to Use Them

Coated carbon and hot-dip galvanized screws deliver strong value for general outdoor use. Stainless steel delivers superior corrosion resistance and total cost of ownership (TCO) in wet/coastal and high-maintenance environments. Coated deck screws (polymer- or ceramic-filled coatings) balance performance and price for decks, fences, and general construction, while stainless is preferred where rust risk and service access costs are high.

| Screw Type | Typical Materials | Corrosion Rating (Outdoor) | Typical Price Tier (USD per 1,000 pcs) | Best-Fit Applications | Key Trade-offs |

|---|---|---|---|---|---|

| Exterior coated deck screws | Case-hardened carbon steel + polymer/ceramic coating, lubricated | Good (depends on coating thickness/grade; surface-only protection) | ~$25–$60 (varies with length, drive, corrosion grade) | Decks, fences, treated lumber, general exterior | Lowest upfront cost; coating can chip; service life sensitive to coastal/marine exposure |

| Hot-dip galvanized (HDG) | Steel with zinc coating (zinc thickness per ASTM A153/A123) | Very good (robust zinc barrier) | ~$70–$110 (coarse-thread wood screws; varies by size) | Structural outdoor, fences, treated lumber | Slower drive due to zinc thickness; surface-only corrosion protection; can show zinc oxidation |

| Stainless steel (A2/A4) | Austenitic stainless (304/316) | Excellent (material-wide corrosion resistance; 316 for marine/coastal) | ~$150–$350 (head/drive/length dependent) | Coastal/marine, wet climates, high maintenance-cost assemblies | Higher upfront; slightly lower drive speeds/torque margin; 316 costs more than A2 |

| Stainless steel fasteners, polymer-composite coated (option) | Stainless + advanced coating | Excellent | Varies | Ultra-low maintenance | Highest upfront; niche |

2) Price-Setting Factors

- Size and length: More material per screw, higher manufacturing and logistics cost.

- Material grade: Stainless premium over carbon; 316 premium over 304/A2.

- Drive/head: Torx/Pozisquare reduce cam-out; deeper recess/tooling can affect price.

- Surface and lubrication: Coatings, lubricants, and die-rolled threads influence performance and cost.

- Packaging: Bulk vs. bulk-packed in small cartons vs. retail blister packs (retail packs add material/labor and margin).

- Compliance and certification: RoHS/REACH for EU; conflict minerals reporting; ASTM/EN standard adherence.

- Supplier tier: Factory-direct vs. distributor; distributor adds margin but provides speed/availability.

- Region: Freight, duties, VAT change delivered pricing significantly (USA vs. EU).

3) Cost Breakdown by Material (Illustrative Ranges)

Costs vary by spec, region, and supplier, but the following distributions are typical:

| Material Family | Material Share | Labor & Overhead Share | Logistics/Delivery Share |

|---|---|---|---|

| Coated carbon (deck screws) | 20–35% | 40–55% | 10–25% |

| Hot-dip galvanized carbon | 30–45% | 35–50% | 10–20% |

| Stainless steel (A2/A4) | 55–70% | 20–35% | 10–20% |

Notes:

– Stainless material share is higher because raw alloy and scrap costs are a larger share of total.

– Coated carbon relies more on processing, tooling, and surface technology; labor/overhead share is higher.

– Logistics share varies with distance, mode, packaging density, and INCOTERMS.

4) Logistics and Regional Considerations (USA vs. Europe)

Logistics cost drivers include freight mode, handling units, palletization, and customs.

Illustrative Image (Source: Google Search)

| Region | Typical Logistics Share | Key Cost Levers | Terms Guidance |

|---|---|---|---|

| USA | 10–20% | Freight lane, LTL vs. FTL, packaging density, fuel surcharge | Prefer FOB/CIF; consider DDP for landed planning; Section 301/anti-dumping can apply to some origins |

| EU | 10–20% (higher in smaller orders) | VAT (19–27%), customs clearance, packaging compliance, palletization | Prefer DAP/DDP for predictable total; check CE/RoHS/REACH; ensure EORI and HS classification (7318.15) |

| Packaging | Typical Minimums | Typical MOQ | Landed Cost Impact |

|---|---|---|---|

| Bulk in cartons on pallets | N/A | 5–20 pallets (supplier dependent) | Lowest cost per unit; best for repetitive projects |

| Small retail packs (carton + polybag + label) | 1–5 cartons | 50–200 cartons | Adds materials/labor; best for B2C or kits; higher unit cost |

| Distributor assortments | N/A | Distributor stock profiles | Highest unit cost; fastest availability and service |

5) Cost Optimization: Material Choice and Application

- General outdoor (non-coastal) decks/fences: Coated carbon deck screws typically offer the best $/service-year if climate is moderate and inspections are feasible. Choose higher coating grades for cedar/pressure-treated lumber.

- Long-life, low-maintenance, or wet/coastal: Stainless steel (A2; A4 near salt spray) minimizes maintenance, callbacks, and replacement—improving TCO even with higher upfront cost.

- Structural or heavy-duty exterior: HDG delivers robust protection at mid cost; verify zinc thickness and torque limits in design.

6) Practical Tips to Save Cost Without Compromising Quality

- Standardize sizes and drives to increase volume per SKU and reduce switching costs.

- Specify features that prevent cam-out and stripping (e.g., Torx/Pozisquare), lowering rework and warranty risk.

- Set clear corrosion specs (e.g., stainless grade; HDG thickness; coated deck screw salt-spray hours) to avoid over-specifying.

- Negotiate packaging to bulk where possible; avoid retail packs unless required.

- Consolidate shipments; target FTL or dense LTL to reduce freight per 1,000 pieces.

- Use DDP/DAP when planning project budgets; include VAT/duties/fuel surcharges upfront.

- Align supplier schedules to production cadence to reduce expedite fees.

- For distributors: consider blended strategies—factory-direct for core SKUs, distributor for fill-in/urgency.

- Audit landed cost (material + freight + duties + handling + storage) and focus negotiations on the largest share.

- Run a small pilot in a harsh zone (coastal exposure) to validate actual service life before full rollout.

7) Sample Landed Cost Comparison (Illustrative)

Prices vary by spec; use as a directional model.

| Scenario | Unit Price (USD/1,000) | Freight/Logistics (USD/1,000) | Duties/VAT (USD/1,000) | Landed Cost (USD/1,000) |

|---|---|---|---|---|

| Coated carbon deck screw (bulk, 3″, Torx) | 35 | 3 | 0 (domestic USA) | 38 |

| Hot-dip galvanized (bulk, 3″, square drive) | 90 | 5 | 0 (domestic USA) | 95 |

| Stainless A2 (bulk, 3″, Torx) | 220 | 7 | 0 (domestic USA) | 227 |

| Stainless A2 (EU, DDP, VAT 20%) | 235 | 8 | 47 (20% VAT on freight-inclusive base) | 290 |

Interpretation:

– Stainless’s advantage grows where service-life and maintenance costs dominate; coated carbon remains cost-effective where corrosion risk is moderate and maintenance access is acceptable.

– Region and terms materially shift delivered costs; always calculate landed DDP/DAP for EU and domestic US freight.

8) Procurement Checklist

- Define corrosion class and environment (humidity, salt, chemicals) per application.

- Specify material grade and coating: stainless A2/A4; HDG zinc thickness; coated deck screw corrosion rating.

- Select head/drive optimized for installation to reduce stripping and rework.

- Set packaging (bulk preferred) and MOQs; align with warehouse handling.

- Select INCOTERMS (FOB/CIF for factory-direct; DAP/DDP for predictable landed cost).

- Confirm compliance (RoHS/REACH for EU; ASTM/EN standards; conflict minerals documentation).

- Pilot test in the harshest expected site; review TCO after first season before scaling.

Alternatives Analysis: Comparing best screws for outdoor use With Other Solutions

Alternatives Analysis: Comparing best screws for outdoor use with other solutions

Across wet outdoor applications, stainless steel screws generally deliver the best long‑term corrosion resistance, but they trade off strength and cost. Two widely used alternatives—hot‑dip galvanized (HDG) carbon steel and coated “deck” screws—offer lower price points and higher torque capability, at the expense of overall corrosion durability.

Side‑by‑side comparison

| Attribute | Stainless steel (304/316) | Hot‑dip galvanized carbon steel | Coated deck screw (carbon steel + protective coating) |

|---|---|---|---|

| Corrosion resistance (long‑term wet/marine) | Highest; inherently corrosion‑resistant through the cross‑section | High; zinc sacrificially protects steel; performance drops once zinc is consumed/coating damaged | Moderate; coating integrity is critical; performance depends on coating type/thickness and handling |

| Typical grades | 304, 316 (marine/coastal) | G185, G90 for exterior structural fasteners | Zinc‑electroplate, Climadur®, GRK R4®, Headcote®, coated deck screws; manufacturer‑specific |

| Strength/hardness vs brittleness | Softer; more prone to cam‑out and head damage if over‑torqued | Harder than stainless; higher torque capability | Hard; can be brittle with thick coatings; torque control still needed |

| Galvanic risk (stainless paired with pressure‑treated lumber or dissimilar metals) | Higher; avoid direct contact with ACQ/CCA lumber; use stainless‑compatible isolation or upgrade fasteners | Lower than stainless; zinc corrodes preferentially | Typically moderate; coatings help but can pinhole if damaged |

| Installation tolerance to coating wear | Minimal issue | Minor edge wear tolerance; HDG provides lasting protection | Sensitive; even small nicks/chips can initiate corrosion at exposed steel |

| Cost (relative) | Highest | Moderate | Low‑to‑moderate |

| Typical regions/standards | AISI/ASTM; ISO 3506‑1 for mechanical properties; ISO 12944 for environment classification | ASTM A153 (hot‑dip); ASTM B633 (electroplating) for plating | ASTM/Manufacturer specifications; ISO 12944 for environment guidance |

| Maintenance impact | Minimal if correctly specified and installed | May need inspection/replacement in aggressive marine/coastal zones | Inspect often in wet/coastal conditions; replace failed fasteners |

| Best use case | Wet/coastal, food‑grade/architectural, high‑reliability outdoor projects | Cost‑sensitive exterior/structural applications with adequate corrosion allowance | General outdoor/DIY projects in mild exposure; budget‑conscious exterior framing |

When stainless steel is the right choice

- Severe exposures (ISO C5/CX zones), coastal/marine, high humidity, splash zones, and wet architectural assemblies.

- Long‑life, low‑maintenance requirements; projects where removal or disassembly is expected in future.

- Consider 316 stainless for marine/coastal and acidic environments; 304 for most other wet outdoor uses.

When HDG carbon steel is the right choice

- Budget‑constrained structural or exterior projects where life‑cycle corrosion is tolerable and service life planning is in place.

- Assemblies with higher torque needs or where head cam‑out is a concern.

- Avoid long‑term immersion or severe splash zones; monitor zinc consumption over time.

When coated deck screws are the right choice

- Mild‑to‑moderate exposure with short‑to‑moderate life expectations.

- Interior/exterior framing where cost is the primary driver.

- Use thicker, high‑quality coatings and minimize installation damage; expect earlier replacement in wet climates.

Practical selection guidance

- Classify exposure per ISO 12944/Corrosion Categories (C3–C5/CX).

- Match fastener material to exposure and design life; stainless (316) for C5/CX, HDG for C3–C5 where budgets are tight.

- Avoid dissimilar‑metal contact and ACQ lumber with stainless fasteners; isolate with compatible bushings or use stainless in treated lumber.

- Design for corrosion allowance and inspection plans; monitor fasteners in aggressive environments.

Sources used to inform analysis include practitioner guidance indicating stainless steel’s superior rust resistance and practical limitations, alongside standard material/finish families commonly specified in US and EU markets. Actual prices, lead times, and performance vary by region, manufacturer, and lot—validate with local distributors before final specification.

Illustrative Image (Source: Google Search)

Essential Technical Properties and Trade Terminology for best screws for outdoor use

Essential Technical Properties and Trade Terminology for best screws for outdoor use

What to specify for outdoor wood applications

- Substrate and environment

- Wood species and density (e.g., Douglas fir, oak; density in kg/m³ or lb/ft³)

- Exposure (exterior, ground contact/UC4A–UC4B per EN 1995-1-1, coastal, industrial pollution)

-

Corrosivity category (EN ISO 12944-2): C2 (mild rural/urban), C3 (urban/industrial), C4 (coastal), C5 (heavy industrial/coastal)

-

Material

- Stainless steel: austenitic 304/305 (A2) or 316 (A4); duplex 2205 (EN 1.4462) for C5

-

Carbon steel with protective coating (see “Coatings and corrosion performance”)

-

Fastener geometry and design

- Head style: bugle, flat countersunk, pan, hex; drive: Torx/T30–T40, Phillips #2, Pozi, hex

- Shank: fully threaded (FT) vs. partial thread (PT); if PT, shank diameter ≈ thread diameter

- Thread: coarse (for softwoods), fine (for hardwoods), or alternating (e.g., STARDRIVE)

- Point: Type 17 (auger), gimlet/needle for hardwoods

-

Sizes: diameter (e.g., #8, #10, M4–M8) and length (inches or mm), packaging length range per SKU

-

Performance and installation

- Ultimate tensile strength (UTS) and torque per diameter; drive cam-out resistance (e.g., T-drive best)

- Max penetration speed and pre-drilling requirements (e.g., hardwood)

- Minimum edge/end distance and spacing per local codes or wood design standard

-

Heat treatment: case-hardened for coated deck/structural screws, austenitic for stainless

-

Coatings and corrosion performance

- Type and thickness (e.g., zinc-electroplating per ASTM B633, hot-dip galvanized per ASTM A153)

- Environmental class per EN ISO 12944-2; blue/yellow/zinc-alloy grades correlate to service life in similar environments

-

Galvanic compatibility with connectors/metal framing (stainless preferred with aluminum/stainless; avoid stainless with bare carbon steel without isolation)

-

Certification and compliance

- Relevant standards: ASTM F1667 (fasteners for wood), ASTM F3125 (structural screws), ASTM A153 (HDG), ASTM B633 (zinc plating), ASTM G85 (salt-spray test), EN ISO 12944-2 (environment), EN 1995-1-1 (timber design), REACH, RoHS

-

Product certifications and traceability (lot/batch, COC, material certs)

-

Packaging and logistics

- Packaging: bulk, contractor buckets, strips/collated for auto-feed

- Master carton, palletization, labeling, barcode/QR per SKU

-

Logistics: MOQ, lead time, INCOTERMS (e.g., DDP/DDU/FOB), HS code for customs

-

Quality and testing

- QC plan (dimensional, torque/UTS, corrosion test reports), AQL inspection level

- Installation trials on target species and density

Coatings and corrosion performance (EN ISO 12944-2)

| Environment (EN 12944-2) | Typical conditions | Recommended carbon steel coating | Recommended stainless steel | Notes |

|---|---|---|---|---|

| C2 (mild) | Rural/low pollution | Zinc-electroplating (ASTM B633) or equivalent | 304 (A2) | Cobalt/ceramic coating variants also suitable |

| C3 (urban/industrial) | Moderate pollution, frequent wetting | Yellow/blue zinc-alloy coating (≥100 h ASTM B117) or Class I HDG | 304/305 (A2) | Avoid bare carbon steel |

| C4 (coastal) | Sea spray, salt air | Class I hot-dip galvanized (ASTM A153) | 316 (A4) | Stainless avoids white-rust issues |

| C5 (heavy industrial/coastal) | High salinity, aggressive pollution | Heavy HDG or engineered polymer/ceramic overlay; isolate from dissimilar metals | 316 (A4) or 2205 duplex | Consider cathodic compatibility and sealing hardware |

Guidance on “deck screws” vs. stainless and coated carbon:

– “Deck screws” are carbon steel with protective coatings. They resist corrosion well in C2–C3 but not in C4–C5. Surface coatings can wear at drive heads/slots during installation, risking corrosion initiation. HDG “deck screws” improve performance for C4 but are still not equivalent to stainless in high corrosivity zones.

– Stainless steel (304/316) has corrosion resistance through the material, not just surface. Slightly softer; adjust driving parameters to prevent head cam-out or stripping. Best for C3–C5 and whenever disassembly is anticipated.

Material comparison matrix for outdoor wood applications

| Material | Corrosion resistance (outdoor) | Strength/hardness | Drive compatibility | Cost (relative) | Best environments | Notes |

|---|---|---|---|---|---|---|

| 304/305 (A2) stainless | Very good (C3) | Medium | Excellent with Torx | High | Non-coastal exterior; outdoor furniture, framing | Not for C4–C5 coastal without isolation; can cam-out with Phillips |

| 316 (A4) stainless | Excellent (C4–C5) | Medium | Excellent with Torx | Highest | Coastal, marine-adjacent decks, dock hardware | Lower galling risk vs. 304/316; follow torque |

| HDG carbon steel (ASTM A153) | Good (C3–C4) | High | Good with hex; Torx preferred | Medium | Coastal decks, treated lumber framing | Zinc protects but can wear; consider isolation from aluminum/stainless |

| Zinc-electroplated carbon (ASTM B633) | Fair (C2–C3) | High | Good | Low–Medium | Outdoor projects in mild climates | Thin coating; not for C4–C5 or ground contact |

| Polymer/ceramic-coated carbon | Fair–good (C2–C3; some C4) | High | Good | Medium | Decking in non-coastal settings | Coating can chip at high torque/impact |

Drive systems: selection guidance

| Drive | Cam-out resistance | Tooling availability | Typical use | Notes |

|---|---|---|---|---|

| Torx (hexalobular) | Excellent | Widely available | Outdoor wood, composite decking | Highest torque-to-drive fit; minimizes head damage |

| Phillips/Pozi | Moderate–Low | Ubiquitous | General purpose | Higher risk of cam-out; use appropriate depth-setting |

| Hex | High | Common | Structural and heavy-duty | Requires socket driver; less prone to cam-out |

Common head and point styles

| Feature | Options | When to use | Key property |

|---|---|---|---|

| Head | Bugle (self-countersinking), flat, pan, hex | Softwoods/composite decking (bugle); hardwoods (flat), structural (pan/hex) | Countersinking without splitting; flush finish |

| Thread | Coarse, fine, alternating | Softwoods (coarse), hardwoods (fine), mixed species (alternating) | Pull-out performance |

| Point | Type 17 (auger), gimlet/needle | Softwoods treated lumber (Type 17), hardwoods (gimlet) | Reduced splitting, easy start |

Trade terminology frequently requested in outdoor screw procurement

- MOQ (Minimum Order Quantity): lower MOQs increase per-unit cost; typical MOQs vary with packaging (bulk vs. collated).

- Lead time: 2–6 weeks standard; extended for special coatings or made-to-order sizes.

- OEM/ODM: custom head stamping, color-match coatings, or non-standard packaging.

- Drop-ship: direct-to-site shipments with barcoded labels and compliance docs.

- Packaging: bulk, poly bags, contractor buckets, collated strips/bandolier.

- Labelling and traceability: SKU barcode, lot/batch code, COO, date code.

- Certifications: REACH, RoHS, conflict minerals (CMRT), material certificates on request.

- Quality and testing: ISO 9001 supplier, AQL inspection level, mechanical and corrosion test reports (e.g., ASTM B117/G85).

- Compliance documentation: COC, MSDS (coatings), declaration of conformity for EU.

- Logistics: Incoterms (DDP/DDU/FOB/CIF), HS code per product (confirm with broker), palletization and dunnage.

- Customization: special thread (e.g., ladder/alternating), self-drilling tips (TEK) for metal-to-wood, or corrosion-resistant stackable inserts.

- Warranty: performance claims linked to environment classification and installation guidelines.

Selection quick guide by exposure

| Exposure | Recommended screw/material | Drive/head | Point/thread | Notes |

|---|---|---|---|---|

| C2 (mild) | Zinc-electroplated carbon or 304 stainless | Torx bugle/flat | Type 17 coarse | Cost-sensitive projects; pre-drill hardwoods |

| C3 (urban/industrial) | 304 stainless or coated carbon (yellow/blue) | Torx hex/bugle | Type 17 coarse | Avoid Phillips in high-torque conditions |

| C4 (coastal) | 316 stainless | Torx hex/bugle | Type 17 coarse | Use isolation washers with aluminum/stainless connectors |

| C5 (heavy/coastal) | 316 stainless or 2205 duplex | Torx hex | Type 17 coarse | Avoid galvanized/carbon in direct salt exposure |

Installation notes that affect performance

- Use Torx or hex to minimize drive damage; predrill hardwoods/end grain and near edges.

- Control torque/penetration speed, especially with stainless.

- In mixed metal assemblies (e.g., aluminum ledgers), isolate stainless from bare carbon steel; use sealed washers and compatible gaskets.

- For ground contact (UC4A/UC4B), prefer 316 stainless or heavy HDG; avoid thin electroplating.

Common specifications to include in RFQs

- Environment class per EN ISO 12944-2; service-life target.

- Head/drive and size (diameter x length), thread type, point, shank (FT/PT).

- Material grade (A2/A4, or HDG class), coating type/thickness.

- Packaging, labeling, and traceability requirements.

- Standards and certifications required; test report samples (corrosion, mechanical).

- MOQ, lead time, Incoterms, HS code; site delivery instructions for drop-ship.

Navigating Market Dynamics and Sourcing Trends in the best screws for outdoor use Sector

Navigating Market Dynamics and Sourcing Trends in the Best Screws for Outdoor Use Sector

Current market trends shaping outdoor fastener choices

- Materials shift in coastal and high-salinity regions:

- USA: Strong preference for 316/A4 stainless near coasts; interior projects widely use 304/A2 stainless to balance cost and corrosion performance.

- Europe: A2 (304) dominates non-coastal; A4 (316) remains standard for marine/coastal. Buyers increasingly screen hexavalent chromium in legacy coatings and request REACH-compliant finishes.

- Premiumization of coated carbon fasteners:

- Demand is rising for engineered corrosion-resistant coatings (e.g., proprietary organic and zinc-alloy systems) that deliver near-stainless appearance and service life at lower cost.

- Decking, mass timber, exterior cladding, and outdoor furniture projects are adopting coated decks screws in interiors and low-salinity exteriors to reduce risk vs. bare zinc.

- Price and availability volatility:

- Stainless surcharges and stainless-specific mill lead times fluctuate with alloy inputs and energy costs. Stainless premium over coated carbon typically ranges 1.5–3.0×, but spikes can exceed that.

- Hot-dip galvanized (HDG) remains the most cost-effective corrosion barrier per year in neutral environments but is impractical for small-diameter wood screws; mechanical galvanized (Grade 5) offers a pragmatic alternative for smaller sizes.

- Compliance and sustainability pressures:

- European buyers demand REACH-compliant finishes and reduced hexavalent chromium. North American projects increasingly favor stainless steel or EPD-backed coated products.

- Carbon impact and circularity are emerging selection criteria—lower-pigment systems and longer service life reduce total lifecycle cost and emissions.

- Installation quality as a reliability lever:

- Despite material selection, corrosion failures frequently originate from installation damage to coatings (notably Phillips cam-out) and over-torquing.

Sourcing strategies by region

- USA

- Specify A2 (304) stainless as default for non-coastal outdoor; A4 (316) for coastal, waterfront, and saltwater exposure.

- Use coated carbon or mechanical galvanized (Grade 5) where stainless price, torque limitations, or fastener diameter constraints apply.

- For mass timber and exterior assemblies, pilot, avoid cam-out (choose pozidriv, Torx), and pre-drill to protect coatings.

- Engage distributors offering:

- Transparent surcharge indices and lead-time visibility for stainless.

- Certification to ASTM/ASME standards (e.g., A2/A4 compliance, mechanical properties per ASTM F3125 for structural screws).

- Europe

- Default A2 stainless; specify A4 for marine/coastal conditions.

- Require REACH and RoHS compliance declarations and hexavalent chromium screening for coatings; avoid legacy yellow chromate on new projects.

- For coastal and high-chloride zones, prioritize 316/A4 stainless or approved engineered coating systems; consider duplex systems where service life requirements exceed coated carbon performance.

- Work with suppliers providing:

- EPDs or cradle-to-gate carbon footprints for fasteners.

- Standardization across markets to reduce SKU sprawl (e.g., harmonizing head types, drive styles, and coating families).

Sustainability drivers shaping decisions

- Lifecycle and maintenance:

- Longer service life, fewer replacements, and no stripping solvents during removal drive favorable environmental outcomes. Stainless’s embodied impact is offset by longer in-service time in harsh environments.

- Material transparency:

- Zinc sourcing and coating type matter for circularity; buyers increasingly track zinc alloy chemistry and pigmenting. Coatings with low/no chromates and reduced pigment loads score better on sustainability assessments.

- Logistics and packaging:

- Lightweight packaging and regional distribution hubs improve transport-related emissions; however, stainless’s weight should be managed in load planning.

Quick comparison for specification decisions

- A2 stainless steel (304):

- Corrosion resistance: High in non-coastal; modest in marine/coastal.

- Strength/torque: Moderate (slightly lower strength than hardened carbon).

- Price positioning: Mid-high; surcharges are variable.

- Risks: Cam-out during installation; higher installed cost but low maintenance.

- A4 stainless steel (316):

- Corrosion resistance: Very high; recommended for coastal/marine exposures.

- Strength/torque: Similar to A2; careful installation reduces head damage risk.

- Price positioning: High premium; long service life.

- Risks: Higher cost; careful torque and pilot drilling recommended.

- Galvanized steel:

- HDG: Excellent corrosion barrier; impractical for small wood screws; great for structural bolts.

- Mechanical galvanized (Grade 5): Good barrier for small screws; performance sensitive to coating thickness and integrity.

- Risks: Coating damage during installation leads to underfilm corrosion; cam-out and over-torquing damage are common failure points.

- Deck/treated lumber screws:

- Organic or zinc-alloy engineered coatings offer strong protection and appearance; performance varies by chemistry and application.

- Risks: Installation-induced damage reduces service life; specification by proven coating families is essential.

Practical sourcing and specification recommendations

- Anchor selection to environment and service life:

- Non-coastal outdoors with moderate exposure: A2 stainless; engineered coated carbon where cost is the primary driver.

- Coastal/marine/high chloride: A4 stainless; when stainless is not feasible, specify a documented corrosion-resistant coating system with proven marine performance.

- Reduce lifecycle risk at installation:

- Eliminate Phillips drives where possible; use Pozidriv or Torx to minimize cam-out.

- Pilot drill and avoid over-torquing; maintain consistent fastener line (do not mix stainless with incompatible metals in tight assemblies to limit galvanic coupling).

- Manage supply volatility:

- Use indexed pricing and quarterly reviews for stainless; build stock on high-run SKUs; standardize drives, heads, and coatings across project portfolios to stabilize supply.

- Align with policy and compliance:

- Europe: Request REACH and RoHS documentation; exclude hexavalent chromium pigments on new contracts.

- USA: Include ASTM/ASME compliance clauses; specify coating families with documented performance in the target exposure class.

What you can operationalize now

- Define environment-based specs per application (e.g., A2 interior/exterior non-coastal; A4 marine/coastal; coated carbon for low-salinity/short service or budget projects).

- Enforce installation quality standards (drive selection, pilot drills, torque control).

- Refresh supplier contracts to include surcharge visibility, compliance documentation, and coating family performance records.

- Pilot EPD-backed products where carbon transparency is required and track total cost of ownership over the maintenance cycle.

This approach ensures you match material and coating choices to real exposure conditions, contain total lifecycle cost, and meet evolving sustainability and compliance requirements across USA and Europe.

Illustrative Image (Source: Google Search)

Frequently Asked Questions (FAQs) for B2B Buyers of best screws for outdoor use

Frequently Asked Questions (FAQs) – Outdoor Screws for B2B Buyers

1. Which material provides the highest corrosion‑resistance for outdoor screws?

Stainless steel (grades 304 or 316) is the best performer. Unlike surface‑coated fasteners, stainless steel is corrosion‑resistant throughout its volume, so minor coating wear does not lead to rust. Grade 316 adds molybdenum for extra protection against chlorides and is preferred for coastal and marine exposures.

2. How do stainless steel, galvanized, and coated deck screws compare on cost and performance?

| Attribute | Stainless (304/316) | Galvanized (zinc‑coated carbon steel) | Coated Deck Screws (polymer/ceramic) |

|---|---|---|---|

| Corrosion resistance | Excellent, intrinsic | Good, surface‑only (zinc) | Good, depends on coating integrity |

| Typical upfront cost (per 1000 pcs) | Highest | Low‑Medium | Medium |

| Tensile / shear strength | Moderate (≈ 70‑80 % of carbon steel) | Higher | Higher |

| Installation torque needs | Careful control; softer material | Standard | Standard |

| Expected outdoor lifespan | 15‑25 yr (316 in marine) | 5‑10 yr (varies with environment) | 5‑10 yr (coating‑dependent) |

| Recommended use | Critical, high‑moisture, coastal | General outdoor, budget‑sensitive | Light‑duty, decorative, low‑risk |

3. What stainless‑steel grades are recommended for USA vs. European climates?

| Region / Environment | Preferred Grade | Reason |

|---|---|---|

| Continental USA (mid‑west, plains) | 304 | Adequate corrosion resistance for most suburban/outdoor conditions. |

| Coastal USA (Atlantic, Gulf, Pacific) | 316 | Enhanced chloride resistance. |

| Northern Europe (non‑coastal) | 304 | Suitable for temperate, low‑chloride conditions. |

| Coastal Europe (e.g., UK, Netherlands, Spain) | 316 | Marine‑grade protection. |

| Industrial / high‑pollution zones (both regions) | 316 | Better resistance to acid rain and atmospheric pollutants. |

4. Are there torque and installation considerations specific to stainless‑steel screws?

- Lower shear strength – stainless screws are softer; over‑tightening can strip heads or cause snap‑off.

- Pre‑drill pilot holes, especially in hard or dense timbers.

- Use proper driver bits (e.g., Torx, Square) to minimize cam‑out and coating damage.

- Control torque per manufacturer’s specification (typically 20‑30 % lower than carbon‑steel equivalents).

5. Do stainless‑steel screws work with pressure‑treated lumber and metal fasteners?

- Compatibility: Stainless steel is chemically compatible with ACQ‑, CA‑, and CCA‑treated wood; it does not accelerate corrosion of the wood.

- Galvanic isolation: When used with steel brackets, washers, or fasteners, add a non‑conductive (plastic or stainless) barrier to prevent galvanic corrosion.

6. What specifications should be included in a purchase order for outdoor screws?

| Field | Required Detail |

|---|---|

| Material | Stainless steel grade (e.g., 304, 316) or carbon steel + coating type (hot‑dip galvanized, polymer, ceramic). |

| Head style | Flat, bugle, pan, hex, etc. |

| Drive type | Phillips, Torx, Square, Hex, etc. |

| Thread & Point | Coarse, fine, self‑drilling, self‑tapping. |

| Length & Diameter | Exact dimensions (e.g., #10 × 3 in). |

| Coating thickness (if applicable) | Min. μm (e.g., 5 µm zinc for galvanized). |

| Standards compliance | ASTM F3125 (structural), ISO 898 (wood), EN 1995 (Eurocode), ASTM B117 (salt‑spray test). |

| Corrosion test results | Salt‑spray hours, ASTM B117 rating. |

| Packaging | Bulk, cartons, pallets; labeling. |

| Documentation | Mill test certificates, RoHS/REACH (EU) compliance. |

7. How do expected service lives differ among the three screw types?

- Stainless steel (316): 15‑25 years in coastal or high‑moisture environments; 20‑30 years in temperate, non‑coastal zones.

- Stainless steel (304): 10‑15 years in moderate climates; 5‑10 years in severe industrial or marine settings.

- Galvanized (zinc‑coated carbon steel): 5‑10 years depending on zinc thickness and exposure; may require replacement after 5 years in high‑chloride or high‑humidity areas.

- Coated deck screws: Similar lifespan to galvanized, 5‑10 years, but heavily dependent on coating integrity; UV and abrasion can accelerate wear.

8. Can coated deck screws replace stainless‑steel screws in non‑critical outdoor applications?