The global beryllium copper alloy market is experiencing steady growth, driven by rising demand across aerospace, electronics, automotive, and oil & gas industries. According to Grand View Research, the global copper alloys market was valued at USD 24.7 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 4.1% from 2023 to 2030, with beryllium copper playing a critical role due to its exceptional strength, conductivity, and corrosion resistance. Beryllium copper’s unique properties—such as non-sparking and non-magnetic characteristics—make it indispensable in high-performance and safety-critical applications. As industries increasingly prioritize material reliability and efficiency, investment in advanced copper alloys continues to rise. With North America and Asia Pacific leading in industrial adoption, the competitive landscape is shaped by manufacturers focusing on innovation, quality certifications, and scalable production. This report highlights the top 9 beryllium copper alloy manufacturers shaping the market, based on production capacity, technological expertise, global reach, and strategic initiatives.

Top 9 Beryllium Copper Alloy Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Aviva Metals

Domain Est. 2017

Website: avivametals.com

Key Highlights: Aviva Metals is the leading manufacturer of bronze, brass & copper alloys. We keep a ready stock of of these metals in a variety of shapes & sizes….

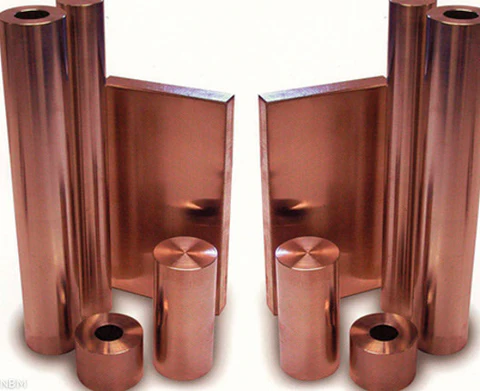

#2 NGK Beryllium Copper

Domain Est. 1996

Website: ngkmetals.com

Key Highlights: NGK Metals is the world leader in beryllium copper. Ranging from beryllium copper plates, rods, sheet, and more. Choose NGK Metals and contact us today!…

#3 Beryllium Copper

Domain Est. 1996

Website: fiskalloy.com

Key Highlights: Engineering Unparalleled Copper Alloy Wire and Conductor Systems. Beryllium Copper alloys combine formability with very high strength properties when aged….

#4 Beryllium Copper Alloy Supplier

Domain Est. 1998

Website: farmerscopper.com

Key Highlights: Farmer’s Copper Ltd. is a Beryllium Copper supplier in round rod and strip. The small ratio of beryllium to copper creates a family of high-copper alloys….

#5 Materion Is a Leading Supplier of Beryllium Products

Domain Est. 1999

Website: materion.com

Key Highlights: Materion is a world leader in mining and supplying beryllium products, including beryllium metal, copper-beryllium alloys, metal matrix composites and technical ……

#6 Beryllium Copper Supplier

Domain Est. 1999

Website: meadmetals.com

Key Highlights: We carry beryllium copper in a range of sizes and tempers. Available in sheets and coils. Request a quote for more details on inventory and availability….

#7

Domain Est. 2009

Website: ibcadvancedalloys.com

Key Highlights: The Copper Alloy Specialists. IBC casts copper and copper alloy ingots and manufactures custom forged copper-based products to your exacting specifications….

#8 Beryllium Copper Alloy

Domain Est. 2010

Website: yamatogokin.com

Key Highlights: At Yamato Gokin, we manufacture seven types of beryllium copper alloys with characteristics and mechanical properties optimized for use in the manufacturing ……

#9 NGK Berylco: World Leader in Beryllium

Domain Est. 2013

Website: ngk-alloys.com

Key Highlights: For over 50 years, NGK Berylco France has been supplying strips, wires, rods and other beryllium-copper alloy products for all industries….

Expert Sourcing Insights for Beryllium Copper Alloy

H2: Projected Market Trends for Beryllium Copper Alloy in 2026

By 2026, the global beryllium copper alloy market is expected to experience steady growth, driven by rising demand across high-performance industrial sectors and advancements in manufacturing technologies. Key trends shaping the market include:

-

Increased Demand from Aerospace and Defense

The aerospace and defense industries are anticipated to remain the largest consumers of beryllium copper alloys due to their exceptional strength, non-magnetic properties, and ability to perform under extreme temperatures. With ongoing modernization of military equipment and expansion of commercial aerospace programs (e.g., next-generation aircraft and satellite systems), demand for reliable, lightweight, and corrosion-resistant materials like beryllium copper will rise. Governments’ investments in defense infrastructure, particularly in North America and Asia-Pacific, will further bolster market growth. -

Growth in Electric Vehicles (EVs) and Automotive Electronics

Beryllium copper alloys are critical in high-reliability connectors, sensors, and switch components in electric and hybrid vehicles. As EV adoption accelerates globally—supported by regulatory mandates and infrastructure development—the need for durable, high-conductivity materials will increase. The alloy’s fatigue resistance and electrical performance make it ideal for use in battery management systems and charging infrastructure, positioning it as a key enabler in the EV supply chain. -

Expansion in Oil & Gas and Downhole Tools

The oil and gas sector will continue to utilize beryllium copper in downhole drilling tools and safety-critical components due to its non-sparking and non-magnetic characteristics, which are essential in hazardous environments. Despite fluctuations in oil prices, the industry’s shift toward deeper and more complex wells will sustain demand for high-performance alloys that ensure operational safety and reliability. -

Advancements in Miniaturization and Electronics

The trend toward smaller, more powerful electronic devices is driving demand for precision components made from beryllium copper. Its use in micro-springs, lead frames, and connectors in smartphones, wearables, and medical devices is expected to grow. Innovations in 5G infrastructure and IoT devices will further expand applications, particularly in RF components where signal integrity and durability are paramount. -

Sustainability and Recycling Initiatives

Environmental concerns and supply chain risks related to beryllium mining are prompting increased focus on recycling and closed-loop manufacturing. By 2026, leading producers are likely to adopt more sustainable practices, including enhanced recycling of scrap beryllium copper, reducing environmental impact and improving cost-efficiency. Regulatory pressures in Europe and North America will accelerate these initiatives. -

Regional Market Dynamics

- North America: Expected to dominate the market due to strong aerospace, defense, and energy sectors, along with established manufacturing infrastructure.

- Asia-Pacific: Projected to witness the highest growth rate, fueled by expanding electronics manufacturing in China, Japan, and South Korea, as well as rising defense budgets in India and Japan.

-

Europe: Growth will be driven by automotive innovation and green energy projects, though constrained by strict environmental regulations on beryllium handling.

-

Price Volatility and Supply Chain Challenges

Beryllium is a critical but strategically controlled material, with limited global suppliers (primarily in the U.S. and China). Geopolitical tensions and export restrictions may lead to price volatility. Companies are expected to mitigate risks through long-term supply agreements and investment in alternative alloy development.

In summary, the beryllium copper alloy market in 2026 will be shaped by technological innovation, sector-specific demand, and sustainability trends. While niche in volume, its irreplaceable performance attributes ensure continued relevance in mission-critical applications across high-growth industries.

H2: Common Pitfalls in Sourcing Beryllium Copper Alloy – Quality and Intellectual Property Concerns

Sourcing Beryllium Copper (BeCu) alloy—particularly for high-performance applications in aerospace, defense, medical, and electronics industries—requires careful consideration of both material quality and intellectual property (IP) risks. Below are the most common pitfalls organizations encounter:

- Inconsistent Material Quality and Certification

- Pitfall: Suppliers may provide BeCu alloy that does not meet required chemical composition, mechanical properties, or industry standards (e.g., ASTM B194, MIL-B-24767, AMS 4530).

- Risk: Substandard alloys can lead to premature component failure, especially in high-stress or high-temperature environments.

-

Mitigation: Insist on full material test reports (MTRs), third-party certifications, and traceability (mill test certificates). Conduct independent testing when necessary.

-

Lack of Process Control and Heat Treatment Verification

- Pitfall: Beryllium copper’s performance depends heavily on precise heat treatment (e.g., age hardening). Poor control during processing significantly impacts strength, conductivity, and fatigue resistance.

- Risk: Inconsistent or incorrect heat treatment leads to non-compliant or unreliable parts.

-

Mitigation: Require documented heat treatment procedures (including time, temperature, and atmosphere) and verify through microhardness testing or metallography.

-

Contamination and Impurity Risks

- Pitfall: Impurities (e.g., iron, lead, or excessive beryllium oxide) can compromise material integrity and safety.

- Risk: Reduced performance and potential safety hazards, especially during machining or welding.

-

Mitigation: Specify stringent impurity limits and request spectrographic analysis. Monitor supplier refining and melting practices.

-

Intellectual Property (IP) Infringement

- Pitfall: Some BeCu alloys are proprietary (e.g., Alloy 25, Alloy 172, or specific formulations by Materion or NGK). Unauthorized production or replication by third-party suppliers may infringe on patents or trade secrets.

- Risk: Legal liability, product recalls, or supply chain disruptions if IP rights are violated.

-

Mitigation: Verify that the supplier holds proper licenses or produces under legitimate technology transfer agreements. Conduct IP due diligence before contract finalization.

-

Counterfeit or Misrepresented Materials

- Pitfall: Illicit suppliers may label inferior copper alloys as beryllium copper to command higher prices.

- Risk: Catastrophic failure in mission-critical applications; reputational and safety consequences.

-

Mitigation: Use supply chain audits, require material traceability to the original mill, and employ testing (e.g., XRF or OES analysis) upon receipt.

-

Inadequate Regulatory Compliance (Especially for Beryllium)

- Pitfall: Beryllium is a hazardous material regulated by OSHA, REACH, and other bodies. Improper handling or documentation can lead to non-compliance.

- Risk: Legal penalties, workplace safety issues, and import/export restrictions.

-

Mitigation: Ensure suppliers comply with safety data sheets (SDS), provide proper worker protection protocols, and meet international regulatory standards.

-

Limited Supplier Qualification and Transparency

- Pitfall: Relying on unqualified or opaque suppliers, especially from regions with weak oversight.

- Risk: Unverified production methods, lack of quality assurance, and exposure to IP theft.

- Mitigation: Qualify suppliers through on-site audits, review their quality management systems (e.g., ISO 9001, AS9100), and require transparency in sourcing and manufacturing.

Conclusion:

To mitigate risks when sourcing BeCu alloy, prioritize certified suppliers with verifiable quality systems and legal rights to produce the material. Implement rigorous material verification, enforce contractual IP protections, and maintain a transparent, auditable supply chain. This approach ensures performance reliability and safeguards against legal and operational pitfalls.

H2: Logistics & Compliance Guide for Beryllium Copper Alloy

Beryllium copper (BeCu) alloy, known for its high strength, conductivity, and non-sparking properties, is widely used in aerospace, defense, oil and gas, and electronics industries. Due to the presence of beryllium—a toxic element when inhaled as dust or fumes—transportation, handling, and regulatory compliance require strict adherence to safety and legal standards. This guide outlines key logistics and compliance considerations for the safe and lawful management of beryllium copper alloy.

1. Classification and Regulatory Framework

- Chemical Classification: Beryllium copper typically contains 0.5% to 3% beryllium. While solid forms are generally stable, processing (e.g., grinding, welding) can release hazardous beryllium particles.

- Regulatory Authorities:

- OSHA (Occupational Safety and Health Administration) – Enforces permissible exposure limits (PEL) for beryllium (0.2 µg/m³ as an 8-hour TWA).

- EPA (Environmental Protection Agency) – Regulates beryllium under the National Emission Standards for Hazardous Air Pollutants (NESHAP).

- DOT (Department of Transportation) – Governs safe transportation of materials (though solid BeCu is generally not classified as hazardous for transport if unprocessed).

- REACH (EU) – Requires registration and communication of substances; beryllium compounds are on the Candidate List for SVHC (Substances of Very High Concern).

- RoHS & REACH Exemptions – BeCu may be exempt from RoHS restrictions in specific high-performance applications.

2. Handling and Storage

- Safe Handling:

- Use appropriate personal protective equipment (PPE): NIOSH-approved respirators, gloves, and protective clothing when machining or grinding.

- Prohibit eating, drinking, or smoking in areas where beryllium copper is handled.

- Implement local exhaust ventilation (LEV) in processing areas.

- Storage:

- Store in dry, well-ventilated areas away from acids or oxidizing agents.

- Keep material in original, labeled packaging to prevent confusion and contamination.

- Segregate from incompatible materials.

3. Transportation and Logistics

- Domestic (U.S.):

- Solid beryllium copper alloys are typically not regulated as hazardous materials under DOT 49 CFR when in bulk, solid form.

- However, powders, fines, or waste materials containing beryllium may be classified as hazardous waste (EPA) or hazardous material (DOT).

- International Shipping:

- IATA/IMDG: Solid BeCu is generally not subject to dangerous goods regulations unless in powdered or waste form.

- Check country-specific import restrictions (e.g., EU REACH, UK REACH).

- Provide Safety Data Sheets (SDS) compliant with GHS standards.

4. Waste Disposal and Recycling

- Waste Classification:

- Beryllium-containing waste (e.g., machining swarf, dust, sludge) may be classified as hazardous waste under RCRA (EPA) due to toxicity (D004-D011).

- Disposal:

- Use licensed hazardous waste disposal facilities.

- Never landfill untreated beryllium-contaminated waste.

- Recycling:

- Beryllium copper scrap is often recycled through specialized metal recyclers.

- Ensure recyclers are permitted to handle beryllium-containing materials.

5. Workplace Safety and Compliance Programs

- Exposure Monitoring:

- Conduct air monitoring to ensure compliance with OSHA’s beryllium standards.

- Implement a beryllium-specific exposure control plan (ECP).

- Training:

- Train employees on beryllium hazards, PPE use, hygiene practices, and emergency procedures.

- Maintain records of training and exposure monitoring.

- Medical Surveillance:

- Required for workers with potential beryllium exposure exceeding action levels.

- Includes periodic medical exams and lung function testing.

6. Documentation and Reporting

- Maintain updated Safety Data Sheets (SDS) – Section 15 must reflect regional regulatory requirements.

- Keep records of:

- Exposure monitoring

- Medical surveillance

- Waste disposal manifests

- Training logs

- Report spills or releases per CERCLA/Superfund regulations if applicable.

7. Best Practices Summary

- Treat all beryllium copper machining operations as potentially hazardous.

- Use engineering controls to minimize airborne particulates.

- Label all containers with “Contains Beryllium – Do Not Grind or Weld Without Protection.”

- Partner with certified suppliers and waste handlers.

- Regularly audit compliance with OSHA, EPA, and DOT regulations.

By following this guide, organizations can ensure the safe, legal, and responsible logistics management of beryllium copper alloy throughout its lifecycle—from procurement to disposal.

Conclusion for Sourcing Beryllium Copper Alloy

Sourcing beryllium copper alloy requires a strategic and informed approach due to its critical role in high-performance applications across industries such as aerospace, electronics, defense, and oil & gas. As a high-strength, non-sparking, and corrosion-resistant material with excellent thermal and electrical conductivity, beryllium copper offers unique advantages but also presents specific challenges in procurement.

Key considerations in the sourcing process include supplier reliability, material certification (especially compliance with ASTM, AMS, or NADCAP standards), and adherence to health and safety regulations due to beryllium’s toxicity during machining and handling. Establishing relationships with reputable, certified suppliers—preferably those with vertical integration and robust quality management systems—is essential to ensure consistency, traceability, and regulatory compliance.

Additionally, supply chain resilience, lead times, and cost volatility—driven by limited global producers and the strategic nature of beryllium—necessitate long-term planning and potential dual sourcing strategies. Environmental, health, and safety (EHS) protocols must be strictly maintained throughout handling, processing, and disposal.

In conclusion, successful sourcing of beryllium copper alloy hinges on balancing performance requirements with regulatory compliance, supply chain security, and safety considerations. A proactive, well-vetted procurement strategy ensures not only material quality and availability but also operational safety and long-term project viability.