The global bendy plywood market is experiencing steady growth, driven by rising demand in furniture, interior design, and architectural applications. According to Grand View Research, the global plywood market size was valued at USD 36.5 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 6.8% from 2023 to 2030—fueled by innovations in flexible wood composites and increasing preference for curved, aesthetic designs in residential and commercial spaces. Bendy plywood, known for its ability to bend along multiple axes without compromising structural integrity, has become a material of choice for designers and manufacturers seeking versatility and sustainability. As the market evolves, a select group of manufacturers are leading the charge in quality, innovation, and production capacity. Here are the top 7 bendy plywood manufacturers shaping the industry’s future.

Top 7 Bendy Ply Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Mohawk Industries, Inc.

Domain Est. 1996

Website: mohawkind.com

Key Highlights: A wide variety of high thermal performance PIR insulation products for residential and commercial new construction and renovation projects….

#2 Products

Domain Est. 2001

Website: naply.com

Key Highlights: North American Plywood Corporation is proud to be a premier wholesaler and manufacturer of high quality plywood panels and value added components….

#3 Flexi Plywood Manufacturer & Supplier

Domain Est. 2017

Website: teshagroup.com

Key Highlights: Flexi Plywood is also called Bendy plywood. Because it is flexible, it is used to make things that need to be curvy….

#4 Flexible Plywood Manufacturer

Domain Est. 2019

Website: bhutantuffindia.com

Key Highlights: Rating 5.0 (5) Bhutan Tuff has redefined the possibilities of plywood with its range of Flexible Plywood Sheets, designed to bend and contour effortlessly to intricate shapes….

#5 Bending Plywood 3/8

Domain Est. 1999

Website: plywoodcompany.com

Key Highlights: 30-day returnsThis amazing flexible board will shape to almost any curved contour. Its ability to flex in long-grain or cross-grain directions makes it a versatile panel for ……

#6 Atlantic Plywood

Domain Est. 1999

Website: atlanticplywood.com

Key Highlights: Wholesale Supplier of Hardwood Plywood, Panel Product and More! … Since our inception in 1974, Atlantic Plywood Corporation has prided itself on delivering the ……

#7 Flexible Ordinary Plywood

Domain Est. 2001

Website: madar.com

Key Highlights: High-quality 8mm Flexible Plywood (1220x2440mm) for creating smooth, curved surfaces in furniture, cabinetry, and architectural design. Easy to bend and finish….

Expert Sourcing Insights for Bendy Ply

H2 2026 Market Trends Analysis for Bendy Ply

As we look toward the second half of 2026, the global market for bendy plywood (flexible plywood or curve-grade plywood) is poised for continued evolution, driven by shifts in construction, design innovation, sustainability demands, and supply chain dynamics. Below is a comprehensive analysis of key trends expected to shape the bendy ply market during H2 2026.

1. Rising Demand in Architectural and Interior Design

Trend: Increased adoption in curved architectural elements and bespoke interior solutions.

Analysis:

Designers and architects are increasingly embracing organic, flowing forms in both residential and commercial projects. Bendy ply’s ability to bend radially without cracking makes it ideal for curved walls, ceilings, staircases, and custom furniture. In H2 2026, the trend toward biophilic and experiential design will accelerate demand, especially in high-end retail spaces, hospitality, and cultural institutions. The growth of parametric design software also enables more complex forms, further pushing the use of bendy ply as a preferred material.

2. Sustainability and Eco-Certification as Market Drivers

Trend: Strong preference for FSC/PEFC-certified and low-emission bendy ply.

Analysis:

Environmental regulations and consumer awareness are pushing manufacturers and specifiers toward sustainable materials. By H2 2026, procurement policies—especially in Europe and North America—will increasingly require certified sustainable wood sourcing and low-VOC adhesives (e.g., formaldehyde-free resins like EPI or soy-based). Brands offering eco-transparent supply chains and carbon footprint labeling will gain competitive advantage.

3. Expansion in Transportation and Recreational Applications

Trend: Growth in use for RVs, yachts, and mass transit interiors.

Analysis:

The demand for lightweight, durable, and moldable materials in the mobility sector is rising. Bendy ply is being used in curved paneling, cabinetry, and structural components for recreational vehicles, marine interiors, and even public transport (e.g., curved seats and wall linings). As the global RV and eco-tourism markets expand in H2 2026, so will the need for moisture-resistant, marine-grade bendy ply variants.

4. Regional Market Shifts and Supply Chain Localization

Trend: Increasing production and consumption in Asia-Pacific and Eastern Europe.

Analysis:

While Europe remains a leader in design innovation, Asia-Pacific (particularly China, India, and Vietnam) is emerging as a major manufacturing and consumption hub. Local production of bendy ply is rising to meet demand from booming construction and furniture sectors. Supply chain resilience post-pandemic and geopolitical uncertainties will encourage regional sourcing. By H2 2026, expect more localized manufacturing hubs reducing dependency on long-haul imports.

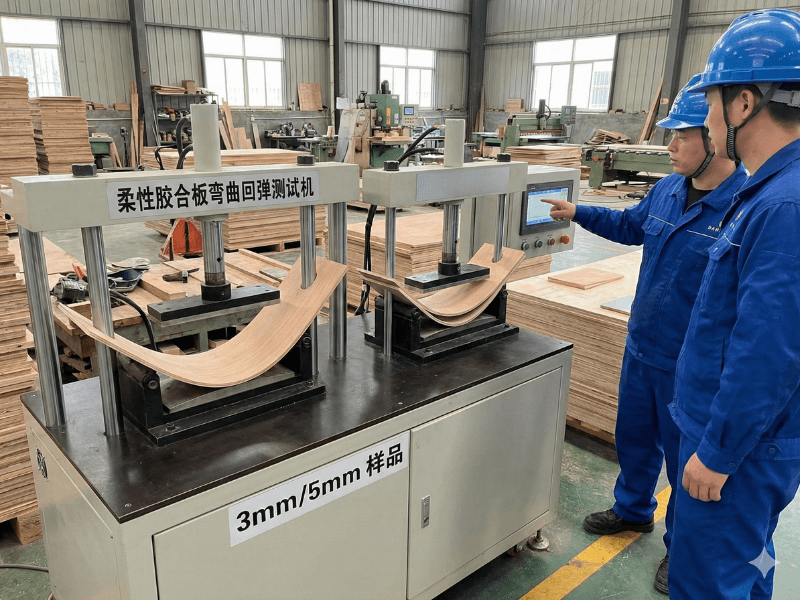

5. Technological Advancements in Manufacturing

Trend: Automation and digital integration in production.

Analysis:

Manufacturers are investing in CNC pre-formation, automated veneer layering, and AI-driven quality control to enhance consistency and reduce waste. Digital templating and BIM (Building Information Modeling) integration allow for precise pre-fabrication of curved components, minimizing on-site labor. These advancements will improve cost-efficiency and scalability, making bendy ply more accessible for mid-tier projects by late 2026.

6. Competitive Pricing and Material Substitution Pressures

Trend: Price sensitivity amid competition from engineered alternatives.

Analysis:

While bendy ply offers unique aesthetic and structural benefits, it faces competition from materials like flexible MDF, thermally bent plywood, and composite panels. Fluctuations in raw material costs (e.g., tropical hardwoods, adhesives) may impact pricing. However, innovation in using fast-growing, plantation-sourced woods (e.g., birch, eucalyptus) will help stabilize costs and maintain bendy ply’s value proposition.

7. Customization and On-Demand Manufacturing

Trend: Growth of made-to-order and small-batch production.

Analysis:

The rise of digital fabrication and direct-to-manufacturer platforms enables architects and designers to order custom radii, thicknesses, and finishes. In H2 2026, we expect more suppliers to offer modular bendy ply systems and design support services, reducing lead times and supporting the trend toward personalized, small-scale projects.

Conclusion:

H2 2026 will be a pivotal period for the bendy plywood market, marked by strong growth in design-led applications, intensified focus on sustainability, and technological innovation. Success will depend on manufacturers’ ability to balance cost, customization, and environmental responsibility. Companies that invest in eco-certification, digital manufacturing, and regional supply chains are best positioned to capture emerging opportunities in architecture, mobility, and premium interiors.

Common Pitfalls When Sourcing Bendy Ply: Quality and Intellectual Property Issues

Sourcing bendy ply (flexible plywood) can present several challenges, particularly concerning material quality and intellectual property (IP) risks. Being aware of these pitfalls helps ensure a reliable supply chain and protects your project or product.

Poor Material Quality and Inconsistent Performance

One of the most frequent issues when sourcing bendy ply is receiving inconsistent or substandard material. Low-quality ply may delaminate under stress, have weak glue lines, or lack the flexibility required for tight-radius curves. Suppliers—especially those outside regulated markets—may use inferior adhesives (e.g., urea-formaldehyde instead of waterproof phenolic resins), leading to reduced durability and moisture resistance. Additionally, inconsistent veneer thickness or poor core construction can result in warping or breakage during bending, increasing waste and project costs.

Lack of Certification and Traceability

Many bendy ply suppliers fail to provide proper certification for their products, such as compliance with European EN 636 or equivalent standards, or proof of sustainable forestry (e.g., FSC or PEFC). Without these certifications, buyers cannot verify the material’s structural integrity or environmental claims. This lack of traceability also increases the risk of receiving illegally sourced timber, which can lead to legal and reputational damage.

Misrepresentation of Product Specifications

Some suppliers may exaggerate the bending capabilities of their ply, claiming tight radii that the material cannot actually achieve without cracking or delaminating. This misrepresentation often stems from generic marketing rather than tested performance data. Buyers may end up with a product unsuitable for their application, leading to costly redesigns or project delays.

Intellectual Property Infringement Risks

When sourcing bendy ply for design-intensive applications (e.g., furniture or architectural elements), there’s a risk of inadvertently using materials or designs that infringe on existing patents or trademarks. Some manufacturers produce plywood with proprietary lamination techniques or surface finishes protected by IP laws. Sourcing from unauthorized suppliers or copying branded products (e.g., mimicking designs from well-known brands like James Hardie or Italian engineered ply producers) can expose businesses to legal action, especially in export markets with strong IP enforcement.

Sourcing from Unverified or Grey-Market Suppliers

Using third-party platforms or unverified distributors increases the risk of counterfeit or rebranded products. Some suppliers repackage lower-grade plywood as premium bendy ply, misleading buyers about origin and performance. These grey-market products often lack warranties and technical support, making it difficult to resolve quality disputes.

Inadequate Technical Support and Documentation

Reliable bendy ply suppliers should provide detailed technical data sheets, bending guidelines, and support for fabrication. Many budget suppliers fail to offer this information, leaving designers and fabricators to guess optimal bending radii, glue recommendations, or finishing techniques. This lack of support can compromise safety and performance, especially in structural applications.

Avoiding these pitfalls requires due diligence: vetting suppliers, requesting material samples and certifications, verifying IP status for design-sensitive uses, and prioritizing transparency and technical accountability in procurement decisions.

Logistics & Compliance Guide for Bendy Ply

Bendy Ply, also known as flexible plywood or bendable plywood, is a specialized engineered wood product designed to curve and conform to non-linear shapes. Proper logistics and compliance management are essential to ensure product integrity, timely delivery, and adherence to legal and safety standards throughout the supply chain.

Product Characteristics and Handling Requirements

Bendy Ply is typically constructed from thin veneers bonded with flexible adhesives, making it susceptible to moisture, rough handling, and improper storage. Key handling considerations include:

– Avoid exposure to excessive humidity or direct water contact.

– Store flat and supported to prevent warping or edge damage.

– Handle with care to prevent cracking or delamination, especially at cold temperatures.

– Keep in original packaging until ready for use.

Packaging and Palletization

To maintain quality during transit:

– Bendy Ply sheets should be bundled securely with moisture-resistant wrapping.

– Use edge protectors to prevent chipping or crushing.

– Stack on sturdy pallets and avoid overloading.

– Clearly label packages with “Fragile,” “This Side Up,” and product specifications.

Transportation Guidelines

- Use enclosed, dry vehicles to protect against weather and moisture.

- Secure loads to prevent shifting during transport.

- Avoid extreme temperature fluctuations; do not leave in unheated trucks during winter.

- Provide documentation including delivery notes, packing lists, and safety data sheets (SDS) if applicable.

Regulatory Compliance

Ensure all shipments comply with relevant local and international regulations:

– REACH & RoHS (EU): Confirm that adhesives and resins used in Bendy Ply do not contain restricted substances.

– CARB & EPA TSCA Title VI (USA): Comply with formaldehyde emission standards for composite wood products.

– Customs Documentation: Provide accurate HS codes (e.g., 4412.31 or 4412.32 for plywood), certificates of origin, and import/export declarations where required.

Fire Safety and Building Codes

- Verify that Bendy Ply meets fire resistance standards (e.g., ASTM E84, EN 13501-1) if used in construction or interior applications.

- Provide fire classification documentation to clients and authorities as needed.

- Label products with fire rating and compliance marks where applicable.

Sustainability and Certification

- Source Bendy Ply from suppliers with FSC® (Forest Stewardship Council) or PEFC™ certification to ensure sustainable forestry practices.

- Retain chain-of-custody documentation for certified products.

- Include environmental product declarations (EPDs) when available.

Import and Export Considerations

- Check phytosanitary requirements; some countries require heat treatment certification (e.g., ISPM 15 for wooden packaging).

- Confirm tariff classifications and duty rates with customs brokers.

- Be aware of restrictions on certain wood species or treated products.

Quality Assurance and Documentation

- Conduct pre-shipment inspections to verify thickness, flexibility, and surface quality.

- Maintain batch traceability for compliance and recall management.

- Provide technical data sheets (TDS), test reports, and compliance certificates with each shipment.

By following this guide, businesses can ensure safe, efficient, and compliant handling and transportation of Bendy Ply, minimizing risk and supporting sustainable and legal supply chain operations.

Conclusion for Sourcing Bendy Plywood:

In conclusion, sourcing bendy plywood requires careful consideration of several key factors including material quality, thickness, grain direction, supplier reliability, and cost-effectiveness. It is essential to identify suppliers who specialize in flexible or bendable plywood, such as those offering birch or poplar veneer cores with cross-banded layers designed for curved applications. Engaging with reputable suppliers—whether local or online—ensures access to consistent product performance and technical support. Additionally, requesting samples, verifying certifications, and assessing lead times and shipping costs contribute to a successful procurement process. Ultimately, selecting the right bendy plywood from a trusted source not only supports the structural and aesthetic demands of the project but also enhances efficiency and reduces waste during fabrication.