The global aluminum extrusion market, a critical segment underpinning industries such as construction, automotive, and consumer electronics, is experiencing robust growth driven by demand for lightweight, durable, and sustainable materials. According to a 2023 report by Mordor Intelligence, the market was valued at USD 108.3 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 5.4% from 2024 to 2029. This expansion is fueled by increasing infrastructure development and the push for energy-efficient transportation solutions. In this context, Benada, a key industrial hub in China, has emerged as a prominent cluster for aluminum product manufacturing—hosting a concentration of specialized extrusion and fabrication firms. These manufacturers leverage local supply chain advantages, advanced production technologies, and proximity to port infrastructure to serve domestic and international markets. Based on production capacity, export volume, and technological investment, the following six manufacturers represent the leading players in Benada’s aluminum products sector.

Top 6 Benada Aluminum Products Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Benada Aluminum Products

Domain Est. 2001

Website: aluminum-extrusions.net

Key Highlights: Benada Aluminum Products is a well-established company renowned for its expertise in the manufacturing and distribution of high-quality aluminum extrusions….

#2 Sunny Outlook for Florida Powder Coater

Domain Est. 1997

Website: pfonline.com

Key Highlights: Benada Aluminum rebounds their business with improved chemistries and equipment in their powder coating operations….

#3 P2 Search

Domain Est. 1997

Website: enviro.epa.gov

Key Highlights: Facility Comparison Report for TRI Facilities Meeting Selected Criteria: Industry: Aluminum Extruded Product Manufacturing … Benada Aluminum Of Florida (FL) ……

#4 Search Trade Adjustment Assistance Petitions

Domain Est. 1997

Website: dol.gov

Key Highlights: Benada Aluminum Products LLC, Sanford, FL, Certified, 05/18/2012, 06/28/2012, 05/19/2010, 05/19/2012, State. 70861, Parkdale America ……

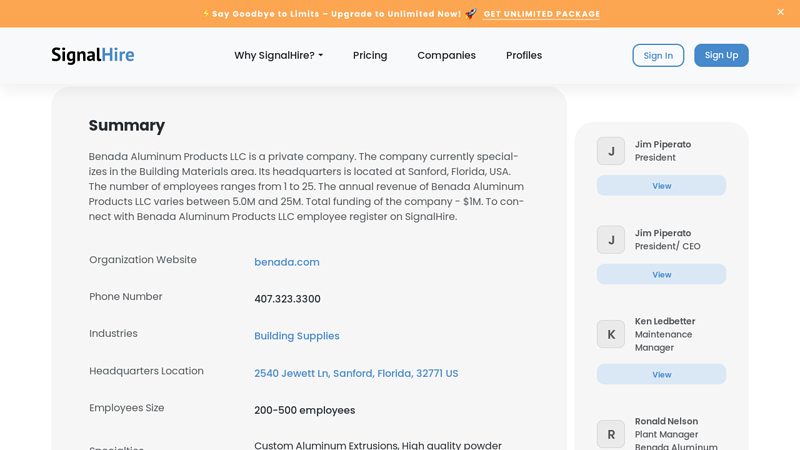

#5 Benada Aluminum Products LLC Information

Domain Est. 2013

Website: signalhire.com

Key Highlights: Benada Aluminum Products LLC is a private company. The company currently specializes in the Building Materials area. Its headquarters is located at Sanford, ……

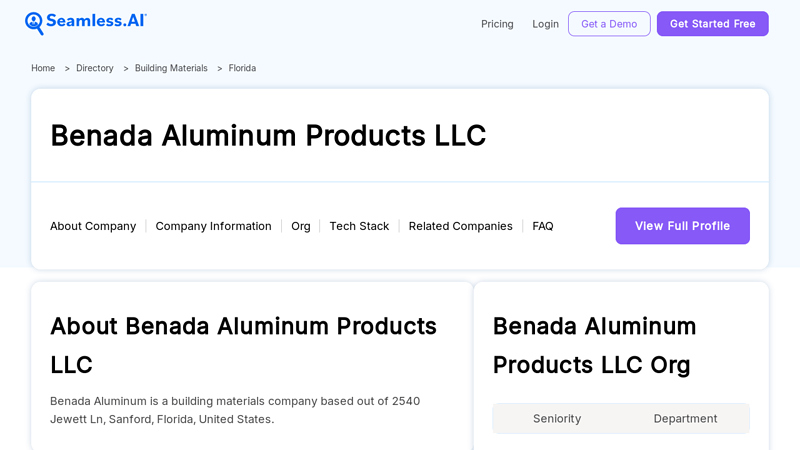

#6 Benada Aluminum Products LLC Staff Directory, Phone & Corp Office

Domain Est. 2017

Website: seamless.ai

Key Highlights: What is the Benada Aluminum Products LLC’s official website? Benada Aluminum Products LLC’s official website is benada.com. What is Benada Aluminum Products ……

Expert Sourcing Insights for Benada Aluminum Products

H2: Market Trends for Benada Aluminum Products in 2026

By 2026, Benada Aluminum Products is expected to operate within a dynamic global market shaped by technological innovation, sustainability mandates, and shifting industrial demand. Key trends influencing the company’s market position include:

-

Growth in Lightweight Materials Demand: Driven by automotive and aerospace sectors seeking fuel efficiency and reduced emissions, demand for high-strength, lightweight aluminum alloys is projected to rise significantly. Benada is well-positioned to capitalize on this trend through its focus on engineered aluminum solutions for transportation applications.

-

Sustainability and Circular Economy Integration: Regulatory pressures and corporate ESG (Environmental, Social, and Governance) goals are accelerating the shift toward recycled aluminum. With lower carbon footprints compared to primary production, recycled content is becoming a competitive advantage. Benada’s investments in closed-loop recycling and low-carbon manufacturing processes will enhance its appeal to environmentally conscious clients.

-

Expansion in Renewable Energy Infrastructure: The global push for solar, wind, and energy storage systems is increasing demand for aluminum in structural components, mounting systems, and conductive applications. Benada’s ability to supply customized, corrosion-resistant profiles aligns with the needs of renewable energy developers, presenting a high-growth market segment.

-

Digitalization and Smart Manufacturing: Adoption of Industry 4.0 technologies—such as AI-driven quality control, IoT-enabled production lines, and digital twins—is optimizing efficiency and reducing waste. By 2026, Benada’s integration of smart manufacturing practices will improve production scalability, reduce lead times, and support just-in-time delivery models.

-

Geopolitical and Supply Chain Resilience: Ongoing supply chain disruptions and trade policy shifts are prompting companies to regionalize sourcing and production. Benada may benefit from nearshoring trends in North America and Europe, particularly if it strengthens local supply chains and reduces dependency on volatile raw material imports.

-

Rise of E-Mobility and EV Components: Electric vehicle (EV) production is expected to surge, with aluminum playing a critical role in battery enclosures, chassis, and thermal management systems. Benada’s expertise in precision extrusions and thermal conductivity positions it as a strategic supplier in the EV value chain.

In summary, the 2026 market landscape for Benada Aluminum Products will be defined by sustainability, technological innovation, and strategic alignment with high-growth industries. By leveraging these trends, Benada can strengthen its competitive edge and expand into emerging markets with tailored, value-added aluminum solutions.

Common Pitfalls Sourcing Benada Aluminum Products (Quality, IP)

Sourcing aluminum products from Benada, or any supplier, carries specific risks related to both quality consistency and intellectual property (IP) protection. Being aware of these common pitfalls can help mitigate potential issues.

Quality Inconsistencies and Specifications Mismatches

One major risk when sourcing from Benada—or any manufacturer—is receiving products that fail to meet agreed-upon quality standards. This can manifest as dimensional inaccuracies, surface defects (such as scratches or uneven finishes), or deviations in alloy composition. Often, these issues arise from lax quality control processes, inconsistent raw material sourcing, or misinterpretation of technical specifications. Without clear, detailed product specifications and a robust inspection protocol (including pre-shipment inspections), buyers may receive substandard goods that do not perform as expected, leading to rework, delays, or product failures.

Lack of Intellectual Property Safeguards

Another significant pitfall involves intellectual property exposure. When sharing custom designs, molds, or proprietary technical data with Benada to manufacture aluminum components, there is a risk that the supplier may replicate or resell these designs to competitors—especially in regions with weaker IP enforcement. Without strong contractual protections, such as non-disclosure agreements (NDAs), explicit IP ownership clauses, and restrictions on tooling usage, companies risk losing control over their innovations. Additionally, verifying Benada’s history of respecting IP rights and conducting due diligence on their subcontracting practices is essential to avoid unauthorized production or counterfeiting.

Logistics & Compliance Guide for Benada Aluminum Products

This guide outlines the essential logistics and compliance considerations for the handling, transportation, and regulatory adherence of Benada Aluminum Products. Adherence to these standards ensures safety, legal conformity, and efficient supply chain operations.

Product Classification and Handling

Benada aluminum products—including sheets, extrusions, coils, and fabricated components—are classified as non-hazardous materials under international transport regulations. However, proper handling is critical to prevent physical damage and maintain product integrity. All personnel must use appropriate personal protective equipment (PPE), including gloves and safety footwear, when handling raw materials and finished goods. Products should be stored in dry, ventilated areas, away from corrosive substances and direct exposure to moisture to prevent oxidation or surface degradation.

Packaging and Labeling Standards

All Benada aluminum products must be packaged in accordance with internal quality standards and customer specifications. Protective materials such as plastic wraps, edge protectors, and wooden pallets or cradles are required to prevent scratching, denting, or warping during transit. Each shipment must include accurate labeling with product type, alloy grade, dimensions, batch/lot number, heat number (if applicable), and handling instructions (e.g., “Fragile,” “This Side Up”). Labels must be durable and weather-resistant for international shipping.

Domestic and International Transportation

Transportation of Benada aluminum products domestically and internationally must comply with applicable regulations, including:

- Road Transport (e.g., FMCSA in the U.S.): Ensure loads are properly secured using straps or chains to prevent shifting. Weight distribution must comply with axle load limits.

- Rail Transport: Follow carrier-specific loading procedures and placard shipments appropriately.

- Maritime Shipping (IMO/IMDG Code): Although aluminum is not classified as dangerous cargo, compliance with the International Maritime Organization (IMO) guidelines for stowage and segregation is required. Use containerized or break-bulk methods as appropriate, ensuring moisture barriers are in place.

- Air Freight (IATA): Confirm packaging meets IATA standards for dimensional stability and weight. Aluminum products are generally permitted on passenger and cargo aircraft under non-hazardous classification.

Customs Compliance and Documentation

For cross-border shipments, Benada must provide complete and accurate documentation, including:

- Commercial Invoice

- Packing List

- Bill of Lading or Air Waybill

- Certificate of Origin (preferably with NAFTA/USMCA or regional trade agreement certification)

- Material Test Reports (MTRs) or Mill Test Certificates, when required

Ensure Harmonized System (HS) codes are correctly applied (typically under Chapter 76 – Aluminum and Articles Thereof). Stay updated on import/export restrictions, tariffs, and trade sanctions in target markets.

Environmental, Health, and Safety (EHS) Regulations

Benada aluminum products must comply with relevant environmental and workplace safety regulations, including:

- REACH (EU): Confirm that no restricted substances are present in surface treatments or coatings.

- RoHS (EU): Applicable if aluminum components are used in electrical/electronic equipment.

- OSHA (U.S.): Follow guidelines for safe material handling, storage, and worker protection during loading/unloading operations.

- EPA Regulations: Comply with rules related to scrap metal recycling and waste management.

Quality Assurance and Traceability

Maintain full traceability of aluminum products from raw material sourcing through production and delivery. Each batch must be assigned a unique identifier linked to production records, quality inspections, and test results. This supports compliance with customer audits, industry standards (e.g., ISO 9001, AS9100 for aerospace), and recall readiness.

Import/Export Licensing and Restricted Parties Screening

Ensure that Benada does not engage in transactions with entities on denied or restricted parties lists (e.g., U.S. OFAC, EU Consolidated List). Conduct regular screening of customers, suppliers, and partners. Obtain necessary export licenses if shipping to embargoed countries or for dual-use applications.

Continuous Compliance and Training

All logistics and operations staff must undergo regular training on compliance procedures, safety protocols, and regulatory updates. Assign a compliance officer or team to monitor changes in international trade laws, transportation regulations, and environmental standards affecting aluminum product distribution.

By adhering to this guide, Benada ensures the reliable, legal, and efficient movement of its aluminum products across global markets.

Conclusion for Sourcing Beneda Aluminum Products:

Sourcing aluminum products from Beneda presents a strategic advantage for businesses seeking high-quality, durable, and precision-engineered solutions. Beneda’s strong reputation for advanced manufacturing capabilities, strict quality control, and commitment to innovation ensures reliable performance and consistency across a wide range of industrial applications. Their comprehensive product portfolio, combined with a customer-focused approach, makes them a competitive and dependable supplier in the aluminum market.

Moreover, Beneda’s adherence to international standards and sustainable practices supports long-term partnerships aligned with environmental and regulatory requirements. By choosing Beneda as a sourcing partner, companies can benefit from cost efficiency, technical support, and timely delivery, enhancing overall supply chain resilience.

In conclusion, sourcing aluminum products from Beneda is a prudent decision that supports operational excellence, product reliability, and sustainable growth. Establishing a long-term collaboration with Beneda can provide a significant competitive edge in today’s demanding industrial landscape.