The belt grinder market, particularly for industrial-grade 1×30 models used in metalworking, tool fabrication, and precision grinding, has seen steady expansion driven by growing demand in manufacturing and metal fabrication sectors. According to Grand View Research, the global grinding equipment market was valued at USD 5.2 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. This growth is fueled by advancements in automation, increased need for high-precision tools, and rising investments in industrial infrastructure. As demand for reliable, high-performance 1×30 belt grinders intensifies, manufacturers are innovating with improved motor efficiency, dust extraction systems, and modular designs. Based on performance metrics, market presence, customer reviews, and technological advancements, here are the top 7 manufacturers leading the 1×30 belt grinder segment.

Top 7 Belt Grinder 1X30 Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 VEVOR Belt Grinder Sander, 30 x 1

Domain Est. 2009

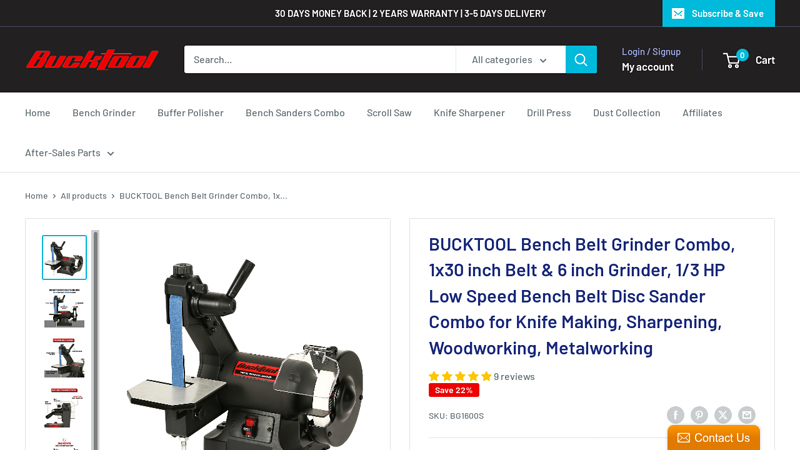

#2 Bucktool 1×30 Belt & 6″ Disc Sander Combo

Domain Est. 2010

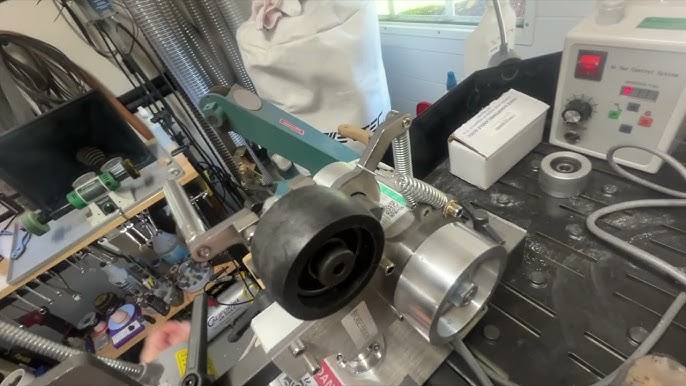

#3 amktactical.com, 2×72 belt grinder, disc grinder, knifegrinder

Domain Est. 2013

Website: amktactical.com

Key Highlights: Need 1×30 sharpener belts or 2×72 grinder belts? Contact our supplier Combat Abrastives at 714-203-2541 or click here for 1×30 belts or click here for 2×72 ……

#4 1″ x 30″ Belt Starter Kit

Domain Est. 2015

Website: combatabrasives.com

Key Highlights: In stock Rating 4.9 (129) The 1″ x 30″ Starter Kit is a great value – offering 39 belts ranging from 60 to 800 grit. If you are a beginner knife maker or a knife sharpener, this …

#5 1 X 30 Inch Knife Making Sanding Belt Assortment

Domain Est. 2015

Website: redlabelabrasives.com

Key Highlights: In stock Rating 4.9 (76) Red Label Abrasives offers seven different 1 x 30 assortment packs for knife makers. Each pack contains a different assortment of sanding belts….

#6 Desktop Belt Grinder 1×30 Desktop Belt Sander

Domain Est. 2021

Website: pmkshoes.com

Key Highlights: Alright DIYers and workshop enthusiasts, this 1×30 desktop belt sander is seriously versatile! It’s got a powerful 0.55KW brushless motor that runs on 110V AC – ……

#7 Clearance 1 x 30 belt grinder 2026 Variable Speed 1

Website: cschenois.ch

Key Highlights: In stock Rating 4.7 (2,066) Product: 1 x 30 belt grinder. EX ELECTRONIX EXPRESS Mini 1 x 30 Belt Sander 3400 RPM Power, A 1, Knifemaking for beginners Do not underestimate 1×30, …

Expert Sourcing Insights for Belt Grinder 1X30

H2: Projected 2026 Market Trends for 1×30 Belt Grinders

The 1×30 belt grinder, a staple tool in metalworking, knife-making, and fabrication industries, is expected to experience notable shifts in market dynamics by 2026. Driven by advancements in technology, evolving consumer demands, and industrial growth, the following trends are poised to shape the 1×30 belt grinder market:

-

Increased Demand from the Artisan and DIY Sectors

The rise of maker culture and home-based workshops continues to fuel demand for mid-range 1×30 belt grinders. By 2026, a growing number of hobbyists and small-scale knife makers are anticipated to invest in affordable yet durable models, accelerating the expansion of entry-level and prosumer-grade equipment. -

Integration of Smart Features and Digital Controls

Equipment manufacturers are increasingly incorporating smart technologies such as variable speed controls, digital RPM displays, and motor load monitoring into 1×30 grinders. These enhancements improve precision and user experience, appealing to both professional fabricators and serious hobbyists. -

Growth in Industrial Automation and Customization

Industrial applications are shifting toward customized grinding solutions. By 2026, demand for OEM 1×30 belt grinders with modular designs—allowing integration into automated production lines—is expected to rise, particularly in automotive and aerospace component manufacturing. -

Material and Motor Efficiency Innovations

Advancements in motor efficiency (e.g., brushless DC motors) and heat-resistant abrasive belts will enhance performance and reduce operational costs. These improvements contribute to longer tool life and lower energy consumption, aligning with global sustainability goals. -

Expansion in Emerging Markets

Regions such as Southeast Asia, India, and Latin America are witnessing growth in metal fabrication and small-scale manufacturing. This trend, coupled with improved accessibility to industrial tools via e-commerce, is expected to expand the global footprint of 1×30 belt grinder sales. -

Sustainability and Eco-Friendly Manufacturing

As environmental regulations tighten, manufacturers are focusing on recyclable materials, energy-efficient production processes, and reduced packaging waste. Brands promoting green manufacturing practices will likely gain a competitive edge by 2026. -

Consolidation and Brand Differentiation

The market is expected to see increased competition and consolidation, with leading brands differentiating themselves through warranties, customer support, and comprehensive accessory ecosystems (e.g., platen attachments, contact wheels, dust collection).

In summary, the 1×30 belt grinder market in 2026 will be characterized by technological innovation, diversification of user segments, and geographic expansion. Manufacturers who adapt to these evolving trends—particularly in usability, efficiency, and sustainability—are likely to capture greater market share.

Common Pitfalls When Sourcing a 1×30 Belt Grinder (Quality, IP)

Sourcing a 1×30 belt grinder—especially for industrial or high-performance applications—requires careful evaluation to avoid costly mistakes. Below are key pitfalls related to quality and IP (Ingress Protection) rating that buyers often encounter:

Poor Build Quality and Material Selection

Many low-cost 1×30 belt grinders use substandard materials such as thin-gauge steel, plastic housings, or undersized motors. This leads to premature wear, vibration, and reduced lifespan. Avoid grinders with flimsy contact wheels, poorly machined platens, or inconsistent belt tracking. Always verify motor durability (e.g., TEFC motors) and frame rigidity to ensure long-term performance.

Inadequate or Misrepresented IP Rating

A common issue is misleading or absent IP ratings. Some suppliers claim “dust-resistant” without a valid IP certification. For workshop environments with metal dust and coolant, an IP54 or higher is recommended. Beware of grinders that lack sealed bearings, motor enclosures, or electrical components, as these are vulnerable to contamination and pose safety risks.

Lack of Thermal and Overload Protection

Low-quality grinders may omit essential motor protections. Without thermal overload cutouts or duty cycle ratings, motors can overheat during continuous use, leading to burnout. Always confirm the inclusion of thermal protection and check manufacturer specifications for duty cycle limits.

Inconsistent Belt Tracking and Tensioning

Poorly designed tensioning and tracking systems cause frequent belt misalignment, reducing grinding efficiency and increasing consumable costs. Avoid models with manual-only adjustments or flimsy tension mechanisms. Look for reliable, repeatable tracking systems—preferably with dual adjustment knobs and precision bearings.

Missing Safety Features and Compliance

Some imported 1×30 grinders lack basic safety certifications (e.g., CE, UL) or essential guards. Ensure the unit includes emergency stops, proper belt guards, and complies with regional safety standards. Non-compliant equipment can lead to workplace hazards and legal liability.

Inaccurate or Missing Documentation

Poor documentation—such as missing assembly instructions, maintenance guides, or IP certification details—indicates low overall quality. Reliable suppliers provide clear specifications, wiring diagrams, and maintenance schedules. Lack of documentation complicates troubleshooting and voids warranties.

Overlooking After-Sales Support and Spare Parts

Even with decent initial quality, poor access to spare parts (belts, wheels, motors) or technical support can render a grinder unusable over time. Confirm the availability of replacement components and responsive customer service before purchasing—especially with overseas suppliers.

By addressing these pitfalls proactively, buyers can source a durable, safe, and efficient 1×30 belt grinder suitable for demanding applications. Always prioritize verified quality, legitimate IP ratings, and supplier reliability over upfront cost savings.

Logistics & Compliance Guide for Belt Grinder 1X30

This guide outlines the key logistics considerations and compliance requirements for the safe and legal transport, handling, storage, and use of the Belt Grinder 1X30.

Product Classification and Documentation

The Belt Grinder 1X30 is classified as industrial machinery with an electric motor. Proper documentation must accompany the unit during shipping and be retained for compliance. Required documents include:

- Product Manual (including safety instructions and technical specifications)

- CE Declaration of Conformity (for EU markets)

- Electrical Safety Certification (e.g., UL, CSA, or equivalent depending on region)

- Packing List and Commercial Invoice (for international shipments)

- Material Safety Data Sheet (MSDS), if applicable for lubricants or coatings

Ensure all documentation is up to date and reflects the current configuration of the unit.

Packaging and Handling Requirements

To prevent damage during transit, the Belt Grinder 1X30 must be securely packaged using the following standards:

- Use a rigid, double-walled cardboard or wooden crate with internal foam or custom-cut inserts.

- Secure all moving parts (platen, drive wheel, tension system) with shipping locks or protective straps.

- Protect the motor, belt tracking mechanism, and control panel with anti-static and moisture-resistant wrap.

- Clearly label the package with: “Fragile,” “This Side Up,” and “Do Not Stack.”

- Use palletized shipping for commercial freight; secure the unit with straps or shrink wrap.

Handlers must use mechanical lifting equipment (e.g., forklift or pallet jack) when moving units over 30 kg.

Shipping and Transportation

When arranging shipment of the Belt Grinder 1X30, observe the following:

- Use freight carriers experienced in handling industrial equipment.

- Declare accurate weight (typically 45–60 kg depending on configuration) and dimensions (approx. 90 cm L × 45 cm W × 80 cm H).

- For air or sea freight, comply with IATA or IMDG regulations if batteries or hazardous materials are included (not typical for standard models).

- Insure shipments against loss or damage, especially for international deliveries.

- Confirm delivery location has accessibility for large packages and receiving equipment.

Import/Export Compliance

For cross-border movement of the Belt Grinder 1X30, adhere to regional trade regulations:

- Harmonized System (HS) Code: 8461.30 (Grinding or polishing machines)

- Provide correct customs declarations including value, origin, and end-use.

- Verify compliance with destination country electrical standards (e.g., voltage: 110–120V or 220–240V; frequency: 50/60 Hz).

- Confirm no export restrictions apply (typically none for this category in most jurisdictions).

- Maintain records of export documentation for a minimum of 5 years.

Safety and Regulatory Compliance

The Belt Grinder 1X30 must meet relevant safety and environmental standards:

- Electrical Safety: Compliant with IEC 60204-1 (Safety of machinery – Electrical equipment of machines).

- EMC Directive: Complies with electromagnetic compatibility standards (e.g., EN 55014, EN 61000).

- CE Marking: Required for sale in the European Economic Area; affixed only after full conformity assessment.

- ROHS Compliance: Ensure all electronic components are free of restricted substances (lead, cadmium, etc.).

- Noise Emissions: Meets local noise regulations; typical operating noise <85 dB(A).

End users must follow local workplace safety regulations (e.g., OSHA in the U.S., HSE in the UK) including use of personal protective equipment (PPE).

Storage Conditions

Store the Belt Grinder 1X30 in a clean, dry, temperature-controlled environment:

- Temperature range: 5°C to 40°C (41°F to 104°F)

- Relative humidity: <80%, non-condensing

- Keep away from corrosive chemicals, dust, and direct sunlight

- Store upright to prevent damage to base or motor mounts

- Cover with breathable fabric to prevent dust accumulation

Inspect units after long-term storage before deployment.

End-of-Life and Environmental Responsibility

Dispose of or recycle the Belt Grinder 1X30 in accordance with WEEE (Waste Electrical and Electronic Equipment) Directive or local e-waste regulations:

- Separate components: metal housing, electric motor, electronic controls, and plastic parts.

- Recycle through certified e-waste recyclers.

- Do not dispose of in general landfill.

- Document recycling or disposal for compliance audits.

Ensure users are informed of proper decommissioning procedures via the product manual.

Conclusion for Sourcing a 1×30 Belt Grinder:

After thorough evaluation of available options, it is clear that sourcing a 1×30 belt grinder requires balancing performance, durability, cost, and intended use—whether for knife making, metal fabrication, or general workshop tasks. Both commercial and DIY solutions offer viable paths, each with distinct advantages. Commercial models from reputable brands provide reliability, precision, and warranty support, making them ideal for professionals or high-volume users. On the other hand, DIY kits or custom-built grinders offer cost savings and customization, appealing to hobbyists and experienced fabricators.

Critical factors such as motor power (preferably 1 to 2 HP), variable speed control, durable contact wheels, and adjustable tension/ tracking systems significantly impact performance and user satisfaction. Additionally, availability of replacement parts, customer support, and shipping logistics should be considered, especially when sourcing from international suppliers.

In conclusion, the optimal sourcing decision depends on individual needs, skill level, and budget. For consistent, long-term use, investing in a quality commercial 1×30 belt grinder from a trusted manufacturer is recommended. For those seeking a hands-on experience with room for customization, a well-designed DIY kit offers excellent value. Ultimately, careful research and alignment with project requirements will ensure a successful and productive addition to your workshop.