The global beehive market has seen steady growth in recent years, driven by rising demand for honey, growing awareness of pollination’s role in agriculture, and the expansion of apiculture among hobbyists and commercial beekeepers. According to Grand View Research, the global honey market was valued at USD 9.3 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 5.4% from 2023 to 2030. This surge in beekeeping activity has increased the demand for durable, cost-effective, and low-maintenance beehives—spurring innovation in materials, particularly plastic. Once considered a niche alternative to traditional wooden hives, plastic beehives are now gaining traction due to their lightweight design, resistance to pests and weather, and ease of mass production. As of 2024, manufacturers specializing in plastic beehives are playing a pivotal role in modernizing apiculture, especially in regions prioritizing scalable and sustainable beekeeping solutions. This growing segment reflects broader shifts in agricultural technology and environmental stewardship, positioning plastic hive manufacturers at the forefront of a transforming industry. Here’s a look at the top 9 plastic beehive manufacturers driving this evolution.

Top 9 Bee Hives Plastic Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Plastic Bee Frames

Domain Est. 1996

Website: mannlakeltd.com

Key Highlights: Free delivery over $150Upgrade your hive with durable plastic bee frames. Easy to clean, weather-resistant, pest-proof. Ideal for hobbyists and pros. Free shipping over $150….

#2 Plastic Beekeeping Equipment Nicot

Domain Est. 1998

Website: nicotplast.fr

Key Highlights: All our plastic articles are made with raw materials suitable for food contact according to the declarations of our suppliers. All our plastic articles intended ……

#3 Flow Hive

Domain Est. 2004

Website: honeyflow.com

Key Highlights: Flow is a revolutionary beehive invention, allowing you to harvest honey without opening the hive and with minimal disturbance to the bees….

#4 Pierco Beekeeping Equipment

Domain Est. 2004

Website: pierco.com

Key Highlights: Pierco Beekeeping Equipment – Wood/Plastic Frames, Snap-In Foundation, Tools, Hive Kits, Protective Gear & Nutrients. For all your beekeeping needs come to the…

#5 Blythewood Bee Company

Domain Est. 2006

Website: blythewoodbeecompany.com

Key Highlights: Discover premium beekeeping supplies and expert advice at Blythewood Bee Company. Explore our wide range of high-quality bee hives, tools, and protective ……

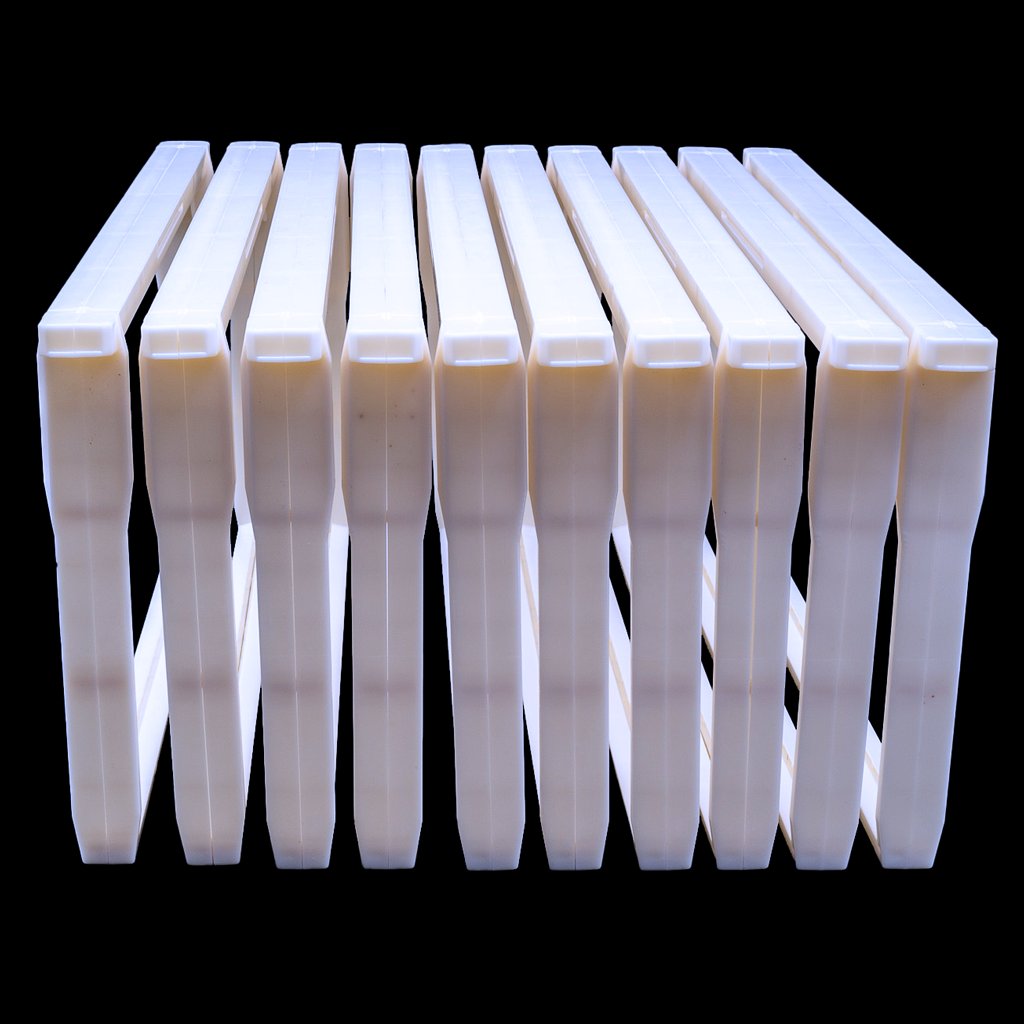

#6 Plastic Beehive Frames

Domain Est. 2013

#7 Apimaye Insulated Beehive

Domain Est. 2015

Website: apimaye-usa.com

Key Highlights: The Apimaye beehive was developed to make it easier to manage a colony of bees and produce more honey. The innovative all-round double layer insulation…

#8 HillCo, LLC

Domain Est. 2024

Website: hillco.buzz

Key Highlights: We carry a variety of beekeeping equipment, including beehives and components, bee suits, smokers, uncapping tools, uncapping tanks, honey tanks, and especially ……

#9 Plastic Bee Hive Suppliers

Website: hivehaven.com.au

Key Highlights: We are a plastic bee hive supplier. We source our raw material responsibly where possible and locally to support Australian manufacturing….

Expert Sourcing Insights for Bee Hives Plastic

2026 Market Trends for Plastic Bee Hives

The global market for plastic bee hives is poised for significant evolution by 2026, driven by technological advancements, environmental concerns, and shifts in agricultural practices. This analysis explores key trends shaping the plastic bee hive industry over the coming years.

Rising Demand for Sustainable Apiculture Solutions

As bee populations face threats from climate change, pesticides, and habitat loss, there is growing emphasis on sustainable beekeeping practices. Plastic bee hives offer a durable, lightweight, and cost-effective alternative to traditional wooden models. By 2026, demand is expected to increase due to their resistance to rot, pests, and moisture, which reduces hive replacement costs and supports long-term colony health.

Innovation in Hive Design and Material Science

Manufacturers are investing in advanced polymers and composite materials to improve thermal regulation, structural integrity, and UV resistance. By 2026, next-generation plastic hives incorporating antimicrobial additives and modular designs are anticipated to dominate the market. These innovations help maintain optimal hive conditions, reduce disease transmission, and simplify hive management for both hobbyist and commercial beekeepers.

Expansion of Urban and Backyard Beekeeping

The rise of urban agriculture and eco-conscious consumerism is fueling interest in home-based beekeeping. Plastic hives, being easier to assemble, clean, and transport, are particularly suited for city environments. By 2026, this segment is expected to see double-digit growth, especially in North America and Europe, where municipalities are increasingly supporting pollinator initiatives.

Integration with Smart Beekeeping Technologies

The convergence of IoT and beekeeping is a key trend. By 2026, many plastic hive models will likely come embedded with sensors to monitor temperature, humidity, hive weight, and bee activity. These data-driven insights enable early detection of swarming, disease, or colony collapse, improving hive productivity and survival rates. Plastic’s moldability makes it ideal for integrating electronic components seamlessly.

Environmental and Regulatory Challenges

Despite their benefits, plastic hives face scrutiny over microplastic shedding and long-term environmental impact. By 2026, regulatory pressure may increase, prompting manufacturers to adopt biodegradable or recyclable plastics. Certifications for eco-friendly materials and production processes will become critical for market differentiation.

Regional Market Dynamics

While Europe leads in adoption due to strong apiculture traditions and EU support programs, Asia-Pacific is expected to be the fastest-growing region by 2026, driven by expanding agricultural sectors in India and China. Government-backed pollination initiatives and rising honey demand will further accelerate plastic hive uptake.

Conclusion

By 2026, the plastic bee hive market will be shaped by innovation, sustainability, and digital integration. Success will depend on balancing functionality with environmental responsibility, meeting the evolving needs of a global beekeeping community committed to preserving vital pollinator populations.

Common Pitfalls When Sourcing Plastic Bee Hives (Quality & Intellectual Property)

Sourcing plastic bee hives can offer benefits like durability, consistency, and ease of handling, but buyers often encounter significant challenges related to product quality and intellectual property (IP) rights. Being aware of these pitfalls helps ensure a reliable, legal, and sustainable supply.

Poor Material Quality and Durability

One of the most frequent issues is receiving hives made from substandard plastic that degrades quickly under UV exposure, extreme temperatures, or mechanical stress. Low-quality polymers may become brittle, warp, or leach harmful chemicals, compromising bee health and hive longevity. Always verify the type of plastic used (e.g., UV-stabilized polypropylene or HDPE) and request material certifications or third-party test reports.

Inconsistent Manufacturing Standards

Suppliers, especially those in regions with lax quality control, may produce hives with inconsistent dimensions, weak joints, or poorly finished surfaces. These inconsistencies can affect hive assembly, bee behavior, and compatibility with standard beekeeping equipment. Insist on samples, conduct factory audits, and use detailed technical specifications in purchase agreements.

Lack of Ventilation and Thermal Regulation

Plastic hives must be carefully designed to prevent overheating and moisture buildup, which can be fatal to colonies. Some low-cost models lack adequate ventilation or reflective properties, leading to poor hive microclimates. Evaluate design features such as air gaps, vented covers, and light-colored materials that help regulate internal temperature and humidity.

Intellectual Property Infringement Risks

Many innovative hive designs (e.g., Flow Hive, Dadant adaptations) are protected by patents, trademarks, or design rights. Sourcing generic copies or clones from unverified suppliers can expose buyers to legal liability for IP infringement. Always confirm the supplier’s right to manufacture and sell the design, and avoid “look-alike” products that mimic patented features.

Misrepresentation of Design Origin and Compliance

Some suppliers falsely claim their hives are “patent-free” or “original designs” when they closely replicate protected models. Others may assert compliance with international beekeeping standards (e.g., modified Langstroth) without verification. Conduct due diligence by comparing designs to registered patents and consulting with legal or industry experts.

Limited After-Sales Support and Spare Parts

Low-cost suppliers may not offer long-term support, replacement components, or warranties. If a critical part breaks and cannot be replaced, the entire hive system may become unusable. Choose suppliers with a clear support structure and availability of spare parts to ensure longevity and user satisfaction.

Environmental and Regulatory Non-Compliance

Plastic hives must comply with environmental regulations regarding recyclability and chemical safety. Some suppliers use recycled plastics containing contaminants or fail to meet REACH, RoHS, or local agricultural standards. Request documentation on material sourcing and regulatory compliance to avoid legal and ecological issues.

By proactively addressing these quality and IP-related pitfalls, buyers can source plastic bee hives that are durable, legal, and beneficial for both beekeepers and pollinators.

Logistics & Compliance Guide for Bee Hives Plastic

Overview

This guide outlines the key logistics and compliance considerations for the transportation, handling, and regulatory adherence related to plastic bee hives. Proper planning ensures product integrity, regulatory compliance, and efficient supply chain operations.

Product Specifications

Plastic bee hives are typically made from durable, food-safe polypropylene (PP) or high-density polyethylene (HDPE). They are designed to be weather-resistant, lightweight, and stackable. Common configurations include Langstroth, top-bar, or Warre styles. Dimensions and weight vary by model but generally range from 15–30 kg per assembled hive.

Packaging Requirements

- Use sturdy, recyclable cardboard or reusable plastic pallets for transport.

- Individual hive components should be shrink-wrapped or boxed to prevent damage.

- Nesting or stacking designs must be secured with straps or corner boards to avoid shifting.

- Clearly label packages with “Fragile,” “Stackable,” and orientation arrows.

- Include product codes, batch numbers, and handling instructions on outer packaging.

Storage Conditions

- Store in dry, shaded areas to prevent UV degradation.

- Avoid exposure to extreme temperatures (above 60°C or below -20°C).

- Keep off concrete floors using pallets to minimize moisture absorption.

- Ensure good ventilation to prevent condensation and mold growth.

- Max stacking height: 5–6 units, depending on pallet strength and component type.

Transportation Guidelines

- Use clean, enclosed trucks or containers to protect from dust, moisture, and contaminants.

- Secure loads with straps or load bars to prevent movement during transit.

- Avoid mixing with hazardous or strongly odored materials.

- For international shipments, comply with ISPM 15 for wooden pallets (if used).

- Track shipments via GPS if high-value or time-sensitive.

Regulatory Compliance

Environmental Regulations

- Ensure materials comply with REACH (EU) and RoHS directives (where applicable).

- Confirm recyclability and provide disposal instructions to customers.

- Avoid restricted substances (e.g., phthalates, heavy metals) in manufacturing.

Food & Agriculture Compliance

- Although not storing food, plastic bee hives may contact honey; use food-grade plastics (FDA 21 CFR or EU 10/2011 compliant).

- Provide documentation verifying non-toxic, bee-safe materials.

International Trade

- Classify products under correct HS Code (e.g., 3923.90 for plastic horticultural articles).

- Prepare commercial invoices, packing lists, and certificates of origin.

- Comply with import regulations in destination countries (e.g., APHIS in the U.S., CFIA in Canada).

- Declare hive types and materials to avoid agricultural inspection delays.

Certification & Documentation

- Maintain Material Safety Data Sheets (MSDS) or Safety Data Sheets (SDS).

- Provide product compliance certificates (e.g., FDA, CE, ISO 9001).

- Keep records of quality control tests (impact resistance, UV stability).

- Include user manuals with assembly instructions and compliance details.

Sustainability & End-of-Life

- Design for disassembly and recyclability.

- Offer take-back or recycling programs where feasible.

- Label products with resin identification codes (e.g., PP #5).

- Communicate environmental benefits (longevity, reduced wood harvesting).

Incident Response & Recalls

- Establish a recall procedure in case of material defects or compliance issues.

- Maintain batch traceability from production to delivery.

- Train staff on reporting and handling non-compliant shipments.

Summary

Effective logistics and compliance for plastic bee hives require attention to packaging, environmental conditions, regulatory standards, and documentation. By adhering to this guide, manufacturers and distributors can ensure safe, legal, and sustainable delivery of beekeeping products worldwide.

In conclusion, sourcing plastic bee hives presents a modern, durable, and cost-effective alternative to traditional wooden hives. Their lightweight design, resistance to pests and weather, and low maintenance requirements make them particularly suitable for beginner beekeepers and commercial operations alike. Additionally, plastic hives offer consistent manufacturing quality and can contribute to more sustainable beekeeping practices when produced from recycled or recyclable materials. However, careful consideration should be given to ventilation, insulation, and environmental impact when selecting plastic models. By choosing reputable suppliers and high-quality materials, beekeepers can successfully integrate plastic hives into their apiaries, supporting hive longevity and colony health while streamlining hive management. Ultimately, sourcing plastic bee hives can be a strategic decision that balances innovation, efficiency, and bee welfare in modern apiculture.