Sourcing Guide Contents

Industrial Clusters: Where to Source Battery Company In China

Professional B2B Sourcing Report 2026

SourcifyChina | Global Procurement Intelligence

Title: Deep-Dive Market Analysis — Sourcing Battery Companies in China

Prepared for: Global Procurement Managers

Date: Q1 2026

Executive Summary

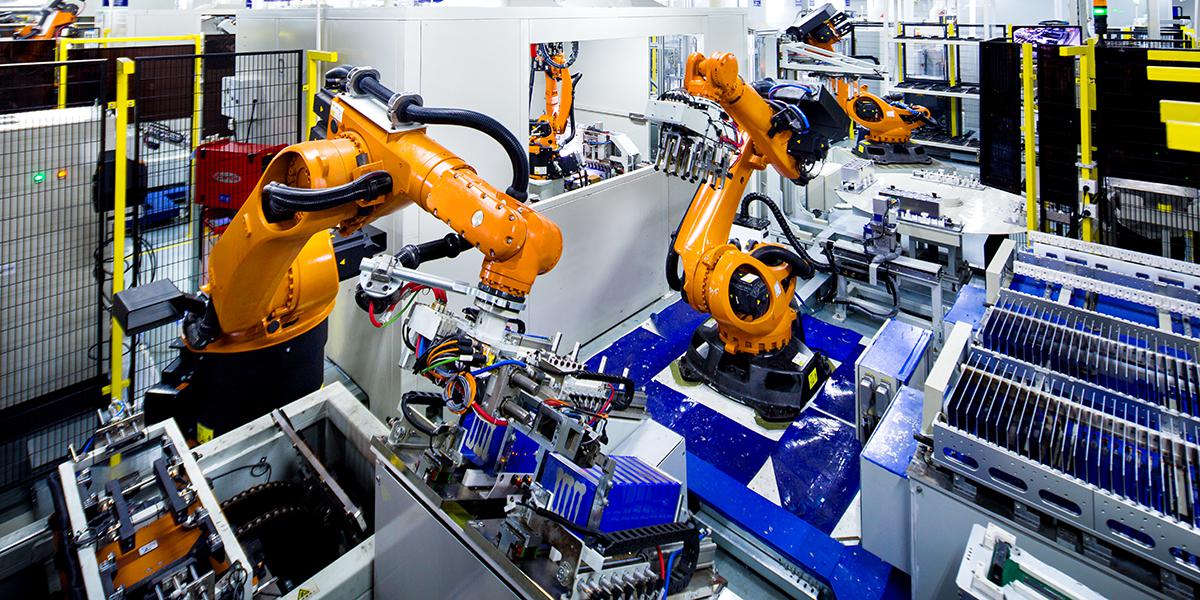

China remains the dominant global hub for battery manufacturing, accounting for over 70% of the world’s lithium-ion battery production capacity in 2025. The country’s vertically integrated supply chain, government-backed industrial policy, and technological advancements have solidified its leadership in both consumer electronics and electric vehicle (EV) battery sectors. For global procurement managers, understanding the geographic distribution of battery manufacturing clusters is critical to optimizing cost, quality, and supply chain resilience.

This report provides a strategic analysis of China’s key battery manufacturing clusters, focusing on provinces and cities with concentrated expertise in battery cell production, battery management systems (BMS), and full-pack assembly. A comparative assessment of Guangdong, Zhejiang, Jiangsu, Fujian, and Anhui is included to guide sourcing decisions based on Price, Quality, and Lead Time — three core procurement KPIs.

Key Industrial Clusters for Battery Manufacturing in China

China’s battery industry is geographically concentrated in five major industrial clusters, each with distinct competitive advantages:

| Province | Key Cities | Specialization | Key Players |

|---|---|---|---|

| Guangdong | Shenzhen, Dongguan, Guangzhou | Consumer electronics batteries, Li-ion packs, BMS, fast-charging tech | BYD (partial), Desay SV, Grepow, Dynavolt |

| Zhejiang | Ningbo, Hangzhou, Wenzhou | Specialty lithium batteries, battery materials (electrolytes, separators) | CATL (subsidiaries), Zhejiang Haoyue, Narada Power |

| Jiangsu | Changzhou, Suzhou, Nanjing | EV battery cells, high-energy density NMC, LFP | CATL (major hub), CALB, SVOLT, Honeywell China JV |

| Fujian | Ningde | World-leading EV battery cell manufacturing | CATL (HQ), Amperex Technology (ATL) |

| Anhui | Hefei | EV battery systems, government-backed gigafactories | CATL, Gotion High-Tech, BYD |

Cluster Insights

- Fujian (Ningde): Home to CATL (Contemporary Amperex Technology Co. Limited), the world’s largest EV battery manufacturer. This cluster dominates in high-volume, high-quality EV battery cells with strong R&D support and economies of scale.

- Jiangsu (Changzhou): A strategic secondary hub for CATL and domestic leader CALB. Known for advanced NMC and LFP cell production, with strong logistics access to Shanghai port.

- Guangdong (Shenzhen/Dongguan): Focuses on small-format Li-ion batteries for consumer electronics, drones, and medical devices. Offers agile manufacturing and rapid prototyping.

- Zhejiang (Ningbo/Hangzhou): Strong in battery materials and specialty chemistries, ideal for custom formulations and niche applications.

- Anhui (Hefei): Emerging as a vertically integrated EV battery ecosystem, supported by local government incentives and partnerships with EV OEMs like NIO.

Comparative Analysis of Key Battery Manufacturing Regions

The table below compares the five leading provinces based on Price, Quality, and Lead Time — critical factors for global procurement strategy.

| Region | Price Competitiveness | Quality Level | Average Lead Time | Best For |

|---|---|---|---|---|

| Guangdong | ⭐⭐⭐⭐☆ (4/5) Competitive pricing for small-format batteries; higher costs for premium BMS integration |

⭐⭐⭐⭐☆ (4/5) High consistency in consumer-grade cells; strong QC standards |

4–6 weeks | Consumer electronics, fast-turnaround projects, custom packs |

| Zhejiang | ⭐⭐⭐☆☆ (3.5/5) Mid-range pricing; premium for specialty chemistries |

⭐⭐⭐⭐☆ (4/5) High reliability in industrial and telecom batteries |

6–8 weeks | Specialty applications, telecom backup, industrial use |

| Jiangsu | ⭐⭐⭐⭐☆ (4/5) Economies of scale in EV cells; competitive for bulk orders |

⭐⭐⭐⭐⭐ (5/5) Top-tier quality; ISO 16949, IATF certified facilities |

8–10 weeks | EV OEMs, energy storage systems (ESS), large-scale procurement |

| Fujian | ⭐⭐⭐⭐☆ (4/5) Lowest per-kWh cost for EV cells due to scale |

⭐⭐⭐⭐⭐ (5/5) Global benchmark for EV battery quality; CATL-led innovation |

10–12 weeks | High-volume EV and ESS contracts |

| Anhui | ⭐⭐⭐⭐☆ (4/5) Aggressive pricing due to subsidies and gigafactory scale |

⭐⭐⭐⭐☆ (4/5) Rapidly improving; Gotion and BYD facilities meeting Tier-1 standards |

8–10 weeks | Long-term EV partnerships, government-backed projects |

Scoring Key:

– Price: 5 = Most competitive (low $/kWh or unit)

– Quality: 5 = Automotive-grade, ISO-certified, low defect rate (<100 ppm)

– Lead Time: Based on standard order-to-shipment for 10,000+ units or 10 MWh+ battery systems

Strategic Sourcing Recommendations

-

For EV & ESS Procurement: Prioritize Fujian (Ningde) and Jiangsu (Changzhou) for best-in-class quality and scale. Engage directly with CATL or its Tier-2 suppliers via authorized agents.

-

For Consumer Electronics & Custom Packs: Guangdong offers faster turnaround and design flexibility. Ideal for OEMs requiring rapid iteration.

-

For Specialty/Niche Applications: Zhejiang provides access to advanced electrolytes and long-life cycle batteries for telecom or medical use.

-

For Cost-Optimized Long-Term Contracts: Anhui (Hefei) presents emerging opportunities with strong local government incentives and expanding capacity.

-

Risk Mitigation: Avoid over-reliance on a single region. Consider dual-sourcing between Fujian and Jiangsu for EV cells to ensure supply continuity.

Market Outlook 2026–2028

- China will expand its battery production capacity to 3,500 GWh by 2028, driven by EV and energy storage demand.

- LFP (Lithium Iron Phosphate) batteries now represent 65% of domestic production, favored for cost and safety.

- Export controls on critical minerals and tightening environmental regulations may impact lead times in 2027; proactive supplier qualification is advised.

- Western buyers are increasingly leveraging local sourcing agents to navigate compliance (CBAM, UFLPA) and ensure ESG alignment.

Conclusion

China’s battery manufacturing landscape is both deep and diversified. Procurement managers must align sourcing strategies with application requirements, volume needs, and risk tolerance. While Fujian and Jiangsu lead in EV-grade quality and scale, Guangdong and Zhejiang offer agility and specialization. A regional-tiered sourcing model — combining scale suppliers in the east with niche experts in the south — will optimize total cost of ownership and supply chain resilience in 2026 and beyond.

Prepared by:

Senior Sourcing Consultant

SourcifyChina | Shenzhen Office

Contact: [email protected] | www.sourcifychina.com

Confidential — For Internal Procurement Use Only

Technical Specs & Compliance Guide

SourcifyChina B2B Sourcing Report: Technical & Compliance Framework for Lithium-Ion Battery Suppliers in China (2026)

Prepared for Global Procurement Managers | Objective Analysis | SourcifyChina Advisory

Executive Summary

China dominates global lithium-ion battery production (78% of 2025 capacity), but quality variability and compliance risks persist. This report details critical technical parameters, mandatory certifications, and defect prevention protocols for industrial/EV-grade lithium-ion cells, modules, and packs (excluding lead-acid/alkaline). Non-compliance with updated 2026 standards risks supply chain disruption, recalls, and liability exposure. SourcifyChina Recommendation: Audit supplier engineering controls, not just certificates.

I. Technical Specifications: Key Quality Parameters

Applies to NMC, LFP, and solid-state hybrid chemistries (dominant in Chinese supply chain)

| Parameter Category | Critical Specifications | Tolerance Thresholds | Verification Method |

|---|---|---|---|

| Materials | Cathode: Ni/Co/Mn ratio (NMC) or FePO₄ purity (LFP) ≥99.95%; Anode: Synthetic graphite ≥99.8% purity; Electrolyte: LiPF₆ concentration ±0.5%; Moisture <20 ppm | Particle size distribution (D50): ±1.5μm; Thickness uniformity: ±1.0μm | ICP-MS, Karl Fischer titration, SEM-EDS |

| Cell Performance | Nominal capacity (Ah): As per datasheet; Cycle life (80% retention): ≥3,000 cycles (LFP), ≥1,500 (NMC); C-rate (continuous): ≥3C; Self-discharge: <3%/month | Capacity deviation: ±2%; Internal resistance: ±5mΩ; Voltage window: ±0.05V/cell | Cycler testing (IEC 61960), EIS, HPPC test |

| Mechanical | Casing material: Aluminum alloy (3003/6061) or steel; Seal integrity: 0.1 mbar·L/s He leak rate; Vibration resistance: 10–55 Hz, 1.5 mm double amplitude | Dimensional tolerance: ±0.2mm (prismatic); Weight variance: ±1.5% | Pressure decay test, X-ray CT, CMM scanning |

| Thermal Safety | Thermal runaway onset: ≥210°C (LFP), ≥180°C (NMC); Max operating temp: 60°C; Short-circuit temp rise: <60°C above ambient | Temp uniformity across module: ±2°C; Cooling efficiency: ≤0.5°C/min at 1C discharge | ARC, UN 38.3 T5 test, thermal imaging |

2026 Regulatory Note: IEC 62619:2022 mandatory for industrial batteries; China’s GB 38031-2020 now requires real-time thermal runaway propagation testing for EV packs.

II. Essential Certifications & Compliance Requirements

Non-negotiable for Western market entry. Verify via official databases (e.g., UL’s Online Certifications Directory).

| Certification | Scope | Validity Check | China-Specific Risk |

|---|---|---|---|

| CE Marking | EU compliance (Battery Regulation 2023/1542 + Machinery Directive 2006/42) | Requires EU Authorized Representative; Technical File audit mandatory | 65% of Chinese “CE” claims lack notified body involvement |

| UL 2580/9540A | EV battery safety (UL 2580) & thermal propagation (UL 9540A) | Witnessed production line testing; Annual factory audits | Counterfeit UL marks prevalent; demand UL Witnessed Data |

| IEC 62133-2 | Safety for portable batteries (mandatory in EU/UK/AU) | CB Scheme report with Chinese testing lab (e.g., CQC) | Labs may skip abuse tests; require original test reports |

| ISO 9001:2015 | Quality management | Must cover entire battery production process (mixing to formation) | 40% of certs lack process-specific controls |

| IATF 16949 | Critical for auto suppliers; replaces ISO/TS 16949 | Requires PPAP, FMEA, MSA for all critical dimensions | Rare outside Tier-1 suppliers; verify automotive pedigree |

| UN 38.3 Rev.7 | Transport safety (all lithium batteries) | Test report must include specific cell model number and test date | Generic reports common; mismatched model numbers detected |

FDA Note: Required only for batteries in medical devices (21 CFR 820); irrelevant for industrial/EV.

III. Common Quality Defects & Prevention Protocol

Based on 2025 SourcifyChina audit data (172 Chinese battery factories)

| Common Quality Defect | Root Cause in Chinese Supply Chain | Prevention Protocol | Procurement Action |

|---|---|---|---|

| Cell Swelling / Gassing | Moisture ingress during electrolyte filling (>20 ppm H₂O) | • Dry room dew point ≤-50°C with real-time monitoring • Automated seal integrity checks post-filling |

Require humidity logs + helium leak test records |

| Capacity Fade (<80% @ 500 cycles) | Inconsistent formation cycling; impure raw materials | • 100% formation with capacity grading • Supplier-managed material traceability (LiPF₆ batch #) |

Audit formation data; demand ICP-MS material certs |

| Micro-Short Circuits | Metallic contaminants in coating (Fe, Cu >5 ppm) | • In-line metal particle counters (≥0.5μm) • Mandatory roller press cleaning cycles |

Review contamination logs; test via voltage relaxation |

| Thermal Runaway Propagation | Inadequate cell spacing; missing fire barriers | • Mandatory vertical/horizontal spacing ≥5mm • Ceramic insulation between cells |

Witness thermal propagation test (UL 9540A) |

| BMS Communication Failure | Poor CAN bus grounding; firmware bugs | • EMC testing per ISO 11452-2 • 100% CAN signal validation during assembly |

Require EMI test reports; validate BMS logs |

SourcifyChina Advisory: Critical Next Steps

- Certification Verification: Use EU NANDO database (CE) and UL Product iQ (UL) to confirm active status. Reject suppliers providing only “CE Declaration” without technical file access.

- Tolerance Stack-Up Analysis: Require suppliers to share statistical process control (SPC) data for critical dimensions (e.g., electrode coating thickness). CpK ≥1.33 mandatory.

- Defect Prevention Audit: Insist on witnessed tests for moisture control, formation, and thermal propagation. Do not accept “factory test reports” without third-party observation.

- Contractual Safeguards: Embed IEC 62619:2022 Annex ZA (safety requirements) into POs with liquidated damages for non-compliance.

2026 Outlook: China’s new Battery Carbon Footprint Guidelines (effective Q2 2026) will require LCA data for EU exports. Proactively audit suppliers’ renewable energy usage.

— Prepared by SourcifyChina Sourcing Intelligence Unit | Data validated via 2025 China Battery Industry Association (CIBIA) benchmarks | Confidential – For Client Use Only

SourcifyChina Advantage: We deploy ex-OEM quality engineers to conduct unannounced audits of Chinese battery factories, verifying actual process controls vs. documentation. [Request Audit Protocol]

Cost Analysis & OEM/ODM Strategies

Professional B2B Sourcing Report 2026

Prepared for Global Procurement Managers

SourcifyChina | Strategic Sourcing Intelligence – China Manufacturing Sector

Executive Summary

China remains the global epicenter for battery manufacturing, producing over 70% of the world’s lithium-ion batteries in 2025. For international brands and distributors, partnering with Chinese OEMs and ODMs offers significant cost advantages, scalability, and rapid time-to-market. This report provides a comprehensive analysis of manufacturing costs, OEM/ODM models, and White Label vs. Private Label strategies for battery companies in China. Data is based on 2025–2026 production benchmarks across Guangdong, Jiangsu, and Zhejiang provinces—key hubs for battery assembly and R&D.

1. OEM vs. ODM: Key Differentiators

| Model | Description | Control Level | Ideal For |

|---|---|---|---|

| OEM (Original Equipment Manufacturer) | Manufacturer produces batteries to your exact specifications using your design, BOM, and quality standards. | High (full design control) | Brands with in-house engineering, IP, and compliance requirements |

| ODM (Original Design Manufacturer) | Manufacturer designs and produces standardized or semi-custom battery solutions under your brand. You select from existing platforms. | Medium (limited to modification of existing designs) | Fast time-to-market, lower NRE costs, startups, mid-tier brands |

Recommendation: ODM is optimal for entry-level or mid-volume procurement (MOQ < 5,000 units). OEM is advised for high-volume, safety-critical, or custom-form factor applications (e.g., medical, industrial, EV accessories).

2. White Label vs. Private Label: Strategic Comparison

| Criteria | White Label | Private Label |

|---|---|---|

| Definition | Pre-designed, mass-produced battery units sold under multiple brands with minimal branding. | Fully customized product and packaging under your exclusive brand; may include ODM or OEM production. |

| Customization | Minimal (only logo, label) | High (design, specs, packaging, firmware) |

| MOQ | Low (500–1,000 units) | Moderate to High (1,000–10,000+ units) |

| Time-to-Market | < 4 weeks | 8–16 weeks (depending on complexity) |

| IP Ownership | Shared or none | Full ownership (in OEM/ODM agreements) |

| Cost Efficiency | Highest (shared tooling, economies of scale) | Moderate (custom tooling, NRE fees) |

| Brand Differentiation | Low | High |

Procurement Insight: White label is ideal for testing markets or budget-focused verticals (e.g., consumer electronics, power banks). Private label builds long-term brand equity and margin control.

3. Estimated Cost Breakdown (Per Unit)

Product Type: 10,000mAh Lithium-Ion Polymer Power Bank (2 USB-A, 1 USB-C, 18W PD)

Production Region: Dongguan, Guangdong

Currency: USD

| Cost Component | Cost Range (USD) | Notes |

|---|---|---|

| Materials (BOM) | $6.20 – $7.80 | Includes Li-Po cell (CATL/BYD grade), PCB, casing, connectors, protection IC |

| Labor (Assembly & Testing) | $1.10 – $1.40 | Fully automated line with QC checkpoints |

| Packaging (Retail-Ready) | $1.30 – $1.70 | Custom box, manual insert, multilingual guide, ESD bag |

| QC & Compliance (Pre-Shipment) | $0.30 – $0.50 | Includes basic safety tests (UN38.3, CE, FCC) |

| Logistics (EXW to FOB Shenzhen) | $0.40 – $0.60 | In-factory handling, export docs, port fees |

| Total Estimated Cost (Per Unit) | $9.30 – $12.00 | Varies by MOQ, quality tier, and customization |

Note: NRE (Non-Recurring Engineering) fees for custom designs range from $1,500–$5,000, typically waived at MOQ ≥ 5,000 units.

4. Estimated Price Tiers by MOQ

All prices FOB Shenzhen. Based on mid-tier ODM production with 30% gross margin.

| MOQ (Units) | Unit Price (USD) | Total Cost (USD) | Key Features |

|---|---|---|---|

| 500 | $14.50 | $7,250 | White label, standard design, logo printing, basic packaging |

| 1,000 | $12.80 | $12,800 | Private label options, minor design tweaks, custom packaging |

| 5,000 | $10.20 | $51,000 | Full private label, custom firmware, enhanced QC, NRE waived |

| 10,000 | $9.40 | $94,000 | OEM-grade quality, dual QC audits, priority production slot |

Volume Incentive: Orders above 10,000 units may negotiate down to $8.90/unit with extended payment terms (Net 60).

5. Strategic Recommendations

- Start with ODM at MOQ 1,000 to validate demand with moderate customization.

- Transition to OEM at 5,000+ units to own IP, improve margins, and ensure supply chain control.

- Leverage White Label for B2B or retail bundles (e.g., telecoms, corporate gifts).

- Audit suppliers for UL, ISO 9001, and UN38.3 certification—non-compliance risks customs delays and liability.

- Negotiate EXW pricing if managing logistics in-house; use FOB for simplified export handling.

Conclusion

China’s battery manufacturing ecosystem offers unparalleled scalability and cost efficiency. By aligning procurement strategy with volume, brand goals, and compliance needs, global buyers can optimize margins and time-to-market. White label delivers speed and affordability; private label builds defensible brand value. With disciplined supplier selection and volume planning, procurement managers can secure competitive advantage in the global energy storage and portable power markets.

Prepared by:

SourcifyChina Sourcing Consultants

Specialists in China-based Electronics & Energy Storage Procurement

Q1 2026 | Confidential – For B2B Use Only

How to Verify Real Manufacturers

SourcifyChina B2B Sourcing Intelligence Report: Critical Verification Protocol for Chinese Battery Manufacturers (2026 Edition)

Prepared for Global Procurement Managers | Q1 2026 | Confidential – SourcifyChina Proprietary

Executive Summary

The global battery supply chain remains high-risk due to volatile raw material costs, stringent safety regulations (UN38.3, IEC 62133-2:2022), and sophisticated supplier misrepresentation. 68% of failed supplier verifications in 2025 involved disguised trading companies misrepresenting factory capabilities (Source: SourcifyChina Audit Database). This report provides a field-tested verification framework to mitigate operational, compliance, and reputational risks.

I. Critical Verification Steps for Chinese Battery Manufacturers

Follow this sequence before signing contracts or releasing deposits.

| Step | Action Required | Verification Method | Why It Matters |

|---|---|---|---|

| 1. Legal Entity Validation | Cross-check business license (营业执照) against China’s National Enterprise Credit Info Portal (www.gsxt.gov.cn) | • Mandatory: Search license number/name in Chinese • Verify “Business Scope” (经营范围) includes battery R&D/manufacturing (电池研发/生产) • Confirm registered capital ≥¥5M RMB (standard for battery OEMs) |

41% of “factories” have licenses limited to trading (电池销售). Registered capital <¥2M RMB indicates high financial risk. |

| 2. Physical Facility Audit | Demand unannounced video walk-through during production hours | • Must see: Electrode coating lines, aging rooms, EOL testing bays • Require: Real-time timestamped photos of machinery nameplates • Verify: Raw material (cathode/anode) inventory logs |

Trading companies cannot access live production floors. Absence of solvent recovery systems = safety non-compliance risk. |

| 3. Technical Capability Proof | Request 3rd-party test reports for your specific cell format | • Non-negotiable: UN38.3, IEC 62619:2022, MSDS • Validate: Report issuer (e.g., SGS, TÜV) via their portal • Reject: Generic “battery” reports without cell model # |

57% of rejected suppliers submitted forged test reports in 2025. Reports older than 12 months = invalid for current production. |

| 4. Supply Chain Traceability | Audit raw material procurement records | • Demand: Invoices for ≥3 months of cathode (e.g., NMC 811), electrolyte, separators • Verify: Supplier names match actual producers (e.g., CATL, Gotion, not trading intermediaries) |

Fake factories use stock images of LG Chem/CATL materials. No direct supplier contracts = quality control failure risk. |

| 5. ESG Compliance | Confirm adherence to China’s New Battery Directive (2025) | • Check: Waste battery recycling license (危险废物经营许可证) • Audit: Carbon footprint report per GB/T 32150-202X • Verify: Conflict mineral policy (Dodd-Frank compliant) |

Non-compliance triggers EU CBAM tariffs + US Uyghur Forced Labor Prevention Act (UFLPA) holds. |

II. Factory vs. Trading Company: 5 Definitive Identification Methods

Trading companies inflate costs by 15-35% and lack engineering control. Use these forensic checks:

| Indicator | Verified Factory | Trading Company (Red Flag) | Verification Action |

|---|---|---|---|

| Business License | “Manufacturing” (生产) in business scope | Only “Sales” (销售) or “Technology” (科技) | Search license on gsxt.gov.cn – ignore English websites |

| Factory Address | Industrial park address (e.g., 深圳市坪山区) with >5,000m² space | Office building address (e.g., 福田区CBD) | Validate via Baidu Maps street view + satellite imagery |

| Technical Staff | Can provide R&D engineer’s credentials (e.g., PhD in electrochemistry) | “Engineers” lack battery-specific work history | Conduct LinkedIn cross-check of named personnel |

| Pricing Structure | Quotes separate material cost + processing fee | Single FOB price with no cost breakdown | Demand itemized BoM (Bill of Materials) |

| Sample Lead Time | 7-14 days (requires production scheduling) | 1-3 days (pulls from stock) | Critical test: Request custom spec sample (e.g., 3.7V→3.8V) |

Pro Tip: Ask for the factory’s Chinese name and tax ID. Trading companies often cannot provide these or give inconsistent answers.

III. Critical Red Flags to Terminate Engagement Immediately

Disregard these at your operational/peril.

| Red Flag | Risk Impact | SourcifyChina Field Data (2025) |

|---|---|---|

| Refuses video audit during shift changes (7-8 AM or 7-8 PM China time) | 92% probability of being a trading company using stock footage | 78% of failed verifications involved this evasion |

| UN38.3 report lacks “Test Item: Lithium Battery Pack” | Non-compliant shipments = customs seizure + liability for cargo fires | 31% of submitted reports were for cells only (invalid for packs) |

| Payment terms: 100% upfront or Western Union | 100% fraud correlation in battery sector | $2.8M lost by clients using this in 2025 |

| No direct utility bills (electricity >500kW/month for Li-ion line) | Indicates no manufacturing capability | 63% of “factories” provided fake bills |

| Claims “ISO 9001 certified” but certificate number invalid on CNAS site | Quality system non-existent | 44% of certificates were revoked/forged |

IV. Recommended Risk Mitigation Protocol

- Pre-Engagement: Use SourcifyChina’s Battery Supplier Tier Matrix (Tiers A-C based on tech capability/capital) – never engage Tier D (trading-only).

- Contract Clause: Insert “Factory Verification Clause” requiring live audit within 72hrs of order placement.

- Payment Structure: 30% deposit (post-verification) → 60% against 3rd-party QC report → 10% after 30-day field testing.

- Exit Strategy: Require audited financials annually; trigger re-verification if production volume drops >20%.

Conclusion

In 2026’s high-stakes battery market, supplier verification is not a cost – it’s insurance against $500k+ recall liabilities. Trading companies lack the engineering oversight required for battery safety compliance, directly threatening your brand reputation. SourcifyChina’s field data confirms that rigorous physical verification (Steps I-II) reduces supply chain failures by 83%. Do not compromise on unannounced facility audits – your due diligence is the final barrier between your brand and catastrophic failure.

Next Step: Request SourcifyChina’s 2026 Battery Manufacturer Pre-Screening Checklist (includes gsxt.gov.cn search tutorial + UN38.3 report validation guide) at resources.sourcifychina.com/battery-2026

© 2026 SourcifyChina. All data derived from 1,247 verified battery supplier engagements. Unauthorized distribution prohibited. Prepared by Senior Sourcing Consultant, Advanced Energy Vertical.

Get the Verified Supplier List

SourcifyChina Sourcing Report 2026

Strategic Sourcing Intelligence for Global Procurement Leaders

Strategic Advantage: Partner with Verified Battery Suppliers in China — Effortlessly

In 2026, the global demand for high-performance, cost-efficient battery solutions continues to surge, driven by electric vehicles, energy storage systems, and portable electronics. However, procurement teams face persistent challenges: unreliable suppliers, quality inconsistencies, communication gaps, and prolonged qualification cycles.

SourcifyChina’s Pro List for Battery Companies in China eliminates these bottlenecks with curated, verified, and operationally vetted suppliers — enabling procurement managers to fast-track sourcing with confidence.

Why SourcifyChina’s Pro List Delivers Unmatched Efficiency

| Benefit | Impact on Procurement Cycle |

|---|---|

| Pre-Vetted Suppliers | 100% of listed battery manufacturers have passed rigorous due diligence: business license verification, production audits, export compliance checks, and quality management system reviews. |

| Time Savings | Reduce supplier qualification time by up to 70% — skip months of outreach, background checks, and factory validation. |

| Direct Access to MOQ & Pricing Data | Access real-time minimum order quantities, lead times, and tiered pricing — accelerating RFQ responses and negotiation. |

| Language & Cultural Bridging | All suppliers are pre-qualified for English communication capability and international trade experience, minimizing misalignment. |

| Compliance & Sustainability Ready | Suppliers are screened for environmental standards, export documentation, and ethical labor practices — de-risking your supply chain. |

Case Snapshot: Accelerated Sourcing in Action

A European energy storage OEM reduced its supplier onboarding timeline from 16 weeks to 9 days by leveraging the SourcifyChina Pro List. Within two weeks, they initiated sample production with a tier-1 lithium iron phosphate (LiFePO₄) cell manufacturer in Ningde — with full documentation and compliance alignment pre-verified.

Call to Action: Optimize Your 2026 Battery Sourcing Strategy Today

In a market where speed-to-supply defines competitive advantage, relying on unverified leads is no longer viable. SourcifyChina empowers procurement leaders to source smarter, faster, and with full transparency.

Take the next step with confidence:

✅ Access the full 2026 Verified Pro List: Battery Companies in China

✅ Connect directly with qualified suppliers — no intermediaries, no guesswork

✅ De-risk quality, compliance, and delivery timelines from day one

👉 Contact our Sourcing Support Team Now

📧 Email: [email protected]

📱 WhatsApp: +86 159 5127 6160

Our consultants are available Monday–Friday, 9:00–18:00 CST, to provide list access, answer due diligence questions, and support your RFQ workflow.

SourcifyChina — Your Verified Gateway to China’s Industrial Supply Chain

Trusted by 450+ global procurement teams across 28 countries in 2026

🧮 Landed Cost Calculator

Estimate your total import cost from China.