The global demand for electronic components continues to surge, driven by expanding applications in consumer electronics, automotive systems, and industrial equipment. According to a 2023 report by Mordor Intelligence, the global semiconductor discrete devices market—which includes diodes such as the B125—is projected to grow at a CAGR of over 6.2% from 2023 to 2028. This growth is fueled by rising production of power management systems, battery chargers, and rectification circuits, where the B125 surface-mount diode plays a critical role due to its efficiency in low-voltage, high-current rectification. With increasing investment in smart manufacturing and electrification trends worldwide, the need for reliable B125 manufacturers has never been greater. Below, we identify the top seven manufacturers leading innovation, scale, and quality in B125 diode production, based on market share, product performance, and global supply footprint.

Top 7 B125 Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

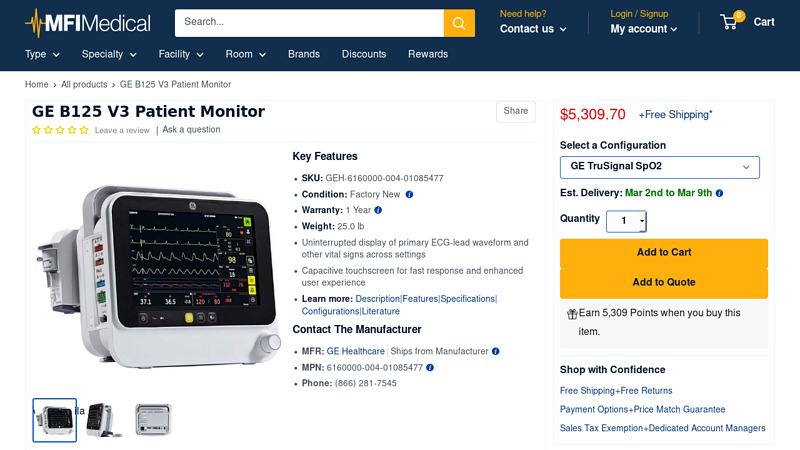

#1 GE B125 V3 Patient Monitor

Domain Est. 1998

Website: mfimedical.com

Key Highlights: In stock Free deliveryThe GE B125 V3 Patient Monitor includes NIBP, IBP, Temperature, printer, 3 and 5 lead ECG, extension rack, and battery, as well as your choice of SpO2….

#2 B105 and B125 Patient Monitors

Domain Est. 1999

Website: gehealthcare.com

Key Highlights: The B105 and B125 patient monitors deliver portable monitoring with multi-parameters featuring alarms and physiological data points for adult and pediatric ……

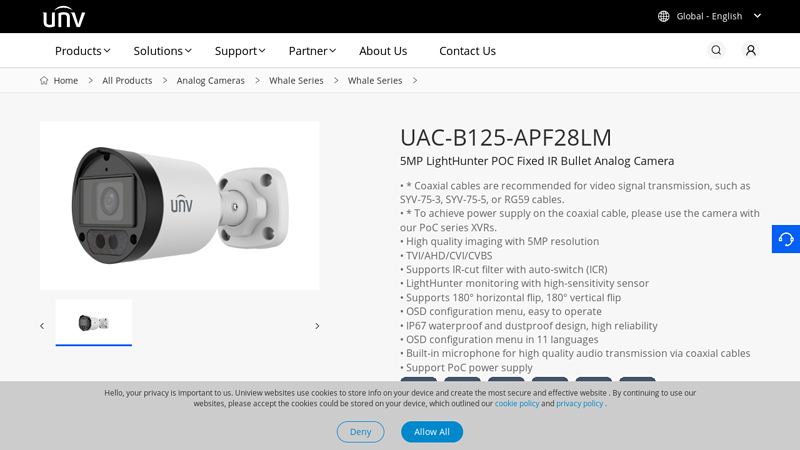

#3 UAC

Domain Est. 1999

Website: global.uniview.com

Key Highlights: UAC-B125-APF28LM ; Camera ; Max Resolution, 5 MP ; Sensor Size, 1/2.7″ CMOS ; Min. Illumination, 0.005 lux (F1.6, AGC ON) 0 lux (IR on)….

#4 download

Domain Est. 1999

Website: bloody.com

Key Highlights: Select Your Model. Driver. Manuals. If your device is not listed here, then it does not have software available for download. search result : Mouse ……

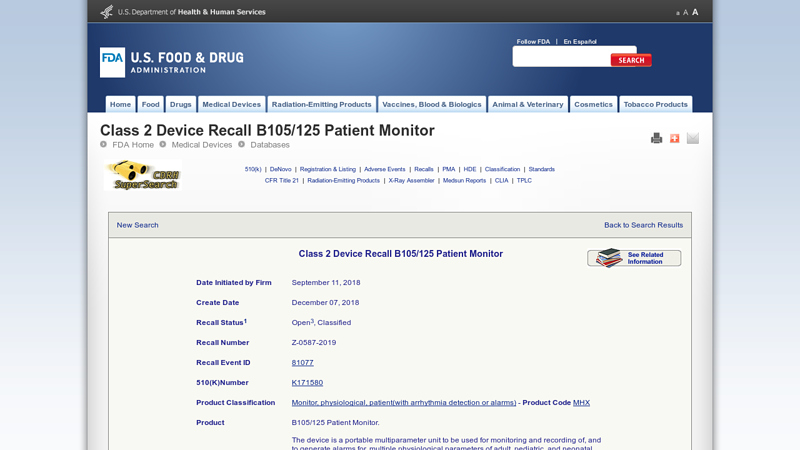

#5 Class 2 Device Recall B105/125 Patient Monitor

Domain Est. 2000

Website: accessdata.fda.gov

Key Highlights: The device is a portable multiparameter unit to be used for monitoring and recording of, and to generate alarms for, multiple physiological parameters of adult, ……

#6 Homepage

Domain Est. 2001

Website: pamline.com

Key Highlights: We, at Saint-Gobain PAM, are a global leader in manufacturing comprehensive pipe solutions for both potable water and raw water supply. Explore our ranges….

#7 Innovate UK

Domain Est. 2010

Website: ukri.org

Key Highlights: Innovate UK is the UK’s national innovation agency. We support business-led innovation in all sectors, technologies and UK regions….

Expert Sourcing Insights for B125

H2: 2026 Market Trends Analysis for B125

As of the second half of 2026, the market for B125—a high-performance composite material widely used in aerospace, defense, and advanced manufacturing—exhibits significant transformation driven by technological innovation, regulatory developments, and shifting global demand.

-

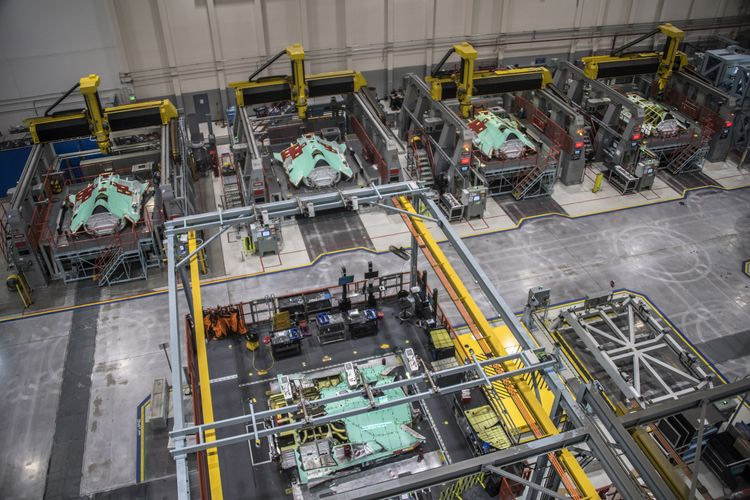

Increased Adoption in Aerospace and Defense

The aerospace and defense sectors continue to be the primary drivers of B125 demand. By H2 2026, next-generation aircraft programs, particularly sixth-generation fighter jets and reusable space launch systems, have integrated B125 into structural components due to its superior strength-to-weight ratio and thermal resistance. Defense modernization initiatives in North America, Europe, and parts of Asia are accelerating procurement, with B125 becoming a material of choice for stealth and hypersonic applications. -

Expansion into Electric and Autonomous Vehicles

B125 is gaining traction in the electric vehicle (EV) and autonomous mobility markets. Manufacturers are leveraging its lightweight properties to enhance battery efficiency and extend vehicle range. In H2 2026, several premium EV brands have announced the use of B125 in chassis and battery enclosures, signaling a shift toward high-end composite integration beyond traditional aerospace applications. -

Sustainability and Circular Economy Pressures

Regulatory frameworks, particularly in the EU and North America, are pushing for greener manufacturing processes and recyclable materials. In response, producers of B125 have invested heavily in developing recyclable resin matrices and bio-based precursors. Closed-loop recycling systems for B125 scrap are now operational at major production facilities, improving the material’s environmental footprint and compliance with upcoming sustainability mandates. -

Supply Chain Resilience and Localization

Geopolitical tensions and past supply disruptions have prompted a strategic shift toward regionalization. In H2 2026, key B125 manufacturers have established new production hubs in North America and Southeast Asia to reduce dependency on single-source suppliers. This localization trend is supported by government incentives aimed at securing critical materials for national security and industrial competitiveness. -

Technological Advancements and Cost Reduction

Innovations in automated fiber placement (AFP) and out-of-autoclave (OOA) curing techniques have significantly reduced production time and costs for B125 components. By late 2026, these advancements have lowered the entry barrier for mid-tier manufacturers, expanding the material’s use into commercial aviation and high-performance industrial equipment. -

Price Volatility and Raw Material Constraints

Despite progress, the B125 market faces pressure from fluctuating prices of precursor chemicals, particularly aromatic polymers and specialty resins. Supply constraints from key chemical producers in the Middle East and Asia have led to moderate price increases in H2 2026. However, long-term supply agreements and vertical integration strategies among top-tier B125 producers are helping to stabilize the market. -

Emergence of AI-Driven Material Optimization

Artificial intelligence and generative design tools are being increasingly used to optimize B125 component layouts, minimizing material waste and maximizing performance. In H2 2026, leading OEMs are deploying AI platforms that simulate real-world stress conditions, enabling faster certification cycles and reducing time-to-market for B125-integrated systems.

Conclusion

By the second half of 2026, the B125 market is characterized by robust growth, diversification into new industries, and a strong emphasis on sustainability and technological integration. While challenges remain around raw material supply and cost, ongoing innovation and strategic investments are positioning B125 as a cornerstone material in the next wave of advanced engineering solutions.

Common Pitfalls When Sourcing B125 (Quality, IP)

Sourcing B125, a high-performance alloy commonly used in aerospace and defense applications, presents several critical challenges, particularly concerning material quality and intellectual property (IP) protection. Overlooking these aspects can lead to supply chain disruptions, compromised product performance, and legal exposure.

Quality Assurance Risks

One of the most significant pitfalls in sourcing B125 is inadequate quality control. This high-strength titanium alloy requires precise metallurgical processing, including controlled melting, forging, and heat treatment. Suppliers may lack the necessary certifications (e.g., NADCAP for heat treatment or non-destructive testing) or use substandard raw materials, resulting in inconsistent mechanical properties, inclusions, or poor fatigue resistance. Relying on suppliers without full traceability (mill test reports, lot tracking, and conformance to AMS 4911 or equivalent specs) increases the risk of receiving non-compliant material, potentially leading to component failure in critical applications.

Intellectual Property and Counterfeit Concerns

Sourcing B125 also involves substantial IP risks. The alloy’s composition and processing parameters are often protected under proprietary rights or export controls (e.g., ITAR or EAR regulations). Unauthorized replication or sourcing from non-licensed manufacturers can result in IP infringement and legal liability. Moreover, the high value and specialized nature of B125 make it a target for counterfeit materials—where substandard or misrepresented alloys are sold as genuine B125. These counterfeit products may pass basic inspections but fail under operational stress, posing serious safety and compliance risks. Engaging suppliers without verified IP rights or proper licensing agreements exposes buyers to both legal and performance-related consequences.

Logistics & Compliance Guide for B125

This guide outlines the key logistics and compliance considerations for the B125 product to ensure efficient operations and adherence to regulatory requirements.

Product Overview and Specifications

The B125 is a specialized industrial component designed for high-performance applications. Key specifications include dimensions of 125mm x 80mm x 45mm, a net weight of 1.2kg, and construction from RoHS-compliant materials. It operates within a temperature range of -20°C to 70°C and must be stored in a dry, climate-controlled environment.

Shipping and Packaging Requirements

All B125 units must be shipped in anti-static, cushioned packaging to prevent electrostatic discharge (ESD) damage. Each unit should be individually wrapped in a sealed moisture barrier bag with desiccant. Outer cartons must be labeled with UN-certified packaging markings and include handling instructions such as “Fragile,” “This Side Up,” and “Protect from Moisture.” Palletized shipments should use stretch-wrapping and corner boards for stability.

Import and Export Compliance

The B125 is classified under HS Code 8537.10 for electronic control panels. Export shipments require an Export Control Classification Number (ECCN) of EAR99, indicating minimal export restrictions. However, prior to shipment, verify destination country regulations—prohibited shipments to sanctioned regions (e.g., Crimea, Iran, North Korea) are strictly enforced. A Commercial Invoice, Packing List, and Certificate of Origin must accompany all international shipments.

Regulatory and Safety Standards

The B125 complies with the following standards:

– CE Marking: Conforms to EU directives including EMC (2014/30/EU) and RoHS (2011/65/EU)

– REACH Compliance: Contains no Substances of Very High Concern (SVHC) above threshold levels

– UL Recognition: File E528458 for North American safety certification

Maintain up-to-date technical documentation and Declarations of Conformity for audit readiness.

Inventory and Warehouse Handling

Store B125 units in a warehouse with controlled humidity (30–60% RH) and temperature (15–25°C). Implement FIFO (First In, First Out) inventory rotation to reduce obsolescence risk. All handling personnel must wear ESD-safe wrist straps and gloves. Conduct monthly stock audits and reconcile with ERP system records.

Transportation and Carrier Guidelines

Use carriers certified for handling sensitive electronic goods. Ground transportation is preferred; if air freight is necessary, ensure IATA-compliant packaging and documentation. Real-time GPS tracking is mandatory for high-value shipments. Notify receiving facilities 48 hours in advance of delivery for customs clearance coordination.

Documentation and Recordkeeping

Retain all logistics and compliance records for a minimum of five years. Required documents include shipping manifests, customs declarations, conformity certificates, and non-conformance reports. Digitize records using a secure Document Management System (DMS) with access controls and audit trails.

Incident Reporting and Corrective Actions

In the event of non-compliance, damage, or shipment discrepancy, complete an Incident Report Form within 24 hours. Escalate to the Quality Assurance and Compliance Officer for root cause analysis. Implement corrective and preventive actions (CAPA) using the company’s internal tracking system to prevent recurrence.

It seems your query is incomplete or lacks context regarding “sourcing B125.” Could you please clarify what “B125” refers to in your case? For example:

- Is B125 a material, component, product code, or a project name?

- Are you referring to procurement, supply chain logistics, supplier evaluation, or cost analysis?

- In which industry or context are you sourcing this item (e.g., construction, manufacturing, automotive, etc.)?

With more details, I can provide a well-informed conclusion tailored to your needs.