The global axial blower market is experiencing robust expansion, driven by rising demand across HVAC, industrial ventilation, and wastewater treatment sectors. According to Grand View Research, the global industrial blower market size was valued at USD 5.8 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 5.2% from 2023 to 2030. Similarly, Mordor Intelligence forecasts a CAGR of approximately 4.8% over the next five years, highlighting increasing investments in energy efficiency and process optimization as key growth catalysts. Amid this upward trend, technological advancements and stringent environmental regulations are pushing leading manufacturers to innovate in design, materials, and energy performance. As competition intensifies, a select group of nine manufacturers has emerged at the forefront, demonstrating consistent engineering excellence, global reach, and strong market presence. These companies are shaping the future of airflow solutions across critical industries worldwide.

Top 9 Axial Blower Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Cofimco

Domain Est. 1997

Website: cofimco.com

Key Highlights: Cofimco is the world’s leading manufacturer of extruded aluminum fans, and is one of the leaders in the fiberglass fan field….

#2 Orion Fans

Domain Est. 1997

Website: orionfans.com

Key Highlights: Orion Fans is a global manufacturer and JIT supplier of AC fans, DC fans, Fan trays, blowers, motorized impellers, specialty fans, and fan accessories….

#3 Axial Fans

Domain Est. 1997

Website: ia.omron.com

Key Highlights: Axial Fans. OMRON’s complete lineup includes water-resistant AC Axial Fans with superior resistibility to water and dirt, and General-purpose AC Axial Fans….

#4 Axial Fans » Industrial Fan Specialists » ACI Inc [US]

Domain Est. 2003

Website: aircontrolindustries.com

Key Highlights: Our range of axial fans offer flow rates of up to 75000m3/hr (44143CFM) and static pressures up to 3In.Swg (75mmWG). Each range has a choice of finishes and ……

#5 Inline Axial Fans

Domain Est. 1996

Website: nyb.com

Key Highlights: Inline Axial Fan units have a straight-through airflow design allowing for compact size for high volume, low-pressure applications….

#6 Axial Fans – Boyd

Domain Est. 1996

Website: boydcorp.com

Key Highlights: Maximize Air Cooling of Heat Exchangers and Heat Sinks with Axial Fans designed and fabricated by Boyd….

#7 Axial fans

Domain Est. 1998

Website: ebmpapst.com

Key Highlights: Axial fans from ebm-papst move air for heat or cold exchange. They impress with their low installation depth, low noise level and excellent efficiency….

#8 Axial Fans

Domain Est. 1998

Website: cincinnatifan.com

Key Highlights: Cincinnati Fan provides quality axial fans, tube fans, and exhaust fans at competitive prices, backed by dependable service….

#9 Fans & Blowers

Domain Est. 2021

Website: fairbanksmorsedefense.com

Key Highlights: Durable, high-efficiency air movement solutions for demanding marine environments. Browse FMD’s trusted range of fans and blowers….

Expert Sourcing Insights for Axial Blower

H2: 2026 Market Trends for Axial Blower

The global axial blower market is poised for significant transformation by 2026, driven by technological advancements, increasing industrial automation, and growing demand for energy-efficient ventilation systems. Several key trends are expected to shape the market landscape in the coming years.

-

Rising Demand in HVAC and Industrial Applications

Axial blowers are integral components in heating, ventilation, and air conditioning (HVAC) systems, as well as in industrial processes such as cooling, exhaust, and material handling. With urbanization and infrastructure development accelerating—especially in Asia-Pacific and Latin America—demand for efficient HVAC solutions is rising. This directly fuels the need for high-performance axial blowers, particularly in commercial buildings, data centers, and manufacturing facilities. -

Shift Toward Energy Efficiency and Green Technologies

Regulatory pressures and sustainability goals are pushing manufacturers to adopt energy-efficient equipment. In 2026, axial blower designs are increasingly incorporating aerodynamic improvements, variable speed drives (VSDs), and smart motor controls to reduce power consumption. Compliance with international energy standards such as IE4 and IE5 will become a competitive advantage, especially in Europe and North America. -

Integration of Smart and IoT-Enabled Systems

The Industrial Internet of Things (IIoT) is transforming traditional ventilation systems. By 2026, smart axial blowers equipped with sensors and connectivity features will allow for real-time monitoring, predictive maintenance, and remote control. This trend is particularly strong in smart factories and intelligent buildings, where operational efficiency and uptime are critical. -

Growth in Renewable Energy and Waste Management Sectors

Axial blowers are seeing expanded applications in renewable energy installations such as biogas plants and wastewater treatment facilities. These sectors require reliable air movement systems for aeration and gas handling. As governments invest in circular economy initiatives and clean energy, demand for specialized axial blowers in environmental engineering applications is expected to grow. -

Regional Market Dynamics

Asia-Pacific is projected to dominate the axial blower market by 2026, led by China, India, and Southeast Asian countries. Rapid industrialization, increasing construction activities, and government support for clean air initiatives are key growth drivers. Meanwhile, North America and Europe will focus on retrofitting existing systems with energy-efficient models, driven by strict environmental regulations. -

Competitive Landscape and Innovation

Market consolidation and product differentiation are underway, with leading manufacturers investing in R&D to enhance blower performance, noise reduction, and durability. Customization for specific industrial needs—such as corrosion-resistant materials for chemical plants or explosion-proof designs for mining—is becoming increasingly important.

In conclusion, the 2026 axial blower market will be characterized by a strong emphasis on efficiency, digital integration, and sustainability. Companies that innovate in smart technology and energy optimization are likely to capture significant market share amid evolving industrial and environmental demands.

Common Pitfalls When Sourcing Axial Blowers: Quality and IP Rating Issues

Sourcing axial blowers involves more than just matching airflow and pressure specifications. Critical aspects like build quality and Ingress Protection (IP) ratings are often overlooked, leading to performance issues, premature failure, and safety hazards. Here are the most common pitfalls to avoid:

1. Overlooking Build Quality and Material Selection

A low initial price tag can be deceptive if the blower is constructed with substandard materials. Cheap plastic housings, undersized motors, or poorly balanced impellers result in excessive vibration, noise, and shortened lifespans. Always verify the materials used—especially in corrosive or high-temperature environments—and request certifications or test reports to validate durability claims.

2. Misunderstanding or Misrepresenting IP Ratings

The IP (Ingress Protection) rating is crucial for ensuring the blower can withstand environmental conditions like dust, moisture, or washdowns. A common mistake is assuming a higher first digit (solid particle protection) implies protection against liquids. For example, IP54 offers limited dust resistance and splash protection but is not suitable for high-humidity or outdoor use. Selecting an inadequate IP rating—such as using IP42 in a wet environment—leads to motor failure and safety risks.

3. Ignoring Certification and Compliance Documentation

Many suppliers claim IP ratings without third-party verification. Always request official test reports from accredited laboratories (e.g., IEC 60529 certification) and ensure the rating applies to the fully assembled unit, not just the motor. Lack of documentation often indicates the rating is merely theoretical or self-declared.

4. Neglecting Application-Specific Environmental Demands

Failing to match the blower’s IP rating and build quality to the actual operating environment is a major pitfall. For instance, using a standard indoor-rated blower (IP54) in a food processing plant requiring washdowns (needing at least IP65 or IP66) will lead to rapid deterioration. Always assess ambient conditions—humidity, particulates, temperature, and exposure to chemicals—when specifying IP and material requirements.

5. Choosing Based Solely on Price or Availability

Prioritizing cost or lead time over quality and suitability often results in higher total cost of ownership due to frequent replacements, downtime, and maintenance. Investing in a properly specified, high-quality blower with the correct IP rating reduces long-term operational risks and improves system reliability.

By carefully evaluating build quality and verifying accurate, application-appropriate IP ratings with documented proof, buyers can avoid these common sourcing pitfalls and ensure reliable, efficient, and safe blower operation.

Logistics & Compliance Guide for Axial Blower

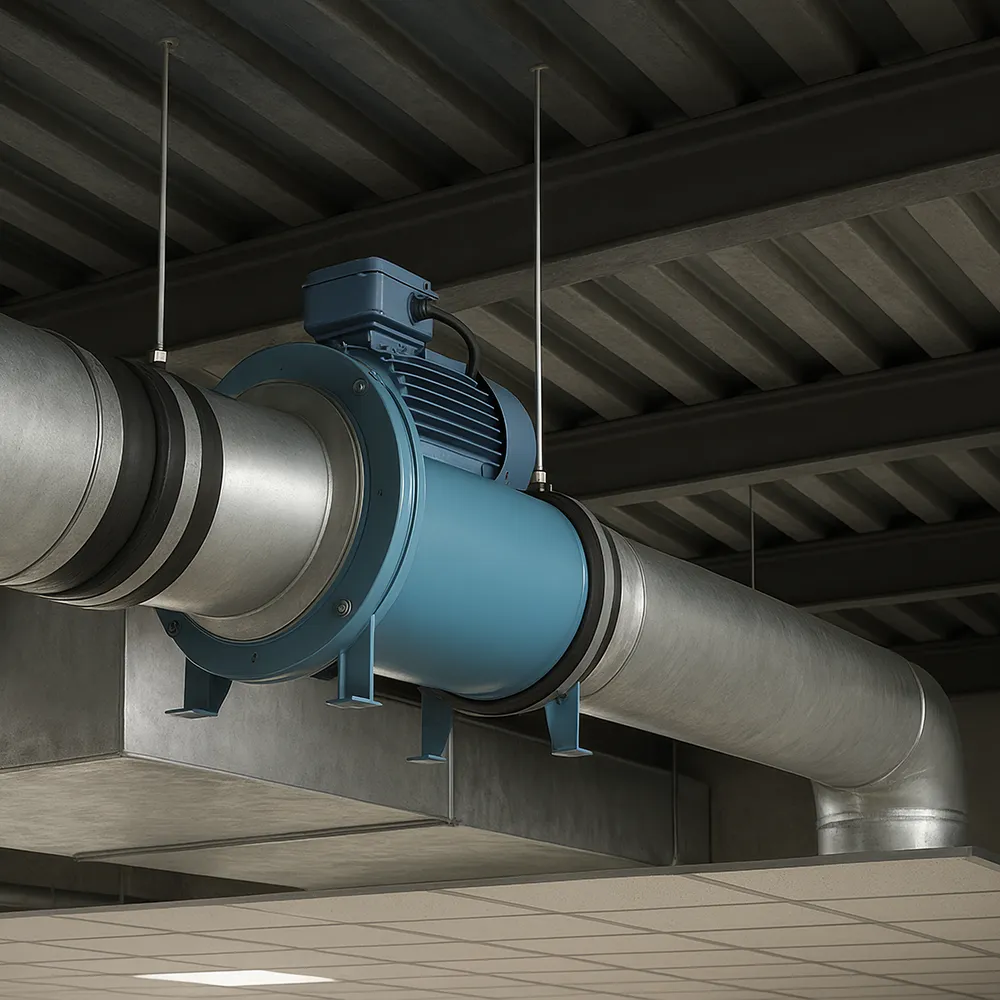

Product Overview

An axial blower is a type of fan that moves air or gas parallel to the shaft about which the blades rotate. These blowers are commonly used in HVAC systems, industrial ventilation, cooling processes, and exhaust applications. Proper logistics handling and regulatory compliance are essential to ensure safe, efficient, and legal transportation and use.

Packaging & Handling

Ensure axial blowers are securely packaged in robust, moisture-resistant materials to prevent damage during transit. Use wooden crates or heavy-duty cardboard with internal bracing to protect fan blades, motors, and housings. Clearly label packages with “Fragile,” “This Side Up,” and “Do Not Stack” indicators where applicable. Avoid exposing equipment to extreme temperatures or humidity during storage and transport.

Transportation Requirements

Ship axial blowers using carriers experienced in handling industrial machinery. For international shipments, confirm compliance with IATA (air), IMDG (sea), or ADR (road) regulations if applicable. Secure units in vehicles to prevent shifting, and use cushioning materials to absorb shocks. For oversized or heavy units, coordinate special transport arrangements and permits.

Import/Export Compliance

Verify that the axial blower meets export control classifications under applicable trade regulations (e.g., EAR in the U.S.). Check if the product contains controlled materials or technologies requiring export licenses. For international destinations, ensure compliance with local import standards, including customs documentation, certificates of origin, and conformity assessments (e.g., CE, UKCA, EAC).

Regulatory Standards & Certifications

Confirm that the axial blower complies with relevant safety and performance standards:

– CE Marking (EU): Complies with Machinery Directive 2006/42/EC and EMC Directive 2014/30/EU

– UL/CSA (North America): Meets safety standards for motors and electrical components

– RoHS & REACH (EU): Restriction of hazardous substances in electrical equipment

– ERP Directive (EU): Energy-related products efficiency requirements

Maintain technical documentation and Declaration of Conformity for audit purposes.

Electrical & Safety Compliance

Ensure motors meet voltage, frequency, and insulation class requirements for the destination market. Provide proper grounding and protection against overcurrent. Include safety warnings and installation instructions in local languages. Confirm compliance with OSHA (U.S.), WHMIS (Canada), or similar workplace safety regulations where applicable.

Documentation Requirements

Prepare and retain the following documents:

– Commercial invoice and packing list

– Bill of lading or air waybill

– Certificate of Conformity (CE, UL, etc.)

– Material Safety Data Sheet (MSDS), if applicable

– Export license (if required)

– Warranty and user manuals

Environmental & Disposal Compliance

Adhere to WEEE (Waste Electrical and Electronic Equipment) directives for end-of-life management in Europe. Provide guidance for proper recycling of motors, metals, and electronic components. Avoid disposal in regular landfill; use certified e-waste recyclers.

Quality Assurance & Traceability

Maintain batch/serial number tracking for each axial blower to support warranty claims, recalls, and compliance audits. Conduct pre-shipment inspections to verify functionality and packaging integrity.

Contact & Support

For compliance inquiries, logistics coordination, or technical support, contact:

Logistics Team: [email protected] | +1 (555) 123-4567

Compliance Officer: [email protected] | +1 (555) 123-4568

Conclusion for Sourcing Axial Blowers

In conclusion, sourcing axial blowers requires a comprehensive evaluation of technical specifications, operational requirements, environmental conditions, and long-term cost considerations. Axial blowers offer advantages such as high airflow rates, energy efficiency, and compact design, making them suitable for applications in ventilation, cooling, industrial processes, and HVAC systems.

The selection process should prioritize factors including airflow capacity (CFM), static pressure requirements, motor efficiency, noise levels, material durability, and compliance with industry standards (e.g., AMCA, CE, or UL certifications). Additionally, sourcing from reputable suppliers with a proven track record ensures product reliability, warranty support, and access to technical assistance.

Considering total cost of ownership—encompassing initial investment, energy consumption, maintenance, and lifespan—will lead to a more sustainable and cost-effective solution. Where applicable, opting for variable speed drives or smart control systems can further enhance performance and energy savings.

Ultimately, a well-informed sourcing decision, aligned with the specific application needs and future scalability, will ensure optimal system performance, improved operational efficiency, and reduced downtime. Proper due diligence in supplier evaluation and product selection is essential to achieve long-term success in implementing axial blower systems.

![Axial Fans » Industrial Fan Specialists » ACI Inc [US]](https://www.fobsourcify.com/wp-content/uploads/2026/01/axial-fans-industrial-fan-specialists-aci-inc-us-596.jpg)