The global automatic pulley system market is experiencing robust growth, driven by rising demand for efficient material handling solutions across industries such as automotive, manufacturing, and logistics. According to a report by Grand View Research, the global industrial pulley market size was valued at USD 7.2 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.3% from 2023 to 2030. This growth is fueled by increased automation, advancements in conveyor technologies, and the integration of smart systems in production environments. As industries prioritize operational efficiency and precision, automatic pulley systems have become critical components in conveyor and drive mechanisms. With a competitive landscape comprising both established players and emerging innovators, identifying the top manufacturers offering reliable, high-performance solutions is essential for businesses aiming to optimize their material handling infrastructure. This list highlights the top eight automatic pulley system manufacturers leading the market through technological innovation, global reach, and proven performance.

Top 8 Automatic Pulley System Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Industrial Pulley Manufacturer

Domain Est. 1998

Website: jkpulley.com

Key Highlights: We are a premier industrial pulley manufacturer across several sectors including: Manufacturing and automation. Pulleys are vital in conveyor systems that move ……

#2 B&B Manufacturing

Domain Est. 1999

Website: bbman.com

Key Highlights: At B&B Manufacturing®, distributors and original equipment manufacturers (OEM) in the power transmission and precision mechanical component industries trust us ……

#3 BRECOflex: Timing Belt Manufacturer

Domain Est. 1996

Website: brecoflex.com

Key Highlights: BRECOflex CO., L.L.C. manufacturers timing belts, pulleys and drive components for linear drives, conveying & power transmission applications….

#4 Robotunits

Domain Est. 1998

Website: robotunits.com

Key Highlights: The simplest, fastest and most flexible Modular Automation System in the world! Conveyor Technology, Linear Motion System, Extrusion & Fastening Technology….

#5 Miki Pulley

Domain Est. 2013

Website: mikipulley-us.com

Key Highlights: Miki Pulley is a manufacturer providing precision standard & custom speed control products including brakes, clutches, couplings and variable speed belt ……

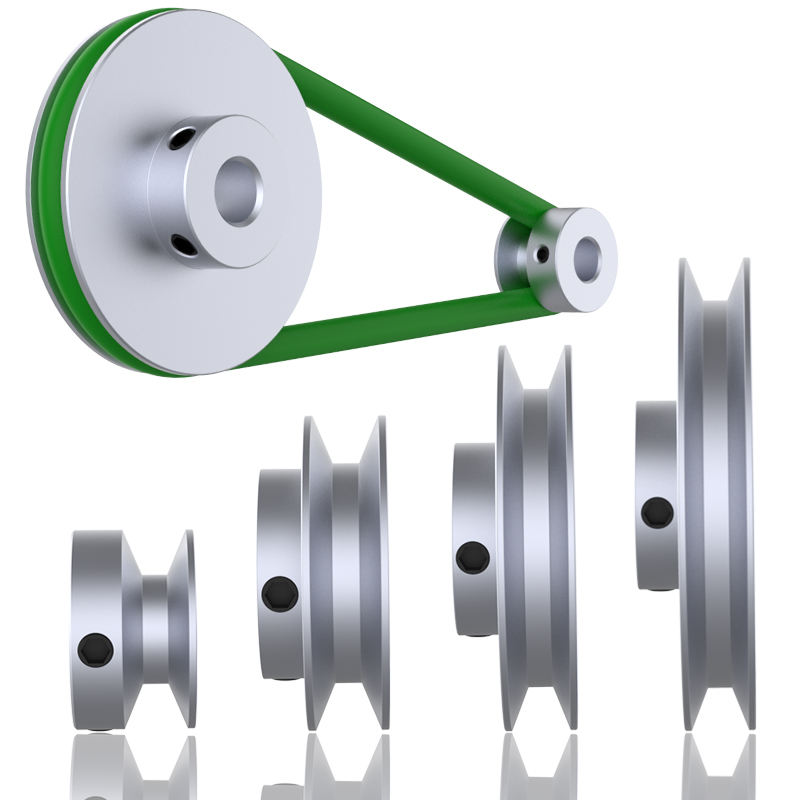

#6 Small Mechanical Components

Domain Est. 1995

Website: sdp-si.com

Key Highlights: SDP/SI is the leader in the design and manufacture of precision mechanical components, such as precision gears, gear assemblies, timing belts, timing belt ……

#7 Heavy

Domain Est. 1995

Website: magnetics.com

Key Highlights: Our comprehensive line of powerful permanent Magnetic Separation Pulleys are typically installed as head pulleys in conveyor system applications….

#8 Hi-Lo Manufacturing

Domain Est. 1996

Website: hi-lo.com

Key Highlights: Hi-Lo Manufacturing offers torque sensing design: pulleys with belt tension regulated to the load requirements. Bushing wear is reduced by the peripheral ……

Expert Sourcing Insights for Automatic Pulley System

2026 Market Trends for Automatic Pulley System

The global market for Automatic Pulley Systems is poised for significant transformation by 2026, driven by advancements in automation, increasing demand for energy efficiency, and the expansion of smart manufacturing across industries. As industries continue their shift toward Industry 4.0 technologies, automatic pulley systems—integral components in material handling, automotive, aerospace, and industrial automation—are evolving in design, functionality, and integration capabilities. This analysis explores the key market trends shaping the Automatic Pulley System sector in 2026.

Rising Adoption in Industrial Automation

One of the most prominent trends in 2026 is the accelerated integration of automatic pulley systems in smart factories and automated production lines. With the Industrial Internet of Things (IIoT) enabling real-time monitoring and predictive maintenance, pulley systems are being equipped with embedded sensors and connectivity modules. This allows for seamless data exchange, optimizing belt tension, speed, and alignment automatically. Manufacturers in automotive and logistics sectors are leading the adoption, seeking to minimize downtime and improve operational efficiency.

Demand for Energy-Efficient and Low-Maintenance Systems

Sustainability remains a core driver of innovation. In 2026, there is a growing preference for automatic pulley systems that reduce energy consumption and require minimal maintenance. New materials such as composite polymers and self-lubricating bearings are being incorporated to extend service life and lower friction losses. Variable-speed pulley systems, which adjust torque and speed based on load requirements, are gaining traction, especially in conveyor systems used in warehousing and distribution centers.

Growth in E-Commerce and Logistics Infrastructure

The booming e-commerce industry continues to fuel demand for automated material handling solutions. By 2026, fulfillment centers and automated sorting hubs are expected to deploy advanced pulley-driven conveyor systems capable of high-speed, precise movement of packages. Automatic tensioning and alignment features ensure consistent performance even under fluctuating loads, reducing wear and operational costs. This trend is particularly strong in regions like North America, Europe, and Southeast Asia.

Technological Integration with AI and Machine Learning

Artificial intelligence is beginning to play a pivotal role in enhancing pulley system performance. In 2026, AI-powered diagnostic tools analyze operational data to predict failures before they occur, recommend optimal configurations, and self-adjust system parameters. These intelligent pulley systems are becoming essential in critical applications where reliability is paramount, such as pharmaceutical manufacturing and aerospace assembly lines.

Regional Market Expansion

Asia-Pacific is emerging as the fastest-growing market for automatic pulley systems, driven by industrial modernization in China, India, and Vietnam. Government initiatives promoting smart manufacturing and automation are accelerating investments in advanced pulley technologies. Meanwhile, North America and Europe maintain strong demand, particularly in retrofitting older systems with automated, sensor-enabled pulleys to meet energy and safety regulations.

Competitive Landscape and Innovation

The competitive landscape is becoming increasingly dynamic, with both established industrial component manufacturers and tech-focused startups introducing modular, scalable pulley solutions. Key players are focusing on R&D to enhance durability, precision, and compatibility with robotic systems. Strategic partnerships between pulley manufacturers and automation software providers are also on the rise, enabling end-to-end integrated solutions.

Conclusion

By 2026, the Automatic Pulley System market will be characterized by intelligent, connected, and energy-efficient solutions tailored to the needs of modern industries. As automation becomes ubiquitous, the role of pulley systems will expand beyond mere mechanical transmission to become critical nodes in smart industrial ecosystems. Companies that invest in innovation, sustainability, and digital integration are likely to lead the market in this transformative phase.

Common Pitfalls When Sourcing an Automatic Pulley System: Quality and Intellectual Property Risks

Sourcing an Automatic Pulley System can introduce critical risks related to both product quality and intellectual property (IP) protection. Overlooking these areas may lead to operational failures, legal disputes, or financial losses.

Poor Component Quality and Inadequate Manufacturing Standards

One of the most frequent pitfalls is selecting suppliers who compromise on material quality or manufacturing precision. Low-grade bearings, substandard cables, or poorly machined pulleys can lead to premature system failure, increased maintenance, and safety hazards. Additionally, inconsistent tolerances in automated systems may result in misalignment, slippage, or inconsistent performance, especially under load or in demanding environments.

Lack of Certifications and Testing Documentation

Many suppliers, especially in cost-driven markets, may not provide necessary quality certifications (e.g., ISO 9001) or performance test reports. Without documented proof of load testing, durability trials, or environmental resistance (e.g., corrosion protection), buyers risk deploying unreliable systems that do not meet operational requirements.

Inadequate or Missing Intellectual Property Protections

When sourcing automatic pulley systems—particularly custom or innovative designs—there is a significant risk of IP infringement or misappropriation. Using designs, mechanisms, or control algorithms protected by patents without proper licensing can lead to costly legal action. Furthermore, if the buyer provides proprietary specifications, there’s a risk the supplier may replicate or resell the design to competitors without contractual safeguards.

Ambiguous Ownership of Custom Designs

In custom development scenarios, failure to define IP ownership in the supply agreement can result in disputes. Suppliers may claim partial rights to modified designs or software integrations, limiting the buyer’s ability to manufacture, service, or improve the system independently in the future.

Use of Counterfeit or Reverse-Engineered Components

Some suppliers may integrate counterfeit sensors, motors, or control units to cut costs. These components not only degrade system performance but may also infringe on third-party patents or trademarks, exposing the buyer to liability even if unknowingly used.

Insufficient Warranty and After-Sales Support

Low-cost suppliers may offer limited or vague warranty terms, making it difficult to claim recourse for quality defects. Without reliable technical support or access to spare parts, downtime can increase significantly, undermining the benefits of automation.

To mitigate these risks, buyers should conduct thorough supplier audits, require detailed technical documentation, secure clear IP clauses in contracts, and consider engaging legal and engineering experts during the sourcing process.

Logistics & Compliance Guide for Automatic Pulley System

This guide outlines the essential logistics considerations and compliance requirements for the transportation, handling, installation, and operation of an Automatic Pulley System. Adherence to these guidelines ensures safety, regulatory compliance, and optimal system performance.

Shipping and Transportation

Ensure the Automatic Pulley System is securely packaged in a robust, weather-resistant crate suitable for international or domestic shipping. Use skids or pallets to facilitate forklift handling. Clearly label all packages with “Fragile,” “This Side Up,” and handling instructions. Provide detailed shipping documentation, including a packing list, bill of lading, and hazardous material declarations (if applicable). Confirm carrier compliance with IATA, IMDG, or local transport regulations for machinery.

Import and Customs Clearance

Prepare all necessary import documentation, including commercial invoice, certificate of origin, packing list, and bill of lading/airway bill. Verify tariff classification (HS Code) for pulley systems or industrial machinery in the destination country. Ensure compliance with local standards (e.g., CE, UKCA, UL, CCC) and provide conformity certificates. Be aware of import duties, taxes, and potential regulatory inspections. Engage a licensed customs broker if required.

Storage and Handling

Store the Automatic Pulley System in a dry, climate-controlled environment protected from dust, moisture, and extreme temperatures. Keep components in original packaging until installation. Use appropriate lifting equipment (e.g., overhead crane, forklift with sling) when moving heavy pulley units; never drag or drop components. Follow manufacturer-recommended orientation during storage and handling to prevent internal damage.

Installation Requirements

Installation must be performed by qualified personnel in accordance with the manufacturer’s technical manual. Verify structural integrity of mounting surfaces to support dynamic loads. Ensure electrical connections comply with local codes (e.g., NEC, IEC) and use proper grounding. Maintain adequate clearance around the system for ventilation, maintenance access, and safety. Conduct alignment checks and tension calibration per specifications before operation.

Safety and Operational Compliance

The Automatic Pulley System must comply with relevant safety standards such as ISO 12100 (Safety of Machinery), OSHA 29 CFR 1910.212 (Machine Guarding), and applicable regional directives (e.g., EU Machinery Directive 2006/42/EC). Install protective guards, emergency stop devices, and warning labels in visible locations. Conduct initial safety inspections and routine maintenance as scheduled. Operators must be trained in safe operating procedures and emergency response.

Environmental and Disposal Regulations

Operate the system in compliance with local environmental regulations regarding noise, lubricant use, and energy efficiency. Collect and dispose of waste materials (e.g., used lubricants, packaging) according to EPA, EU WEEE, or equivalent regulations. At end-of-life, recycle components where possible in accordance with RoHS and WEEE directives. Maintain records of disposal and recycling activities.

Documentation and Recordkeeping

Maintain a complete compliance dossier including user manuals, safety certifications, installation records, maintenance logs, and inspection reports. Keep records for a minimum of seven years or as required by local regulations. Provide digital and physical copies to the end-user and regulatory authorities upon request. Update documentation for any system modifications or retrofits.

Conclusion for Sourcing Automatic Pulley System:

After a comprehensive evaluation of suppliers, technical specifications, cost-effectiveness, and long-term maintenance requirements, sourcing an automatic pulley system is a strategic investment aimed at enhancing operational efficiency, reducing manual labor, and improving process reliability. The chosen system offers advanced automation features, seamless integration with existing machinery, and scalability for future production needs. By partnering with a reputable supplier that provides strong technical support and warranty coverage, the organization can ensure sustained performance and minimal downtime. Overall, the implementation of an automatic pulley system aligns with our goals of modernization, productivity improvement, and cost optimization, making it a justified and forward-looking procurement decision.