The global automotive soundproofing materials market is undergoing significant expansion, driven by increasing consumer demand for enhanced in-cabin comfort and stricter noise regulations. According to Mordor Intelligence, the market was valued at USD 2.8 billion in 2023 and is projected to grow at a CAGR of over 6.2% from 2024 to 2029. This growth is further validated by Grand View Research, which highlights rising vehicle production and the growing adoption of lightweight, high-performance acoustic materials in both passenger and commercial vehicles. As automakers and aftermarket suppliers prioritize noise, vibration, and harshness (NVH) reduction, innovation in soundproofing solutions has intensified. This surge has elevated the prominence of specialized manufacturers developing advanced composites, damping pads, and foam-based insulation systems. Based on market presence, product innovation, and technological advancement, the following list highlights the top 10 auto soundproofing material manufacturers shaping the industry’s future.

Top 10 Auto Sound Proofing Material Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Design Engineering Inc.

Domain Est. 1997

Website: designengineering.com

Key Highlights: DEI specializes in heat and sound insulation products. This includes heat wrap for headers or exhaust systems, heat shields, sleeve products, & more….

#2 CTK

Website: ctk.world

Key Highlights: CTK is a leading manufacturer of advanced sound dampening solutions. We offer the best car noise insulation products to reduce unwanted noise, vibration and ……

#3 Automotive Sound Solutions – Acoustic Management

Domain Est. 1988

Website: 3m.com

Key Highlights: At 3M, we have spent decades helping to effectively manage noise, vibration and harshness (NVH) in your automotive designs without adding weight….

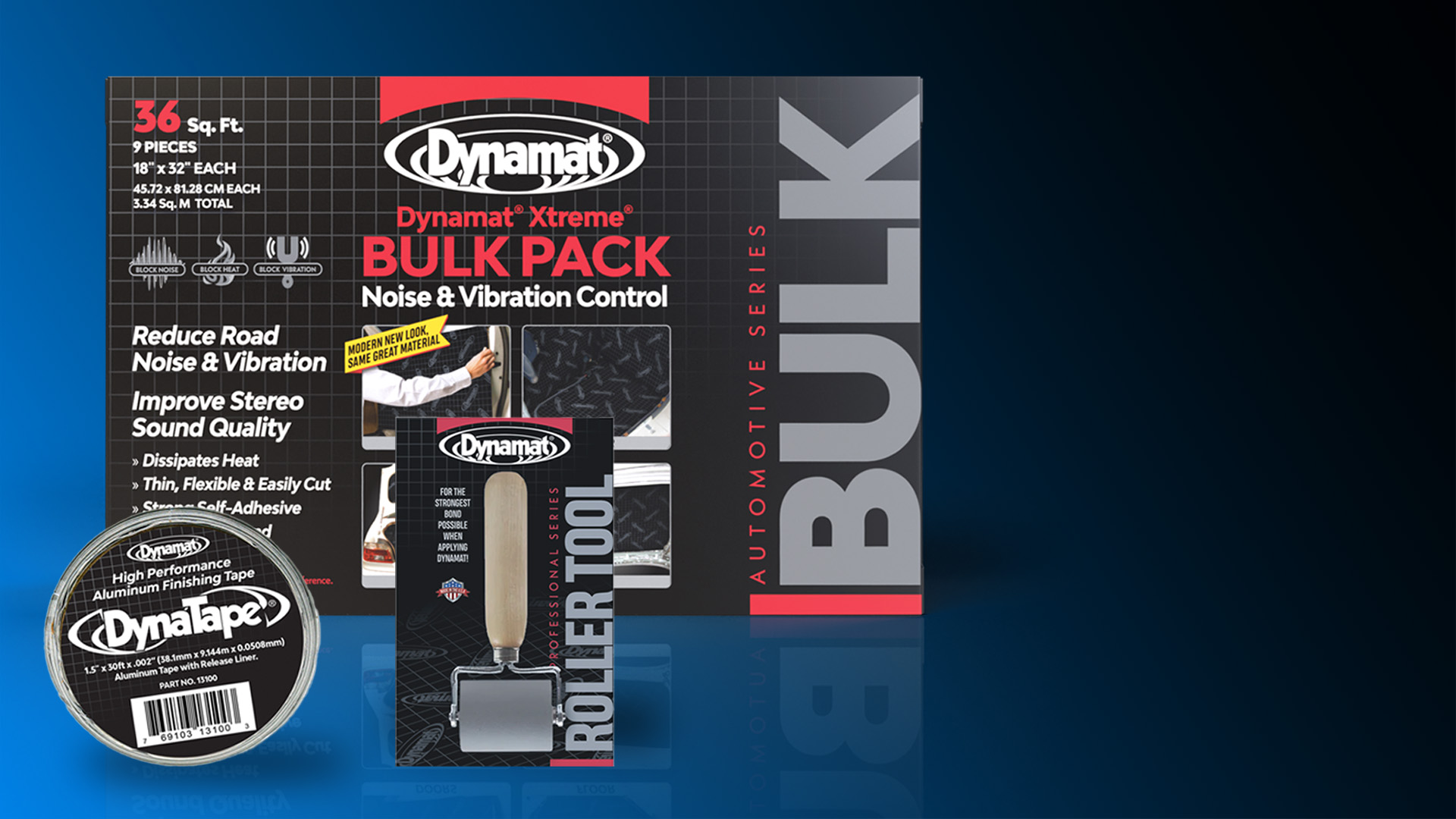

#4 Number 1 trusted name in sound deadening and heat insulation

Domain Est. 1996

Website: dynamat.com

Key Highlights: Dynamat is a thin, flexible, easy to cut and mold sheet that actually stops noise causing resonance and vibration, by using visco-elastic qualities that promote ……

#5 Sound Dampening, Vibration Damping, Thermal Insulation for …

Domain Est. 2003

Website: hushmat.com

Key Highlights: HushMat, pioneering top-of-the-line products for sound deadening, vibration control, and thermal insulation in the automotive market….

#6 LizardSkin

Domain Est. 2003

Website: lizardskin.com

Key Highlights: LizardSkin reduces heat and noise for your vehicle. LizardSkin Insulation is developed by Mascoat, leader in insulating coatings….

#7 Car Soundproofing & Sound Deadening Materials

Domain Est. 2008

Website: soundproofcow.com

Key Highlights: With car soundproofing materials from Soundproof Cow, you can reduce loud engine noises, harsh volume levels, poor audio quality and raised voices….

#8 Kilmat

Domain Est. 2016

Website: kilmat.com

Key Highlights: Kilmat presents sound deadening and insulation materials for cars. Kilmat sound deadening mat – excellent soundproofing at a bargain price….

#9 SoundSkins Global

Domain Est. 2017

Website: soundskinsglobal.com

Key Highlights: Buy the best sound deadening material for car audio in the USA & Canada. Find top-quality products near me for sale at SoundSkins Global. Shop online now!…

#10 ResoNix Sound Solutions

Domain Est. 2019

Website: resonixsoundsolutions.com

Key Highlights: ResoNix Sound Solutions: Premium automotive sound deadener and high-end car audio products for unmatched performance….

Expert Sourcing Insights for Auto Sound Proofing Material

2026 Market Trends for Auto Sound Proofing Material

The auto sound proofing material market is poised for significant evolution by 2026, driven by advancements in automotive technology, rising consumer demand for comfort, and stringent noise regulations. Below is an analysis of key trends expected to shape the industry in the coming years.

Growing Demand for Electric Vehicles (EVs)

The rapid adoption of electric vehicles is a major driver for the auto sound proofing market. While EVs eliminate engine noise, they introduce new sources of sound, such as electric motor whine and road noise, which become more noticeable in quiet cabins. As automakers focus on enhancing passenger comfort and delivering a premium driving experience, demand for high-performance sound deadening materials is increasing. By 2026, EV-integrated sound proofing solutions are expected to dominate new vehicle designs.

Advancements in Material Technology

Innovation in materials is transforming the sound proofing landscape. Lightweight, eco-friendly, and high-efficiency composites such as butyl-based mats, acoustic foams, and nano-fiber insulation are gaining traction. These materials offer superior sound absorption and thermal insulation without adding significant weight—critical for EV efficiency. Additionally, bio-based and recyclable sound proofing materials are emerging in response to sustainability mandates, aligning with global environmental goals.

Stricter Noise Regulations

Governments and regulatory bodies worldwide are tightening noise emission standards for vehicles, especially in urban areas. The European Union and regions like India and China are implementing stricter cabin and exterior noise limits. These regulations are compelling automakers to integrate advanced sound proofing during manufacturing, boosting demand for compliant and certified materials by 2026.

Rising Consumer Expectations for In-Car Comfort

Consumers are increasingly prioritizing in-cabin comfort, treating the vehicle as an extension of their personal space. Features such as noise cancellation, premium audio systems, and quiet ride quality are becoming standard expectations, even in mid-tier vehicles. This shift is pushing OEMs and aftermarket providers to invest in comprehensive sound insulation solutions, expanding market opportunities.

Expansion of the Aftermarket Sector

The aftermarket for auto sound proofing materials is growing steadily, fueled by car customization trends and DIY culture. Enthusiasts and fleet operators alike are retrofitting vehicles with sound deadening kits to improve comfort and reduce fatigue during long drives. Online retail platforms and easy-to-install products are making these solutions more accessible, contributing to market growth through 2026.

Regional Market Dynamics

Asia-Pacific is expected to lead global market growth due to booming automotive production in China and India, coupled with rising disposable incomes. North America and Europe will maintain strong demand, driven by premium vehicle sales and environmental regulations. Localized manufacturing and supply chain optimization will play a crucial role in meeting regional needs efficiently.

Integration with Active Noise Cancellation (ANC) Systems

By 2026, passive sound proofing materials will increasingly be used in conjunction with active noise cancellation technologies. This hybrid approach allows automakers to reduce overall material usage while achieving superior acoustic performance. Integration with vehicle audio systems enables real-time noise suppression, offering a competitive edge in luxury and high-performance segments.

Conclusion

The auto sound proofing material market in 2026 will be shaped by technological innovation, regulatory pressure, and shifting consumer preferences. With the rise of EVs and demand for quieter, more comfortable vehicles, the industry is set for robust growth. Stakeholders who invest in sustainable, lightweight, and high-performance solutions will be well-positioned to capitalize on emerging opportunities.

Common Pitfalls When Sourcing Auto Sound Proofing Material (Quality, IP)

Sourcing auto sound proofing materials involves navigating a complex landscape where quality inconsistencies and intellectual property (IP) risks can significantly impact product performance, compliance, and brand reputation. Overlooking these pitfalls can lead to subpar acoustic performance, legal disputes, or damage to customer trust. Below are key challenges to avoid:

Poor Material Quality and Inconsistent Performance

One of the most frequent issues is receiving materials that fail to meet advertised specifications. Low-quality sound deadeners may use inferior bitumen, lack proper adhesive strength, or have inconsistent thickness, leading to reduced vibration damping and noise insulation. Materials sourced from unverified suppliers often vary between batches, compromising vehicle acoustic comfort and long-term durability under temperature fluctuations.

Misrepresentation of Technical Specifications

Suppliers may exaggerate sound transmission loss (STL), damping coefficient (loss factor), or fire resistance ratings. Without independent lab testing or verifiable certifications (e.g., ISO 10534, ASTM E1050), buyers risk integrating materials that underperform in real-world conditions. This is especially critical in OEM environments where performance standards are strictly enforced.

Lack of Compliance with Safety and Environmental Regulations

Many soundproofing materials must comply with regional regulations such as REACH, RoHS, or FMVSS 302 (flammability). Sourcing from manufacturers who do not provide proper documentation can expose companies to regulatory penalties, vehicle recalls, or supply chain disruptions. Halogen-free, low-VOC, and non-toxic formulations are increasingly required, especially in electric vehicles.

Intellectual Property Infringement Risks

Using soundproofing materials that replicate patented technologies—such as multi-layer composite structures, constrained layer damping designs, or proprietary adhesive formulas—can lead to IP litigation. Some suppliers, particularly in regions with weak IP enforcement, may produce near-identical copies of branded materials (e.g., resembling products from 3M, Dynamat, or Hushmat), exposing the buyer to legal liability even if unintentional.

Inadequate Supply Chain Transparency

Opaqueness in the manufacturing process or raw material sourcing increases risks related to quality control and IP. Without clear traceability, it’s difficult to audit for compliance or verify claims about recycled content, sustainability, or origin of raw polymers. This lack of transparency also complicates efforts to ensure ethical labor practices.

Failure to Verify Supplier Credentials and Testing Data

Relying solely on supplier-provided data sheets without third-party validation is a critical oversight. Reputable suppliers should provide access to accredited lab reports, material safety data sheets (MSDS), and sample testing under real automotive conditions (e.g., thermal cycling, adhesion after humidity exposure). Skipping due diligence can result in integrating materials unsuitable for automotive-grade requirements.

Overlooking Long-Term Durability and Aging Performance

Some materials perform well initially but degrade prematurely due to oil, moisture, or UV exposure. Without accelerated aging tests or real-world validation, sourced materials may delaminate or lose damping effectiveness over time, leading to warranty claims and customer dissatisfaction.

Conclusion

To mitigate these pitfalls, automotive suppliers and manufacturers must conduct thorough due diligence—requiring verified test reports, ensuring IP clearance, auditing supply chains, and prioritizing partners with proven automotive industry experience. Proactive quality and IP management safeguard both product performance and brand integrity.

Logistics & Compliance Guide for Auto Sound Proofing Material

This guide outlines key logistics considerations and compliance requirements for handling, transporting, and selling automotive soundproofing materials globally. Proper adherence ensures safety, regulatory compliance, and efficient supply chain operations.

Product Classification and Identification

Automotive soundproofing materials typically include but are not limited to: butyl rubber sheets, bituminous dampers, foam insulation, mass-loaded vinyl (MLV), and composite barrier materials. Accurately classify each product using the Harmonized System (HS) code, which varies by material composition (e.g., 3921.90 for plastic sheets, 4008.21 for rubber-based sheets). Correct classification is essential for customs clearance, duty assessment, and import/export documentation.

Regulatory Compliance

Compliance with regional and international regulations is mandatory. Key standards include:

- REACH (EU): Ensure all chemical substances (e.g., plasticizers in PVC-based materials) are registered and do not contain restricted substances above permissible limits.

- RoHS (EU/UK/Asia): Verify that materials are free of lead, mercury, cadmium, and other hazardous substances, especially in products with electronic or metallic components.

- FMVSS 302 (USA): All interior automotive materials must meet the flammability resistance requirements set by the U.S. Department of Transportation. Testing for flame spread rate is required.

- UL 94 (Global): Used for evaluating flammability of plastic materials, often referenced in automotive applications.

- VOC Emissions (e.g., China GB/T 27630, French AFSSET): Ensure low volatile organic compound (VOC) emissions to meet indoor air quality standards, especially for cabin-installed materials.

Packaging and Labeling Requirements

Use durable, moisture-resistant packaging to prevent damage during transit. Clearly label each package with:

- Product name and composition

- Batch/lot number

- Net weight and dimensions

- Handling symbols (e.g., “Do Not Stack,” “Protect from Moisture”)

- Safety warnings (e.g., “For Automotive Use Only”)

- Compliance marks (e.g., CE, RoHS, REACH)

- Manufacturer/importer contact information

Include multilingual labels where required by destination countries.

Transportation and Handling

Transport soundproofing materials as general cargo, but observe:

- Temperature Control: Avoid extreme heat or cold, especially for bituminous or adhesive-backed materials that may degrade or lose adhesion.

- Stacking Limits: Respect manufacturer stacking guidelines to prevent compression damage.

- Hazardous Materials: Most soundproofing materials are non-hazardous, but verify if any components (e.g., solvent-based adhesives) require hazardous goods classification (e.g., UN 1263, Class 3 Flammable Liquid).

- Documentation: Prepare commercial invoice, packing list, bill of lading/air waybill, and certificates of compliance (e.g., CoC, test reports).

Import/Export Documentation

Ensure all shipments include:

- Commercial Invoice (with HS codes and values)

- Packing List

- Certificate of Origin (preferably Form A for preferential tariffs under trade agreements)

- Material Safety Data Sheet (MSDS/SDS) – required for customs and safety compliance

- Test Reports (e.g., FMVSS 302, REACH SVHC screening)

- Import Permits (if required by destination country)

Storage and Inventory Management

Store materials in a dry, well-ventilated warehouse away from direct sunlight and heat sources. Maintain inventory using FIFO (First In, First Out) to prevent aging of adhesive layers or material degradation. Monitor shelf life, especially for products with pressure-sensitive adhesives.

Environmental and Disposal Compliance

Provide end-of-life guidance in product documentation. Most soundproofing materials are not recyclable through standard municipal systems. Ensure compliance with local waste disposal regulations (e.g., EU Waste Framework Directive). Encourage proper disposal through specialized industrial waste channels.

Supplier and Manufacturer Due Diligence

Audit suppliers to ensure:

- Raw material traceability

- Compliance with environmental and labor standards

- Consistent product testing and quality control

- Valid certifications (ISO 9001, ISO 14001, IATF 16949 for automotive suppliers)

Maintain records of supplier compliance documentation for audits and customs requests.

Final Notes

Staying updated on evolving regulations (e.g., EU Green Deal, U.S. TSCA amendments) is critical. Partner with experienced freight forwarders and customs brokers familiar with automotive components. Proactive compliance reduces delays, penalties, and reputational risk in global trade.

Conclusion on Sourcing Auto Soundproofing Material:

Sourcing high-quality auto soundproofing materials is essential for achieving optimal noise reduction, enhancing in-cabin comfort, and improving the overall acoustic performance of a vehicle. After evaluating various options, it is clear that effective soundproofing requires a strategic combination of materials such as butyl-based dampers, mass-loaded vinyl (MLV), foam insulators, and thermal barriers, selected based on specific vehicle needs and budget considerations.

Key factors in successful sourcing include material effectiveness (measured by sound transmission class and damping properties), ease of installation, thermal resistance, durability, and compliance with safety and environmental standards. Additionally, sourcing from reputable suppliers ensures consistent quality, product authenticity, and access to technical support.

In conclusion, investing time in researching and selecting the right soundproofing materials from reliable suppliers leads to long-term satisfaction, improved driving experience, and increased vehicle resale value. Whether for personal use or commercial application, a well-informed sourcing strategy ensures performance, reliability, and cost-efficiency in automotive soundproofing projects.