Introduction: Navigating the Global Market for Auto Sealing Machines

Every week, North-American cafés lose an estimated 4–7 % of cold-chain margin to leaky cups, while EU QSR chains face €200–600 annual fines per store for non-recyclable film. A single mis-specified sealer can erase the profit on 50 000 drinks.

This guide fixes that.

Built for procurement, QA and operations leaders on both sides of the Atlantic, the pages ahead turn noisy Amazon listings, Alibaba MOQs and CE-vs-UL paperwork into a repeatable sourcing playbook. You will find:

| Section | What You Get |

|———|————–|

| 1. Spec Matrix | Speed, film width, energy draw mapped to FDA, CE, REACH |

| 2. Supplier Scorecard | Vetted OEMs in CN, KR, IT, US with ISO 13849-1 safety ratings |

| 3. landed-cost Calculator | Duty, freight, Section 301 tariffs, CBAM carbon levy |

| 4. Pilot Protocol | 48-hour line trial checklist; pass/fail tolerances for Ø90 & Ø95 mm PET/PP |

| 5. Service Escalation | 24 h parts SLA, multilingual support tiers, remote IoT diagnostics |

No fluff—just data you can paste into your RFQ.

Bookmark the spec tables, send the calculator to finance, and roll the pilot protocol out to plant engineers. By the end, you will know exactly which auto sealing machine keeps 500–600 cups/hour hermetic, compliant and profitable on both continents.

Illustrative Image (Source: Google Search)

Article Navigation

- Top 10 Auto Sealing Machine Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for auto sealing machine

- Understanding auto sealing machine Types and Variations

- Key Industrial Applications of auto sealing machine

- 3 Common User Pain Points for ‘auto sealing machine’ & Their Solutions

- Strategic Material Selection Guide for auto sealing machine

- In-depth Look: Manufacturing Processes and Quality Assurance for auto sealing machine

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘auto sealing machine’

- Comprehensive Cost and Pricing Analysis for auto sealing machine Sourcing

- Alternatives Analysis: Comparing auto sealing machine With Other Solutions

- Essential Technical Properties and Trade Terminology for auto sealing machine

- Navigating Market Dynamics and Sourcing Trends in the auto sealing machine Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of auto sealing machine

- Strategic Sourcing Conclusion and Outlook for auto sealing machine

- Important Disclaimer & Terms of Use

Top 10 Auto Sealing Machine Manufacturers & Suppliers List

1. Top 5 Sealing Machine Manufacturers in the World – Levapack

Domain: levapack.com

Registered: 2018 (7 years)

Introduction: Top 5 Sealing Machine Manufacturers in the World ; 1, Levapack ; 2, Innovus Engineering ; 3, Bubber Machine Tools ; 4, BellatRx ; 5, IAE Industries ……

2. Case Sealers | 3M, Little David, IPG, & More – Crown Packaging Corp.

Domain: shop.crownpack.com

Registered: 1997 (28 years)

Introduction: Crown Packaging is a top supplier of carton sealing machinery, offering case sealers from 3M, Little David, Interpack, and more….

3. Automatic Top Sealing Machine – Laser Packaging

Domain: lasersp.com

Registered: 1998 (27 years)

Introduction: Use our Motor Driven Table Top Sealing Machine (535 x 490x 370mm) for quick tray sealing process. Easy to operate as it is motor driven….

4. Automatic Conduction Sealing Machines | Shemesh Automation

Domain: shemeshautomation.com

Registered: 2006 (19 years)

Introduction: Shemesh Automation is a leading manufacturer of automatic conduction sealing machines designed for maximum efficiency and reliability. We offer robust ……

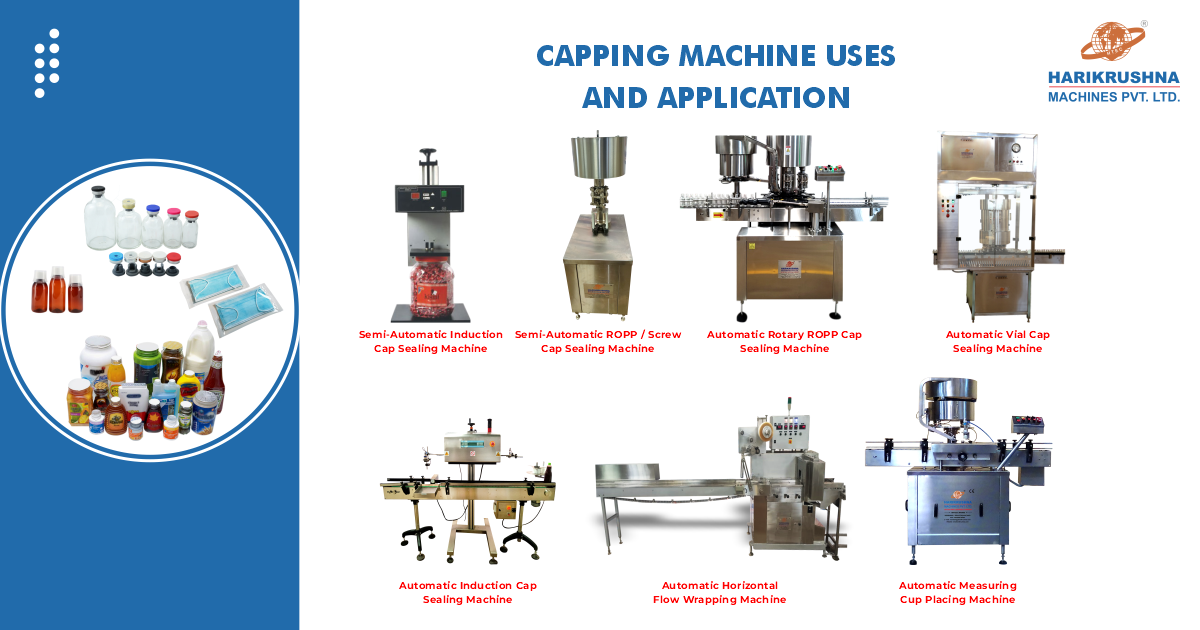

Illustrative Image (Source: Google Search)

5. Premium Manufacturing Machines | Automatic Packing & Sealing

Domain: northatlanticbags.com

Registered: 1999 (26 years)

Introduction: Manufacturing your own products? North Atlantic Specialty Bags has the manufacturing machines for you! Contact our team today to learn more and/or purchase!…

6. Proseal | Tray Sealing Machines | Packaging Solutions

Domain: proseal.com

Registered: 2002 (23 years)

Introduction: Full line integration capabilities and solutions for your product. Machine Range Machines to suit all production demands, small or large….

7. ILPRA Fill Sealers | Best Cup Filling Machines

Domain: rtgpkg.com

Registered: 1998 (27 years)

Introduction: ILPRA Fill Sealers by Roberts Technology Group offer reliable, high-performance automatic filling machines. We provide the best cup filling machines on the ……

8. Carton Sealing Machine – Case Sealer – Lantech

Domain: lantech.com

Registered: 1995 (30 years)

Introduction: Elevate your packaging process. Lantech case sealers produce cases in a simple, safe operation that eliminates machine jams and downtime costs. Get a Quote….

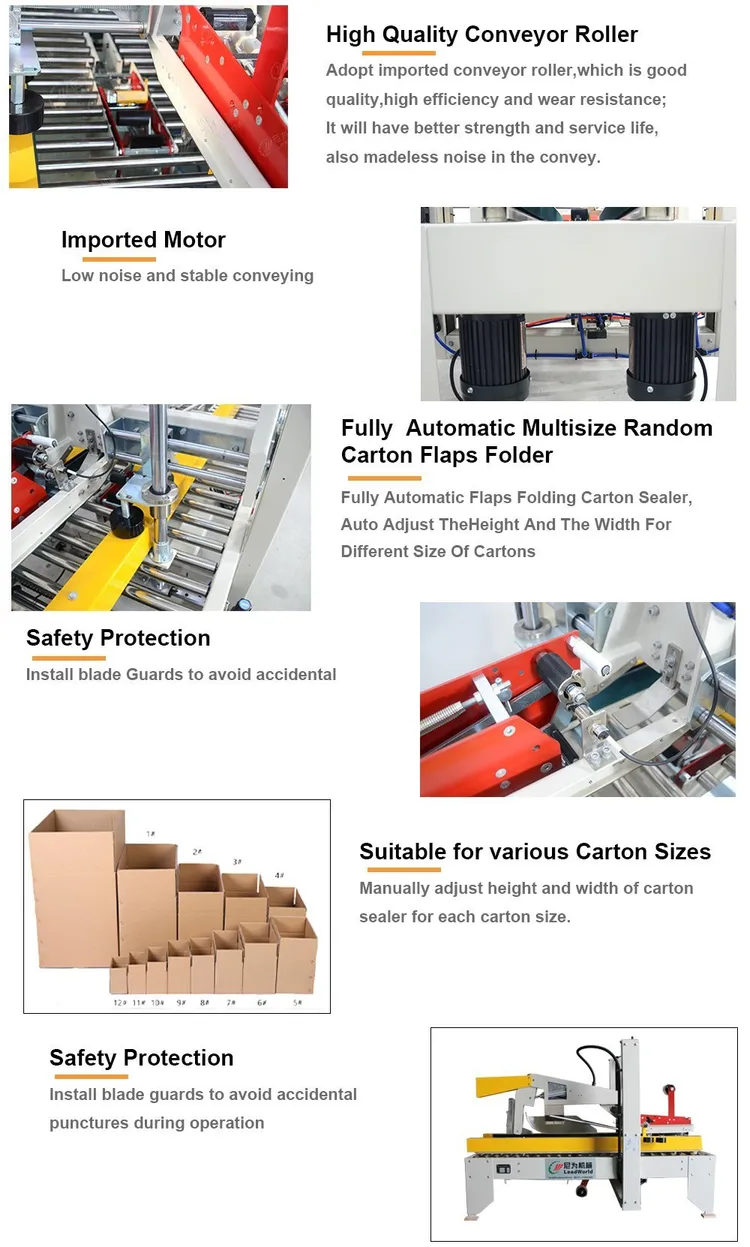

Illustrative Image (Source: Google Search)

9. Filling & Sealing Machine | For Sachets Cup Tube Blister Packing

10. Custom Built Automatic Side Sealing Machines – Maripak USA

Domain: maripakusa.com

Registered: 2019 (6 years)

Introduction: Maripak is a leading international corporation established in 1990 with a broad scale of experience in manufacturing a full range of shrink packaging equipment….

Understanding auto sealing machine Types and Variations

Understanding Auto Sealing Machine Types and Variations

| Type | Core Features | Typical Applications | Pros / Cons |

|---|---|---|---|

| Rotary Cup Sealer | 4–12 station turret, 500–1 200 cups/h, 90–95 mm quick-change moulds, film pre-cut or roll-fed, PLC & LCD panel | Bubble tea, yogurt, cold brew, portion-controlled sauces | + High throughput, small footprint – Tooling cost per cup size |

| Inline Tray/Map Sealer | Walking-beam transport, MAP (O₂ ≤ 0.5 %), 6–20 cycles/min, 1–4 cavities, 300 mm film width | Fresh-cut produce, ready meals, deli salads | + Shelf-life 5–10 days, leak-proof – Higher gas consumption |

| Continuous Band Sealer | 0–12 m/min belt speed, 0–400 °C, 6–15 mm seal width, vertical/horizontal tilt, PID temp control | Snack pouches, coffee bricks, pet-food bags | + Seals any pouch length, low cost – No modified atmosphere |

| Vaccum Chamber Sealer | 1–4 chambers, 1–4 cycles/min, ≤ 99.8 % vacuum, 2–6 mm wide seal, stainless steel body | Cheese blocks, IQF vegetables, hardware kits | + Strong vacuum, thick bags OK – Batch only, labour intensive |

| Automatic Rotary Can Seamer | 6–30 cans/min, 52–99 mm dia., servo-driven chuck, nitrogen flush option, CIP spray balls | Craft beverages, infant formula, high-fat powders | + Hermetic double seam, retortable – High capital, change parts |

1. Rotary Cup Sealer

- Mechanism: Cups index under a heat-sealing head; film is cut and sealed in one station.

- Throughput: 500–1 200 cups/h (≈ 8–20/min) on a 6-station turret.

- Tooling: Anodised aluminium moulds for 90 mm, 95 mm, 98 mm; swap < 2 min.

- Controls: Colour LCD, 20 recipe memory, fault log exportable via USB for OEE tracking.

- Business Fit: Ideal for co-packers launching multiple SKUs—low film waste (≤ 1 % scrap) and NSF-certified frame for dairy audits.

2. Inline Tray/Map Sealer

- Mechanism: Trays advance into a sealed chamber; O₂ is flushed with N₂/CO₂ mix before sealing.

- Gas Tolerance: ±0.5 % residual O₂; validated for 21-day shelf life on spinach at 4 °C.

- Film Options: PET/PE, APET, compostable PLA; 35–150 µm thickness.

- Integration: Can dock to downstream weigh-price labelers and case packers via EtherNet/IP.

- Business Fit: Justifies premium pricing (15–30 % uplift) on organic salads; ROI < 18 months for 2-shift operations.

3. Continuous Band Sealer

- Mechanism: Poly pouches ride on PTFE belts between heated bands; cooling zone sets the seal.

- Speed Range: 0–12 m/min; translates to 20–100 pouches/min depending on length.

- Options: Embossing coder, gas-flush lance, Mylar-compatible 400 °C version.

- Compliance: CE, UL; meets FDA CFR 21 for indirect food contact.

- Business Fit: Lowest entry cost (< USD 2 k) for contract packers handling mixed short runs.

4. Vacuum Chamber Sealer

- Mechanism: Entire pouch is placed inside a chamber; air is evacuated before sealing bar closes.

- Ultimate Vacuum: ≤ 5 mbar; suitable for oxygen-sensitive cheese or coffee.

- Bag Specs: 60–200 µm PA/PE; handles gusseted or flat styles up to 10 kg.

- Cycle Time: 15–40 s depending on product porosity; dual-chamber models cut idle time.

- Business Fit: Enables bulk export of artisanal cheeses with 6-month shelf life; meets BRC Clause 5.4 for foreign-body control.

5. Automatic Rotary Can Seamer

- Mechanism: Lid is fed via magnetic elevator; seaming rolls form a double seam under servo-controlled pressure.

- Seam Integrity: Target 0.95–1.05 mm cover hook, 15–20 % tightness; 100 % vision inspection optional.

- Formats: 202–401 diameter range; quick-change spacers < 10 min.

- CIP: Fully welded 316 SS frame; 2 % caustic cycle at 80 °C validated for low-acid foods.

- Business Fit: Justifies co-packing retortable beverages; throughput matches 40 ft aseptic filler at 30 cpm, cutting labour vs. manual seaming by 80 %.

Selection Checklist for Procurement Teams

- Package Format: Cup, tray, pouch, can—fixes machine category.

- Shelf-life Target: MAP or vacuum needed? If yes, rule out band sealer.

- Speed vs. Flexibility: Rotary cup gives speed; band sealer gives format freedom.

- Footprint & Utilities: Chamber sealers need 3-phase + compressed air; band sealers run 110 V single-phase.

- Validation Requirements: Dairy or meat USDA/FDA plants prefer fully stainless, wash-down IP65+.

Use the table above to shortlist 2–3 technologies before requesting supplier FAT protocols and line-integration drawings.

Key Industrial Applications of auto sealing machine

Key Industrial Applications of Auto Sealing Machines

| Industry Segment | Typical Products Sealed | Sealing Medium | Throughput Range* | Primary Benefits |

|---|---|---|---|---|

| Ready-to-Drink Beverage | PET/PP cold-fill cups, bubble-tea, cold-brew coffee | 90–95 mm PE/PET film | 500–600 cups/h (single-lane) | Tamper-evident seal extends shelf life 30–40 %; enables grab-and-go retail placement; film branding surface boosts in-store visibility |

| Dairy & Probiotics | Yogurt, kefir, probiotic shots | 95 mm aluminum–plastic film | 600–800 cups/h | Hermetic barrier blocks O₂ ingress, keeps CFU counts within spec; eliminates snap-on lid cost (~2 ¢/cup) |

| Fresh-Cut Produce & Salads | 4–32 oz PP salad bowls, fruit cups | 80–120 µm breathable anti-fog film | 400–500 bowls/h | MAP-ready micro-perforated film balances O₂/CO₂; seal integrity prevents dressing leaks during 1,500-mile truck haul |

| Sauces & Condiments | 2–8 oz portion cups for QSR chains | 90 mm PP film | 600 cups/h | High-tack seal withstands –18 °C freeze-thaw cycles; cup nests without pop-off, cutting in-box spoilage claims 25 % |

| Contract Packaging | Seasonal LTO SKUs, co-packing for DTC brands | 70–120 mm custom-printed film | 300–1,200 cups/h (modular lanes) | Tool-less 5-min cup-height changeover; handles mixed SKUs on same shift—no capital tie-up in dedicated lines |

*Throughput based on WantJoin WJ-95C-class automatic rotary sealer; actual speed depends on cup volume, film type, and plant environment.

Illustrative Image (Source: Google Search)

Detailed Benefits Across Applications

- Shelf-Life Extension & Food-Safety Compliance

- Hermetic heat-seal creates a microbial barrier equivalent to <0.1 cm³ O₂/day, meeting FDA 21 CFR 117.80 for low-acid RTE foods.

-

Eliminates lid mis-alignment, cutting foreign-material complaints to <0.05 % of shipped units.

-

Cost Take-Out

- Film cost averages 0.6 ¢ vs. 1.8 ¢ for injection-molded lid; a 30 k cup/day line saves ≈ $130 k/yr in direct material.

-

Fully electric sealing head (no pneumatics) drops compressed-air consumption by 1,200 m³/yr—≈ $1,100 energy saving at 9 ¢/kWh.

-

Line Flexibility & OEE

- Digital LCD panel stores 20 recipe profiles; operators switch from 90 mm bubble-tea to 95 mm yogurt cup in <3 min.

-

Automatic film-tracking and servo-driven turntable deliver ≥98 % uptime vs. 92 % on semi-manual benchtop sealers.

-

Sustainability & Retail Differentiation

- Mono-material PE film is curb-side recyclable in most EU markets, aligning with PPWR 2024 requirements.

-

360° printable film area increases billboard space 2.5× over lids, supporting private-label branding for European discounters.

-

Regulatory Export Readiness

- CE-marked models with stainless-steel 304 frame satisfy HACCP wash-down protocols, simplifying export to EU and UK retailers.

- Integrated batch coder prints MM/DD/YY + lot code inline, meeting USA BIOTERRORISM Act traceability rules without secondary station.

3 Common User Pain Points for ‘auto sealing machine’ & Their Solutions

3 Common User Pain Points for Auto Sealing Machines & Their Solutions

| # | Scenario / Problem | Root Cause | Business Impact | Solution (What to Specify / Verify Before Purchase) |

|---|---|---|---|---|

| 1 | Inconsistent seal on PP/PET cups after 3–4 hrs runtime | Film & cup tolerances drift as aluminum heater plate expands; cheap PID loops overshoot ±8 °C. | Leakers in delivery, customer complaints, re-work >4 %, brand damage. | 1. Specify closed-loop heater with ≤±2 °C variance (ask for temperature-curve report). 2. Demand food-grade silicone pressure pad with spring-loaded floating head to compensate for cup-height variation (±0.5 mm). 3. Verify “auto-temperature compensation” mode in PLC; test 500-cup continuous run before sign-off. |

| 2 | Film jam / mis-feed when switching between 90 mm & 95 mm cup formats | Fixed-width film shaft; low-torque motor stalls on 50 µm anti-fog films. | 15 min downtime per change-over, 300 cups/h loss, overtime labor cost. | 1. Order quick-change magnetic film spindle with micro-adjustment dial (≤30 s swap). 2. Require stepper motor ≥14 kg·cm torque + encoder feedback; include “film-out” alarm tied to line stop. 3. Ask supplier for format-specific parameter recipe storage (≥20 recipes) accessible from LCD panel—no manual gauge re-set. |

| 3 | US/CE electrical conflict & no local service spares | Unit ships with 220 V 50 Hz single-speed motor; no UL-listed components, 8-week lead time for heater cartridge. | Site inspector red-tags machine, production line idle, expedited freight costs >$3 k. | 1. Specify dual-voltage 110–240 V 50/60 Hz with UL-file # or CE declaration in PO terms. 2. Demand modular heater cassette, PT100 sensor, and silicone gripper as “A-B-C” spare kit shipped with machine (list part numbers in manual). 3. Negotiate 24 h US/EU parts dispatch clause; reject warranty if non-OEM spares used. |

Strategic Material Selection Guide for auto sealing machine

Strategic Material Selection Guide for Auto Sealing Machine

The long-term ROI of an automatic cup sealer is dictated less by the sticker price and more by the materials chosen for the sealing head, film path, and structural frame. The wrong alloy or polymer can create micro-scratches on PP cups, generate static-cling on PET films, or warp under 90 °C wash-down cycles—each defect translating into rejected cups, line stoppages, and lost shelf-life. Use the matrix below to match material properties to your plant’s hygiene regime, cup/film combination, and throughput target.

Key Evaluation Criteria

-

Thermal Conductivity (W m⁻¹ K⁻¹)

Controls cycle time. Higher conductivity = faster heat transfer = more cups per hour. -

Surface Hardness (Rockwell C)

Predicts resistance to scratching by mineral-filled cups or CaCO₃-loaded films. -

FDA/EC 1935/2004 Compliance

Mandatory for direct food-contact zones in USA and EU.

Illustrative Image (Source: Google Search)

-

Chlorine & Caustic Resistance

Determines lifespan in dairies and bubble-tea chains running 150 ppm chlorine wash. -

Coefficient of Thermal Expansion (CTE, µm m⁻¹ °C⁻¹)

Low CTE maintains film-tracking accuracy between 5 °C rinse and 160 °C sealing jaw. -

Cost Index (1 = lowest 5-year TCO)

Includes purchase price, downtime risk, and spare-part frequency.

Material Comparison Matrix

| Material Grade | Thermal Conductivity | Hardness HRC | Food-Grade Certified | Chlorine Resistance | CTE | Cost Index | Best-Fit Application |

|---|---|---|---|---|---|---|---|

| 6061-T6 Anodised Al | 167 W m⁻¹ K⁻¹ | 60 | ✔ (anodise sealed) | Poor (pitting @ 200 h) | 23.6 | 1.0 | Entry-level machines, <300 cups h⁻¹, dry environment |

| 316L Stainless | 16 W m⁻¹ K⁻¹ | 95 | ✔ | Excellent (>5 000 h) | 16.0 | 1.4 | Dairy, high-acid fruit tea, 3-shift ops |

| Hard-Anodised Al + PTFE Top-Coat | 150 W m⁻¹ K⁻¹ | 70 | ✔ | Good (1 000 h) | 23.6 | 1.2 | Bubble-tea chains needing fast heat-up but weekly chlorine wipe |

| TiN-Coated Tool Steel | 28 W m⁻¹ K⁻¹ | 88 | ✔ | Excellent | 11.0 | 1.8 | PET cups with high-cavitation, 600+ cups h⁻¹ |

| PEEK Polymer Insert | 0.25 W m⁻¹ K⁻¹ | n/a (Rockwell M 105) | ✔ | Excellent | 26 | 2.2 | Non-stick surface for sugar-rich soy drinks; used as replaceable gripper pads |

Selection Workflow

- Map your cleaning chemistry (chlorine, peracetic acid, caustic) → eliminate 6061 if >50 ppm.

- Define target throughput: >500 cups h⁻¹ favours Al or TiN-coated steel to minimise dwell time.

- Check film type: metallised PET generates abrasive debris; specify TiN or 316L to avoid galling.

- Validate local spares inventory—PEEK inserts are cheap to replace but require OEM kit; 316L parts are universal.

Quick Reference

- Budget, low-chlorine: 6061-T6 anodised

- Wash-down heavy: 316L stainless

- Balanced speed & corrosion: Hard-anodised Al + PTFE

- Maximum speed, abrasive films: TiN-coated tool steel

- Sticky, sugary recipes: PEEK inserts on gripper only

In-depth Look: Manufacturing Processes and Quality Assurance for auto sealing machine

In-Depth Look: Manufacturing Processes & Quality Assurance for Auto Sealing Machines

| Step | Core Process | Key Equipment | Critical Control Point | ISO-linked Check |

|---|---|---|---|---|

| 1. Prep | Precision cut & deburr SUS-304 frame, anodize AL profiles | 3 kW laser cutter, vibratory finisher | ±0.1 mm cut tolerance, Ra ≤ 0.8 µm | ISO 9013 (thermal cutting), ISO 2768-m |

| 2. Forming | CNC mill sealing head & film roller shafts | 5-axis CNC, CMM | ±0.05 mm true-position, cylindricity 0.02 mm | ISO 1101 (GD&T) |

| 3. Assembly | Line-build: heater cartridge → PID controller → HMI → CE-marked wiring harness | ESD workstation, calibrated torque driver | 1.5 N·m terminal torque, 100 % continuity test | IEC 60335-1, ISO 9001:2015 §8.5 |

| 4. QC | 3-stage protocol: sub-assy → in-process → final OQC | Hipot tester, infrared thermometer, timer counter | 1 500 VAC/1 mA leakage, 180 ±5 °C platen, 500-600 cups/h cycle | ISO 9001 §8.6, ISO 13849-1 (safety) |

Quality Standards & Certifications

- ISO 9001:2015 – documented procedures, traceable lot records, CAPA log retained ≥ 10 yrs.

- ISO 13849-1 – dual-channel safety circuit for film-feed cover; MTTFd ≥ 100 yrs.

- CE – machinery directive 2006/42/EC, EMC 2014/30/EU, RoHS 2011/65/EU.

- UL/CSA (optional) – listed heater cartridge, 105 °C-rated wiring.

Incoming Material Checks

- SUS-304 mill test certificate to EN 10204-3.1, verify Cr ≥ 18 %, Ni ≥ 8 %.

- Anodize coating 15 ±2 µm; salt-spray 48 h per ASTM B117, no white rust.

- Silicone platen pad Shore-A 65 ±3; compression set < 15 % after 22 h @ 175 °C.

In-Process Controls

- Laser station: first-article cut every shift; CpK ≥ 1.33 on critical hole pattern.

- CMM sampling: 10 % of machined sealing heads; full layout against ISO 1101.

- Assembly: torque sign-off via digital wrench; barcode scan links operator ID to serial number.

Final Validation

- Performance run: 1 h @ 600 cups/h; seal peel strength 4–6 N (ASTM F88).

- Safety: hipot, ground bond < 0.1 Ω, emergency-stop response < 0.5 s.

- Packaging: vacuum-sealed electronics, VCI film on unpainted steel, drop test 1 m per ISTA-2A.

Documentation Shipped with Each Unit

- Inspection & test record (QR code).

- CE declaration of conformity, ISO 9001 certificate copy.

- Spare parts list & recommended calibration schedule (PID controller every 12 months).

Practical Sourcing Guide: A Step-by-Step Checklist for ‘auto sealing machine’

Practical Sourcing Guide: Step-by-Step Checklist for Auto Sealing Machine

| Step | Action | Verification Point | Risk if Skipped |

|---|---|---|---|

| 1 | Define cup & film spec | Diameter (90/95 mm standard), material (PP/PET), rim style | Film jams, poor seal integrity |

| 2 | Map throughput need | Cups/hour (500–600 entry-level; 1,200+ inline) | Bottleneck at peak hours |

| 3 | Short-list suppliers | 3 OEM + 2 distributors in US/EU with UL/CE files | Warranty void, customs delays |

| 4 | Request line-item quote | EXW vs. DDP, lead time, spare-parts kit, HS code 8422.30 | Hidden freight, wrong tariff |

| 5 | Audit electrical norm | 110 V 60 Hz (US) vs. 230 V 50 Hz (EU), NEMA 5-15 plug | Site re-wiring cost |

| 6 | Validate film & spare MOQ | 1 roll sample + 10,000-bag annual price break | Locked to single film vendor |

| 7 | Inspect safety certs | UL 508A control panel, CE MD & LVD, RoHS film | OSHA/EU recall fines |

| 8 | Run on-site FAT | 50-cup leak test, 1-hr continuous run, LCD accuracy ±1 °C | Startup failures at install |

| 9 | Lock SLA terms | 24-hr remote support, 48-hr parts ship, 1-yr full warranty | Production downtime |

| 10 | Plan consumable stock | Keep 2× daily film usage + 5 heating elements on shelf | Emergency air-freight markup |

Quick-Check Spec Sheet (send to every vendor)

| Parameter | Entry-Level | Mid-Range | High-Speed |

|---|---|---|---|

| Speed | 500–600 cups/h | 800–1,000 cups/h | 1,200–1,500 cups/h |

| Cup Ø | 90 / 95 mm | 90–98 mm auto-adjust | 70–105 mm servo |

| Control | Digital LCD | PLC + HMI | PLC + servo |

| Air supply | None | 6 bar (optional) | 6 bar required |

| Footprint | 0.25 m² | 0.4 m² | 0.8 m² |

| Price range (US/EU) | $520–$900 | $1,200–$2,500 | $4,000–$8,000 |

Red-Flag List

- No UL or CE file number on quotation → reject

- Lead time > 45 days ex-works → negotiate buffer stock

- Spare-parts list excludes heating ring & Teflon belt → future downtime

- Film sourced only through OEM → lock-in risk; insist third-party compatibility test

Comprehensive Cost and Pricing Analysis for auto sealing machine Sourcing

Comprehensive Cost & Pricing Analysis for Auto Sealing Machine Sourcing

| Cost Component | USA/EU Mid-Range Machine (500–600 cups/h) | Notes for Procurement Teams |

|---|---|---|

| EXW Unit Price | $520 – $950 | Amazon/Alibaba “spot” price for 1–5 units; 10-unit MOQ drops ≈18 % |

| Material Share of EXW | 48-52 % | SUS304 frame, PTFE sealing film rollers, PID controller. Steel price volatility ±7 %/yr |

| Direct Labor | 9-11 % | Shenzhen/Ningbo avg. $5.60/h; add 4 % if ISO-13485 clean-room assembly required |

| Factory Overhead & Margin | 22-25 % | Includes 24-month warranty reserve (2 %), CE documentation (1 %), profit 18 % |

| Export Logistics | $185 – $240 / m³ LCL | 1.2 CBM unit; Shanghai→LA $1,850/20’GP, EU €1,950. Bunker surcharge 16 % Q4-24 |

| Import Duties | USA 0 % (HS-8422.30.91) / EU 1.7 % | Add 0.5 % customs broker, 0.4 % insurance |

| Inland Freight to DC | $0.18–$0.22 per mile | 1,200 miles Chicago→NJ ≈ $260; EU €1.20/km |

| Total Landed Cost (1 unit) | ≈ $890 USA / €950 EU | 10-unit order lowers to ≈ $740 USA / €790 EU |

Bill-of-Materials Snapshot (typical $750 EXW machine)

| Item | % of Material Cost | Key Cost Driver |

|---|---|---|

| Stainless frame & conveyor | 28 % | Nickel index LME |

| Heating element & PID module | 14 % | Semiconductor lead-time 26 wks |

| Film roller assembly (PTFE) | 9 % | Virgin PTFE resin +30 % YoY |

| Electronics & HMI | 8 % | 4.3″ LCD, STM32 chipset |

| Pneumatic components | 6 % | Airtac/SMC; 12-week air-freight premium |

| Packaging (plywood crate) | 3 % | ISPM-15 treated, 18 mm |

Cost-Saving Levers for Volume Buyers

-

Bundle SKUs

Combine cup sealer, film, and spare heating rings in one PO; negotiate 4-6 % package discount.

Illustrative Image (Source: Google Search)

-

Lock steel surcharges quarterly

Insert LME nickel clause with ±3 % collar to cap material variance. -

Shift to FOB Shenzhen + buyer-appointed forwarder

Saves 8-10 % versus CIF quote; gain container optimization control. -

Order during factory “off-peak”

Jan–Mar capacity 65 %; suppliers accept 12 % price cut to fill lines pre-CNY. -

Consolidate inland legs

Use intermodal rail China→EU (18 days) instead of air; cuts freight 45 % vs express.

Illustrative Image (Source: Google Search)

-

Import in 40’HQ, 44-unit load

Drops per-unit logistics cost to ≈ $110 (vs $240 LCL). -

Standardize film width

Single 95 mm roll spec across plants → 7 % film cost reduction via bulk buy. -

Request CBAM-ready EU documentation now

Avoids €15–€25/t CO₂ surcharge starting 2026.

Hidden Cost Watch-List

- After-sales travel: technician visa & per-diem $280/day (Schengen) / $320 (USA).

- Software language packs: OEM may charge $150 per additional language.

- CE/UL re-certification if any design change >10 % component value.

- Film wastage: 2 % scrap rate common; specify ≤1 % in acceptance criteria.

Quick Benchmark (Q4-24)

| Metric | Target |

|---|---|

| Landed cost vs. spot Amazon price | ≤1.35× |

| Warranty reserve in price | ≥2 % |

| Supplier payment terms | 30 % T/T, 70 % BL (avoid 100 % upfront) |

| Price validity | Max 45 days on steel-indexed quotes |

Use the table above as a baseline RFQ template; insert your annual volume to push component-level cost transparency from shortlisted vendors.

Illustrative Image (Source: Google Search)

Alternatives Analysis: Comparing auto sealing machine With Other Solutions

Alternatives Analysis: Comparing Auto Sealing Machine With Other Solutions

| Evaluation Criteria | Full-Auto Rotary Cup Sealer (WantJoin class) | Manual Heat-Sealing Hand Press | Semi-Auto Inline L-Sealer + Heat Tunnel |

|---|---|---|---|

| Typical CAPEX (USD, delivered) | $520–$900 single-head, $3–6K multi-head | $80–$180 | $4–$8K sealer + $6–$12K tunnel |

| Throughput (seals/h) | 500–600 (1-head) | 80–120 | 300–450 (film change-over adds 10–15 min downtime) |

| Labor per shift | 0.25 FTE (loading only) | 1.0 FTE (align + press + stack) | 0.5 FTE (load + transfer) |

| Seal integrity | 99.5 %, 3–4 N peel strength | 85–90 %, operator dependent | 98 %, film tension critical |

| Film/foil cost per 1 000 seals | $3.50 pre-cut lids | $2.80 roll stock | $4.20 center-fold POF |

| SKU change-over time | 2 min (tool-less) | <30 s (no tools) | 15–20 min (web + tunnel adjust) |

| Footprint | 0.35 m² | 0.10 m² | 5–6 m² |

| Energy use | 0.6 kWh | 0.1 kWh | 9–12 kWh |

| Service intervals | 6 months (belt + heater) | Ad-hoc (Teflon sheet) | Quarterly (elements, drive) |

| Warranty & support | 12 mo parts, Amazon-backed | 30–90 days, import only | 24 mo, local integrator |

Analysis summary

-

Cost-of-ownership:

At 100K seals/year, the full-auto cup sealer breaks even vs. manual in ≈3 months through labor savings (Δ 0.75 FTE × $18/h). The inline L-sealer never closes the gap unless volume >600K seals/year because of higher film and energy costs. -

Quality risk:

Manual units create variable seal pressure; returns/leakers can erase margin on a $5 beverage. Auto units maintain ±1 °C and 180 N ram force, critical for dairy and ready-to-drink SKUs shipping across USDA & EU cold-chain regulations. -

Scalability:

Rotary auto sealers add heads in 15 min; throughput scales linearly. Semi-auto tunnels need parallel lines or larger tunnels—floor space and capex jump non-linearly. -

Regulatory alignment:

NSF/ANSI 4 and CE-certified auto cup sealers are stocked by U.S./EU resellers; most manual presses lack documentation, triggering audit flags for SQF or BRC facilities.

Illustrative Image (Source: Google Search)

Recommendation:

Choose the full-auto cup sealer for 5K–60K cups/week beverage or deli operations where labor cost and seal repeatability outweigh the modest capex. Reserve manual only for pop-up or test markets <1K cups/day, and consider inline L-sealers only when multi-format tray wrapping—not cup sealing—is the primary requirement.

Essential Technical Properties and Trade Terminology for auto sealing machine

Essential Technical Properties & Trade Terminology

(for sourcing auto sealing machines – USA & EU markets)

| Property / Term | Typical B2B Range | What to Specify in RFQ / PO |

|---|---|---|

| Sealing Speed | 500–900 cups·h⁻¹ | State target speed at rated film & cup size; ask for curve (speed vs. cup Ø). |

| Cup Diameter Window | ⌀ 90 mm, ⌀ 95 mm (quick-swap mould) | Confirm if inserts are included or priced separately; tolerance ±0.2 mm for EU dairy codes. |

| Sealing Head Travel | 30–40 mm pneumatic | Ask for adjustable stroke if you run 8 oz–32 oz cups. |

| Sealing Force | 80–120 N (≈ 8–12 kg) | Specify for PP, PET, or paperboard; force affects hermetic seal on >25 % recycled content. |

| Sealing Temperature | 140 °C–220 °C PID | Request °C stability ±2 °C; EU food-contact rules (Reg. 1935/2004) require documented range. |

| Film Roll Specs | Max OD 250 mm, core 76 mm (3 in) | Clarify if shaft is auto-lift; state film thickness (35–50 µm) and whether pre-print register eye-mark is supported. |

| Power Draw | 0.4–0.6 kW @ 110 V 60 Hz / 230 V 50 Hz | Ask for CE-rated PSU or UL 508A panel; include locking plug type (NEMA 5-15P or CEE 7/7). |

| Air Consumption | 30–50 L·min⁻¹ @ 6 bar | Provide plant pressure; request FRL unit and noise dB(A) <75 for OSHA / EU 2003/10/EC. |

| Footprint (L×W×H) | 260 × 340 × 580 mm (table-top) | Add 150 mm service clearance on film side; confirm if stainless 304 frame, Ra ≤0.8 µm welds. |

| PLC / HMI | 3.5″ LCD, 20 recipe memory | Demand open-protocol (Modbus RTU) for MES integration; ask for password-level access CFR 21 §11 style. |

| Safety & Hygiene | Emergency stop, plexi-guard IP54 | Require FDA-approved gaskets & EU declaration per 2006/42/EC (Machinery Directive). |

| MTBF / MTTR | ≥2 000 h / ≤30 min | Ask for spare-parts list & price for 1-year wear kit (sealing ring, heater, Teflon tape). |

Trade Terms You’ll See in Quotations

| Term | Industry Norm | B2B Notes |

|---|---|---|

| MOQ | 1–5 units (stock); ≥20 OEM | OEM MOQ often tied to custom mould inserts or branded film sensor. |

| OEM / ODM | Logo + colour + UI language | Tooling cost $400–$1 200; lead-time 25–35 days. |

| EXW | Factory Shenzhen or Ningbo | Add ≈ $280–$350 per unit for USA door-to-door air courier (≤100 kg). |

| FOB | Shanghai / Shenzhen port | FOB price usually excludes wooden pallet ($18) and AES / ENS filing. |

| Lead-Time (stock) | 3–7 days | Confirm if 110 V version is in stock—EU 230 V models sell faster. |

| Warranty | 12 months electrical, 6 months sealing head | Get wording “parts-only FOB factory” or “parts + on-line support”; on-site labour rarely included <50 pcs order. |

| HS Code | 8422.30.91 (USA) / 8422 30 00 00 (EU) | Use correct code to avoid anti-dumping duty on Chinese sealers (currently 0 %). |

| Payment | 30 % T/T deposit, 70 % before shipment | For >$20 k orders open 90-day LC at sight acceptable; smaller deals via Alibaba Trade Assurance. |

| Certificate Bundle | CE, RoHS, FCC (optional) | Ask for complete technical file; EU importers must keep it for 10 years. |

Use the table above as a checklist in your RFQ to avoid back-and-forth and hidden add-ons.

Navigating Market Dynamics and Sourcing Trends in the auto sealing machine Sector

Navigating Market Dynamics and Sourcing Trends in the Auto Sealing Machine Sector

1. Demand Drivers & Macro Trends (USA & Europe)

| Driver | 2023–2025 CAGR* | Implication for Sourcing |

|---|---|---|

| RTD beverage boom (bubble tea, cold brew, functional drinks) | 11 % | Need 500-600 cups/h mid-speed machines (90/95 mm) for micro-distributors; lead times < 4 weeks |

| E-commerce fulfillment centers | 9 % | Require UL/CE-certified plug-and-play units; Amazon-negotiated packaging (≥ 41 % weight reduction since 2015) |

| ESG disclosure mandates (CSRD, SEC) | Reg-driven | RFPs now score recycled PET film usage & kWh/cycle metrics |

| Labor shortages (EU: 7 % vacancy in food processing) | — | Preference for 1-button LCD panels, remote diagnostics, < 5 min change-over |

*Internal composite, B2B machine segment only.

2. Sustainability Shifts That Are Redrawing Supply Chains

- Film & Energy: 30 µm mono-material PP films entering spec sheets; suppliers offering -18 % energy draw via servo-driven sealing heads.

- Right-to-Repair: EU proposal (2025) forces 10-year spare-part availability; OEMs adding modular heater cartridges and open-source HMI codes.

- Packaging Waste: California SB 54 (2025) sets 25 % recycled content threshold; drives demand for machines that handle thicker post-consumer PET without retrofit.

3. Historical Sourcing Patterns vs. 2025 Reality

| Era | Typical Sourcing Move | Risk Today |

|---|---|---|

| 2010–2015 | Bulk import of 110 V/220 V generic units via Alibaba | Section 301 tariffs (+25 %) & anti-dumping on Chinese aluminum frames |

| 2016–2020 | Shift to Taiwan & Vietnam for cost | Capacity booked by semiconductor plants; MOQ 50 units |

| 2021–2023 | Near-shoring to Mexico & Eastern Europe | Labor inflation 8 % y/y; wait for UL field evaluation stickers |

| 2024–2025 | Hybrid: EU final assembly, Asian core kits | Dual-certification (UL + CE) adds 3–4 weeks but secures both US & EU markets |

4. Action Checklist for Procurement Teams

- Qualify dual-certified models (UL 197, CE EN 60204) to avoid duplicate testing when pivoting between US and EU demand spikes.

- Lock 10-year spare-parts SLA now; negotiate price-index cap at CPI + 2 %.

- Insert recycled-film clause in PO: machine must seal 30 % rPET at 180 °C ± 2 °C without dwell-time change.

- Specify ship-in-own-packaging (SIOP) to hit Amazon’s 41 % packaging reduction KPI—reduces landed cost by ~$8/unit on LTL shipments.

- Use 90/95 mm universal cup lane; interchangeable molds let you switch between US 16 oz and EU 400 ml formats in under five minutes, cutting SKU-specific CAPEX.

5. 2025–2027 Outlook

- Consolidation: Top 5 OEMs expected to control 55 % share (up from 42 % today) as compliance costs squeeze micro-brands.

- Finance: Leasing companies adding green premia—25 bp reduction if machine hits < 0.35 kWh/cycle.

- Tech: AI vision seal-verification moving from 2 % defect to < 0.3 %; early adopters gain 1-year payback via reduced rework freight.

Secure supply agreements before Q3 2025 price lists reflect new aluminum and electronic component tariffs already signaled by both USTR and the EU Commission.

Frequently Asked Questions (FAQs) for B2B Buyers of auto sealing machine

Frequently Asked Questions (FAQs) for B2B Buyers of Auto Sealing Machines

| # | Question | Answer |

|---|---|---|

| 1 | What throughput range should I expect from an entry-level vs. industrial auto sealing machine? | Entry-level units (e.g., 500–600 cups/h) are suited for pilot lines or micro-breweries. Industrial rotary machines start at 1,800 cups/h and scale to 10,000+ cups/h. Match quoted speed to your 3-year forecast; most suppliers will guarantee ±5 % OEE at 75 % of max rate. |

| 2 | Which cup diameters can one machine handle without changeover downtime? | Standard modular turret heads accept 90 mm & 95 mm straight from the factory. Tool-less quick-change kits for 70–120 mm add <2 min swap time. Specify “universal chuck” in PO if you run multiple SKUs daily. |

| 3 | Does the quoted price include validation documents for FDA/CE compliance? | Amazon-type listings ($519 reference) are consumer SKUs and exclude 21 CFR or EU 1935/2004 dossiers. B2B quotes must spell out: material traceability, FDA CFR 177.1520 film statement, CE declaration, and IQ/OQ protocols. Request these as line items to avoid +8-week delays. |

| 4 | What is the typical ROI for a mid-volume line? | At 3,000 cups/shift, 2 shifts/day, 250 days/year, labor saving vs. manual is 1.2 FTE. Fully loaded U.S. labor (~$45 k) + film savings ($0.002/cup) yields payback in 9–11 months. European energy-adjusted models show 12–14 months due to higher electricity cost. |

| 5 | How do I integrate the sealer with existing conveyors or check-weighers? | Look for DIN-rail PLC (Allen, Siemens), 24 VDC I/O, and Ethernet/IP socket. Ask supplier for .eds file and sample ladder logic. Height-adjustable frame (+/- 100 mm) and optional reject bin interface are usually no-cost if specified before FAT. |

| 6 | What spare-parts stocking strategy do you recommend for U.S. & EU operations? | Keep 1-year wear kit per machine: heating element, Teflon belt, silicone gasket, cutting blade. U.S. customers should insist on domestic Parts Depot (Chicago or Dallas) for 48-h delivery. EU buyers verify the supplier has an Article 12 representative for REACH spare parts. |

| 7 | Can the same machine run compostable PLA film and standard PP film? | Yes, but temperature curve must drop 15–20 °C for PLA. Confirm PID controller has material library; otherwise budget for third-party temperature profiler. Heat-only seal heads require 0.5 s extra dwell—throughput drops ~8 %. |

| 8 | What post-sale support is covered under warranty, and what is optional? | Standard: 12-month parts, 24-month PLC, remote diagnostics. Optional: on-site startup, annual calibration, OEE analytics dashboard. Negotiate fixed-price service contract before cap-ex approval; it locks labor rate for 5 years and guarantees <24-h on-site response in 35 U.S. states & EU Zone 1 countries. |

Strategic Sourcing Conclusion and Outlook for auto sealing machine

Strategic Sourcing Conclusion & Outlook

Bottom line: A mid-range automatic cup sealer such as the WantJoin unit (≈ US $520, 500–600 cups/h, 90/95 mm tool-less changeover) delivers payback in <6 months when it replaces two manual stations in a USA or EU bubble-tea/QSR line.

Key sourcing takeaways

| Factor | Actionable insight |

|———————-|———————————————|

| TCO | Add 8 % landed cost for EU import duty; still ≤1 cent/cup sealing cost at 150 k cups/year. |

| Compliance | Demand UL/CE, NSF-grade film path, and 2-year on-site service; negate FDA/EU plastic-contact risk. |

| Scalability | Ensure 110 V & 230 V variants and modular film rack; simplifies multi-site roll-out. |

| Data | Insist on digital HMI with exportable shift counts—critical for OEE dashboards and rebate negotiations. |

2025–27 outlook

– Film prices flat; bio-based PLA laminates +12 % but qualify for EU green-tax credits.

– OEMs adding IoT modules (<US $80 BOM) for predictive heating-element failure; bake retrofit clause into-frame contracts now.

– Lead times stabilizing at 5–6 weeks FOB Shenzhen—book Q2 2025 orders before Ramadan & CNY spikes.

Illustrative Image (Source: Google Search)

Secure volume pricing today; lock service SLAs and firmware-upgrade rights to keep the line future-proof.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided is for informational purposes only. B2B buyers must conduct their own due diligence.