The global automotive air conditioning (A/C) evaporator market is experiencing steady growth, driven by rising vehicle production, increasing demand for passenger comfort, and stringent regulations promoting energy-efficient thermal systems. According to Mordor Intelligence, the automotive HVAC market is projected to grow at a CAGR of over 5.2% from 2023 to 2028, with evaporators representing a critical component due to their role in cooling efficiency and cabin air quality. This expansion is further fueled by the surge in electric vehicle (EV) adoption, where compact, lightweight, and high-performance evaporators are essential for optimizing battery range and thermal management. As automakers prioritize enhanced climate control systems, leading manufacturers are investing in advanced materials and innovative designs to meet evolving performance and sustainability standards. In this competitive landscape, the top 10 auto A/C evaporator manufacturers are distinguished by their technological expertise, global supply chain reach, and strategic partnerships with OEMs.

Top 10 Auto Ac Evaporator Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Classic Auto Air

Domain Est. 1999

Website: classicautoair.com

Key Highlights: Classic Auto Air is your source for factory air conditioning parts & AC systems for 70’s & older Ford, GM, Mopar, Porsche, Custom Street Rods & more….

#2 Advanced Distributor Products

Domain Est. 2000 | Founded: 1992

Website: adpnow.com

Key Highlights: ADP #1 producer of residential evaporator coils. Serving the HVAC community since 1992, with offices in Grenada, MS, and Stone Mountain, GA….

#3 address / contact info

Domain Est. 2000

Website: uacparts.com

Key Highlights: Manufacturer. All Competitors, Universal Air Conditioner, AC Delco, ACKOJA, Active Radiator, Acura/Honda, Advance Auto Parts … Evaporator and Components ……

#4 Car Evaporators for Air Conditioning

Domain Est. 2015

Website: valeoservice.us

Key Highlights: Trusted by automotive manufacturers worldwide, Valeo evaporators ensure efficient cooling, dehumidification, and high durability in all driving conditions….

#5 Nissens Evaporator

Domain Est. 1996

Website: nissens.com

Key Highlights: Nissens’ wide range of evaporators for passenger cars, vans, and trucks is perfectly finished for easy & smooth installation. The test proved long ……

#6 Vintage Air

Domain Est. 1996

Website: vintageair.com

Key Highlights: From our advanced Gen 5 systems to heaters and under dash evaporator kits with controls and louver options, you choose the components that work best for your ……

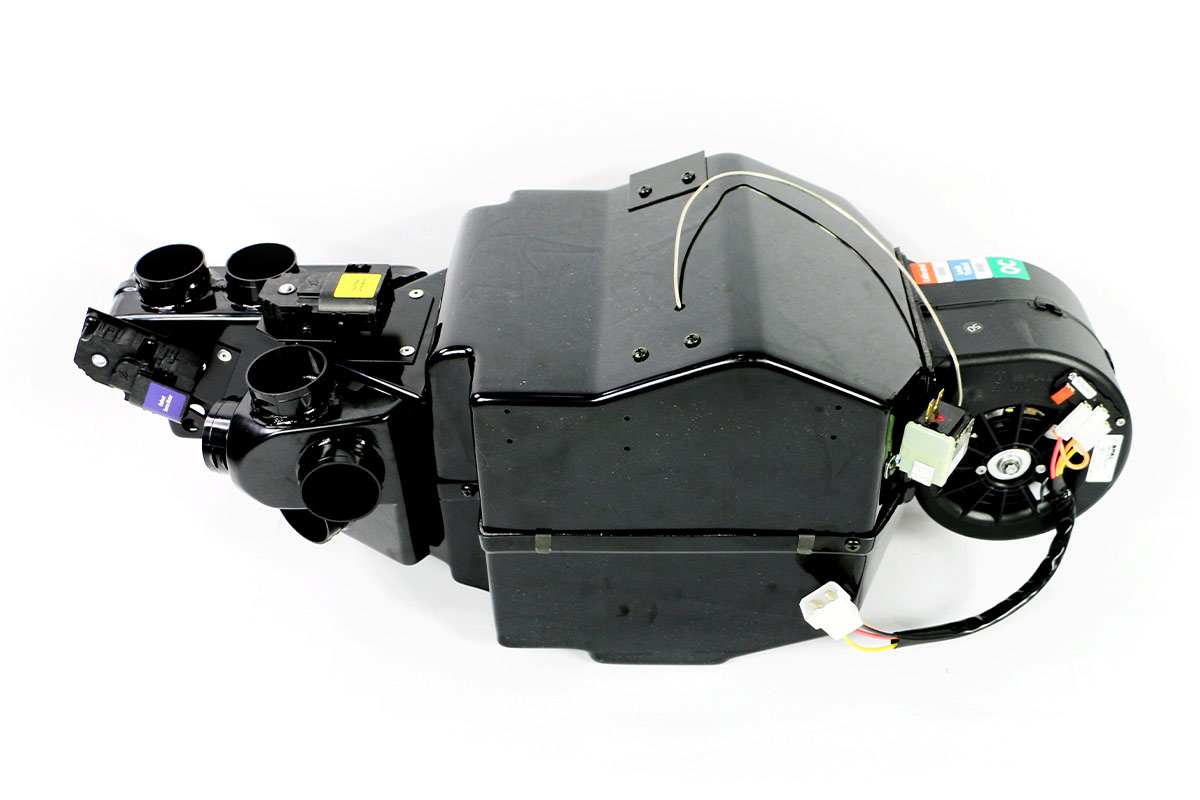

#7 AC Evaporator Coils

Domain Est. 1997

Website: oldairproducts.com

Key Highlights: 3-day delivery 90-day returnsA complete line of replacement evaporator cores for many 1959 & up GM vehicles.The manufacturing process begins by selecting the proper size core and t…

#8 Evaporator Cores

Domain Est. 1997

Website: aircomponents.com

Key Highlights: Free delivery 365-day returnsWe offer a wide range of high-quality evaporator cores and assemblies for all makes and models of vehicles. Our cores and assemblies are made from dura…

#9 Car Air Conditioning Evaporators

Domain Est. 2000

Website: valeoservice.com

Key Highlights: Valeo is a world leader in automotive air conditioning, manufacturing evaporators to supply automakers and the aftermarket….

#10 Thermal Management & Air

Domain Est. 2000

Website: denso.com

Key Highlights: Our compact and easy-to-mount HVAC unit, or our bus air-conditioning unit mounted on the roof provides safe and comfortable cabin space….

Expert Sourcing Insights for Auto Ac Evaporator

H2: 2026 Market Trends for Automotive AC Evaporators

The global automotive air conditioning (AC) evaporator market is poised for significant transformation by 2026, driven by technological innovation, shifting vehicle production trends, and evolving environmental regulations. As a critical component in automotive HVAC systems, the AC evaporator absorbs heat from the cabin air, facilitating cooling through refrigerant phase change. Several key trends are expected to shape the market dynamics in 2026:

-

Increased Demand for Electric Vehicles (EVs)

The rapid adoption of electric vehicles is one of the most influential factors impacting the AC evaporator market. Unlike traditional internal combustion engine (ICE) vehicles, EVs rely entirely on electrically powered HVAC systems, placing greater emphasis on energy efficiency. This has led to the development of advanced evaporators optimized for thermal efficiency and compact design to accommodate limited space in EV platforms. By 2026, the growing EV market—projected to represent over 30% of global vehicle sales—will drive demand for lightweight, high-performance evaporators with integrated thermal management capabilities. -

Shift Toward Environmentally Friendly Refrigerants

Regulatory pressure to reduce greenhouse gas emissions, particularly from mobile air conditioning systems, is accelerating the transition from high-global-warming-potential (GWP) refrigerants like R-134a to lower-GWP alternatives such as R-1234yf and natural refrigerants like CO₂ (R-744). Evaporators designed for CO₂ systems must withstand higher operating pressures and offer enhanced thermal conductivity. By 2026, automakers in Europe, North America, and parts of Asia are expected to widely adopt these next-generation refrigerants, necessitating redesigns of evaporators to ensure compatibility and performance. -

Integration with Advanced Thermal Management Systems

In both EVs and hybrids, evaporators are increasingly integrated into broader vehicle thermal management systems that regulate battery, motor, and cabin temperatures. This integration requires evaporators to function as part of a networked system, often using variable control mechanisms and smart sensors. By 2026, demand will rise for intelligent evaporators capable of adaptive cooling, supporting energy recovery and improving overall vehicle efficiency. -

Growth in Emerging Markets

Rising vehicle ownership and urbanization in regions like India, Southeast Asia, and Latin America are expected to boost demand for comfort-oriented features such as air conditioning. As a result, the AC evaporator market in these regions will expand, particularly for cost-effective, durable solutions tailored to high-temperature climates. Localized manufacturing and supply chain development will support this growth. -

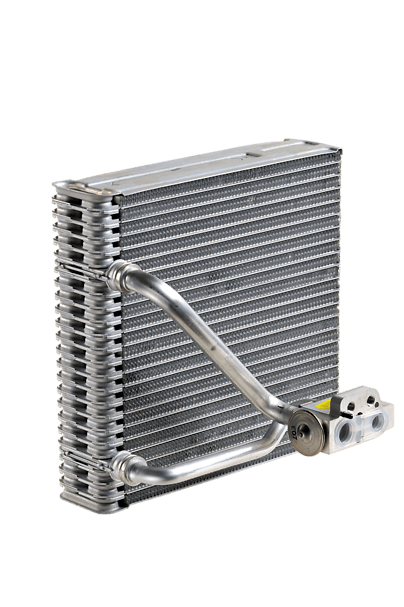

Material and Design Innovation

To meet demands for weight reduction and corrosion resistance, manufacturers are adopting aluminum microchannel evaporators over traditional tube-fin designs. These newer models offer superior heat transfer efficiency and reduced refrigerant charge. By 2026, microchannel evaporators are expected to dominate the market, especially in premium and electric vehicles. -

Consolidation Among Suppliers and OEM Partnerships

The complexity of next-gen HVAC systems is fostering closer collaboration between evaporator manufacturers and OEMs. Companies like Denso, Mahle, and Valeo are investing in R&D to develop proprietary evaporator technologies. Market consolidation is anticipated as smaller players struggle to keep pace with technological demands, leading to strategic mergers and partnerships by 2026.

In conclusion, the 2026 automotive AC evaporator market will be characterized by innovation driven by electrification, sustainability, and system integration. Manufacturers that adapt to these trends by offering efficient, compact, and environmentally compliant solutions will be best positioned for growth in an increasingly competitive landscape.

Common Pitfalls When Sourcing Auto AC Evaporators (Quality & IP)

Sourcing automotive AC evaporators, especially from global or aftermarket suppliers, involves navigating several critical risks related to both product quality and intellectual property (IP). Overlooking these pitfalls can result in system failures, warranty claims, legal disputes, and reputational damage.

Poor Build Quality and Material Defects

One of the most frequent issues is receiving evaporators manufactured with substandard materials or inadequate workmanship. Low-cost suppliers may use undersized tubing, thin aluminum fins, or inferior brazing techniques, leading to premature leaks, reduced heat transfer efficiency, or structural collapse under pressure. Such components often fail to meet OEM performance and durability standards, resulting in increased warranty costs and customer dissatisfaction.

Inaccurate Dimensional Specifications and Fitment Issues

Evaporators must fit precisely within tight engine compartment spaces and align perfectly with ducting, mounting points, and connecting hoses. Poorly sourced units may deviate from OEM specifications—even slightly—causing installation difficulties, air bypass, reduced cooling performance, or damage to surrounding components. Non-standard port placements or tube routing can also complicate retrofitting and increase labor costs.

Use of Non-OEM Refrigerant and Lubricant Compatibility

Some aftermarket evaporators are not properly cleaned or are pre-charged with incorrect lubricants incompatible with modern refrigerants like R-134a or R-1234yf. Residual contaminants such as oils, moisture, or machining debris can circulate through the AC system, leading to compressor failure or blockages in the expansion valve. Ensuring compatibility with current refrigerant standards is critical for long-term reliability.

Intellectual Property (IP) Infringement Risks

Sourcing evaporators that replicate OEM designs without proper licensing exposes buyers to significant legal exposure. Many evaporator designs are protected by patents, trade dress, or technical copyrights. Purchasing or distributing “OEM-identical” aftermarket parts—especially those bearing forged logos or part numbers—can constitute IP infringement, leading to customs seizures, cease-and-desist orders, or litigation from original manufacturers.

Lack of Traceability and Certification

Reputable suppliers provide documentation such as ISO/TS 16949 certification, material test reports, and batch traceability. Many low-cost or unverified sources lack such documentation, making it difficult to verify compliance with industry standards or conduct root-cause analysis in case of field failures. This absence also complicates qualification processes for OEM or fleet customers.

Counterfeit and Gray Market Components

Some suppliers distribute counterfeit evaporators that mimic OEM branding and packaging. These often bypass quality control entirely and may be used, refurbished, or fraudulently labeled. Gray market units—imported without brand owner authorization—can also lack proper support, warranty, or compliance with regional safety and environmental regulations.

Inadequate Testing and Validation

Many non-OEM evaporators are not subjected to rigorous performance and durability testing under real-world conditions. Without evidence of burst pressure tests, thermal cycling, salt spray resistance, or airflow validation, there’s a high risk of in-field failures, especially in extreme climates or heavy-duty applications.

Mitigating these pitfalls requires due diligence: auditing suppliers, verifying certifications, conducting sample testing, and ensuring clear IP compliance in procurement contracts.

Logistics & Compliance Guide for Auto AC Evaporator

Product Overview

The auto AC evaporator is a critical component of a vehicle’s air conditioning system, responsible for absorbing heat from the cabin air. Due to its metal and refrigerant-exposed construction, proper handling, packaging, and regulatory compliance are essential during storage, transport, and distribution.

Packaging Requirements

Use robust, sealed packaging to prevent contamination, moisture ingress, and physical damage. Evaporators must be individually wrapped in anti-corrosion material (e.g., VCI paper) and placed in rigid cardboard or plastic containers. Seal ends of tubing to avoid debris entry. Include desiccants if stored in humid environments.

Storage Conditions

Store in a dry, temperature-controlled environment (10°C to 30°C). Avoid exposure to direct sunlight, extreme temperatures, and high humidity to prevent internal corrosion or seal degradation. Keep upright or as specified by the manufacturer to avoid oil pooling or structural stress.

Transport Regulations

Comply with international and regional transportation standards (e.g., IMDG for sea, ADR for road in Europe). While AC evaporators typically do not contain refrigerant at shipping, confirm residual content. If trace refrigerants are present, classify as hazardous goods under UN 3157 (Refrigerating machines) and follow appropriate labeling and documentation.

Hazardous Materials Compliance

Ensure evaporators are fully evacuated of refrigerants prior to shipment. Residual refrigerants may fall under EPA (USA), F-Gas (EU), or other national regulations. Provide certification of evacuation (e.g., 500-micron vacuum test) when required. Prohibit shipment of units containing ozone-depleting substances (e.g., R-12) unless under specific hazardous waste protocols.

Import/Export Documentation

Prepare accurate commercial invoices, packing lists, and bills of lading. Include HS Code: 8415.90 (parts of air conditioning units). Confirm destination country requirements; some markets (e.g., EU, Australia) require conformity assessments or registration under environmental directives (e.g., EU REACH, RoHS for restricted substances in materials).

Environmental & Safety Standards

Ensure compliance with REACH (EU), RoHS (EU), and TSCA (USA) regarding restricted substances (e.g., lead, cadmium, PBBs). Verify recyclability markings if applicable. Provide Safety Data Sheets (SDS) if residual refrigerants or oils are present.

Labeling & Marking

Label each package with product identification, batch number, manufacturing date, and handling instructions (e.g., “Fragile,” “Keep Dry,” “Do Not Invert”). Include manufacturer details and compliance marks (e.g., CE, E-Mark for automotive parts in Europe).

Customs Clearance Considerations

Anticipate inspections for environmental compliance, especially in regions with strict refrigerant regulations. Maintain records of refrigerant evacuation, material certifications, and conformity declarations. Use authorized customs brokers familiar with automotive parts and environmental controls.

Reverse Logistics & Returns

Establish procedures for handling returned evaporators. Inspect for contamination and ensure safe refrigerant recovery before refurbishment or disposal. Comply with local waste electrical and electronic equipment (WEEE) regulations for end-of-life units.

Carrier & Insurance Selection

Use carriers experienced in automotive components with climate-controlled options if needed. Insure shipments against damage, loss, and environmental liability. Specify coverage for high-value or sensitive consignments.

Audit & Compliance Verification

Conduct periodic audits of packaging, handling, and documentation processes. Verify supplier compliance with environmental and safety standards. Maintain records for traceability and regulatory audits (e.g., EPA, customs authorities).

Conclusion for Sourcing Auto AC Evaporators:

Sourcing auto AC evaporators requires a strategic approach that balances quality, cost, availability, and supplier reliability. After evaluating various suppliers, manufacturing regions, and product specifications, it is clear that selecting the right evaporator involves more than just competitive pricing. Ensuring compatibility with a wide range of vehicle makes and models, adhering to OEM standards, and verifying materials and manufacturing processes are critical to maintaining performance and customer satisfaction.

Sourcing from reputable manufacturers—whether domestic or international—provides long-term value through consistent quality and reduced warranty claims. Additionally, building strong relationships with suppliers who offer technical support, timely delivery, and scalability ensures supply chain resilience. Factors such as certifications (e.g., ISO, TS 16949), testing procedures, and environmental compliance should not be overlooked.

In conclusion, the optimal sourcing strategy combines thorough supplier vetting, quality assurance protocols, and a focus on total cost of ownership rather than initial purchase price. By prioritizing these elements, businesses can secure reliable, high-performance auto AC evaporators that meet market demands and support long-term growth in the automotive aftermarket or OEM sectors.