The global concrete machinery market, including auger concrete equipment, is experiencing steady growth driven by rising infrastructure development and urbanization. According to a report by Mordor Intelligence, the Construction Machinery market is projected to grow at a CAGR of over 5.2% from 2024 to 2029, with increasing demand for efficient concrete mixing and placement solutions fueling adoption of auger-type concrete pumps and mixers. Similarly, Grand View Research valued the global concrete mixer market at USD 5.8 billion in 2022 and forecast a CAGR of 5.4% from 2023 to 2030, citing advancements in automated and site-ready machinery. As contractors prioritize mobility, accuracy, and on-site batching efficiency, auger concrete technology has emerged as a preferred solution in residential, commercial, and remote construction projects. This growing demand has intensified competition among manufacturers, driving innovation in durability, fuel efficiency, and smart control systems. Below, we highlight the top 9 auger concrete manufacturers leading this evolution with proven performance, technological advancement, and global reach.

Top 9 Auger Concrete Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Auger Drives Archives

Domain Est. 1999

Website: cummingsandbricker.com

Key Highlights: Their products include Hydraulic Auger Systems, Post Drivers, Tree & Post Pullers, Pallet Forks and Material Handling Buckets….

#2 Earth Drills, Augers, Trenchers, Skid Steer Brooms, Skid Steer Pallet …

Domain Est. 2005

Website: augertorque.com

Key Highlights: Auger Torque is a global manufacturer of hydraulic attachments which improve efficiency through operational cost savings and productivity….

#3 Auger Cast

Domain Est. 2009 | Founded: 1970

Website: dynamicconcretepumping.com

Key Highlights: Since 1970, Dynamic Concrete Pumping, Inc. has been a trusted leader in deep foundation solutions. Our sole focus on auger piling has allowed us to refine ……

#4 Cement Auger – Fast-Way

Domain Est. 2023

Website: fastwaymfg.com

Key Highlights: As a cement auger manufacturer, we produce heavy-duty Fast-Way Cement Auger. It comes with a bag breaker (when bulk cement is not available) and a small ……

#5 General Equipment Company

Domain Est. 1996

Website: generalequip.com

Key Highlights: Building equipment that rocks! That’s how General Equipment Company has been building value for over 60 years….

#6 Auger Systems

Domain Est. 1996

Website: danuser.com

Key Highlights: Hydraulic EP Series. Manufactured to our engineering design and specifications, the EP Auger System is ideal for various industries and applications….

#7 American Augers

Domain Est. 1997 | Founded: 1970

Website: americanaugers.com

Key Highlights: Founded in 1970, American Augers was born from a desire to innovate within the auger boring industry and take HDD into a whole new weightclass….

#8 Concrete

Domain Est. 2003

Website: johnbaaschauger.com

Key Highlights: To learn more about auger flighting from John Baasch, contact us today at 308-280-8190, fill out our online contact form, or click here for a custom quote….

#9 Digga North America

Domain Est. 2006

Website: diggausa.com

Key Highlights: World leader in Auger, Ground Anchor & Foundation Drives and Augers. Based in Dyersville Iowa we service the piling, screw anchor and foundation ……

Expert Sourcing Insights for Auger Concrete

H2: 2026 Market Trends for Auger Concrete

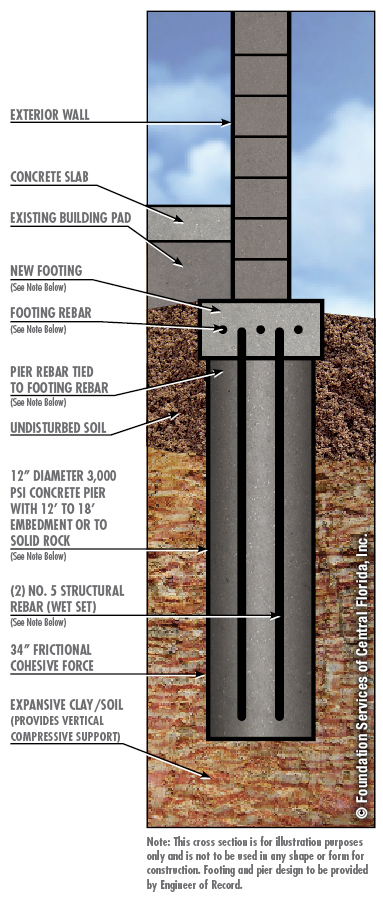

The auger concrete market is poised for notable transformation by 2026, driven by advancements in construction technologies, increasing infrastructure investments, and a growing emphasis on sustainable building practices. Auger concrete, commonly used in deep foundation systems such as drilled shafts and micropiles, is becoming increasingly integral to both commercial and civil engineering projects. Key market trends shaping the auger concrete landscape in 2026 include:

-

Growth in Infrastructure Development

Governments worldwide are prioritizing infrastructure renewal and expansion, particularly in emerging economies and regions recovering from economic disruptions. In North America and Europe, aging infrastructure is spurring large-scale repair and replacement projects, while Asia-Pacific countries continue rapid urbanization. These developments are increasing demand for reliable deep foundation solutions, boosting the adoption of auger concrete techniques. -

Technological Advancements in Equipment

By 2026, auger drilling equipment is expected to incorporate more automation, real-time monitoring, and GPS-guided positioning systems. These innovations enhance precision, reduce labor costs, and improve safety on construction sites. Automated concrete delivery systems synchronized with auger operations are also improving efficiency and minimizing material waste. -

Sustainability and Green Concrete Adoption

Environmental regulations and corporate sustainability goals are accelerating the use of low-carbon concrete mixes in auger applications. Innovations such as supplementary cementitious materials (SCMs), recycled aggregates, and carbon capture technologies are being integrated into auger concrete formulations. By 2026, green auger concrete solutions are anticipated to capture a growing share of the market, particularly in public sector projects requiring environmental compliance. -

Rise of Urban High-Rise and Underground Construction

With urban land constraints pushing developments vertically and underground, the demand for deep foundation systems is rising. Auger concrete piling is a preferred method for high-rise buildings, subway systems, and underground parking due to its minimal vibration and noise—critical in densely populated areas. -

Consolidation and Strategic Partnerships

The auger concrete sector is seeing increased consolidation among contractors and material suppliers. By 2026, larger firms are likely to dominate the market through vertical integration, combining drilling services with concrete supply and engineering expertise. Strategic partnerships with technology providers are also enabling faster adoption of digital project management tools. -

Skilled Labor Shortages and Training Initiatives

A persistent shortage of skilled operators and technicians is driving investment in training programs and apprenticeships. Equipment manufacturers and industry associations are collaborating to standardize best practices and certifications, ensuring safety and quality in auger concrete operations.

In summary, the 2026 auger concrete market will be characterized by technological innovation, sustainability integration, and strong demand from infrastructure and urban development sectors. Companies that embrace automation, green materials, and workforce development will be best positioned to capitalize on emerging opportunities.

Common Pitfalls Sourcing Auger Cast Concrete (Quality, IP)

Sourcing auger cast concrete—often used in deep foundation elements like drilled shafts or continuous flight auger (CFA) piles—requires careful attention to both material quality and intellectual property (IP) considerations. Overlooking these aspects can lead to structural failures, project delays, legal disputes, and increased costs.

Quality-Related Pitfalls

1. Inconsistent Concrete Mix Design

Using a mix not specifically tailored for auger casting can result in segregation, poor pumpability, or inadequate strength development. A mix too dry may clog the auger, while one too wet can lead to necking or washout in unstable soils.

2. Poor Workability and Pumpability

Auger cast concrete must remain fluid enough to flow under pressure through the hollow stem of the auger. If slump or rheology is not properly controlled, blockages can occur, halting operations and compromising pile integrity.

3. Inadequate Monitoring and Testing

Failure to conduct regular on-site testing (slump, air content, temperature, compressive strength) can allow substandard concrete to be placed. Without proper documentation, verifying compliance with project specifications becomes difficult.

4. Lack of Supplier Experience with Auger Applications

Not all concrete suppliers understand the technical demands of auger casting. Inexperienced suppliers may deliver a standard structural mix unsuitable for high-pressure pumping or prolonged placement times.

5. Delayed or Improper Placement

Delays between batching and placement can cause premature setting, especially in hot conditions. This reduces flow characteristics and can lead to cold joints or incomplete piles.

Intellectual Property (IP)-Related Pitfalls

1. Unauthorized Use of Proprietary Methods or Formulations

Some contractors or suppliers use patented concrete admixtures, grouting techniques, or installation methodologies. Sourcing concrete designed for use with such IP without proper licensing can expose the project owner or general contractor to infringement claims.

2. Ambiguous Specification Ownership

If project specifications include proprietary concrete blends or process requirements, unclear IP attribution can lead to disputes over who holds rights or liabilities—especially if performance issues arise.

3. Failure to Address IP in Contracts

Neglecting to define IP ownership, usage rights, and indemnification clauses in procurement agreements may result in legal exposure. For example, using a supplier’s “custom” mix that incorporates patented technology without permission can trigger lawsuits.

4. Reverse Engineering or Copying Trade Secrets

Attempting to replicate a competitor’s high-performance auger concrete mix based on observed results risks violating trade secret laws, particularly if confidential data (e.g., admixture ratios) is improperly obtained.

5. Inadequate Documentation of IP Compliance

Without clear records showing that all materials and methods used are either non-proprietary, properly licensed, or developed in-house, organizations may struggle to defend against IP allegations during audits or litigation.

Mitigating these pitfalls requires due diligence in supplier selection, rigorous quality control protocols, and proactive legal review of technical specifications and contracts to ensure both performance and compliance.

Logistics & Compliance Guide for Auger Concrete

This guide outlines the essential logistics procedures and compliance requirements for Auger Concrete operations to ensure safe, efficient, and legally compliant delivery and installation of concrete products.

Order Processing & Scheduling

All concrete orders must be confirmed via the company’s digital dispatch system at least 24 hours in advance. Key details including mix design, volume, delivery time, and site access requirements must be verified with the customer. Dispatchers must coordinate with the batching plant to ensure raw materials are available and production schedules are aligned. Any changes to delivery times or specifications must be communicated immediately to all relevant parties.

Equipment & Fleet Management

Auger concrete trucks must undergo daily pre-trip inspections to verify mechanical integrity, safety systems, and auger functionality. Maintenance logs must be updated after each service. Only trained and certified operators may handle the equipment. GPS tracking is mandatory for all fleet vehicles to monitor location, delivery progress, and fuel efficiency. Vehicles must be cleaned after each use to prevent contamination and ensure compliance with environmental standards.

Transportation & Delivery Protocols

Drivers must adhere to all federal, state, and local transportation regulations, including hours-of-service (HOS) limits and weight restrictions. Concrete loads must be securely covered during transport to prevent spillage. Upon arrival at the job site, drivers must perform a site safety assessment, confirm placement location, and coordinate with on-site personnel. Deliveries in restricted access zones require prior approval and proper signage/notification.

Safety Compliance

All personnel involved in auger concrete operations must complete OSHA-compliant safety training, including hazard communication, fall protection, and equipment operation. Personal protective equipment (PPE), including hard hats, high-visibility vests, safety boots, and gloves, must be worn at all times on-site. Spill response kits must be carried on every truck, and any spill incident must be reported immediately and cleaned according to environmental guidelines.

Environmental & Regulatory Compliance

Auger Concrete must comply with EPA and local environmental regulations regarding emissions, noise levels, and waste disposal. Washout areas must be designated and lined to prevent soil and water contamination. All wash water must be captured and disposed of through approved methods. The company maintains records of environmental compliance for a minimum of five years and conducts quarterly internal audits.

Documentation & Recordkeeping

Accurate delivery tickets, material certifications, and safety logs must be completed for every job. Electronic records are stored in the company’s cloud-based management system and backed up daily. Customers must sign delivery confirmations acknowledging receipt and acceptance of materials. All compliance documentation, including driver logs, inspection reports, and training records, must be retained for a minimum of three years.

Incident Reporting & Corrective Actions

Any safety incident, delivery error, or compliance deviation must be reported within one hour to the operations manager. A formal incident report must be filed using the company’s standardized form, including witness statements and photographic evidence when applicable. Corrective and preventive actions (CAPA) must be implemented within 48 hours, and follow-up audits conducted to ensure resolution.

Conclusion on Sourcing Auger Concrete

Sourcing auger concrete requires careful consideration of project specifications, site conditions, and quality requirements. Continuous flight auger (CFA) piling relies heavily on the timely and consistent supply of ready-mix concrete with specific workability, slump, and setting characteristics to ensure structural integrity and construction efficiency. Successful sourcing involves establishing reliable relationships with reputable concrete suppliers who can deliver high-quality, pumpable concrete on schedule. Attention must be paid to mixture design, transportation logistics, and real-time coordination between piling crews and suppliers to minimize delays and avoid column segregation or voids. Ultimately, effective sourcing of auger concrete is a critical factor in achieving durable, load-bearing deep foundations and ensuring the overall success of geotechnical construction projects.