The global architectural model supplies market is experiencing steady expansion, driven by rising demand from architecture, urban planning, and real estate development sectors. According to Grand View Research, the global architectural model market was valued at USD 786 million in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 6.3% from 2023 to 2030. This growth is fueled by the increasing need for precise, visually compelling models in design presentation and client communication, particularly as Building Information Modeling (BIM) and sustainable design practices gain traction worldwide. As architectural firms and educational institutions seek higher-quality, durable, and customizable materials, the demand for specialized model-making supplies—from precision-cut acrylics to 3D-printed components—has surged. In this competitive landscape, a select group of manufacturers has emerged as industry leaders, combining innovation, material diversity, and global distribution to meet evolving professional needs. The following list highlights the top nine architectural model supplies manufacturers shaping the future of physical design representation.

Top 9 Architectural Model Supplies Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Modelmakers Ltd

Domain Est. 2008

Website: modelmakers-uk.co.uk

Key Highlights: We specialise in architectural models, but we also create industrial models, exhibition models, display models, fibreglass models, and topographical models….

#2 Revell model making

Domain Est. 1995 | Founded: 1956

Website: revell.com

Key Highlights: Revell model making → Quality kits since 1956 ✓ Planes, cars & ships ✓ Colors & Tools – Discover the whole world of model making….

#3 Plastruct

Domain Est. 1998

Website: plastruct.com

Key Highlights: Plastruct is the world’s leading supplier of Plastic Scale Model Parts for every facet of miniature scale model building….

#4 ArtMolds

Domain Est. 1998

Website: artmolds.com

Key Highlights: Discover ArtMolds’ premium lifecasting and mold-making supplies, including alginates, silicone, latex rubbers, and life casting kits for artists and ……

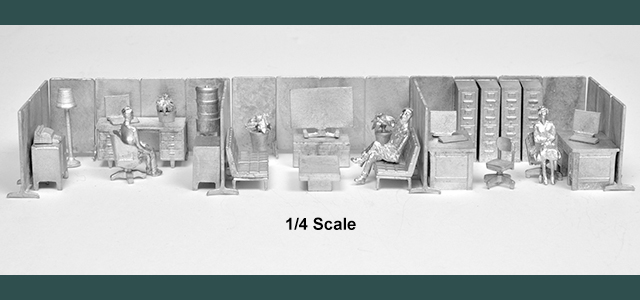

#5 Microform Models

Domain Est. 1999

Website: microformmodels.com

Key Highlights: We offer miniature exact scale model parts for Architects, Engineers, Scale Model Builders, Interior and Set Designers, Doll House Makers and Toy Train ……

#6 Architonic

Domain Est. 2002

Website: architonic.com

Key Highlights: The largest platform for products, materials and concepts for designers and architects. Explore design products and much more on Architonic!…

#7 Tri

Domain Est. 2002

Website: tri-art.ca

Key Highlights: Shop or find local dealers of Tri-Art products, including brands like Rheotech, Art Noise, Tri-Art High Viscosity, Tri-Art Liquids, Liquid Glass and more….

#8 KiwiMill Professional Model Makers

Domain Est. 2011

Website: kiwimill.com

Key Highlights: KiwiMill has 50 years of model making experience to offer, coupled with advanced techniques in the industry, to build your custom model….

#9 QZY Models: Professional Architectural Model Makers

Domain Est. 2013

Website: qzymodels.com

Key Highlights: QZY Models, based in China, comprises a professional team that specializes in crafting high-quality physical models. With 20 years of expertise in model making….

Expert Sourcing Insights for Architectural Model Supplies

2026 Market Trends for Architectural Model Supplies

The architectural model supplies market is poised for notable transformation by 2026, driven by technological advancements, evolving design practices, and sustainability imperatives. This analysis explores key trends shaping the industry, including material innovation, digital integration, and shifting demand patterns across global regions.

Technological Integration and Digital Fabrication

A defining trend in the 2026 market is the increasing convergence of digital tools with traditional model-making. The adoption of 3D printing, laser cutting, and CNC milling has become more accessible and cost-effective, allowing architectural firms and educational institutions to produce highly detailed, accurate models rapidly. By 2026, the integration of AI-driven design software with fabrication tools will enable generative design workflows, where physical models are automatically prototyped from digital iterations. This shift is reducing reliance on manual craftsmanship for complex geometries while increasing demand for compatible modeling materials such as specialty resins, biodegradable filaments, and precision-cut sheet materials.

Sustainability and Eco-Conscious Materials

Sustainability is a growing priority, influencing both product development and consumer choices. By 2026, suppliers are expected to emphasize eco-friendly materials such as recycled cardboard, FSC-certified wood, bioplastics, and compostable modeling components. Regulatory pressure and corporate ESG (Environmental, Social, and Governance) goals are pushing architecture firms to minimize waste in the model-making process. In response, supply manufacturers are innovating with modular systems and reusable base plates, reducing material consumption. Additionally, transparent sourcing and carbon footprint labeling on packaging are becoming standard, especially in European and North American markets.

Expansion in Education and DIY Markets

The architectural education sector continues to be a major driver of demand. As design curricula increasingly emphasize hands-on learning and interdisciplinary collaboration, schools are investing in comprehensive model supply kits and lab infrastructure. Concurrently, the DIY and hobbyist segment is expanding, fueled by online platforms, social media influencers, and accessible tutorials. By 2026, suppliers are tailoring product lines for this growing demographic with affordable starter kits, augmented reality (AR)-assisted assembly guides, and subscription-based delivery models that include curated materials and project plans.

Regional Growth and Market Diversification

Geographically, the Asia-Pacific region is expected to see the fastest growth in architectural model supplies by 2026, due to rapid urbanization and investment in architectural education and smart city development—particularly in China, India, and Southeast Asia. Meanwhile, North America and Western Europe maintain high per-capita consumption, with a focus on premium and sustainable products. Emerging markets in Latin America and the Middle East are also showing increased demand, driven by infrastructure projects and expanding design industries.

E-Commerce and Direct-to-Consumer Distribution

Online retail channels are reshaping how model supplies are purchased. By 2026, e-commerce platforms dominate the distribution landscape, offering global reach, personalized recommendations, and rapid delivery. Leading suppliers are investing in immersive digital experiences, such as virtual showrooms and 3D model configurators, allowing users to visualize materials before purchasing. Subscription services and bulk procurement portals for institutions are gaining traction, improving supply chain efficiency and customer retention.

Conclusion

By 2026, the architectural model supplies market will be characterized by innovation, sustainability, and digital transformation. While traditional materials remain relevant, the industry is adapting to new technologies and consumer values. Suppliers who embrace eco-conscious production, digital integration, and global market diversification are likely to lead in this evolving landscape.

Common Pitfalls When Sourcing Architectural Model Supplies: Quality and Intellectual Property Concerns

Sourcing materials for architectural models involves more than just aesthetics and cost—it requires careful attention to quality consistency and intellectual property (IP) protection. Overlooking these factors can lead to project delays, legal issues, and compromised design integrity. Below are two critical areas where practitioners often encounter challenges.

Quality Inconsistencies in Materials

One of the most frequent issues when sourcing architectural model supplies—especially from third-party or international vendors—is inconsistent material quality. This includes variations in thickness, color, texture, and structural integrity across batches of materials like acrylic, foam board, 3D printing filament, or laser-cut components. Poor-quality materials may warp, discolor, or fail to align precisely during assembly, undermining the model’s accuracy and professional appearance. Additionally, low-grade adhesives or paints can deteriorate over time or emit fumes that damage delicate features. To mitigate this, architects should establish strict material specifications, request samples before bulk ordering, and prioritize suppliers with verifiable quality control processes and consistent product ratings.

Intellectual Property Risks with Custom or Digital Components

Architectural models often incorporate proprietary designs, unique geometries, or digital files that constitute intellectual property. When sourcing custom-machined parts, 3D printing services, or outsourced fabrication, there is a risk of IP exposure—particularly if contracts do not clearly define ownership, confidentiality, or usage rights. Unscrupulous suppliers may replicate or resell designs without permission, especially in regions with weak IP enforcement. To protect sensitive work, firms should use non-disclosure agreements (NDAs), watermark digital files, limit design data shared with vendors, and engage suppliers with established reputations for respecting IP rights. Ensuring that contracts explicitly transfer IP ownership back to the architect or firm is also essential.

Logistics & Compliance Guide for Architectural Model Supplies

This guide outlines key logistics and compliance considerations when sourcing, shipping, and handling architectural model supplies. Adhering to these guidelines ensures smooth operations, regulatory compliance, and the integrity of materials.

Supply Chain Sourcing & Vendor Management

Identify reliable suppliers of precision materials such as balsa wood, acrylic sheets, 3D printing filaments, foam board, and specialty adhesives. Prioritize vendors with documented quality control procedures and compliance certifications (e.g., ISO 9001). Conduct due diligence on sustainability practices, especially for wood-based products—verify FSC or PEFC certification to ensure responsible sourcing.

International Shipping & Customs Compliance

When importing or exporting model supplies, accurately classify goods using Harmonized System (HS) codes. Common classifications include:

– 4407: Sawn wood (e.g., balsa)

– 3920: Plates, sheets, and film of plastics (e.g., acrylic, polystyrene)

– 3506: Adhesives

– 8486: 3D printer components and filament (if applicable)

Prepare complete commercial invoices, packing lists, and certificates of origin. Be aware of country-specific restrictions—some adhesives or aerosols may be classified as hazardous goods.

Hazardous Materials Handling

Certain architectural model supplies—such as spray adhesives, solvent-based paints, and flammable glues—may be regulated as hazardous materials under transportation regulations (e.g., IATA for air, ADR for road in Europe, 49 CFR in the U.S.). Ensure proper labeling, packaging, and documentation when shipping these items. Store flammable substances in approved safety cabinets and maintain Safety Data Sheets (SDS) on file for all hazardous products.

Packaging & Freight Requirements

Use protective packaging to prevent breakage, warping, or scratching of delicate materials like laser-cut acrylic or printed model components. Secure fragile items with edge protectors, void fill, and moisture-resistant wrapping. For oversized items (e.g., large foam boards), utilize pallets and banding. Clearly label shipments with handling instructions such as “Fragile,” “This Side Up,” and “Do Not Stack.”

Regulatory Compliance & Environmental Standards

Comply with REACH (EU), RoHS, and Prop 65 (California) regulations regarding chemical content in plastics, paints, and adhesives. Ensure that materials do not contain restricted substances such as phthalates or heavy metals. For 3D printing supplies, verify filament composition and emissions compliance, especially if used in shared or ventilated workspaces.

Inventory Management & Traceability

Maintain a traceable inventory system that records batch numbers, expiration dates (for adhesives and resins), and supplier details. This supports quality control and enables effective recall management if non-compliant or defective materials are identified.

End-of-Life & Waste Disposal

Dispose of off-cuts, failed prints, and chemical waste in accordance with local environmental regulations. Segregate recyclable materials (e.g., clean cardboard, certain plastics) and use licensed waste handlers for hazardous waste such as solvent-contaminated rags or uncured resin. Promote reuse and recycling within the studio to minimize environmental impact.

Documentation & Audit Readiness

Keep records of supplier agreements, customs documentation, SDS files, waste disposal manifests, and compliance certificates. Regular internal audits help ensure ongoing adherence to logistics and regulatory standards, particularly for firms operating in multiple jurisdictions.

In conclusion, sourcing architectural model supplies requires a strategic approach that balances quality, cost, availability, and sustainability. By identifying reliable suppliers—whether local craft stores, specialized model-making vendors, or online platforms—architects and students can access a wide range of materials such as foam board, balsa wood, acrylic sheets, and precision tools essential for creating accurate and visually compelling models. It is important to consider factors like material durability, scale compatibility, and ease of manipulation to ensure the final model effectively communicates design intent. Additionally, building relationships with suppliers, taking advantage of bulk purchasing, and staying informed about new products and sustainable alternatives can enhance efficiency and creativity in the modeling process. Ultimately, thoughtful sourcing of architectural model supplies supports not only project success but also innovation and environmental responsibility in architectural practice.