The global power tools market, including critical accessories such as angle grinder wrench spanners, is experiencing steady expansion driven by rising demand in construction, metalworking, and industrial manufacturing sectors. According to a 2023 report by Mordor Intelligence, the global power tools market was valued at USD 50.62 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 5.2% from 2023 to 2028. A key segment within this growth includes tool accessories—such as wrench spanners specifically designed for securing grinding discs—where reliability, precision, and safety are paramount. As demand for high-performance angle grinders increases across both professional and DIY user segments, manufacturers of compatible accessories are scaling production and innovation. This growth trajectory is further validated by Grand View Research, which cites expanding infrastructure activities and industrialization in emerging economies as primary drivers. Against this backdrop, a select group of manufacturers has emerged as leaders in producing high-quality angle grinder wrench spanners, combining engineering precision with durable materials to meet rigorous industry standards.

Top 6 Angle Grinder Wrench Spanner Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

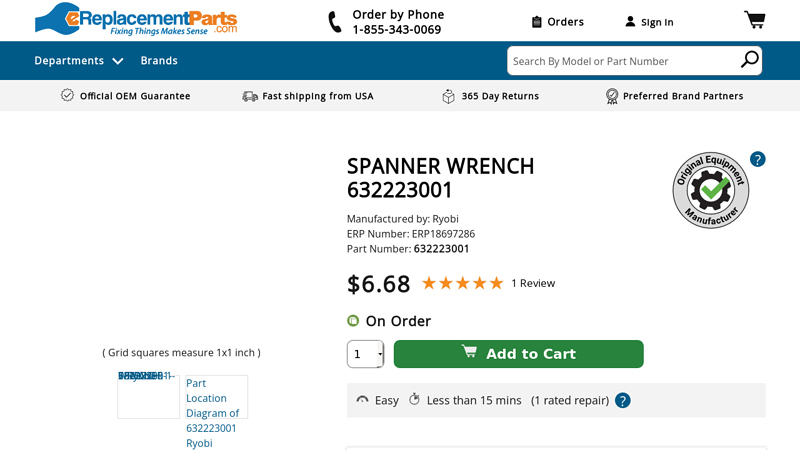

#1 OEM Ridgid 632223001 SPANNER WRENCH

Domain Est. 2004

Website: ereplacementparts.com

Key Highlights: An authentic Ridgid replacement spanner wrench that is supplied by original equipment manufacturer for use with angle grinders. This wrench allows user to ……

#2 Angle grinder accessories

Domain Est. 1995

Website: hilti.com

Key Highlights: Spanner wrench for DCG 700-P #93932. Pin type face wrench B35. Accessory for angle grinders. Choose options. Pack size. 1 pc. Product options….

#3 Spanner wrench

Domain Est. 1997

Website: metabo.com

Key Highlights: Spanner wrench from Metabo – High-quality, reliable and long-lasting. Learn about professional power tools from Metabo now….

#4 Spanners and Wrenches

Domain Est. 2015

Website: edingtools.com

Key Highlights: Our spanners and ratchets are comply with DIN and ANSI standard. Find the right spanners and ratchet wrenches that can fit for your application and can be ……

#5 Universal Wrench

Domain Est. 2021

Website: delitoolsglobal.com

Key Highlights: Explore Deli Tools’ range of Combination Spanner, Double Open End Spanner, 10Mm Ratcheting Spanner, Offset Ring Spanner, and more….

#6 ADJUSTABLE GRINDER SPANNER

Website: toptools.co.jp

Key Highlights: ADJUSTABLE GRINDER SPANNER. For attaching and detaching wheel nut of disc grinder. Able to use for each makers’ wheel nut of disc grinder….

Expert Sourcing Insights for Angle Grinder Wrench Spanner

H2: 2026 Market Trends for Angle Grinder Wrench Spanner

The global market for angle grinder wrench spanners—specialized tools designed for securing and removing flanges on angle grinders—is poised for moderate but steady growth through 2026. Driven by advancements in power tool technology, rising demand in construction and metalworking industries, and increasing emphasis on tool safety and ergonomics, several key trends are expected to shape the market landscape.

-

Growing Demand in Construction and Metal Fabrication

The construction, automotive repair, and metal fabrication sectors remain primary end-users of angle grinders and their associated accessories, including wrench spanners. With infrastructure development accelerating in emerging economies—particularly in Asia-Pacific and Africa—demand for durable, high-performance wrench spanners is expected to rise. The increasing use of angle grinders in demolition, cutting, and grinding tasks directly fuels the need for reliable wrench tools to maintain and operate these machines. -

Shift Toward Ergonomic and Multi-Functional Designs

Manufacturers are increasingly focusing on ergonomic improvements, such as anti-slip grips, lightweight materials (e.g., reinforced polymers and aluminum alloys), and compact designs. Multi-functional wrench spanners that integrate features like hex key holders or compatibility with multiple grinder models are gaining popularity. These innovations reduce user fatigue and improve efficiency, aligning with broader occupational safety standards. -

Integration with Smart Tool Ecosystems

As smart power tools become more prevalent, there is a nascent trend toward integrating accessories like wrench spanners into digital maintenance ecosystems. By 2026, some premium wrench models may feature embedded RFID tags or QR codes for inventory tracking, usage analytics, or compatibility verification with specific grinder models—supporting industrial IoT (Internet of Things) adoption in professional workshops. -

Rise of Aftermarket and Replacement Accessories

The aftermarket segment for angle grinder accessories is expanding due to the long lifecycle of power tools. As users seek to replace worn-out or lost spanners, demand for OEM and third-party wrench spanners is increasing. Online retail platforms and e-commerce marketplaces are facilitating easier access to replacement tools, boosting market penetration. -

Sustainability and Material Innovation

Environmental considerations are influencing material choices. Recyclable metals and bio-based composites are being explored to reduce the carbon footprint of manufacturing. Additionally, longer-lasting, corrosion-resistant coatings are being adopted to extend product life and support sustainability goals. -

Regional Market Dynamics

North America and Europe will continue to dominate in terms of value due to strict safety regulations and high adoption of professional-grade tools. Meanwhile, the Asia-Pacific region is expected to register the highest growth rate, driven by industrialization, urbanization, and the expansion of manufacturing hubs in countries like India and Vietnam. -

Impact of Standardization and Safety Regulations

Increasing regulatory focus on workplace safety is pushing standardization in tool design. ISO and ANSI compliance will become more critical for wrench spanners, ensuring compatibility and reducing the risk of accidents caused by improper tool use. This trend will favor established brands with certification capabilities.

In conclusion, the 2026 market for angle grinder wrench spanners will be shaped by innovation in design, digital integration, and growing industrial demand. Companies that prioritize user safety, sustainability, and adaptability to diverse grinder models will be best positioned to capture market share in this niche but essential segment of the power tool accessory industry.

Common Pitfalls Sourcing Angle Grinder Wrench Spanner (Quality, IP)

Sourcing angle grinder wrench spanners—especially those used for tightening or loosening grinding disc flanges—requires careful attention to quality and intellectual property (IP) concerns. Overlooking these aspects can lead to safety hazards, product failures, legal risks, and reputational damage. Below are key pitfalls to avoid:

Poor Material Quality and Durability

Many low-cost wrench spanners are manufactured using substandard metals or incorrect heat treatment processes, resulting in tools that deform, twist, or break under torque. This compromises user safety, especially when working with high-speed angle grinders. Always verify material specifications (e.g., chrome vanadium steel) and ensure the tool meets minimum hardness requirements.

Inaccurate Dimensions and Fit

Non-compliant spanners often have incorrect opening sizes or tolerances, leading to slippage on the grinding flange nut. This not only damages the tool and equipment but increases the risk of injury. Confirm dimensional accuracy through sample testing and adherence to ISO or DIN standards.

Lack of Safety Certification

Reputable wrench spanners should comply with relevant safety standards (e.g., ISO 6788 for hand tools). Sourcing from suppliers who cannot provide certification or test reports increases the risk of non-compliance with regional market regulations, potentially resulting in product recalls or import denials.

Copying Branded or Patented Designs

Some manufacturers produce wrench spanners that closely mimic the design of well-known power tool brands (e.g., Bosch, Makita). These designs may be protected by design patents or trademarks. Sourcing such products exposes buyers to IP infringement claims, customs seizures, and legal liabilities. Always conduct due diligence on design ownership and avoid “look-alike” tools.

Inadequate Supplier Verification

Engaging with unverified or uncertified suppliers, particularly through online marketplaces, heightens the risk of receiving counterfeit or poor-quality goods. Avoid suppliers who cannot provide factory audits, quality control documentation, or product liability insurance.

Ignoring IP Clearance in Target Markets

Even if a wrench design appears generic, it may be protected under intellectual property laws in specific countries. Failure to perform IP clearance searches in your target markets (e.g., EU, USA, Australia) can result in legal disputes or blocked shipments. Consult IP professionals when sourcing for international distribution.

Overlooking Packaging and Branding Risks

Including branded logos, part numbers, or packaging that resembles established manufacturers may constitute trademark infringement. Ensure all branding is original or properly licensed to avoid misleading consumers and triggering IP enforcement actions.

By addressing these pitfalls early in the sourcing process—through rigorous supplier vetting, quality testing, and IP due diligence—buyers can ensure they procure safe, compliant, and legally sound angle grinder wrench spanners.

Logistics & Compliance Guide for Angle Grinder Wrench Spanner

Product Classification & HS Code

The Angle Grinder Wrench Spanner is classified as a hand tool accessory for power tools. The recommended Harmonized System (HS) code is 8204.20, which covers “Spanners and wrenches, including torque metered (torque) wrenches, adjustable spanners (wrenches).” Accurate classification ensures correct duty rates and compliance with international trade regulations.

Packaging & Labeling Requirements

Ensure each wrench spanner is securely packaged in polybag or blister pack to prevent damage during transit. Outer cartons must be sturdy and clearly labeled with:

– Product name and model number

– Quantity per box

– Net and gross weight

– Country of origin (e.g., “Made in China”)

– Barcode or SKU

– Handling symbols (e.g., “Fragile,” “Do Not Stack”)

Labels must be durable and legible in the language of the destination country.

Import & Export Documentation

Prepare the following documents for smooth customs clearance:

– Commercial Invoice (with detailed product description, value, and Incoterms)

– Packing List

– Bill of Lading (B/L) or Air Waybill (AWB)

– Certificate of Origin (if claiming preferential tariffs under trade agreements)

– Export Declaration (as required by the exporting country)

Regulatory Compliance

Verify compliance with destination market standards:

– United States: No specific safety certification required for hand tools, but must meet general consumer product safety standards under the CPSA. Labeling in English is mandatory.

– European Union: CE marking not typically required for standalone wrench spanners, but ensure conformity with the General Product Safety Directive (2001/95/EC). RoHS compliance may apply if the tool contains restricted substances.

– United Kingdom: UKCA marking not required for tools unless part of a larger system. Comply with UK General Product Safety Regulations 2005.

– Australia/New Zealand: Comply with AS/NZS 2041 for hand tools if applicable; otherwise, meet general safety standards under the Australian Consumer Law.

Restricted Materials & Substances

Ensure the wrench spanner is free from prohibited substances:

– Comply with REACH (EU) and RoHS directives regarding restricted chemicals (e.g., lead, cadmium, phthalates).

– Verify no conflict minerals (tin, tungsten, tantalum, gold) are used in production unless sourced responsibly and reported as per U.S. Dodd-Frank Act Section 1502.

Transportation & Handling

- Use palletized freight for bulk shipments; secure cartons with stretch wrap.

- Avoid exposure to moisture; include desiccants if shipping overseas.

- Follow IATA/IMDG regulations if air or sea freight is used—wrench spanners are generally non-hazardous and unrestricted.

- Optimize packaging dimensions to reduce volumetric weight charges.

Customs Duties & Tariff Rates

Duty rates vary by country:

– United States: Typically duty-free under HTSUS 8204.20.00

– EU: 4–6% import duty depending on member state

– Canada: 0% under HS 8204.20.00

Confirm rates using the destination country’s customs tariff database and consider using an Authorized Economic Operator (AEO) or bonded carrier for faster clearance.

Product Liability & Insurance

- Obtain product liability insurance covering manufacturing defects or misuse-related injuries.

- Include disclaimers on packaging: “Use with appropriate personal protective equipment. Follow tool manufacturer instructions.”

- Retain records of quality control checks and supplier certifications for traceability.

Returns & Reverse Logistics

Establish a clear returns policy for damaged or incorrect shipments:

– Provide RMA (Return Merchandise Authorization) numbers.

– Use prepaid return labels where feasible.

– Inspect returned items and document reasons for return to improve supply chain efficiency.

Sustainability & End-of-Life

Encourage recycling by designing products with recyclable materials (e.g., chrome-vanadium steel). Provide disposal guidance: “Recycle at end of life through local metal recycling programs.” Comply with WEEE directive if sold as part of an electrical tool kit in the EU.

In conclusion, sourcing an angle grinder wrench or spanner requires careful consideration of compatibility, quality, and supplier reliability. It is essential to identify the specific make and model of the angle grinder to ensure the wrench fits the flange nut correctly—typically 22mm or 7/8″ for most standard grinders. Opting for durable, heat-treated steel tools from reputable manufacturers ensures longevity and safe operation. Sourcing from trusted suppliers, whether local hardware stores or established online platforms, helps avoid counterfeit or substandard products. Additionally, considering multi-functional wrenches or combi spanners can offer added value and convenience. Ultimately, investing time in sourcing the right angle grinder wrench contributes to efficient tool maintenance, enhanced safety, and optimal performance on the job.