The global welding equipment market is experiencing robust growth, driven by rising industrialization, infrastructure development, and increasing demand across the automotive, construction, and energy sectors. According to Grand View Research, the market was valued at USD 22.8 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. This surge in demand has catalyzed innovation and competition among manufacturers, particularly in the segment of Andeli welders—renowned for their durability, efficiency, and cost-effectiveness in both professional and DIY applications. As the market landscape evolves, three key manufacturers have emerged as leaders, combining advanced technology with strong distribution networks to capture significant market share. These top players are not only meeting current industry standards but are also shaping the future of welding technology through data-informed product development and customer-centric innovation.

Top 3 Andeli Welder Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1

Domain Est. 2017

Website: myandeli.com

Key Highlights: We offer more than 300 product series, including welding machines, cable solutions, circuit protection devices, transformers, industrial control equipment, and ……

#2 ANDELI Welder: ANDELI

Domain Est. 2020

Website: andelimall.com

Key Highlights: ANDELI: Your one-stop shop for welding machines, safety helmets & replacement parts. High-performance tools for metal fabrication, car repair & DIY projects ……

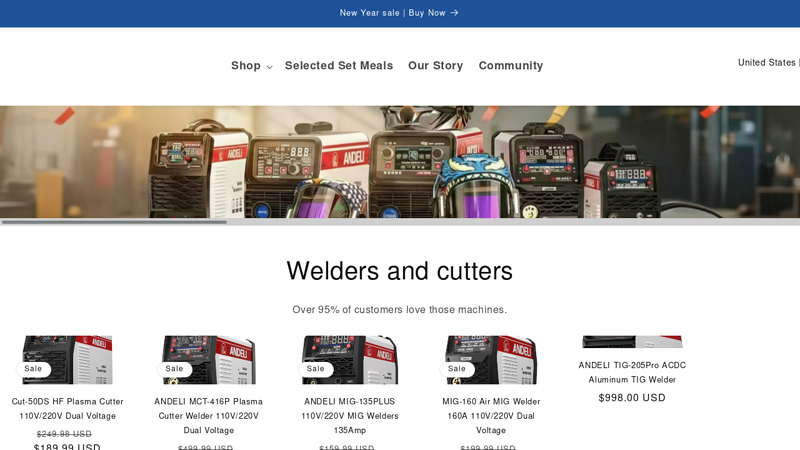

#3 featured products

Domain Est. 2021

Website: andelitools.com

Key Highlights: Welding Guide. ANDELI welding experts will work with you to find the best way to weld that fits your specific requirements and helps you achieve a reasonable ……

Expert Sourcing Insights for Andeli Welder

H2 2026 Market Trends Analysis for Andeli Welder

As of mid-2026, Andeli Welder operates within a dynamic global industrial equipment market shaped by technological innovation, shifting manufacturing demands, and sustainability imperatives. Based on current trajectories and macroeconomic indicators, the following key trends are influencing Andeli’s position and strategy in H2 2026:

1. Accelerated Adoption of Smart and IoT-Enabled Welding Equipment

The industrial sector continues its push toward Industry 4.0 integration. By H2 2026, Andeli faces increasing demand for welders equipped with IoT connectivity, real-time monitoring, and predictive maintenance capabilities. Customers—especially in automotive, heavy machinery, and precision fabrication—prioritize equipment that integrates with digital production systems. Andeli has responded by expanding its smart inverter and TIG/MIG lines with cloud-based analytics, enhancing remote diagnostics and operational efficiency. This trend positions Andeli as a mid-tier innovator, bridging affordability with digital functionality.

2. Growth in Renewable Energy and Infrastructure Projects

Global investments in wind, solar, and hydrogen infrastructure—driven by climate targets and energy security concerns—are boosting demand for heavy-duty welding solutions. In H2 2026, Andeli benefits from participation in large-scale construction and energy projects, particularly in emerging markets and parts of Southeast Asia and the Middle East. Demand for high-amperage, durable welding machines suitable for field operations remains strong. Andeli’s cost-effective yet reliable semi-automatic and manual welders are well-positioned to capture market share in these capital-intensive sectors.

3. Supply Chain Resilience and Localization Pressures

Ongoing geopolitical tensions and trade dynamics have reinforced the need for supply chain diversification. Andeli, primarily manufacturing in China, is adapting by strengthening regional distribution hubs and exploring localized assembly options in key markets like India, Eastern Europe, and Latin America. This shift helps mitigate tariffs and logistics risks while improving delivery times—a competitive advantage in time-sensitive industrial projects.

4. Sustainability and Energy Efficiency as Competitive Differentiators

Environmental regulations and corporate ESG goals are influencing procurement decisions. By H2 2026, energy-efficient inverter technology is no longer a premium feature but an expectation. Andeli has emphasized energy-saving designs in its latest product releases, achieving higher power factors and lower idle consumption. Additionally, recyclable packaging and modular designs for easier repair align with circular economy principles, enhancing brand appeal among environmentally conscious clients.

5. Competition from Global and Niche Players Intensifies

While Andeli maintains a strong foothold in mid-range welding equipment, competition is escalating. European and North American brands emphasize precision and automation, while new entrants from India and Vietnam offer aggressive pricing. In response, Andeli is investing in R&D to improve duty cycles, arc stability, and user interface design. Strategic partnerships with vocational training centers also help strengthen brand loyalty among new welders.

6. E-Commerce and Digital Customer Engagement

Industrial B2B purchasing increasingly shifts online. In H2 2026, Andeli’s digital transformation includes an enhanced e-commerce platform, AR-assisted product demonstrations, and AI-powered customer support. These tools improve accessibility for small and medium enterprises (SMEs) and remote buyers, broadening Andeli’s customer base beyond traditional distribution channels.

Conclusion

H2 2026 presents both opportunities and challenges for Andeli Welder. The company’s focus on balancing affordability with smart features, sustainability, and global market adaptability positions it well for sustained growth. Success will depend on continued innovation, agile supply chain management, and deepening digital engagement with a diverse and evolving customer base.

Common Pitfalls When Sourcing Andeli Welders (Quality and Intellectual Property)

Sourcing Andeli welders—whether directly from the manufacturer or through third-party suppliers—can present several challenges, particularly concerning product quality and intellectual property (IP) integrity. Being aware of these common pitfalls helps mitigate risks and ensures a reliable supply chain.

Inconsistent Product Quality

One of the most frequent issues when sourcing Andeli welders is variability in quality. While Andeli is known for affordable welding equipment, quality control can fluctuate between production batches or manufacturing partners. Buyers may receive units with substandard components, inconsistent arc performance, or premature failures. This is especially common when purchasing through unauthorized distributors or third-party marketplaces lacking direct oversight.

Counterfeit or Replica Units

Due to Andeli’s brand recognition in the budget welding segment, counterfeit versions of their welders are prevalent. These replicas often mimic the branding and model names but use inferior materials and electronics. They may not meet safety standards, lack proper certifications (such as CE or CCC), and pose serious risks to users. Distinguishing genuine Andeli products from counterfeits requires due diligence in verifying suppliers and product documentation.

Intellectual Property Infringement Risks

Sourcing Andeli welders from unauthorized channels—especially generic OEM manufacturers claiming to produce “Andeli-style” units—can expose buyers to IP infringement risks. Some suppliers may illegally use Andeli’s trademarks, designs, or technical specifications without licensing. Purchasing or distributing such products could lead to legal liability, particularly in regions with strong IP enforcement. Always confirm that the supplier has legitimate rights to distribute Andeli-branded products.

Lack of After-Sales Support and Warranty

Genuine Andeli welders typically come with manufacturer or distributor-backed warranties and access to technical support. However, when sourcing from unofficial channels, buyers often receive no warranty, spare parts, or service support. This becomes a critical issue when maintenance or repairs are needed, increasing total cost of ownership and downtime.

Misleading Product Specifications

Some suppliers may exaggerate or falsify technical specifications—such as duty cycle, input voltage range, or output current—to make Andeli-style units appear more capable than they are. This misrepresentation can lead to equipment failure under real working conditions and potential safety hazards.

Supply Chain Transparency Issues

Without direct engagement with authorized Andeli distributors or the manufacturer, supply chains can lack transparency. Components may be sourced from unverified subcontractors, raising concerns about ethical manufacturing practices, component traceability, and compliance with regional import regulations.

Conclusion

To avoid these pitfalls, always source Andeli welders through authorized distributors, verify product authenticity with serial numbers and certifications, and conduct supplier audits when possible. Prioritizing quality assurance and IP compliance protects both end-users and downstream businesses from financial and legal risks.

Logistics & Compliance Guide for Andeli Welder

Overview

This guide outlines the essential logistics and compliance procedures for the import, distribution, and use of Andeli Welder products. Adherence to these standards ensures smooth operations, regulatory compliance, and customer safety across international markets.

Product Classification & HS Codes

Andeli welding equipment typically falls under the following Harmonized System (HS) codes:

– 8515.31: Arc-welding machines using electrical energy

– 8468.20: Hand-operated mechanical tools for grinding, sanding, or polishing

Verify the exact HS code with local customs authorities, as classifications may vary by country and product model.

Import & Export Documentation

Ensure the following documents accompany every shipment:

– Commercial Invoice (with detailed product description, unit price, and total value)

– Packing List (itemizing contents, weights, and dimensions per package)

– Bill of Lading (for sea freight) or Air Waybill (for air freight)

– Certificate of Origin (often required for tariff determination)

– Product Compliance Certificates (e.g., CE, RoHS, ISO)

Regulatory Compliance

Andeli Welder products must meet regional safety and environmental standards:

– European Union: CE Marking per Machinery Directive 2006/42/EC and Low Voltage Directive 2014/35/EU. RoHS compliance required.

– United States: Compliance with OSHA safety standards and FCC regulations for electromagnetic interference (if applicable).

– Canada: CSA certification or recognition under CSA Z462 (Electrical Safety in the Workplace).

– Australia & New Zealand: RCM Mark per AS/NZS 60974.1 (Safety of welding equipment).

Always confirm local certification requirements before shipment.

Packaging & Labeling Requirements

- Use robust, shock-resistant packaging suitable for international transit.

- Label each unit with:

- Model and serial number

- Input voltage and power rating

- Safety warnings in the local language (if required)

- CE, FCC, or other applicable marks

- Include multilingual user manuals and safety instructions.

Shipping & Transportation

- Use freight forwarders experienced in handling electrical and industrial equipment.

- Clearly mark packages as “Fragile” and “This Side Up.”

- Ensure compliance with IATA (air) or IMDG (sea) regulations if batteries are included.

- Insure shipments against loss, damage, or delay.

Customs Clearance

- Provide accurate product descriptions to avoid delays or misclassification.

- Declare the correct country of origin (typically China for Andeli products).

- Be prepared to pay applicable duties, VAT, or import taxes. Duty rates vary by destination—consult local tariff schedules.

After-Sales & Warranty Compliance

- Maintain records of product serial numbers and distribution channels.

- Support local warranty service through authorized partners.

- Comply with national consumer protection laws, including right-of-return policies and repair timelines.

Environmental & Disposal Regulations

- Inform customers of proper end-of-life disposal procedures.

- Comply with WEEE (Waste Electrical and Electronic Equipment) directives in applicable regions.

- Avoid hazardous substances per RoHS or similar regulations.

Recordkeeping & Audits

- Retain shipping, compliance, and certification documents for a minimum of 5 years.

- Conduct annual audits of logistics partners and compliance status.

- Update documentation promptly when product specifications or regulations change.

Contact & Support

For compliance or logistics inquiries, contact Andeli’s international support team:

– Email: [email protected]

– Phone: +86-XXX-XXXX-XXXX (China HQ)

Local distributors should maintain up-to-date compliance files and liaise with regional authorities as needed.

Conclusion for Sourcing Andeli Welder:

After a thorough evaluation of the welding equipment market, Andeli emerges as a competitive and reliable option for sourcing welding machines. The brand offers a range of products that balance cost-effectiveness with solid performance, making them suitable for various industrial and workshop applications. Andeli welders are known for their durability, user-friendly design, and compliance with international safety and quality standards.

Sourcing Andeli welders presents several advantages, including competitive pricing, consistent product availability, and growing global distribution networks. Additionally, Andeli’s commitment to technological innovation—such as energy-efficient inverter technology and multifunctional welding capabilities—ensures that their products meet modern industry demands.

However, potential buyers should conduct due diligence on suppliers to ensure authenticity, warranty coverage, and after-sales service support. While Andeli may not carry the same brand prestige as some premium Western or Japanese manufacturers, their value proposition makes them a strong contender in the mid-tier welding equipment segment.

In conclusion, sourcing Andeli welders is a strategic choice for businesses aiming to balance performance, reliability, and cost-efficiency. With proper supplier vetting and quality control, Andeli can be a dependable partner in meeting welding needs across diverse applications.