The global anchor fastening market is experiencing robust growth, driven by escalating demand across construction, infrastructure, and industrial sectors. According to a report by Mordor Intelligence, the anchor fastening market was valued at USD 6.8 billion in 2023 and is projected to reach USD 9.2 billion by 2029, growing at a CAGR of 5.2% during the forecast period. This expansion is fueled by rising urbanization, increasing investment in commercial and residential construction, and the need for high-performance structural fastening solutions in seismic and high-load environments. Additionally, Grand View Research highlights the growing adoption of advanced materials—such as stainless steel and composite anchors—in corrosive environments, further propelling market dynamics. As demand intensifies, innovation and reliability have become critical differentiators among manufacturers. In this competitive landscape, nine key players have emerged as leaders, combining technological expertise, global reach, and product diversity to meet the evolving needs of modern engineering and construction projects.

Top 9 Anchor Fastening Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Anchor Fasteners Industrial co., Ltd.

Domain Est. 1998 | Founded: 1986

Website: anchorfast.com.tw

Key Highlights: For more than 30 years since 1986, Anchor has been dedicated in manufacturing high quality fasteners for the Construction, Automotive and Electronic industries….

#2 Portland Bolt

Domain Est. 1998

Website: portlandbolt.com

Key Highlights: Portland Bolt provides anchor bolt and nonstandard construction fasteners directly to contractors, steel fabricators, OEMs, worldwide….

#3 Fortress Anchors

Domain Est. 1996

Website: fortressanchors.com

Key Highlights: Fortress Anchors is the world’s leading manufacturer of aluminum magnesium alloy anchors. See why Fortress Anchors are the best anchors for any boat….

#4 Anchoring Systems

Domain Est. 1990

Website: cmc.com

Key Highlights: Explore CMC’s advanced anchoring systems, including precision-engineered anchor bolt cages, designed for strength and stability in transmission, substation, ……

#5 Fasteners

Domain Est. 1995

Website: hilti.com

Key Highlights: Mechanical anchors · Chemical anchors · Anchor rods & elements · Cast-in anchors · Cast-in anchor channels · Screws · Nails · Threaded studs & standoffs….

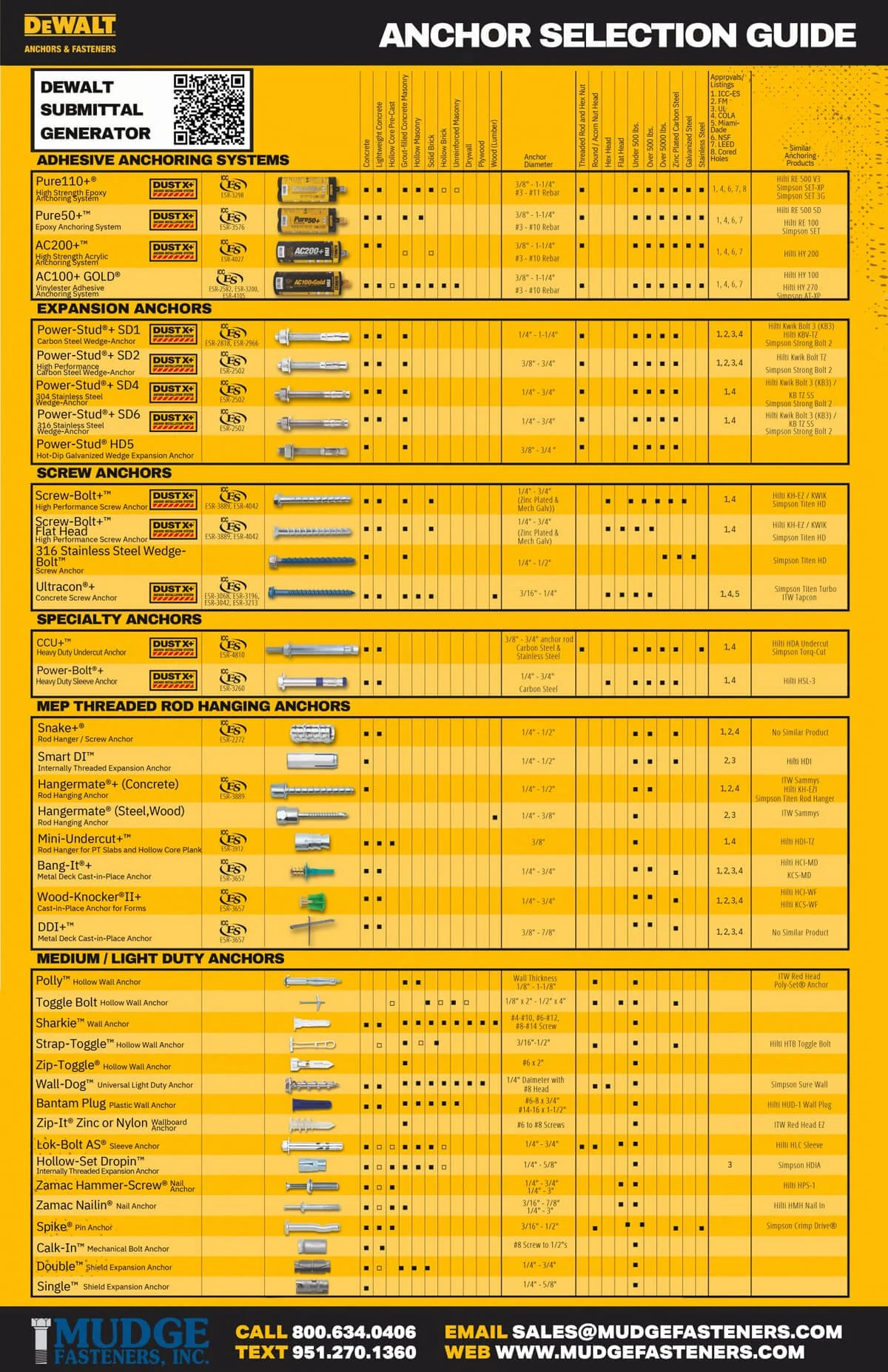

#6 Anchoring and Fastening Systems from DEWALT Anchors & Fasteners

Domain Est. 1997

Website: anchors.dewalt.com

Key Highlights: DEWALT is the leader in contractor power tools including cordless drills, woodworking tools and professional power tools….

#7 Anchoring and Fastening Systems from DEWALT

Domain Est. 1997

Website: powers.com

Key Highlights: Innovative Anchoring and Installation Systems. Now United Under One Brand. The site can be accessed at the following url: https://anchors.dewalt.com/anchors….

#8 Cobra Anchors

Domain Est. 1999

Website: cobraanchors.com

Key Highlights: Discover Cobra Anchors’ strong, easy-to-install anchors and hanging hardware for drywall, masonry, concrete, and other projects….

#9 Anchor Systems

Website: hilti.group

Key Highlights: We offer a wide range of anchor fastenings in metal, plastic, cast-in and chemical mortars for light, medium and heavy-duty applications….

Expert Sourcing Insights for Anchor Fastening

H2: 2026 Market Trends for Anchor Fastening

The anchor fastening industry is poised for significant transformation by 2026, driven by advancements in construction technologies, sustainability mandates, and evolving global infrastructure demands. As a critical component in structural integrity across sectors such as construction, manufacturing, and renewable energy, anchor fasteners are adapting to meet the requirements of modern engineering and environmental standards.

-

Growth in Infrastructure and Urban Development

By 2026, continued urbanization—particularly in emerging economies—will fuel demand for robust construction materials. Governments investing in public infrastructure, transportation networks, and smart cities will drive the need for high-performance anchor fastening systems. Retrofitting aging infrastructure in developed regions like North America and Europe will further boost the aftermarket segment for specialized anchors. -

Adoption of High-Strength and Corrosion-Resistant Materials

The shift toward durable, long-life building materials will increase demand for anchor fasteners made from stainless steel, duplex alloys, and composite materials. With climate resilience becoming a priority, corrosion-resistant anchors will be essential in coastal, humid, and chemically aggressive environments. -

Sustainability and Green Building Standards

Regulations such as LEED, BREEAM, and the EU Green Deal will influence anchor fastener design and sourcing. Manufacturers will focus on recyclable materials, low-carbon production processes, and lifecycle assessments. Anchor systems enabling modular and prefabricated construction—known for reduced waste and faster assembly—will gain market share. -

Technological Innovation and Smart Fastening Systems

By 2026, digitalization in construction will expand the role of smart anchor systems. Embedded sensors for load monitoring, vibration detection, and structural health diagnostics will emerge, particularly in high-risk applications like bridges, high-rises, and industrial plants. Integration with Building Information Modeling (BIM) will enhance precision in anchor placement and load calculations. -

Rise of Renewable Energy Projects

The global push toward clean energy will significantly impact anchor fastener demand. Offshore wind farms, solar panel mounting systems, and battery storage facilities require specialized anchoring solutions capable of withstanding dynamic loads and harsh environmental conditions. This sector will become a key growth driver for high-capacity and seismic-rated anchors. -

Regional Market Dynamics

Asia-Pacific will remain the largest market due to rapid industrialization and construction activity in India, Southeast Asia, and China. North America and Europe will see steady growth driven by infrastructure renewal and strict building codes. The Middle East’s Vision 2030 projects will also contribute to regional demand. -

Supply Chain Resilience and Localization

Post-pandemic supply chain challenges have prompted companies to localize production and diversify sourcing. By 2026, anchor fastening manufacturers will increasingly invest in regional manufacturing hubs to reduce logistics costs and mitigate geopolitical risks.

In conclusion, the 2026 anchor fastening market will be shaped by innovation, sustainability, and infrastructure modernization. Companies that invest in R&D, adhere to green standards, and align with digital construction trends will be best positioned to capture emerging opportunities.

Common Pitfalls in Sourcing Anchor Fastening (Quality, IP)

Sourcing anchor fastening components—such as chemical anchors, mechanical anchors, and expansion bolts—requires careful attention to quality and intellectual property (IP) considerations. Overlooking these factors can lead to structural failures, legal disputes, and reputational damage. Below are common pitfalls to avoid:

Poor Quality Control and Non-Compliance

Many suppliers offer anchor fasteners that appear identical to high-performance products but fail to meet required mechanical and environmental standards. Common issues include inadequate tensile strength, poor corrosion resistance, and inconsistent manufacturing tolerances. Sourcing from uncertified or unverified manufacturers increases the risk of non-compliant products entering critical construction or infrastructure projects. Always verify third-party certifications (e.g., ETA, ICC-ES, CE marking) and request test reports under real-world loading and fire conditions.

Counterfeit or Reverse-Engineered Products

Anchor fastening technology often involves proprietary designs and formulations, especially in chemical anchors where resin composition is critical. Unethical suppliers may reverse-engineer branded products or produce counterfeit versions that mimic appearance but lack performance integrity. These imitations may infringe on IP rights and pose safety risks. Sourcing from unauthorized distributors or gray market channels significantly increases exposure to counterfeit goods.

Lack of Traceability and Documentation

Reputable anchor fasteners come with full traceability—including batch numbers, installation guidelines, and performance data. Poor documentation makes it difficult to verify authenticity, ensure proper installation, or respond to failures. In regulated industries, missing or falsified documentation can result in project delays, liability, or rejection by building inspectors.

Ignoring Intellectual Property Rights

Using or sourcing anchor systems that infringe on patented technologies—such as unique sleeve designs, setting mechanisms, or resin chemistries—can lead to legal action from original equipment manufacturers (OEMs). Even if unintentional, procurement teams can be held liable for contributory infringement. Always confirm that suppliers have legitimate rights to manufacture and sell the products, and request IP compliance statements.

Inadequate Technical Support and Training

Low-cost anchor fasteners often come without proper technical support, installation training, or engineering backing. Incorrect installation due to lack of guidance can compromise structural integrity, regardless of the anchor’s inherent quality. Reliable suppliers provide access to design software, load calculation tools, and certified training for installers.

Overlooking Long-Term Performance and Warranty

Some low-quality anchors degrade prematurely under stress, moisture, or temperature fluctuations. Without manufacturer-backed warranties or long-term performance data, project owners bear the risk of future remediation. Ensure the supplier offers comprehensive warranty coverage and proven track record in similar applications.

By addressing these pitfalls—prioritizing certified quality, verifying IP legitimacy, and demanding full documentation—organizations can mitigate risks and ensure the safety and compliance of anchor fastening systems in critical applications.

Logistics & Compliance Guide for Anchor Fastening

Overview

This guide outlines the essential logistics and compliance considerations for the handling, transportation, storage, and regulatory adherence related to anchor fastening products. Proper management ensures product integrity, safety, and conformity with international and regional standards.

Product Classification and Specifications

Anchor fasteners—such as wedge anchors, sleeve anchors, and chemical anchors—are classified based on material (e.g., carbon steel, stainless steel), diameter, length, and load capacity. Accurate classification is essential for correct labeling, packaging, and customs documentation.

Packaging and Labeling Requirements

- Packaging: Fasteners must be packaged to prevent corrosion, deformation, and contamination. Use moisture-resistant materials and sealed containers for bulk shipments.

- Labeling: Each package must include: product type, size, material grade, quantity, batch/lot number, manufacturer name, and compliance marks (e.g., CE, ICC-ES, AS/NZS).

- Hazard Labels: If applicable (e.g., chemical anchors with hazardous resins), include GHS-compliant hazard symbols and safety data sheets (SDS).

Transportation and Handling

- Mode of Transport: Anchor fasteners are typically shipped via road, sea, or air. Choose transport methods based on urgency, destination, and product sensitivity.

- Handling: Use appropriate lifting equipment for palletized loads. Avoid dropping or dragging containers to prevent damage.

- Environmental Controls: Store and transport chemical anchors within recommended temperature ranges (usually 10°C to 25°C). Protect from direct sunlight and freezing conditions.

Storage Conditions

- Dry Environment: Store fasteners in a dry, climate-controlled warehouse to prevent rust and degradation.

- Shelving: Use racks to elevate packages off the floor and avoid moisture absorption.

- Chemical Anchors: Keep resin cartridges upright and separated from combustible materials. Observe expiration dates and practice FIFO (First In, First Out) inventory rotation.

Regulatory Compliance

- International Standards: Ensure products meet relevant standards such as:

- ISO 15630 (steel for reinforcement and prestressing)

- ASTM F1554 (anchor bolts)

- EN 14399 (preloaded high-strength structural bolting)

- Regional Certifications:

- EU: CE marking with compliance to Construction Products Regulation (CPR) EN 1090.

- USA: ICC-ES evaluation reports for structural anchors.

- Australia/New Zealand: AS/NZS 1252 and AS 5200.0 series compliance.

- Documentation: Maintain technical files, test reports, Declaration of Performance (DoP), and traceability records.

Import/Export Documentation

- Commercial Invoice

- Packing List

- Bill of Lading or Air Waybill

- Certificate of Origin

- Test Reports and Compliance Certificates (e.g., DoP, ICC-ES)

- SDS for chemical components

- Import Permits (if required by destination country)

Quality Assurance and Traceability

- Implement a traceability system using batch numbers to track materials from production to delivery.

- Conduct periodic audits of logistics partners to ensure compliance with handling standards.

- Retain records for a minimum of 10 years for structural anchor products.

Environmental and Safety Compliance

- Comply with REACH, RoHS, and other environmental regulations for metal and chemical components.

- Train personnel in safe handling, especially for chemical anchors containing irritants or flammable resins.

- Dispose of damaged or expired products according to local environmental regulations.

Conclusion

Effective logistics and compliance management for anchor fastening products ensures operational safety, regulatory adherence, and customer satisfaction. Regular review of standards and supply chain practices is recommended to maintain certification and market access.

Conclusion for Sourcing Anchor Fastening:

Sourcing anchor fastening systems requires a strategic approach that balances technical performance, cost-efficiency, compliance with industry standards, and reliability of supply. After evaluating available options, it is evident that selecting the right anchor fastening solution involves careful consideration of factors such as substrate material, load requirements, environmental conditions, and installation methods. Engaging with reputable suppliers who provide certified products, technical support, and consistent quality assurance is critical to ensuring long-term structural integrity and safety.

Moreover, establishing long-term partnerships with suppliers who offer competitive pricing, timely delivery, and scalability supports project efficiency and sustainability. Ultimately, a well-executed sourcing strategy for anchor fasteners not only reduces project risks and lifecycle costs but also contributes to the overall success and durability of construction and infrastructure applications.