The global ladder market is undergoing rapid transformation, driven by increasing demand in construction, infrastructure, and maintenance sectors. According to Grand View Research, the global ladders market size was valued at USD 7.8 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 5.2% from 2023 to 2030. A key trend fueling this expansion is the rising preference for lightweight, durable materials—particularly aluminum and fiberglass—across residential, commercial, and industrial applications. As safety regulations tighten and end-users prioritize long-term value over initial cost, manufacturers are investing heavily in material innovation and product performance. This has intensified competition among leading aluminum and fiberglass ladder producers, each vying for dominance through engineering excellence, compliance with ANSI and OSHA standards, and global distribution networks. In this data-driven analysis, we examine the top 7 manufacturers shaping the landscape, evaluating their market positioning, product portfolios, and technological differentiation in the ongoing aluminum vs. fiberglass debate.

Top 7 Aluminum Vs Fiberglass Ladders Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Materials Matter

Domain Est. 1996

Website: wernerco.com

Key Highlights: Werner offers ladders made from both fiberglass and aluminum. Each material offers unique benefits suited to particular conditions, applications, or preferences ……

#2 Louisville Ladder

Domain Est. 1997

Website: louisvilleladder.com

Key Highlights: Work safely around electricity with the toughest, strongest, and most tested fiberglass ladders on the market. See Platform Ladders….

#3 Ladders 101

Domain Est. 2000

Website: americanladderinstitute.org

Key Highlights: On the other hand, if there are no electrical power sources in your work area, the aluminum ladder is the lightest weight when compared to fiberglass or wood….

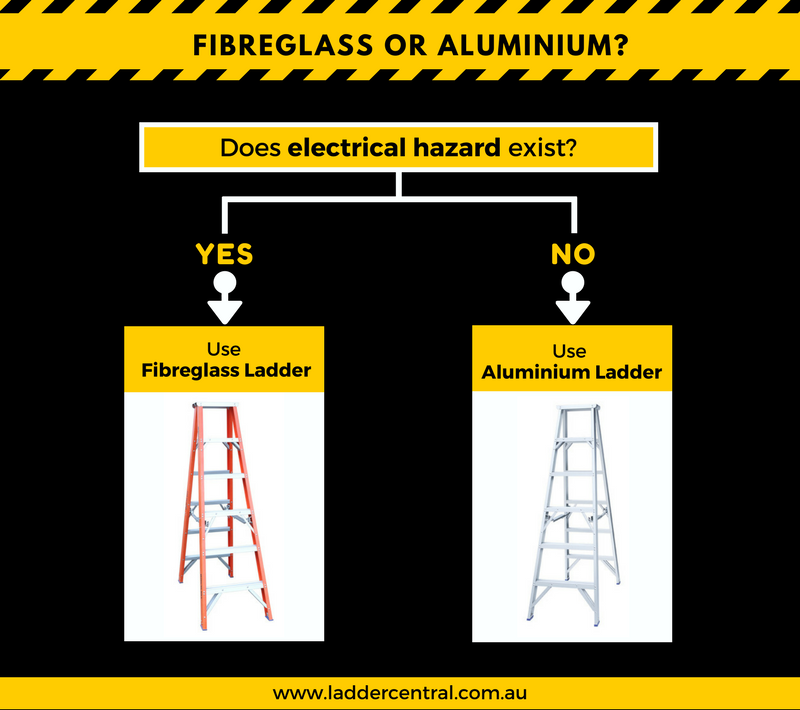

#4 Fiberglass vs aluminum ladder

Domain Est. 2010

Website: erectastep.com

Key Highlights: Aluminum ladders are preferred because they are lightweight and cost-effective. Fiberglass is non-conductive and best for electrical work….

#5 Ladder choice 28′ VS 32′? Fiberglass VS Aluminum

Domain Est. 2011

Website: pressurewashingresource.com

Key Highlights: All these people saying aluminum is lighter than fiberglass. I just checked out the Werner website. A 28′ aluminum type 1A is indeed lighter ……

#6 Choosing Between Aluminum and Fiberglass Ladders

Domain Est. 2014

Website: laddersafetyrails.com

Key Highlights: Aluminum ladders are typically less expensive than fiberglass ladders, offering a cost-effective solution for many users. While they provide ……

#7 Aluminum vs Fiberglass Ladders

Domain Est. 2001

Website: industrialproducts.com

Key Highlights: Aluminum vs fiberglass ladders: compare strength, weight, cost & safety to find the best ladder for your home, electrical, or industrial ……

Expert Sourcing Insights for Aluminum Vs Fiberglass Ladders

H2: Comparative Market Analysis of Aluminum vs. Fiberglass Ladders in 2026

As the global ladder market evolves through 2026, key trends are reshaping consumer preferences and industry dynamics, particularly in the competition between aluminum and fiberglass ladders. Driven by advancements in materials, safety regulations, sustainability concerns, and shifts in end-user demand across residential, industrial, and commercial sectors, the aluminum and fiberglass ladder markets are undergoing distinct transformations.

1. Material Performance and Use Case Diversification

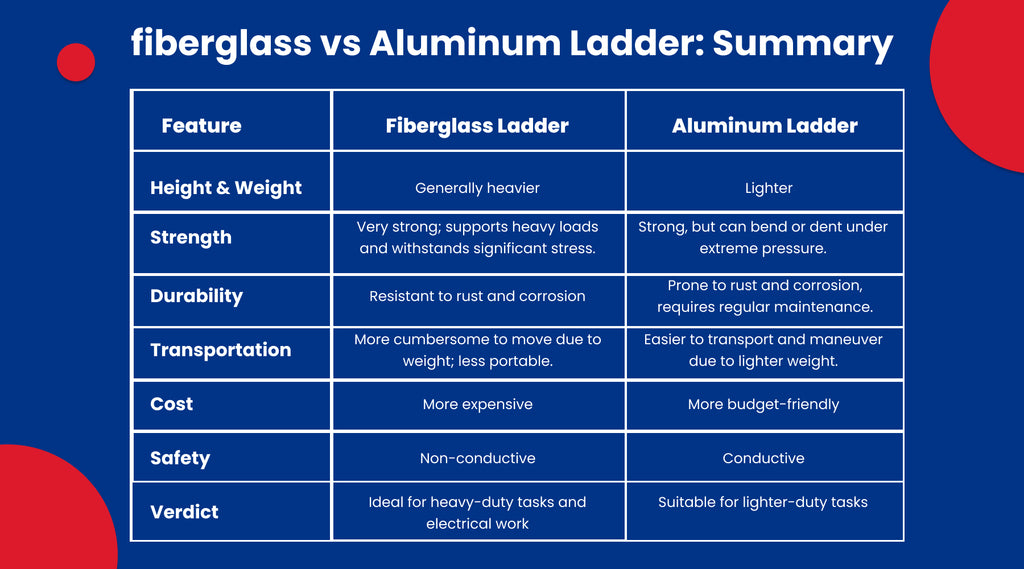

Aluminum ladders continue to dominate the lightweight and portable segment, favored for their strength-to-weight ratio, corrosion resistance, and affordability. They remain popular among contractors, roofers, and DIY users who prioritize ease of transport and frequent mobility. However, in high-risk electrical environments, fiberglass ladders maintain a critical advantage due to their non-conductive properties. This makes them the preferred choice for utility workers, electricians, and industrial maintenance teams—sectors where safety compliance is non-negotiable.

2. Market Growth and Regional Trends

The fiberglass ladder segment is expected to grow at a faster compound annual growth rate (CAGR) through 2026, particularly in North America and Europe, where stringent occupational safety standards (e.g., OSHA and EU directives) mandate non-conductive equipment in electrical work. Meanwhile, aluminum ladders retain strong market penetration in emerging economies such as India and Southeast Asia, where cost sensitivity and infrastructure development favor economical, durable options.

3. Sustainability and Environmental Impact

Environmental considerations are influencing material choices. Aluminum, while energy-intensive to produce, is highly recyclable—over 75% of all aluminum ever produced is still in use. This recyclability enhances its appeal amid growing corporate sustainability goals. Conversely, fiberglass presents challenges in end-of-life disposal due to its composite structure, though innovations in resin technologies and recycling methods are emerging. By 2026, eco-conscious procurement policies in both public and private sectors are expected to favor aluminum in applications where electrical insulation is not required.

4. Technological Innovations and Product Enhancements

Both materials are benefiting from design innovations. Aluminum ladders are seeing improvements in extrusion techniques and alloy compositions, increasing strength while reducing weight. Fiberglass models are incorporating modular designs, anti-slip coatings, and UV-resistant resins to improve durability in outdoor conditions. Smart ladder integrations—such as weight sensors and stability alerts—are more commonly applied to fiberglass platforms due to their robust structure, further enhancing their value proposition in professional settings.

5. Price and Accessibility

Aluminum ladders typically cost 20–30% less than comparable fiberglass models, making them more accessible to price-sensitive consumers and small businesses. This cost differential ensures aluminum’s dominance in the mass retail market, particularly through e-commerce platforms. However, as production efficiencies improve and demand rises, the price gap is expected to narrow slightly by 2026, especially for mid- to high-end fiberglass models.

Conclusion

By 2026, the aluminum vs. fiberglass ladder market will remain segmented by application rather than outright competition. Aluminum will continue to lead in general-purpose and portable use cases, driven by cost and weight advantages. Fiberglass will strengthen its position in safety-critical and industrial applications, supported by regulatory requirements and performance reliability. Ultimately, market growth will be driven not by one material displacing the other, but by continued specialization and innovation tailored to distinct user needs.

Common Pitfalls When Sourcing Aluminum vs. Fiberglass Ladders (Quality & Intellectual Property)

When sourcing ladders, particularly aluminum versus fiberglass models, buyers must navigate several critical pitfalls related to product quality and intellectual property (IP) risks. Understanding these issues helps avoid substandard products, safety hazards, and legal complications.

Quality Risks in Aluminum Ladders

One major pitfall when sourcing aluminum ladders is compromising on material grade and construction standards. Many low-cost suppliers use subpar aluminum alloys (e.g., non-aerospace-grade or non-6000 series) that lack sufficient strength-to-weight ratios, increasing the risk of bending, cracking, or failure under load. Poor welding techniques—such as inconsistent bead quality or inadequate penetration—can further compromise structural integrity. Additionally, inadequate anodizing or powder coating may lead to rapid corrosion, especially in humid or outdoor environments. Buyers may also encounter exaggerated load ratings; third-party testing often reveals that some sourced models fail to meet claimed ANSI or OSHA standards, posing serious safety liabilities.

Quality Risks in Fiberglass Ladders

Fiberglass ladders present their own quality challenges, primarily centered around resin composition, glass fiber density, and curing processes. Inferior resins or insufficient glass-to-resin ratios can result in brittle ladders prone to cracking or delamination under stress or UV exposure. Poorly cured fiberglass may degrade quickly when exposed to sunlight, reducing lifespan and electrical insulation properties—critical for use near power lines. Another common issue is inconsistent wall thickness in molded sections, leading to weak spots. Some suppliers misrepresent dielectric strength, claiming compliance with ASTM F711 without proper certification, exposing end users to electrical hazards.

Intellectual Property Infringement Risks

Sourcing from low-cost manufacturers, especially in regions with weak IP enforcement, increases the risk of inadvertently procuring counterfeit or IP-infringing ladder designs. Many aluminum and fiberglass ladder models—particularly those with patented locking mechanisms, hinge designs, or ergonomic features—are protected by utility or design patents. Suppliers may replicate branded products (e.g.,仿制 models resembling Little Giant or Werner ladders) without authorization, offering them at lower prices. Purchasing such products can expose buyers to legal action, customs seizures, and reputational damage. Due diligence, including patent searches and supplier audits, is essential to ensure designs are either licensed or sufficiently differentiated to avoid infringement.

Lack of Certification and Compliance Verification

A key pitfall across both materials is the assumption that certifications are genuine. Suppliers may falsify or misrepresent compliance with safety standards such as ANSI, OSHA, CSA, or EN131. Aluminum ladders must meet conductivity and weight-bearing standards, while fiberglass ladders require dielectric testing. Without independent verification—such as third-party lab reports or onsite factory audits—buyers risk receiving non-compliant products. “Certification mills” in some regions issue fake or unaccredited certificates, further complicating due diligence.

Supply Chain Transparency and Traceability

Limited visibility into the supply chain increases exposure to quality and IP risks. Aluminum may be sourced from unverified smelters, raising concerns about material consistency and ethical sourcing. For fiberglass, the origin of raw materials (e.g., glass fibers and resins) can impact performance and sustainability. Moreover, multi-tier subcontracting can obscure IP ownership and manufacturing practices, making it difficult to trace design origins or ensure consistent quality control. Establishing direct relationships with manufacturers and requiring full material disclosure helps mitigate these risks.

By proactively addressing these pitfalls—through rigorous supplier vetting, independent testing, and IP diligence—buyers can ensure the safe, compliant, and legally sound procurement of aluminum and fiberglass ladders.

Logistics & Compliance Guide: Aluminum vs. Fiberglass Ladders

When selecting ladders for industrial, commercial, or construction use, understanding the logistics and compliance implications of material choice—aluminum versus fiberglass—is essential. Both materials offer distinct advantages and challenges related to transportation, handling, safety regulations, and compliance standards. This guide outlines key considerations to help inform procurement, storage, and operational decisions.

Material Properties and Safety Compliance

Aluminum and fiberglass ladders differ significantly in their physical and electrical properties, directly impacting safety compliance.

Aluminum Ladders

Aluminum is a conductive metal, making these ladders unsuitable for use near electrical sources. OSHA regulations (29 CFR 1926.1053) prohibit the use of conductive ladders in environments where contact with energized electrical systems is possible. This limits their application in electrical utility work, telecommunications, or any job involving overhead power lines. Compliance with NFPA 70E (Electrical Safety in the Workplace) further reinforces the need to avoid conductive tools and equipment near live circuits.

Fiberglass Ladders

Fiberglass is non-conductive, providing a critical safety advantage in electrically hazardous environments. OSHA and NFPA standards recognize fiberglass as the preferred ladder material when working near electricity. Additionally, fiberglass ladders are more resistant to corrosion and UV degradation, enhancing long-term compliance with safety and durability standards in harsh environments.

Weight and Handling Considerations

Logistics efficiency begins with ease of handling and transport.

Aluminum Ladders

Aluminum ladders are significantly lighter than fiberglass counterparts of the same size. This reduces physical strain during manual handling and lowers transportation costs due to reduced weight per unit. Lighter weight also facilitates easier loading/unloading from vehicles and movement across job sites, improving worker ergonomics and reducing the risk of musculoskeletal injuries.

Fiberglass Ladders

Fiberglass ladders are heavier, which increases handling difficulty and transportation costs. Their weight requires additional labor or mechanical assistance for movement, especially on large-scale job sites. However, their durability and resistance to environmental damage often justify the added handling burden in high-risk or outdoor applications.

Transportation and Storage Logistics

Material choice affects packaging, stacking, and space utilization.

Aluminum Ladders

Aluminum’s light weight reduces fuel consumption and emissions during shipping, offering a logistical and environmental advantage. These ladders are less prone to cracking or chipping during transit but can dent or bend under heavy loads. Proper bracing is required during transport to prevent deformation. In storage, aluminum ladders take up less vertical space when nested but must be protected from moisture to prevent oxidation over time.

Fiberglass Ladders

Fiberglass ladders require more robust packaging to prevent surface scratches or structural damage during shipping. Their weight increases freight costs, especially for large-volume orders. However, they are highly resistant to rust, moisture, and temperature fluctuations, allowing for long-term outdoor or humid storage without degradation. Stackability depends on design, but their durability supports denser, long-term warehousing.

Regulatory and Industry Standards

Both ladder types must comply with national and international safety standards, but material-specific rules apply.

OSHA and ANSI Compliance

All ladders must meet OSHA and ANSI A14 standards, which specify load capacity, rung spacing, labeling, and structural integrity. Both aluminum and fiberglass ladders are rated under ANSI duty classes (e.g., Type IA, I, II, III). However, only fiberglass ladders meet the electrical insulation requirements for use in electrical work per ANSI A14.5.

Labeling and Certification

Fiberglass ladders must display dielectric ratings and warnings about electrical safety. Aluminum ladders should be clearly labeled as conductive. Proper certification tags (e.g., ANSI/ISEA A14) must be visible and undamaged. Compliance audits should verify that ladder materials align with job-specific hazard assessments.

Environmental and Sustainability Factors

Increasing attention to ESG (Environmental, Social, and Governance) standards influences material choices.

Aluminum Ladders

Aluminum is highly recyclable, with up to 75% of all aluminum ever produced still in use. Recycling aluminum requires only 5% of the energy needed for primary production, offering strong sustainability credentials. However, mining and refining bauxite ore carry significant environmental impacts.

Fiberglass Ladders

Fiberglass is less recyclable due to composite structure and resin content. Disposal often involves landfilling, raising environmental concerns. However, the longer service life in corrosive environments may offset lifecycle impacts. Some manufacturers are exploring recyclable resin systems to improve sustainability.

Conclusion and Recommendations

Choosing between aluminum and fiberglass ladders requires balancing safety, logistics, and compliance:

- Use aluminum ladders when weight, cost, and recyclability are priorities, and electrical hazards are absent.

- Use fiberglass ladders when working near electricity, in corrosive environments, or where long-term durability outweighs handling challenges.

Procurement teams should conduct risk assessments, consult OSHA/ANSI guidelines, and consider total cost of ownership—including transport, maintenance, and compliance—when selecting ladder materials. Proper training and clear labeling are critical to ensure ongoing regulatory compliance and worker safety.

Conclusion: Sourcing Aluminum vs. Fiberglass Ladders

When sourcing ladders for industrial, commercial, or home use, the choice between aluminum and fiberglass models depends on specific needs, safety requirements, and environmental conditions.

Aluminum ladders are lightweight, durable, and cost-effective, making them ideal for general-purpose use, especially where portability and ease of handling are priorities. They are corrosion-resistant and well-suited for dry and indoor environments. However, aluminum conducts electricity, making it unsafe for electrical work or use near live circuits.

In contrast, fiberglass ladders offer superior electrical insulation, making them the preferred choice for utility workers, electricians, and jobs involving power lines. They are also highly resistant to weather, chemicals, and UV exposure, ensuring long-term reliability in harsh outdoor conditions. However, they are heavier and more expensive than aluminum ladders.

Ultimately, fiberglass ladders are the safer choice for electrical and outdoor applications, despite their higher cost and weight. Aluminum ladders remain a practical, economical option for non-electrical, lighter-duty tasks where weight and affordability are key considerations. The decision should prioritize safety, job requirements, and long-term value to ensure optimal performance and user protection.