The global aluminum pop rivets market is experiencing steady growth, driven by rising demand across aerospace, automotive, construction, and manufacturing industries. According to Grand View Research, the global rivets market size was valued at USD 9.7 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030, with aluminum pop rivets gaining preference due to their lightweight, corrosion-resistant properties, and ease of installation. Another report by Mordor Intelligence projects the fasteners market—of which aluminum pop rivets are a key segment—to expand at a CAGR of over 5.2% during the forecast period of 2023–2028, citing increased industrial automation and infrastructure development as primary growth catalysts. As demand surges, manufacturers are innovating to meet stringent performance standards, making the competitive landscape both dynamic and highly specialized. Below is a data-driven overview of the top 9 aluminum pop rivets manufacturers shaping the industry’s future.

Top 9 Aluminum Pop Rivets Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Industrial Rivet & Fastener Company

Domain Est. 1995

Website: rivet.com

Key Highlights: Our riveting tools have the most advanced features such as AutoFeed and Error Proofing Technologies, plus they are ergonomic and have up to a 2 year warranty….

#2 Rivets Made in the USA

Domain Est. 2004

Website: adprivet.com

Key Highlights: A Veteran owned US manufacturer of blind rivets. This may be the only rivet manufacturer stocking over a dozen colors of painted blind rivets….

#3 Manufacturer of Rivets & Blind Rivet by Anish Rivets LLP, Vasai

Domain Est. 2024

Website: anishrivets.com

Key Highlights: Established in the year of 2000, “Anish Rivets LLP” are Manufacturer of Solid Rivets, Semi-Tubular Rivets And Blind Rivets etc….

#4 PEM – PennEngineering

Domain Est. 1996

Website: pemnet.com

Key Highlights: PEM offers innovative fastening solutions for a variety of applications across industries like Automotive Electronics, Consumer Electronics, Datacom and more….

#5 5/32 Inch Aluminum Blind Pop Rivets

Domain Est. 1998

Website: oneida-air.com

Key Highlights: In stock $9.50 deliveryBlind rivets are ideal for securing thin sheet metal fittings, such as snap-lock piping, together in applications where there is no access to the other side …

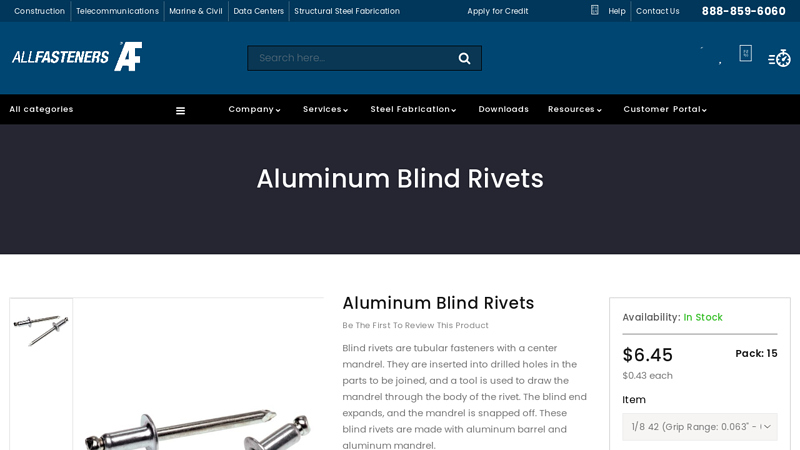

#6 Aluminum Blind Rivets

Domain Est. 2002

Website: allfasteners.com

Key Highlights: These blind rivets are made with aluminum barrel and aluminum mandrel. Availability: In Stock. $6.45. $0.43 each….

#7 Rivets Online

Domain Est. 2009 | Founded: 1948

Website: rivetsonline.com

Key Highlights: Founded in 1948, Jay-Cee Sales & Rivet is the nation’s largest distributor of aluminum blind rivets & special fasteners. Contact us or buy online today!…

#8 POP®

Domain Est. 2012

Website: stanleyengineeredfastening.com

Key Highlights: The POP rivet range includes a wide variety of high-quality fasteners that will meet the needs of your demanding manufacturing assembly process….

#9 Rivets

Domain Est. 2024

Website: arrowtoolgroup.com

Key Highlights: 5-day delivery 30-day returnsOur rivets offer strong, permanent fastening for metal, plastic, and more. Ideal for automotive, construction, and DIY use. Available in multiple sizes…

Expert Sourcing Insights for Aluminum Pop Rivets

H2: Projected Market Trends for Aluminum Pop Rivets in 2026

The global market for aluminum pop rivets is expected to experience steady growth by 2026, driven by expanding industrial applications, technological advancements, and rising demand across key sectors such as automotive, aerospace, construction, and consumer electronics. As lightweight and corrosion-resistant fastening solutions become increasingly critical, aluminum pop rivets are poised to gain further market traction due to their favorable strength-to-weight ratio and ease of installation.

One of the primary drivers shaping the 2026 market landscape is the automotive industry’s ongoing shift toward lightweight vehicle design. With stringent fuel efficiency and emissions regulations in regions like North America, Europe, and China, manufacturers are increasingly substituting steel components with aluminum alternatives—including fasteners. Aluminum pop rivets support this transition by enabling durable, lightweight assemblies in body panels, chassis components, and interior systems.

In the aerospace and defense sector, aluminum pop rivets remain a staple due to their reliability in high-stress environments and compatibility with aluminum alloys commonly used in aircraft construction. Continued growth in commercial air travel and aircraft production—particularly with companies like Boeing and Airbus ramping up deliveries—will bolster demand for high-performance fasteners, including sealed and structural-grade aluminum rivets.

Additionally, the construction and renewable energy industries are emerging as significant growth areas. The adoption of modular construction techniques and the expansion of solar panel installations require efficient, durable fastening solutions. Aluminum pop rivets offer non-magnetic properties, resistance to weathering, and compatibility with composite materials, making them ideal for these applications.

Technological innovation is also influencing the market. By 2026, manufacturers are expected to focus on smart manufacturing practices, including automation and precision tooling, to improve rivet consistency and reduce waste. There will also be a growing emphasis on sustainable production, with increased recycling of aluminum and reduced carbon footprints in manufacturing processes.

Regionally, Asia-Pacific is anticipated to lead market growth, fueled by industrialization in China, India, and Southeast Asia. Meanwhile, North America and Europe will maintain strong demand, supported by advanced manufacturing ecosystems and regulatory support for lightweight materials.

In summary, the 2026 aluminum pop rivet market is set for moderate but consistent expansion, shaped by material science advancements, sector-specific demands, and global sustainability trends. Companies that invest in product innovation, automation, and environmentally responsible practices will be best positioned to capitalize on these evolving opportunities.

Common Pitfalls When Sourcing Aluminum Pop Rivets (Quality, IP)

Sourcing aluminum pop rivets may seem straightforward, but overlooking key quality and intellectual property (IP) considerations can lead to product failures, supply chain disruptions, and legal risks. Below are critical pitfalls to avoid:

Quality Inconsistencies and Material Integrity

One of the most frequent issues in sourcing aluminum pop rivets is inconsistent quality, particularly concerning material composition and mechanical strength. Suppliers—especially those offering low-cost options—may use substandard aluminum alloys that do not meet specified tensile or shear strength requirements. This can result in premature rivet failure, especially in structural or high-vibration applications. Additionally, poor manufacturing processes can lead to inconsistent mandrel break points, incomplete flaring, or cracks in the rivet body, compromising joint integrity.

Buyers should insist on material certifications (e.g., mill test reports) and conduct periodic batch testing. Relying solely on visual inspection or supplier claims without third-party validation increases the risk of receiving non-conforming products.

Lack of Compliance with Industry Standards

Many sourced aluminum pop rivets fail to meet recognized industry standards such as ASTM, ISO, or military specifications (e.g., MS or NAS). Non-compliant fasteners may appear identical but perform poorly under load or in corrosive environments. This is particularly problematic in aerospace, automotive, or construction sectors where regulatory compliance is mandatory.

Ensure suppliers explicitly state conformance to relevant standards and provide documentation. Avoid suppliers who cannot produce test data or traceability records, as this often indicates a higher risk of non-compliance.

Counterfeit or Misrepresented Products

The fastener market is susceptible to counterfeit goods, especially when sourcing from regions with weak regulatory oversight. Some suppliers may label generic or off-spec rivets as premium brands (e.g., Huck, POP brand, or Avdel) without authorization. These counterfeit products often use inferior materials and manufacturing methods, posing serious safety and reliability concerns.

Verify supplier authenticity through authorized distribution channels and request proof of legitimacy, such as distributor agreements or OEM certifications. Be wary of unusually low prices, which can be a red flag for misrepresentation.

Intellectual Property (IP) Infringement Risks

Sourcing generic copies of patented or trademarked rivet designs can expose buyers to IP infringement liabilities. Some suppliers produce “look-alike” rivets that mimic the design and function of proprietary systems protected by patents or utility models. While some designs may be out of patent, others are actively protected, and using unauthorized versions—even if functionally similar—can lead to legal action from IP holders.

Conduct due diligence on the design origins and ensure that the rivets do not infringe on active patents. Work with legal or technical experts to assess IP risks, especially when sourcing for markets with strong IP enforcement, such as the U.S. or EU.

Inadequate Traceability and Documentation

Traceability is essential for quality control and regulatory compliance. Poorly documented or untraceable rivets make it difficult to investigate failures or manage recalls. Suppliers who cannot provide lot numbers, manufacturing dates, or material traceability increase operational risk.

Demand full documentation with every shipment and include traceability requirements in procurement contracts. This is particularly important in regulated industries where audit trails are mandatory.

Conclusion

Avoiding these pitfalls requires proactive supplier vetting, clear specifications, and ongoing quality assurance. Prioritize suppliers with strong reputations, verifiable certifications, and transparency in manufacturing and IP compliance. Investing time upfront in due diligence can prevent costly failures and legal exposure down the line.

Logistics & Compliance Guide for Aluminum Pop Rivets

Overview

Aluminum pop rivets, also known as blind rivets, are widely used in aerospace, automotive, construction, and manufacturing industries due to their lightweight, corrosion-resistant properties, and ease of installation. Proper logistics handling and regulatory compliance are essential to ensure product integrity, safety, and adherence to international trade standards.

Classification & HS Code

- HS Code (Harmonized System): 7616.10

- This code applies to “Other articles of aluminum,” including aluminum rivets and similar fasteners.

- Proper Classification: Confirm classification with local customs authorities, as minor variations in composition or design may affect categorization.

Packaging & Handling

- Primary Packaging:

- Pack in moisture-resistant, sealed plastic bags or blister packs to prevent oxidation and contamination.

- Secondary Packaging:

- Use sturdy cardboard boxes or plastic containers with dividers to prevent movement and damage during transit.

- Clearly label with product specifications (size, type, quantity, material grade).

- Palletization:

- Stack boxes securely on standard pallets (e.g., EUR/EPAL or GMA).

- Use stretch wrap and edge protectors to stabilize loads.

- Handling Precautions:

- Avoid exposure to moisture, salt, or corrosive chemicals.

- Store in dry, temperature-controlled environments (15–25°C recommended).

Storage Conditions

- Environment:

- Maintain low humidity (<60% RH) to prevent surface oxidation.

- Keep away from direct sunlight and extreme temperatures.

- Shelf Life:

- Typically indefinite if stored properly; inspect periodically for discoloration or corrosion.

- Segregation:

- Store away from steel or iron products to avoid galvanic corrosion.

Transportation Requirements

- Domestic & International Shipping:

- Suitable for air, sea, and ground transport.

- Comply with IATA (air), IMDG (sea), and ADR (road) regulations where applicable.

- Hazard Classification:

- Aluminum pop rivets are non-hazardous and not subject to dangerous goods regulations.

- Documentation:

- Commercial Invoice

- Packing List

- Bill of Lading or Air Waybill

- Certificate of Origin (if required for preferential tariffs)

- Material Safety Data Sheet (MSDS/SDS) – typically not required but may be requested.

Regulatory Compliance

- REACH (EU):

- Compliant if no Substances of Very High Concern (SVHC) are present above threshold levels (currently 0.1%). Aluminum metal is generally exempt.

- RoHS (EU):

- Not applicable, as rivets are typically homogenous metal components not falling under RoHS scope for EEE.

- Conflict Minerals (U.S. Dodd-Frank Act):

- Aluminum is not a conflict mineral; no reporting required.

- Proposition 65 (California):

- No significant exposure risk; aluminum metal is not listed as a reproductive toxicant in this form.

- Customs Compliance:

- Ensure accurate declaration of value, origin, and HTS code to avoid delays or penalties.

Export Controls

- EAR (Export Administration Regulations – U.S.):

- Aluminum pop rivets generally fall under EAR99 (low-risk, non-controlled items).

- No license required for most destinations, but verify for embargoed countries (e.g., Iran, North Korea).

- ITAR (International Traffic in Arms Regulations):

- Not applicable unless used in defense articles; standard commercial rivets are not ITAR-controlled.

Quality & Certification

- Material Certifications:

- Provide Mill Test Certificates (MTC) upon request, confirming aluminum alloy (e.g., 5056, 2117).

- Standards Compliance:

- Ensure conformity with relevant standards:

- ISO 15977 (Blind rivets – Pull mandrel type)

- ASTM F1305 (Standard Specification for Structural Blind Rivets)

- DIN 7337 (Aluminum blind rivets)

Sustainability & Waste Disposal

- Recyclability:

- 100% recyclable; aluminum can be reclaimed without quality loss.

- End-of-Life:

- Dispose of as non-hazardous industrial scrap. Follow local regulations for metal waste recycling.

Summary Checklist

- ✅ Confirm HS Code 7616.10

- ✅ Use moisture-protected, secure packaging

- ✅ Store in dry, controlled conditions

- ✅ Provide accurate shipping documentation

- ✅ Verify non-hazardous status for transport

- ✅ Comply with REACH and regional regulations

- ✅ Confirm EAR99 classification for exports

- ✅ Offer material certification if required

Adhering to this guide ensures efficient logistics operations and full regulatory compliance for the global distribution of aluminum pop rivets.

Conclusion for Sourcing Aluminum Pop Rivets:

Sourcing aluminum pop rivets requires a strategic approach that balances quality, cost, reliability, and lead time. After evaluating suppliers, it is clear that selecting a reputable manufacturer or distributor with certifications (such as ISO standards), consistent material quality (e.g., 2117-T4 aluminum alloy), and strong logistical support is crucial. Factors such as rivet diameter, grip range, and head type must align with specific application requirements to ensure structural integrity and ease of installation.

Domestic suppliers may offer faster delivery and easier communication, while international suppliers—particularly from regions with strong manufacturing industries—can provide cost advantages. However, international sourcing requires careful consideration of shipping times, import regulations, and potential quality control challenges.

Ultimately, establishing long-term relationships with trusted suppliers, conducting sample testing, and implementing a clear quality assurance process will help ensure a reliable supply of aluminum pop rivets that meet performance standards and support efficient production. Regular supplier evaluations and staying informed about market trends will further optimize sourcing strategies over time.