The global aluminum handrail market is experiencing robust growth, driven by rising demand for durable, corrosion-resistant, and aesthetically versatile building materials in residential and commercial construction. According to Grand View Research, the global architectural metal products market—encompassing aluminum handrails—was valued at USD 150.3 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 6.8% from 2023 to 2030. This growth is further fueled by increasing infrastructure development, urbanization, and strict safety regulations mandating handrail installations in stairways. Aluminum, in particular, has gained traction due to its lightweight nature, low maintenance, and recyclability, making it a preferred choice for modern stair railing systems. As demand surges, a select group of manufacturers have emerged as leaders, combining innovation, precision engineering, and scalable production to dominate the global supply chain. Here are the top 8 aluminum handrail manufacturers for stairs shaping the industry in 2024.

Top 8 Aluminum Handrail For Stairs Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

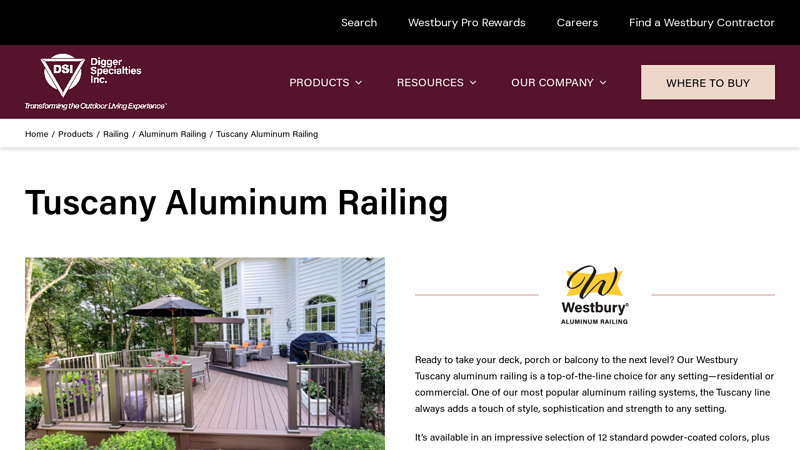

#1 Westbury Tuscany Aluminum Railing

Domain Est. 1998

Website: diggerspecialties.com

Key Highlights: Rating 5.0 · Review by Cody VanceDSI Westbury Tuscany aluminum railing sets the standard for premium quality aluminum deck railing that enhances the beauty of decks, porches a…

#2 Vista Railings: Aluminum Railing Manufacturers

Domain Est. 1999

Website: vistarailings.com

Key Highlights: Vista Railings provides premium aluminum railing and glass railing solutions that meet or exceed the quality standards and safety demands of today’s family ……

#3 Metal Railing

Domain Est. 1996

Website: trex.com

Key Highlights: Crafted from high-quality aluminum or steel, our metal railings deliver the sleek design you want with the lasting durability you can rely on….

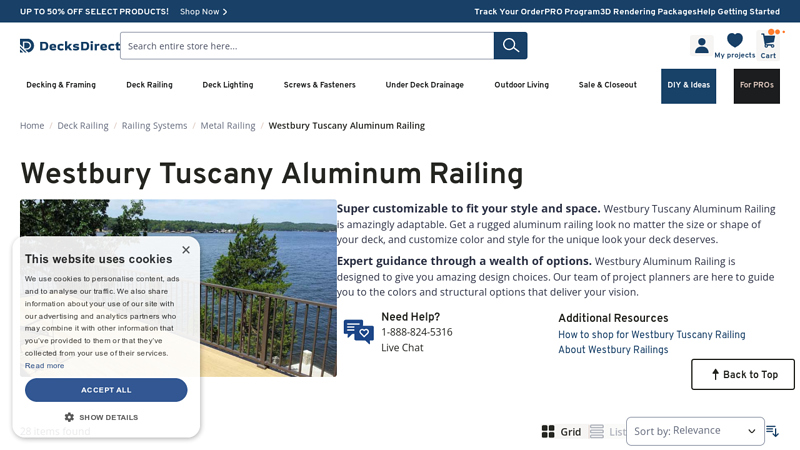

#4 Westbury Tuscany Aluminum Railing

Domain Est. 1998

Website: decksdirect.com

Key Highlights: 3–4 day deliveryWestbury Tuscany Aluminum Railing offers a customizable blend of strength and style to your outdoor spaces. Come shop our full collection now!…

#5 RDI Railing

Domain Est. 2003

Website: rdirail.com

Key Highlights: Find premium deck, porch and stair railing systems at RDI. Complete your perfect outdoor space with our durable vinyl, aluminum, steel & composite options!…

#6 Feeney

Domain Est. 2008

Website: feeneyinc.com

Key Highlights: Discover the combination of beauty, functionality and durability of Feeney luxury cable and aluminum railings, awnings, architectural rods and more….

#7 Century Aluminum Railings

Domain Est. 2012

Website: centuryrailings.com

Key Highlights: Our aluminum railing systems come in a variety of styles to complement both modern and traditional aesthetics. Choose from standard colors or customize your ……

#8 Westbury Railing Collections

Domain Est. 2016

Website: deckandrailsupply.com

Key Highlights: 8-day delivery 30-day returnsWestbury aluminum power-coated deck railing systems offer code-approved, easy-level aluminum posts, signature top rail, and railing infill choices….

Expert Sourcing Insights for Aluminum Handrail For Stairs

2026 Market Trends for Aluminum Handrail for Stairs

The global market for aluminum handrails for stairs is poised for significant evolution by 2026, shaped by technological innovation, shifting consumer preferences, and regulatory developments. This analysis explores the key trends expected to influence the industry in the coming years.

Growing Demand in Residential and Commercial Construction

Urbanization and increased infrastructure development, especially in emerging economies, are driving demand for modern, durable stair solutions. Aluminum handrails are gaining popularity due to their lightweight nature, corrosion resistance, and aesthetic versatility. In residential construction, minimalist and contemporary design trends favor sleek aluminum railings, particularly in high-end apartments and smart homes. In the commercial sector, aluminum handrails are increasingly specified in offices, shopping centers, and public buildings due to compliance with safety standards and low maintenance requirements.

Sustainability and Green Building Initiatives

Sustainability is a critical driver in the building materials sector. Aluminum is 100% recyclable and retains its properties through multiple recycling cycles, making it a preferred choice for green building certifications such as LEED and BREEAM. By 2026, increasing emphasis on carbon footprint reduction and energy-efficient construction will boost demand for recycled aluminum handrails. Manufacturers are expected to adopt eco-friendly production processes and transparent supply chains to meet environmentally conscious customer expectations.

Technological Integration and Smart Features

The integration of smart home technologies is extending to stair safety and accessibility. By 2026, aluminum handrails are likely to incorporate embedded LED lighting, motion sensors, and anti-slip heating elements—particularly in regions with harsh winters. Some high-end models may include touch-sensitive controls or integration with home automation systems. These innovations enhance functionality and safety, appealing to aging populations and luxury property developers.

Focus on Accessibility and Universal Design

With aging populations in North America, Europe, and parts of Asia, there is a growing focus on universal design principles in architecture. Aluminum handrails, known for their strength-to-weight ratio and customizable profiles, are ideal for accessible stairways. By 2026, demand is expected to rise for handrails that comply with ADA (Americans with Disabilities Act) and similar international standards, particularly in retrofit projects and multi-family housing developments.

Regional Market Dynamics

Asia-Pacific is projected to be the fastest-growing market for aluminum handrails due to rapid urbanization in countries like India, Vietnam, and Indonesia. China remains a major producer and consumer of aluminum building products. Meanwhile, North America and Western Europe will see steady growth driven by renovation activities and stringent safety regulations. Latin America and the Middle East are also emerging markets, supported by public infrastructure investments.

Competitive Landscape and Innovation

The market is becoming increasingly competitive, with manufacturers differentiating through design innovation, powder-coated finishes, and modular systems that simplify installation. Customization options—such as color, grip profile, and glass or cable infill compatibility—are becoming standard. By 2026, companies investing in R&D and digital tools like 3D configurators and BIM compatibility will gain a strategic advantage.

Supply Chain and Material Cost Considerations

Fluctuations in aluminum prices due to energy costs and geopolitical factors may impact margins. However, advancements in manufacturing efficiency and localized production are helping mitigate risks. Recycling initiatives and the use of post-consumer aluminum are also expected to stabilize long-term material costs.

Conclusion

By 2026, the aluminum handrail for stairs market will be defined by sustainability, smart functionality, and design flexibility. As construction industries worldwide prioritize safety, accessibility, and environmental responsibility, aluminum handrails will remain a material of choice. Stakeholders who adapt to these trends—through innovation, compliance, and customer-centric offerings—will be well-positioned for growth in this dynamic market.

Common Pitfalls When Sourcing Aluminum Handrails for Stairs (Quality and IP)

Sourcing aluminum handrails for stairs involves more than just selecting a design—it requires careful attention to material quality, structural integrity, and adherence to Ingress Protection (IP) ratings, especially in outdoor or high-moisture environments. Overlooking these factors can lead to premature failure, safety hazards, and increased maintenance costs. Below are the most common pitfalls to avoid.

Choosing Low-Grade Aluminum Alloys

One of the most critical mistakes is selecting handrails made from substandard aluminum alloys. Not all aluminum is created equal. Using alloys like 6061-T6 or 6063-T5 ensures durability, corrosion resistance, and sufficient tensile strength. Opting for lower-grade or recycled aluminum compromises structural performance and longevity, particularly in load-bearing stair applications.

Ignoring Surface Finish and Treatment

The surface finish significantly affects both aesthetics and durability. Anodized or powder-coated finishes protect against corrosion and UV degradation. Skipping proper surface treatment—or using low-quality coatings—leads to chalking, fading, and pitting, especially in coastal or industrial environments. Always verify the thickness and adherence standards (e.g., AAMA 2604 for coatings).

Overlooking Ingress Protection (IP) Ratings for Outdoor Use

For outdoor stair installations, IP ratings are crucial to ensure protection against dust and moisture. A common pitfall is assuming all aluminum handrails are weatherproof. Failing to specify appropriate IP ratings (e.g., IP65 or higher for exposed areas) can result in water ingress into internal components, leading to internal corrosion or damage to integrated lighting systems.

Inadequate Structural Certification and Load Compliance

Handrails must meet building codes (e.g., IBC, ADA) for load capacity and height. Sourcing products without verified structural testing or third-party certification risks non-compliance and liability. Ensure the supplier provides documentation confirming compliance with load requirements (typically 50 lbs/ft or 750 N/m).

Poor Welding and Fabrication Quality

Visible welds, misalignments, or inconsistent joints indicate poor craftsmanship, which affects both safety and appearance. Aluminum requires specialized welding techniques (e.g., TIG welding). Inexperienced fabricators may introduce weaknesses or create porous joints that accelerate corrosion. Always inspect sample pieces before bulk ordering.

Assuming All Suppliers Provide Accurate IP Claims

Some suppliers exaggerate or misrepresent IP ratings without proper testing. Relying solely on marketing claims without requesting test reports from accredited labs can lead to underperforming products. Verify IP certifications with documentation from recognized testing bodies.

Neglecting Compatibility with Environmental Conditions

Aluminum can suffer from galvanic corrosion when in contact with dissimilar metals (e.g., steel fasteners) in wet conditions. Failing to specify compatible materials and insulating components leads to accelerated degradation. Ensure the entire assembly—fasteners, brackets, and connectors—is designed for compatibility.

Skipping Site-Specific Design Reviews

Every stair configuration has unique angles, lengths, and mounting requirements. Ordering standard handrails without a site-specific design review results in fit issues, weak joints, or safety gaps. Engage suppliers early to provide CAD drawings or 3D models for approval prior to fabrication.

Avoiding these pitfalls ensures a durable, safe, and compliant aluminum handrail system that performs well over its intended lifespan. Always prioritize certified materials, verified IP ratings, and collaboration with experienced manufacturers.

Logistics & Compliance Guide for Aluminum Handrail For Stairs

Product Overview and Classification

Aluminum handrails for stairs are architectural components designed to provide safety, support, and aesthetic appeal in residential, commercial, and public buildings. Typically fabricated from extruded aluminum alloys (such as 6063-T5), these handrails are lightweight, corrosion-resistant, and often powder-coated for durability. They may be categorized under HS Code 7610.90 (Other articles of aluminum, including structural components) for international trade purposes.

Regulatory and Safety Compliance

Aluminum handrails must comply with building codes and accessibility standards to ensure user safety. Key regulations include:

– International Building Code (IBC): Specifies handrail height (34–38 inches), grip size, continuity, and load requirements.

– Americans with Disabilities Act (ADA): Requires accessible design, including handrail extensions, clearances, and tactile indicators where applicable.

– OSHA Standards (for commercial/industrial use): Mandates secure installation and fall protection compliance.

– Local Jurisdiction Codes: May impose additional requirements; verification with local authorities is essential.

Material and Environmental Compliance

- RoHS (Restriction of Hazardous Substances): Ensures no restricted substances (e.g., lead, cadmium) in coatings or alloys.

- REACH (EU Regulation): Requires declaration of Substances of Very High Concern (SVHCs).

- LEED Certification: Aluminum is recyclable; using recycled content may contribute to green building points.

- Conflict Minerals Reporting: If applicable, ensure aluminum is sourced responsibly, though less common than for tin or tantalum.

Packaging and Handling Requirements

- Protective Packaging: Use plastic wrap, foam corners, and cardboard sheathing to prevent scratching and oxidation.

- Bundling: Secure sections with non-abrasive straps; avoid direct metal-to-metal contact.

- Labeling: Include product specifications, batch numbers, handling instructions (e.g., “Fragile,” “Do Not Stack”), and compliance marks.

- Moisture Protection: Include desiccants in enclosed packaging to prevent condensation during transit.

Domestic and International Shipping Considerations

- Freight Classification: Classify under NMFC codes for aluminum building products (e.g., 150–175 based on density and handling).

- Containerization: Optimize loading in 20’ or 40’ dry containers; use dunnage to prevent shifting.

- Customs Documentation: Prepare commercial invoice, packing list, certificate of origin, and HS code declaration.

- Import Duties and Taxes: Verify duty rates based on destination country; some countries offer reduced rates for construction materials.

- Incoterms: Clearly define responsibilities (e.g., FOB, CIF) in contracts to allocate shipping and risk obligations.

Quality Assurance and Certification

- Mill Certifications: Provide alloy and temper certifications (e.g., ASTM B221) for raw materials.

- Third-Party Testing: Conduct load, corrosion, and finish adhesion tests as needed.

- Installation Manuals: Include compliance statements, torque specifications, and maintenance guidelines.

End-of-Life and Recycling

- Recyclability: Aluminum handrails are 100% recyclable; promote take-back or recycling programs.

- Disposal Guidelines: Advise against landfill disposal; direct users to certified metal recyclers.

- Environmental Claims: Ensure marketing statements (e.g., “eco-friendly”) are substantiated and compliant with FTC Green Guides.

Summary and Best Practices

To ensure smooth logistics and compliance:

– Verify all regulatory requirements before production and shipment.

– Partner with certified suppliers and logistics providers experienced in building materials.

– Maintain detailed documentation for audits and customs clearance.

– Train staff on proper handling and compliance protocols to reduce damage and liability.

In conclusion, sourcing aluminum handrails for stairs offers a practical, durable, and aesthetically pleasing solution for both residential and commercial applications. Aluminum’s lightweight nature, corrosion resistance, and low maintenance requirements make it an ideal material for indoor and outdoor use. When sourcing, it is essential to consider factors such as structural compliance with safety standards (e.g., building codes and ADA requirements), finish options for longevity and appearance, and compatibility with the architectural style of the space. Working with reputable suppliers or manufacturers ensures quality, customization options, and timely delivery. Ultimately, investing in well-sourced aluminum handrails enhances safety, accessibility, and visual appeal while providing long-term value and minimal upkeep.