The global aluminum market continues to expand, driven by rising demand across industries such as packaging, construction, and consumer goods. According to Grand View Research, the global aluminum market size was valued at USD 237.7 billion in 2023 and is expected to grow at a compound annual growth rate (CAGR) of 4.5% from 2024 to 2030. A key contributor to this growth is the increasing adoption of aluminum alloys known for their formability, corrosion resistance, and excellent thermal conductivity—traits that define Aluminum Alloy 1100. As one of the most widely used commercially pure aluminum alloys, Alloy 1100 (containing 99% aluminum) is particularly favored in applications requiring high workability and weldability, including chemical tanks, heat exchangers, and decorative trims. With growing demand in emerging economies and sustained industrial activity in North America, Europe, and Asia Pacific, the need for reliable, high-quality Alloy 1100 suppliers has never been greater. This list highlights the top 10 manufacturers leading innovation, volume, and quality in the production of Aluminum Alloy 1100, based on production capacity, geographic reach, certifications, and market presence.

Top 10 Aluminum Alloy 1100 Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Aluminum 1100

Domain Est. 2014

Website: alloysintl.com

Key Highlights: Aluminum 1100 is among the softest aluminum alloy, and it is not to be used for high-strength or high-pressure applications. Chemical Composition ……

#2 Leading Aluminum 1100 Manufacturers

Domain Est. 2015

Website: aluminummanufacturers.org

Key Highlights: Find top aluminum 1100 suppliers in the USA for premium solutions and competitive prices. Discover reliable manufacturers near you….

#3 1100 Aluminum

Domain Est. 1991

Website: hydro.com

Key Highlights: Hydro Extrusion in North America is able to produce the non-heat-treatable 1xxx series of aluminum alloy in extruded sections with a purity of at least 99.0% ……

#4 Aluminum Alloy 1100 Data Sheet

Domain Est. 1996

Website: unitedaluminum.com

Key Highlights: Aluminum 1100 is one of the most widely used alloys, with excellent forming properties, especially in the fully soft, annealed temper….

#5 Aluminum 1100

Domain Est. 1998

Website: continentalsteel.com

Key Highlights: Aluminum 1100 is a soft, non-heat-treatable and low strength alloy that offers strong corrosion resistance. Composed of 99% aluminum and 0.12% copper….

#6 1100 Aluminum Coil Stock Supplier & Slitter

Domain Est. 1998

Website: almetals.com

Key Highlights: Almetals is a 1100 aluminum supplier specializing in aluminum coil … This alloy is an aluminum-based alloy in the “commercially pure” wrought family….

#7 Industry Standards

Domain Est. 1998

Website: aluminum.org

Key Highlights: For 70 years, the Aluminum Association has worked with the industry to develop and maintain technical standards for aluminum production….

#8 1100 Aluminum Sheet

Domain Est. 2011

Website: kloecknermetals.com

Key Highlights: Kloeckner Metals sells 1100 aluminum sheet, a commercially pure aluminum known for its superior formability and corrosion resistance….

#9 Aluminum Alloys for Sale

Domain Est. 2013

Website: samaterials.com

Key Highlights: Aluminum Alloys. Welcome to our diverse collection of Aluminum Alloys, where innovation meets versatility in the realm of alloyed materials….

#10 1100 Aluminum Alloy

Domain Est. 2022

Website: aluminum-alloys.com

Key Highlights: 1100 aluminum is an aluminum-based alloy in the commercially pure wrought family. With a minimum of 99.0% aluminum, it is the most heavily alloyed of the ……

Expert Sourcing Insights for Aluminum Alloy 1100

H2: Projected Market Trends for Aluminum Alloy 1100 in 2026

By 2026, the global market for Aluminum Alloy 1100 is expected to experience steady growth, driven by increasing demand across key industrial sectors and a shift toward lightweight, corrosion-resistant materials. Aluminum Alloy 1100, a commercially pure aluminum (99% Al) known for its excellent workability, high thermal and electrical conductivity, and superior corrosion resistance, remains a vital material in industries such as packaging, construction, HVAC, and electronics.

One of the primary drivers of demand in 2026 will be the packaging industry, particularly in the production of foil for food, pharmaceuticals, and consumer goods. As sustainability regulations tighten worldwide, the recyclability and low environmental impact of Aluminum 1100 enhance its appeal. Growing consumer preference for sustainable packaging solutions is expected to boost consumption, especially in emerging markets across Asia-Pacific and Latin America.

In the construction and architectural sectors, Aluminum 1100 will continue to be used in decorative applications, roofing, and insulation materials due to its formability and aesthetic finish. Urbanization and infrastructure development in countries like India, Indonesia, and Vietnam are anticipated to support regional demand. Additionally, the HVAC industry will rely on this alloy for heat exchangers and ductwork, benefiting from its thermal efficiency and resistance to moisture.

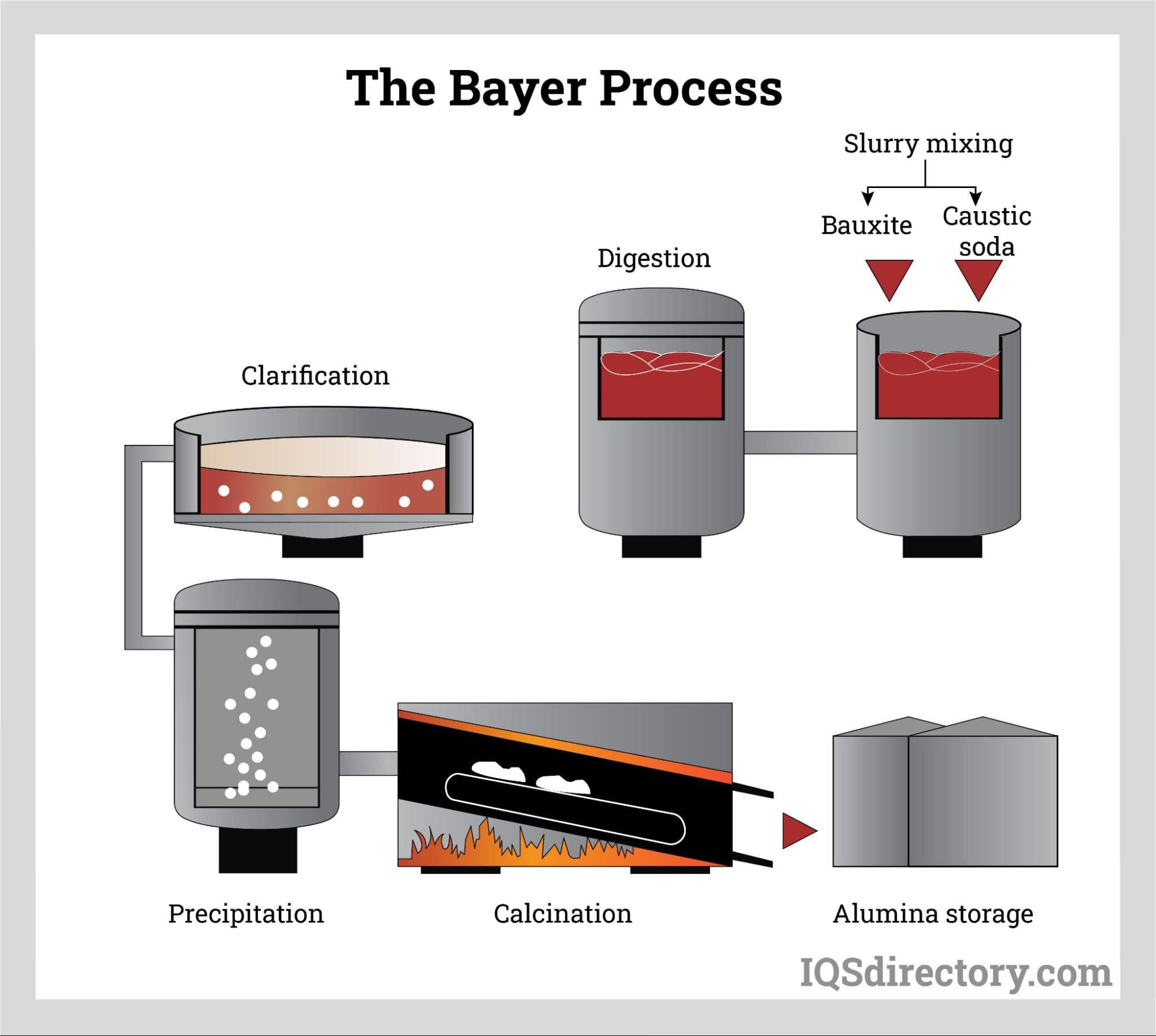

Technological advancements in manufacturing, including roll bonding and precision foil rolling, will improve production efficiency and reduce waste, making Aluminum 1100 more cost-competitive. However, market growth may be moderated by fluctuations in raw bauxite prices and energy costs, particularly in regions dependent on energy-intensive smelting processes.

Geopolitical factors and trade policies could also influence supply chains. Countries with abundant bauxite reserves and established refining capacity—such as China, India, and Russia—are likely to dominate production. Meanwhile, North America and Western Europe may increase recycling efforts to meet environmental targets, further integrating secondary aluminum into the supply chain.

In summary, the 2026 market for Aluminum Alloy 1100 is poised for moderate expansion, underpinned by sustainable packaging trends, infrastructure development, and technological improvements. While price volatility and supply chain dynamics present challenges, the alloy’s inherent material advantages ensure its ongoing relevance in a decarbonizing global economy.

H2: Common Pitfalls When Sourcing Aluminum Alloy 1100 (Quality and Intellectual Property)

Sourcing Aluminum Alloy 1100—known for its high purity (99% Al), excellent corrosion resistance, and good workability—can present several challenges, particularly related to quality assurance and intellectual property (IP) risks. Below are the most common pitfalls to avoid:

- Inconsistent Material Quality and Certification

- Pitfall: Suppliers may provide material that does not meet ASTM B209 or other required standards for Alloy 1100, especially in chemical composition (e.g., excess iron or silicon) or mechanical properties.

- Risk: Substandard alloy can lead to performance failures in applications like chemical tanks, heat exchangers, or decorative components.

-

Prevention: Require certified mill test reports (MTRs) and third-party material verification. Audit supplier quality control processes and insist on compliance with international standards.

-

Lack of Traceability and Proper Documentation

- Pitfall: Some suppliers may not provide full traceability from melt batch to finished product.

- Risk: Inability to verify origin or quality increases exposure to counterfeit or recycled non-conforming materials.

-

Prevention: Enforce strict traceability requirements in contracts and verify lot numbers, heat numbers, and batch certifications.

-

Unclear or Misrepresented Alloy Designation

- Pitfall: Suppliers may mislabel or substitute 1100 with similar-looking alloys (e.g., 1050, 1060) that have different impurity levels or performance characteristics.

- Risk: Functional degradation in corrosive environments or during forming operations.

-

Prevention: Conduct incoming material inspections using spectrographic analysis (e.g., OES or XRF) to confirm alloy identity.

-

Intellectual Property (IP) Risks in Custom Fabrications

- Pitfall: When sourcing custom-formed or fabricated parts made from 1100 alloy, suppliers might replicate proprietary designs without proper IP protection.

- Risk: Unauthorized duplication, reverse engineering, or leakage of design data to competitors.

-

Prevention: Use NDAs, clearly define IP ownership in contracts, and work only with trusted partners who adhere to IP compliance frameworks.

-

Geopolitical and Supply Chain Vulnerabilities

- Pitfall: Sourcing from regions with lax regulatory oversight increases exposure to substandard production practices and IP theft.

- Risk: Disruptions due to trade restrictions, customs violations, or compromised material integrity.

-

Prevention: Diversify supply sources, conduct on-site supplier audits, and prefer vendors with ISO 9001 and IATF 16949 certifications.

-

Inadequate Testing and Process Controls

- Pitfall: Suppliers may skip critical quality checks like tensile testing, bend testing, or surface finish inspections.

- Risk: Defective material entering production lines, leading to costly rework or recalls.

-

Prevention: Specify required testing protocols in purchase orders and conduct periodic quality audits.

-

Misunderstanding Temper Designations

- Pitfall: Confusion between tempers (e.g., H14, H18, O) can result in receiving material with incorrect hardness or formability.

- Risk: Poor performance during fabrication or end-use application.

- Prevention: Clearly specify required temper in procurement documents and verify through mechanical testing.

Conclusion:

To mitigate risks when sourcing Aluminum Alloy 1100, prioritize suppliers with robust quality management systems, transparent documentation, and strong IP safeguards. Implement rigorous qualification processes, material verification, and contractual protections to ensure both material integrity and intellectual property security.

H2: Logistics & Compliance Guide for Aluminum Alloy 1100

Aluminum Alloy 1100 is a commercially pure aluminum (minimum 99.0% aluminum) known for its excellent corrosion resistance, high thermal and electrical conductivity, and good workability. It is commonly used in applications such as chemical processing equipment, heat exchangers, decorative trim, and food processing surfaces. Proper logistics and compliance management are essential to ensure safe handling, transportation, regulatory adherence, and quality preservation of this material.

1. Material Classification & Identification

- UNS Number: A91100

- Common Names: 1100-H14, 1100-O (annealed), 1100-H22/H24 (strain-hardened with partial annealing)

- HS Code (Harmonized System): Typically 7606.12 (Flat-rolled products, not alloyed, of aluminum, of thickness < 0.2 mm) or 7606.91/7606.92 (thicker sheets/plates). Confirm based on form and thickness.

- Hazard Class (if applicable): Non-hazardous under normal conditions (not classified as dangerous goods for transport).

2. Packaging & Handling

- Packaging Requirements:

- Sheets, coils, and plates should be bundled and wrapped in moisture-resistant paper or plastic film to prevent oxidation and surface damage.

- Use wooden pallets or steel racks for stability during transport.

- Interleaving with kraft paper or plastic film is recommended to prevent scratching.

- Handling Precautions:

- Use non-abrasive lifting slings or vacuum lifters to avoid surface marring.

- Avoid direct contact with carbon steel tools or storage racks to prevent galvanic corrosion.

- Handle in dry, clean environments to minimize contamination.

3. Storage Conditions

- Environment: Store indoors in a dry, well-ventilated area with controlled humidity (<60% RH) to prevent surface oxidation or staining.

- Stacking: Keep flat and supported to prevent warping; do not stack excessive weight on top of sheets.

- Segregation: Store separately from corrosive chemicals, salts, or dissimilar metals (especially copper and steel) to prevent galvanic reactions.

4. Transportation

- Modes of Transport: Suitable for road, rail, sea, and air freight.

- Containers: Use dry, enclosed containers or vehicles to protect from moisture and contamination.

- Securement: Load must be properly braced and secured to prevent movement during transit.

- Temperature Considerations: No special temperature controls required, but avoid prolonged exposure to extreme heat or freezing conditions that could affect mechanical handling.

5. Regulatory Compliance

- REACH (EU): Aluminum 1100 is not on the SVHC (Substances of Very High Concern) list. However, ensure compliance with general REACH obligations for registration and communication in the supply chain.

- RoHS (EU): Compliant – contains no restricted hazardous substances (Pb, Cd, Hg, Cr⁶⁺, etc.).

- TSCA (USA): Aluminum is listed and exempt from significant new use rules under TSCA.

- OSHA (USA): No specific exposure limits for solid aluminum; however, aluminum dust (from machining/grinding) is regulated (PEL: 15 mg/m³ total dust). Ensure proper ventilation and PPE during fabrication.

- EPA Regulations: Aluminum scrap is regulated under RCRA if contaminated; ensure clean recycling streams.

6. Customs & Import/Export Documentation

- Required Documents:

- Commercial Invoice

- Packing List

- Bill of Lading or Air Waybill

- Certificate of Origin (may be required for tariff preferences)

- Material Test Report (MTR) or Mill Certificate (confirms alloy composition and mechanical properties)

- Export Controls: Generally not subject to ITAR or EAR restrictions, but verify with local authorities if shipping in large volumes or to sanctioned regions.

7. Environmental & Recycling Compliance

- Recyclability: 100% recyclable without degradation; recycling is encouraged under most environmental regulations.

- Waste Disposal: Aluminum scrap should be recycled through certified metal recyclers. Do not dispose of in regular landfill unless inert and uncontaminated.

- Carbon Footprint: Consider using suppliers with certified low-carbon aluminum production methods (e.g., ELYSIS or hydro-powered smelting).

8. Quality Assurance & Traceability

- Maintain full traceability from mill to end-user.

- Ensure suppliers provide:

- ASTM B209 (Standard Specification for Aluminum and Aluminum-Alloy Sheet and Plate)

- ISO 9001 certification (if applicable)

- Positive Material Identification (PMI) reports upon request

9. Emergency Response

- Fire Hazard: Solid form is non-combustible, but fine powder or shavings can be flammable. Use Class D fire extinguishers for aluminum fires.

- Spill/Leak: Not applicable for solid forms. For scrap or fines, collect with non-sparking tools and avoid dust generation.

10. Best Practices Summary

- Use protective packaging and proper handling to maintain surface quality.

- Comply with international trade regulations and provide accurate documentation.

- Store and transport under dry conditions to prevent corrosion.

- Confirm regulatory status in destination countries, especially for finished products.

- Partner with certified suppliers who adhere to environmental and quality standards.

By following this guide, stakeholders can ensure the safe, compliant, and efficient logistics of Aluminum Alloy 1100 across the supply chain.

In conclusion, sourcing aluminum alloy 1100 is a strategic decision for applications requiring excellent corrosion resistance, high thermal and electrical conductivity, and good workability. Its high purity and formability make it ideal for use in chemical processing equipment, heat exchangers, foil stock, and decorative applications. When sourcing, it is essential to select reputable suppliers who provide certified material that meets industry standards such as ASTM B209. Evaluating factors like material consistency, lead times, cost-efficiency, and supplier reliability ensures the acquisition of high-quality 1100 aluminum alloy that meets technical and operational requirements. Proper sourcing not only enhances product performance but also supports manufacturing efficiency and long-term supply chain stability.