The global aluminium gable vents market is gaining momentum, driven by rising demand for energy-efficient ventilation solutions in residential and commercial construction. According to Grand View Research, the global ventilation equipment market size was valued at USD 39.7 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 6.8% from 2023 to 2030, with aluminium-based ventilation products benefiting from their durability, corrosion resistance, and lightweight properties. Additionally, increasing awareness of indoor air quality and stringent building codes across North America and Europe are accelerating product adoption. As sustainability becomes a priority in construction, manufacturers are innovating with recyclable aluminium designs that align with green building standards. In this expanding landscape, a select group of manufacturers have emerged as leaders in producing high-performance aluminium gable vents—combining engineering precision, climatic resilience, and compliance with industry certifications. The following list identifies the top 10 manufacturers shaping this niche through consistent product innovation, broad distribution networks, and strong market presence.

Top 10 Aluminium Gable Vents Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Gable Vents

Domain Est. 1998

Website: buchnermfg.com

Key Highlights: Buchner has Gable Vents in various sizes, shapes and colours for your next Siding project. Get in touch today to purchase these products….

#2 Gable Vents

Domain Est. 2009

Website: customgablevents.com

Key Highlights: We are Custom Gable Vents Inc. and we manufacture louvered gable vents in every size and shape you can imagine and ship them right to your door….

#3 Master Flow® Gable Wall Louvers

Domain Est. 1996

Website: gaf.com

Key Highlights: Master Flow® Gable Wall Louvers are used for intake or exhaust applications. Get all the features and benefits of our gable louvers here!…

#4 Gable Vents

Domain Est. 1997

Website: lomanco.com

Key Highlights: These heavy gauge, all-aluminum gable vents are tightly constructed with machine tab folds, and feature wide mounting flanges for easy installation. Weather ……

#5 Aluminum Gable Louver Vents

Domain Est. 1997

#6 Louvered And Flush Mount Gable Vents And More!

Domain Est. 1998

#7 Gable Vents

Domain Est. 2002

Website: glenloawningandwindow.com

Key Highlights: Gable vents are an efficient way to help remove heat and humidity from your attic or crawl space. By using them this allows air to flow in and out of the space….

#8 Metal Gable Vents

Domain Est. 2008

Website: vulcanvents.com

Key Highlights: Vulcan Vents makes fire-resistant Metal Gable vents. Our Louvered stainless steel vents are installed on the exterior walls entry point of home for embers….

#9 Urethane Gable Vents

Domain Est. 2009

#10 Ventilation

Domain Est. 2019

Website: gibraltarbuildingproducts.com

Key Highlights: Ridge Vents ensure efficient airflow for attic ventilation to regulate temperature and reduce moisture. Ridge Vents feature external wind baffle to enhance ……

Expert Sourcing Insights for Aluminium Gable Vents

H2: Projected 2026 Market Trends for Aluminium Gable Vents

The global market for aluminium gable vents is poised for steady growth by 2026, driven by a confluence of construction trends, material preferences, and sustainability demands. Several key factors are expected to shape the market landscape over the next few years:

-

Increased Demand in Residential Construction

The residential construction sector remains a primary driver for aluminium gable vents. With housing markets in North America, Europe, and parts of Asia-Pacific showing resilience and recovery, demand for efficient, durable ventilation solutions is rising. Aluminium gable vents are favored for their longevity, resistance to corrosion, and low maintenance—qualities that align with modern building standards. -

Shift Toward Energy Efficiency and Sustainable Building Practices

As building codes and green certifications (such as LEED and BREEAM) emphasize energy efficiency and indoor air quality, proper attic ventilation has become critical. Aluminium gable vents contribute to thermal regulation by allowing hot air to escape, reducing cooling loads and improving HVAC efficiency. This alignment with energy-saving goals is expected to accelerate adoption in both new builds and retrofit projects. -

Advantages of Aluminium Over Alternative Materials

Compared to steel or vinyl, aluminium offers superior resistance to rust and weathering—especially important in coastal or high-humidity regions. Its lightweight nature also simplifies installation, reducing labor costs. By 2026, continued innovation in powder-coated and anodized finishes will further enhance aesthetic appeal and durability, widening its appeal in premium housing segments. -

Growth in DIY and Home Improvement Markets

The expansion of the DIY home improvement sector, particularly in the U.S. and Western Europe, supports demand for user-friendly ventilation products. Pre-finished aluminium gable vents that require minimal tools for installation are gaining popularity among homeowners and contractors alike, bolstering market penetration. -

Regional Market Expansion

While North America remains the largest market due to established building codes and high homeownership rates, growth in the Asia-Pacific region—especially in countries like India and Vietnam—is expected to accelerate. Urbanization and rising disposable incomes are fueling demand for modern, ventilated housing solutions. -

Supply Chain and Raw Material Considerations

Fluctuations in aluminium prices and supply chain dynamics could impact margins. However, advancements in recycling technologies and the high recyclability rate of aluminium (over 70% in the construction sector) are expected to mitigate environmental and cost concerns, reinforcing its long-term viability. -

Technological Integration and Smart Ventilation

By 2026, integration with smart home systems may begin to influence product development. While most gable vents remain passive, some manufacturers are exploring hybrid models with sensors and automated louvers. Although still niche, this trend could open new growth avenues in high-end residential markets.

Conclusion

By 2026, the aluminium gable vent market is expected to grow steadily, supported by durable construction demand, energy efficiency regulations, and material advantages. Manufacturers who innovate in design, sustainability, and ease of installation will be well-positioned to capture market share in an increasingly competitive and environmentally conscious industry.

Common Pitfalls When Sourcing Aluminium Gable Vents (Quality, IP)

Sourcing aluminium gable vents requires careful attention to avoid compromising on quality, durability, and performance. Overlooking key factors can lead to premature failure, reduced ventilation efficiency, and potential structural damage. Below are the most common pitfalls related to quality and IP (Ingress Protection) ratings.

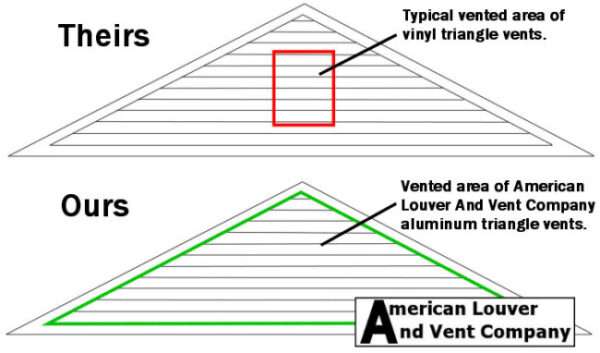

Overlooking Material Thickness and Alloy Quality

One of the most frequent mistakes is selecting vents made from undersized or low-grade aluminium. Thin-gauge aluminium (e.g., below 1.0 mm) is prone to warping, denting, and reduced longevity, especially in harsh climates. Additionally, using non-marine-grade or non-corrosion-resistant alloys (e.g., non-6063-T5 or non-5052) increases the risk of oxidation and pitting over time, particularly in coastal or high-humidity environments.

Ignoring Proper IP Rating for Environmental Conditions

Many buyers assume all gable vents offer adequate weather protection, but without a certified IP rating, moisture and dust ingress can severely impact attic conditions. Selecting a vent with insufficient IP protection—such as IP20 instead of IP44 or higher—can allow rain, snow, or insects to enter the attic space. This compromises insulation performance, promotes mold growth, and may void building compliance in regions with strict ventilation codes.

Assuming All Coatings Provide Equal Durability

Powder coating is common, but not all finishes are equal. Low-quality coatings may fade, chalk, or peel within a few years when exposed to UV radiation and temperature fluctuations. Sourcing vents without specifying durable, weather-resistant finishes (e.g., PVDF or high-quality polyester powder coat) results in premature aesthetic and protective failure, undermining both curb appeal and corrosion resistance.

Failing to Verify Structural Integrity and Wind Load Resistance

In areas prone to high winds or storms, structural performance is critical. Vents with poor frame design, weak joints, or inadequate mounting systems can fail under pressure, leading to detachment or deformation. Always verify that the vents are tested and certified for relevant wind load standards—especially for tall or exposed buildings.

Skipping Third-Party Certification and Testing Validation

Relying solely on supplier claims without requesting test reports or certifications (e.g., for airflow efficiency, fire resistance, or salt spray testing) is a major risk. Reputable suppliers should provide evidence of compliance with industry standards such as ASTM, AS/NZS, or EN. Without verification, buyers may receive substandard products that fail to meet building code requirements.

Underestimating the Importance of Proper Fit and Compatibility

Even high-quality vents can underperform if they are not dimensionally accurate or compatible with existing framing. Custom or non-standard sizes may not seal properly, creating gaps that allow water or pests to enter. Always confirm exact dimensions and installation requirements before procurement to avoid costly rework or retrofitting.

Logistics & Compliance Guide for Aluminium Gable Vents

Product Overview

Aluminium Gable Vents are lightweight, corrosion-resistant ventilation solutions designed to promote airflow in attic or roof spaces. Commonly used in residential and commercial construction, they help regulate temperature and moisture, improving energy efficiency and structural longevity. These vents are typically fabricated from durable, powder-coated or mill-finish aluminium and are installed at the gable ends of roofs.

Packaging & Handling

Aluminium Gable Vents are generally shipped in protective packaging to prevent surface damage during transit. Units should be stored in a dry, covered area, elevated off the ground to avoid moisture exposure. Handle with care to prevent bending or scratching; use gloves to minimize oil transfer from skin. Stacking should be limited to manufacturer-recommended levels to avoid deformation.

Transportation & Storage

Transport vents on flatbed or enclosed trucks, secured with straps to prevent shifting. Avoid exposure to extreme temperatures or prolonged sunlight during transit. Upon receipt, inspect for damage and store indoors in a climate-controlled environment. Keep packaging intact until installation to preserve finish and prevent contamination.

Import & Export Regulations

Ensure compliance with international trade standards when shipping across borders. Key considerations include:

– HS Code: Typically classified under 7610.90 (Other articles of aluminium), but confirm based on design and function.

– Country-Specific Requirements: Check import duties, documentation (commercial invoice, packing list, bill of lading), and product certification demands (e.g., CE marking in the EU, ICC-ES in the U.S.).

– Restricted Substances: Verify that materials comply with REACH (EU), RoHS, or other regional chemical regulations.

Building Code & Safety Compliance

Aluminium Gable Vents must meet local and international building code requirements for ventilation performance and fire safety, including:

– International Building Code (IBC) and International Residential Code (IRC): Require minimum net free vent area (NFVA), typically 1:300 ratio of attic area to vent space.

– NFPA 285 (if part of a wall assembly): May apply in high-rise structures depending on system design.

– Wind Resistance: Products installed in hurricane-prone zones (e.g., Florida) may require Miami-Dade County NOA or ASTM E1886/E1996 certification.

Environmental & Sustainability Standards

Aluminium is recyclable and often contains post-consumer content. Confirm supplier adherence to environmental standards such as:

– ISO 14001 (Environmental Management)

– EPD (Environmental Product Declaration) availability

– LEED contribution potential via recycled content and energy efficiency benefits

Installation & Field Compliance

Only trained personnel should install gable vents per manufacturer instructions. Ensure:

– Proper sealing to prevent air/water infiltration

– Compatibility with existing roofing and siding materials

– Adherence to local wind load and seismic requirements

– Documentation of installation for inspection and warranty purposes

Warranty & Documentation

Maintain records of product specifications, test reports, and compliance certificates. Most manufacturers offer limited warranties (e.g., 10–25 years) against material defects and finish degradation—registration may be required. Provide installers and end-users with operation and maintenance guidelines.

Summary

Successful logistics and compliance for Aluminium Gable Vents require attention to packaging, regulatory standards, and installation protocols. Partner with certified suppliers, verify regional code requirements, and maintain thorough documentation to ensure performance, safety, and regulatory adherence throughout the product lifecycle.

In conclusion, sourcing aluminium gable vents requires careful consideration of material quality, durability, compatibility with existing ventilation systems, and regional environmental factors such as moisture, salt exposure, and temperature fluctuations. Aluminium is an excellent choice due to its lightweight nature, corrosion resistance, and low maintenance requirements, making it ideal for long-term performance in diverse climates. When selecting suppliers, prioritize those offering certified materials, consistent finishes, and compliance with building codes and energy efficiency standards. Additionally, evaluating cost-effectiveness, lead times, and availability of customization options ensures optimal value and project efficiency. By partnering with reputable manufacturers and distributors, builders and contractors can ensure reliable performance, aesthetic consistency, and enhanced airflow for improved indoor air quality and roof longevity.