The global wire and cable manufacturing market is experiencing steady growth, driven by rising demand across industries such as automotive, construction, and renewable energy. According to Grand View Research, the global wire and cable market size was valued at USD 224.7 billion in 2023 and is projected to expand at a compound annual growth rate (CAGR) of 5.1% from 2024 to 2030. This growth is fueled by increasing infrastructure development, stricter safety regulations, and the shift toward electrification and energy-efficient systems. Within this competitive landscape, alliance-based manufacturing models—where companies collaborate to leverage shared technology, scale production, and expand geographic reach—have emerged as a strategic advantage. These partnerships enable firms to meet rising demand while maintaining quality and cost-efficiency. As the market evolves, a select group of alliance-driven wire manufacturers has risen to the forefront, combining innovation, global supply chain integration, and R&D investment to capture significant market share. The following analysis identifies the top four alliance wire manufacturers shaping the future of the industry.

Top 4 Alliance Wire Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Wire and Cable Manufacturers Alliance Inc.

Domain Est. 2006

Website: wcmainc.org

Key Highlights: WCMA is a non-profit corporate business association serving manufacturers of low to high voltage electrical, electronic, and fiber optic wire and cable….

#2 Alliance Cable & Wire Harness: Wiring Manufacturer

Domain Est. 2013

Website: alliance-mfg.com

Key Highlights: At Alliance Cable & Wire Harness, we specialize in design, development, and manufacturing of custom wire harnesses for a wide range of industries….

#3 Alliance Wire & Cable

Domain Est. 1998

Website: alliancewire.com

Key Highlights: Headquartered in Lawrenceville, Georgia just outside of Atlanta, Alliance Wire & Cable maintains an extensive inventory to serve our customers anywhere….

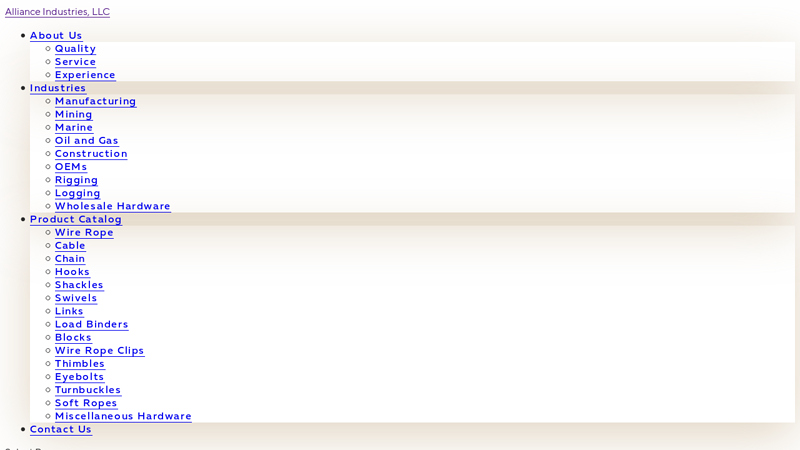

#4 Alliance Industries, LLC

Domain Est. 2012

Website: allianceindustries.us

Key Highlights: Alliance Industries, LLC is a wholesale distributor of wire rope, cable, chain, fittings and related products. We supply both foreign and domestic products….

Expert Sourcing Insights for Alliance Wire

H2 2026 Market Trends Analysis for Alliance Wire

Based on current trajectories in key end markets, technological advancements, and macroeconomic factors, H2 2026 presents a mixed but cautiously optimistic outlook for Alliance Wire. Success will hinge on strategic agility and leveraging core strengths.

1. Key Market Drivers & Opportunities:

-

Accelerated Electrification & Energy Transition:

- EV Boom Continuation: Global EV adoption remains robust, driving significant demand for specialized automotive wiring (high-voltage, lightweight, high-temperature resistant). Alliance Wire’s expertise in automotive-grade wire positions it well to capture growth, especially with Tier 1 suppliers and EV OEMs expanding production.

- Renewables & Grid Modernization: Investment in solar, wind, and energy storage systems continues. Demand for durable, UV-resistant, and high-conductivity wire for solar farms, wind turbines, and grid infrastructure upgrades (smart grids) will be strong. Alliance Wire’s capabilities in building wire and potentially specialized energy cable could see increased demand.

- Energy Efficiency Focus: Stricter regulations (e.g., potential updates to building codes, appliance standards) drive demand for higher-efficiency motors and appliances, requiring advanced magnet wire and winding wire. This is a core strength for Alliance Wire.

-

Industrial Automation & Smart Manufacturing Resurgence:

- Factory 4.0 Momentum: Increased investment in robotics, IIoT sensors, and automated control systems post-2025 will require vast amounts of reliable signal, control, and power cable. Alliance Wire’s portfolio in control and instrumentation wire is well-suited for this market.

- Supply Chain Resilience: Ongoing focus on nearshoring/reshoring, particularly in North America and Europe, benefits domestic manufacturers like Alliance Wire. Customers may prioritize reliable, local suppliers over purely low-cost offshore options, enhancing Alliance Wire’s competitive position.

-

Construction & Infrastructure (Selective Growth):

- Non-Residential & Industrial Construction: While residential construction might moderate, investment in data centers, industrial facilities (especially EV battery plants, semiconductor fabs), and commercial infrastructure (retrofits, smart buildings) will drive demand for building wire, fire alarm cable, and low-voltage cable.

- Government Infrastructure Spending: Continued rollout of multi-year infrastructure bills (e.g., US Bipartisan Infrastructure Law) will support demand for wire in transportation (light rail, EV charging), water systems, and broadband expansion.

-

Technological Advancements & Material Innovation:

- Lightweighting & Efficiency: Demand for aluminum alloy conductors (AAC, AAAC) and smaller-gauge, high-conductivity copper alloys in automotive and aerospace will grow. Alliance Wire’s R&D focus on material science and process optimization will be crucial.

- Enhanced Material Properties: Need for wire with superior flame retardancy (LSZH), higher temperature ratings, better chemical resistance, and improved signal integrity (for data/comm) will persist. Investment in these areas offers premium product opportunities.

- Sustainability Focus: Increased pressure for recyclable materials, reduced environmental footprint in manufacturing, and transparent supply chains. Alliance Wire’s ability to demonstrate sustainable practices and offer eco-friendly product options (e.g., lead-free, recyclable insulation) will be a competitive advantage.

2. Key Challenges & Risks:

-

Persistent Supply Chain Volatility:

- Copper & Commodity Prices: Copper remains the dominant cost driver. H2 2026 could see price fluctuations based on global demand (China’s recovery, green energy push), mining output, and geopolitical factors (e.g., supply disruptions). Effective hedging and passing through costs will be critical.

- Logistics & Lead Times: While improved from 2021-2023 peaks, global logistics could face disruptions (geopolitical tensions, port issues). Maintaining buffer stock for key materials and diversifying logistics partners remains essential.

-

Intensifying Competition:

- Global & Regional Players: Competition from large international wire producers and regional specialists will continue, particularly on price for commoditized products.

- Consolidation: Potential for further industry consolidation could create larger, more vertically integrated competitors.

-

Labor Market Constraints:

- Skilled Workforce Shortage: Finding and retaining skilled technicians, engineers, and machine operators remains a challenge. Investment in automation, training programs, and competitive compensation is vital.

-

Economic Uncertainty & Inflation:

- Interest Rates & Recession Risk: If interest rates remain high or a mild recession impacts H2 2026, capital spending (industrial, construction) could slow, impacting demand. Consumers might delay large purchases (new homes, EVs).

- Inflation Persistence: While potentially moderating, inflation in energy, raw materials (beyond copper, e.g., polymers), and labor requires constant cost management and pricing strategy adjustments.

-

Regulatory & Compliance Burden:

- Evolving Standards: Navigating increasingly complex and region-specific regulations (safety, environmental – RoHS, REACH, PFAS restrictions, energy efficiency) requires dedicated resources and compliance infrastructure.

3. Strategic Imperatives for Alliance Wire in H2 2026:

- Double Down on High-Growth, High-Margin Segments: Prioritize investment and capacity in EV wiring, renewable energy solutions, and specialized industrial automation cables. Focus on engineering support and value-added services.

- Enhance Operational Resilience & Agility:

- Optimize supply chain (diversify sources, strategic partnerships, inventory management).

- Continue investing in automation and process efficiency to mitigate labor costs and improve consistency.

- Strengthen demand forecasting capabilities.

- Innovation & Differentiation: Accelerate R&D in lightweight materials, enhanced performance wire (higher temp, better signal), and sustainable solutions. Protect IP and promote technical leadership.

- Strengthen Customer Partnerships: Move beyond transactional relationships. Offer design-in support, co-development, and long-term supply agreements, especially with key EV and industrial OEMs. Leverage nearshoring appeal.

- Proactive Commodities Management: Maintain a sophisticated hedging strategy for copper and key polymers. Develop transparent and flexible pricing models for customers.

- Talent Development & Retention: Invest in upskilling, safety culture, and a positive work environment. Explore partnerships with technical schools.

- Sustainability as a Core Value: Clearly communicate environmental and social governance (ESG) performance. Explore circular economy models (recycling programs) and reduce manufacturing footprint.

Conclusion:

H2 2026 offers significant growth potential for Alliance Wire, primarily fueled by the unstoppable trends of electrification and automation. However, navigating persistent commodity volatility, intense competition, and economic headwinds requires proactive management. Alliance Wire’s success will depend on its ability to leverage its technical expertise, focus on high-value applications, build resilient operations, innovate continuously, and deliver reliable solutions in an increasingly demanding market. A strategic focus on sustainability and customer partnership will be key differentiators. While challenges exist, the underlying structural trends favor a well-positioned industrial wire manufacturer like Alliance Wire.

Common Pitfalls When Sourcing Alliance Wire (Quality, IP)

Sourcing Alliance Wire—especially for critical applications in aerospace, defense, or high-reliability electronics—requires careful attention to both quality assurance and intellectual property (IP) protection. Overlooking these aspects can lead to performance failures, legal disputes, and supply chain disruptions. Below are key pitfalls to avoid.

Poor Quality Control and Non-Compliance

One of the most significant risks when sourcing Alliance Wire is receiving substandard products that fail to meet required specifications. Many suppliers may claim compliance with military or industry standards (such as MIL-DTL-22759 or MIL-W-22759), but not all adhere to rigorous testing and traceability protocols. Using wire that does not meet these standards can result in electrical failures, reduced lifespan, or safety hazards in harsh environments.

Pitfalls include:

– Lack of certified mill test reports or Certificate of Conformance (CoC)

– Inconsistent insulation thickness or conductor purity

– Absence of lot traceability and batch testing data

– Counterfeit or recycled materials being passed off as new

To mitigate this, always source from authorized distributors or directly from qualified manufacturers listed on the Qualified Products List (QPL) and verify compliance documentation.

Intellectual Property (IP) Infringement and Unauthorized Production

Alliance Wire specifications are often protected under strict IP and licensing agreements. Unauthorized manufacturers may reverse-engineer or replicate wire designs, leading to IP violations and compromised product integrity. Sourcing from such suppliers exposes your organization to legal liability and reputational damage.

Common IP-related pitfalls include:

– Purchasing from non-licensed producers who infringe on proprietary designs

– Lack of transparency in the supply chain, making it difficult to verify IP compliance

– Use of counterfeit trademarks or misleading certifications

Always confirm that the supplier is an authorized licensee of the original wire specification (e.g., from companies like TE Connectivity, Alpha Wire, or other IP holders). Request documentation proving licensing and avoid suppliers offering “equivalent” wires at suspiciously low prices, as these may be unauthorized copies.

Inadequate Supply Chain Transparency

A lack of visibility into the wire’s origin and manufacturing process increases the risk of both quality and IP issues. Intermediaries or gray market suppliers may obscure the true source, making it difficult to ensure authenticity and compliance.

Best practices include:

– Auditing suppliers and conducting on-site inspections when possible

– Requiring full material disclosure and chain-of-custody documentation

– Using blockchain or digital traceability tools where available

Conclusion

To avoid costly setbacks, organizations must prioritize certified quality, enforce IP compliance, and maintain full supply chain transparency when sourcing Alliance Wire. Partnering with reputable, authorized suppliers and conducting due diligence are essential steps in mitigating these common pitfalls.

Logistics & Compliance Guide for Alliance Wire

This guide outlines the essential logistics and compliance procedures for Alliance Wire to ensure efficient operations, regulatory adherence, and supply chain integrity.

Supply Chain Management

Alliance Wire must maintain a structured supply chain process, including sourcing raw materials (e.g., steel, copper, coatings) from certified suppliers. All suppliers must comply with environmental, safety, and quality standards. Regular audits and performance evaluations are required to ensure consistency and traceability.

Transportation & Distribution

All shipments—raw materials and finished wire products—must be transported using approved carriers that meet safety and delivery standards. Freight modes (truck, rail, sea) should be selected based on cost, lead time, and product specifications. Proper packaging and labeling, including hazard warnings for coated or treated wires, are mandatory to prevent damage and ensure safe handling.

Inventory Control

Maintain accurate inventory records using an integrated warehouse management system (WMS). Conduct regular cycle counts and annual physical inventories. FIFO (First-In, First-Out) practices should be enforced for materials with shelf-life considerations, such as insulated or coated wire.

Regulatory Compliance

Alliance Wire must comply with national and international regulations, including:

- OSHA Standards: Workplace safety for handling heavy wire spools and machinery.

- DOT Regulations: Safe transportation of hazardous materials, if applicable (e.g., oil-coated wires).

- REACH & RoHS (EU): Restriction of hazardous substances in electrical and electronic components.

- ITAR/EAR (if applicable): Compliance for export-controlled materials or defense-related products.

- Customs Compliance: Accurate HS codes, commercial invoices, and export documentation for international shipments.

Documentation & Recordkeeping

Maintain complete documentation for all shipments, including:

- Bills of Lading

- Material Safety Data Sheets (MSDS/SDS)

- Certificates of Conformance (CoC)

- Import/Export Licenses (where required)

- Audit trails for traceability

Records must be retained for a minimum of seven years, or as required by jurisdiction.

Quality Assurance & Testing

All wire products must undergo quality inspections per ISO 9001 standards. Testing protocols include tensile strength, conductivity, coating adhesion, and dimensional accuracy. Non-conforming materials must be quarantined and dispositioned in accordance with corrective action procedures.

Sustainability & Environmental Responsibility

Alliance Wire is committed to minimizing environmental impact. This includes:

- Proper disposal of scrap metal and waste coatings in compliance with EPA or local regulations.

- Recycling programs for packaging and production waste.

- Energy-efficient manufacturing practices.

Training & Employee Compliance

All logistics and operations staff must complete regular training on:

- Safe material handling

- Hazardous material protocols

- Regulatory updates

- Internal compliance procedures

Training records must be maintained and updated annually.

Incident Reporting & Corrective Actions

Any logistics or compliance breach (e.g., shipment delay, regulatory violation, safety incident) must be reported immediately. A root cause analysis will be conducted, and corrective actions implemented to prevent recurrence.

By adhering to this guide, Alliance Wire ensures reliable delivery, legal compliance, and long-term operational excellence.

Conclusion:

In conclusion, establishing a sourcing alliance for wiring components offers significant strategic advantages, including enhanced supply chain reliability, cost optimization, improved product quality, and access to specialized technical expertise. By collaborating closely with trusted suppliers, companies can ensure consistent material standards, reduce lead times, and respond more effectively to market demands. Furthermore, long-term partnerships foster innovation and shared growth through joint development and continuous improvement initiatives. As the demand for high-performance and reliable wiring solutions continues to rise across industries such as automotive, aerospace, and electronics, a well-structured sourcing alliance becomes a critical enabler of competitiveness and operational excellence. Therefore, investing in strategic supplier relationships for wire sourcing is not only a prudent operational decision but also a key driver of sustainable success.