The global air suspension components market is experiencing robust growth, driven by increasing demand for enhanced ride comfort, vehicle stability, and load-leveling capabilities across automotive and commercial vehicle segments. According to Grand View Research, the global air suspension market was valued at USD 5.3 billion in 2023 and is projected to expand at a compound annual growth rate (CAGR) of 6.8% from 2024 to 2030. This expansion is fueled by rising adoption in passenger vehicles, luxury cars, and heavy-duty trucks, where air shocks play a critical role in adaptive suspension systems. As a pivotal component, air hose kits ensure reliable airflow delivery to air shocks, making durability, flexibility, and leak resistance key selection criteria. With OEMs and aftermarket suppliers intensifying innovation in air suspension technology, the demand for high-performance air hose kits is on the rise. In this evolving landscape, identifying leading manufacturers of air hose kits for air shocks is essential for ensuring system efficiency and longevity. Based on market presence, product quality, and technical innovation, the following nine manufacturers have emerged as top players shaping the industry.

Top 9 Air Hose Kit For Air Shocks Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

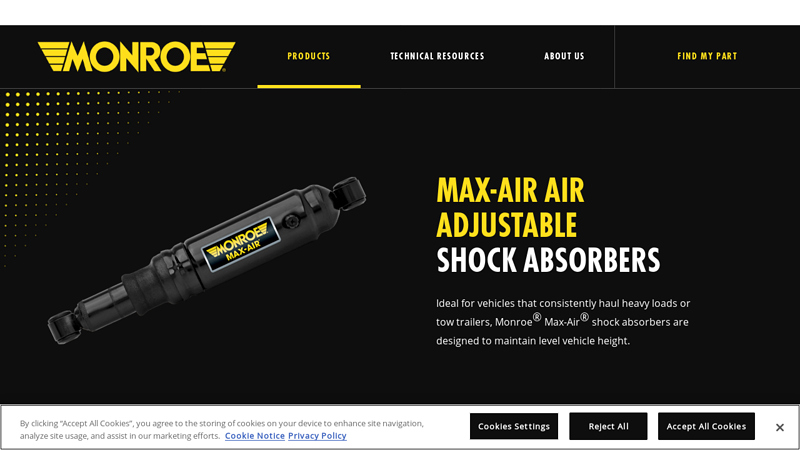

#1 Max-Air Adjustable Air Shocks for Towing

Domain Est. 1995

Website: monroe.com

Key Highlights: Designed to maintain level vehicle height, Monroe Max-Air Air Adjustable Shocks can be inflated or deflated as needed….

#2 Air Lift® Air Springs

Domain Est. 1996

Website: airliftcompany.com

Key Highlights: Air suspension kits and air ride suspension kits (also called air bags or air springs) from Air Lift help with towing and hauling with safety and comfort….

#3 HiJackers Air Shocks

Domain Est. 1996

Website: gabriel.com

Key Highlights: Air pressure of 25 min – 200 max psi; Sold in pairs and includes Gabriel Air Hose Kit when applicable – Air Hose Kit can also be purchased separately; Chrome ……

#4 Firestone Airide

Domain Est. 2006

Website: firestoneairide.com

Key Highlights: Firestone Airide is the world’s leading supplier of air suspension and air springs with over 80 years of experience designing and manufacturing to eliminate ……

#5 AVS

Domain Est. 2006

Website: avsontheweb.com

Key Highlights: AVS – airbagparts.com offers Air Suspension Alarm Sheet Metal Lowering Kits Shaved Door and Suicide Door Kits. Quality parts at value prices….

#6 Arnott Aftermarket Air Suspension Products

Domain Est. 2008

Website: arnottsuspension.com

Key Highlights: Arnott offers air struts & shocks, air springs, air suspension compressors, coil spring conversion kits, dryers, solenoid valve blocks, and ride height sensors ……

#7 Bag Riders

Domain Est. 2009

Website: bagriders.com

Key Highlights: Build your own custom complete air ride kit with your choice of suspension, controller, air tank, and compressor. Shop Complete Kits · Shop Air Suspension ……

#8 Plumbing Kits & Accessories

Domain Est. 2011

#9 Air Management Systems for Air Ride Suspension

Domain Est. 2012

Expert Sourcing Insights for Air Hose Kit For Air Shocks

2026 Market Trends for Air Hose Kit for Air Shocks

The market for air hose kits for air shocks is poised for significant evolution by 2026, driven by advancements in vehicle technology, shifting consumer preferences, and broader industry trends in automotive and industrial sectors. These kits, essential for transferring compressed air to adjustable air springs in suspension systems, are seeing demand influenced by several key factors.

Growing Demand for Enhanced Ride Quality and Customization

Consumer demand for superior ride comfort, handling, and vehicle customization continues to accelerate. In the automotive aftermarket, particularly within the truck, SUV, and performance vehicle segments, air suspension systems offer unparalleled adjustability for ride height, load leveling, and comfort. This directly fuels the need for reliable and durable air hose kits. By 2026, expect increased adoption of air suspension not only in heavy-duty trucks and luxury vehicles but also in performance-oriented and enthusiast-driven light-duty trucks and SUVs, expanding the addressable market for air hose kits.

Expansion in Commercial and Industrial Applications

Beyond passenger vehicles, air hose kits are critical in commercial fleets, trailers, buses, and industrial machinery where air suspension improves load stability, reduces wear, and enhances safety. As fleet operators increasingly prioritize fuel efficiency, cargo protection, and driver comfort, the deployment of air suspension systems in logistics and transportation is expected to grow. This trend will boost demand for industrial-grade air hose kits designed for durability and resistance to harsh environments, contributing significantly to market volume.

Technological Advancements in Materials and Design

By 2026, innovation in hose materials—such as reinforced thermoplastic elastomers (TPE), advanced polyurethanes, and hybrid composites—will enhance flexibility, burst pressure ratings, and resistance to abrasion, UV, ozone, and temperature extremes. Additionally, developments in quick-connect fittings, leak-proof couplings, and modular hose routing systems will improve ease of installation and reliability. Smart air suspension systems with integrated sensors may also drive demand for kits compatible with digital diagnostics and automated inflation controls.

Emphasis on Aftermarket and DIY Installation

The rise of online retail and accessible technical information is empowering DIY enthusiasts to install and maintain air suspension systems. Air hose kits that are pre-cut, labeled, and include comprehensive installation guides or modular components will be highly sought after. Companies offering complete, vehicle-specific kits with optimized hose lengths and routing templates will gain competitive advantage, catering to both professional installers and knowledgeable consumers.

Sustainability and Regulatory Influences

Environmental regulations promoting fuel efficiency and reduced emissions may indirectly support air suspension adoption, especially in commercial transport where weight savings and aerodynamic improvements (via adjustable ride height) can lower fuel consumption. While not a direct driver, this regulatory landscape supports the broader adoption of air suspension technology, thereby increasing demand for associated components like air hose kits.

Market Consolidation and Brand Differentiation

The air hose kit market is likely to see consolidation, with leading brands investing in R&D, quality assurance, and customer support to differentiate themselves. By 2026, trust in brand reputation, product longevity, and warranty support will play a crucial role in purchasing decisions. Niche players may emerge focusing on specialty applications such as off-road, overlanding, or electric vehicle (EV) conversions, where unique packaging and durability requirements exist.

In summary, the 2026 outlook for air hose kits for air shocks is one of steady growth, innovation, and diversification. Success will depend on manufacturers’ ability to deliver high-performance, reliable, and user-friendly products aligned with evolving vehicle technologies and end-user expectations across automotive, commercial, and industrial segments.

Common Pitfalls When Sourcing an Air Hose Kit for Air Shocks

When sourcing an air hose kit for air shocks, especially for vehicles like trucks, SUVs, or heavy-duty applications, buyers often encounter challenges related to quality and intellectual property (IP). Being aware of these pitfalls can help ensure reliable performance, longevity, and legal compliance.

Poor Material Quality and Durability

One of the most frequent issues is receiving air hose kits made from substandard materials. Low-quality rubber or thermoplastic hoses may crack, leak, or degrade prematurely when exposed to heat, UV rays, or oil. Fittings made from cheap metals or plastic can strip or corrode, leading to air leaks and system failure. Always verify that the hose material is rated for high pressure and resistant to environmental stressors.

Inconsistent Pressure Ratings

Some suppliers advertise air hose kits with inflated pressure ratings that don’t match real-world performance. Using a hose not rated for the operating pressure of your air suspension system can lead to blowouts or inconsistent ride height. Ensure the kit meets or exceeds the PSI requirements of your air shocks—typically 150–200 PSI for most automotive applications.

Misrepresentation of Compatibility

Many air hose kits are marketed as “universal fit,” but in practice, they may not align with specific air shock models or compressor systems. Incorrect thread types (e.g., 1/8″ NPT vs. 1/4″ NPT), mismatched hose diameters, or incompatible quick-connect fittings can make installation difficult or impossible without adapters, increasing complexity and potential leak points.

Lack of Intellectual Property Compliance

Sourcing from manufacturers or suppliers that copy patented designs—such as proprietary connector systems or branded hose configurations—can expose buyers to IP risks. Rebranded or counterfeit kits that mimic well-known brands (e.g., Firestone, RideTech, or AccuAir) may infringe on design patents or trademarks. This not only raises legal concerns but often correlates with lower quality and lack of technical support.

Inadequate Documentation and Certification

Reputable air hose kits usually come with performance certifications (e.g., ISO standards) and detailed installation guides. Kits lacking documentation may not have undergone proper testing for safety or durability. Without traceability or compliance data, it’s harder to verify authenticity or qualify the product for commercial or fleet use.

Conclusion

To avoid these pitfalls, source air hose kits from reputable suppliers with verifiable quality control processes and clear IP compliance. Look for third-party testing certifications, detailed product specifications, and customer support. Investing in a high-quality, legally compliant kit reduces long-term maintenance costs and ensures optimal performance of your air suspension system.

Logistics & Compliance Guide for Air Hose Kit For Air Shocks

This guide outlines the essential logistics and compliance considerations for the import, export, distribution, and use of Air Hose Kits designed for air shocks. These kits are commonly used in automotive, truck, and industrial suspension systems to deliver compressed air to air springs. Ensuring regulatory compliance and efficient logistics management is critical for product safety, reliability, and market access.

1. Product Classification and Harmonized System (HS) Code

Proper product classification ensures accurate customs clearance and duty assessment.

- Recommended HS Code (Example: US): 8481.80.00 – “Other taps, cocks, valves and similar appliances for pipes, boiler shells, tanks, vats or the like, including pressure-reducing valves and thermostatically controlled valves.”

- Alternative (if part of a kit): 8708.29.50 – “Parts and accessories of motor vehicles, other: air suspension components.”

- Note: HS codes may vary by country. Confirm with local customs authorities. Example classifications:

- EU: 8481 80 90

- Canada: 8481.80.00

- Australia: 8481.80.90

2. Import and Export Regulations

- Export Controls: Air hose kits are generally not subject to export restrictions (e.g., ITAR, EAR). However, confirm with exporting country regulations if shipping to sanctioned regions.

- Import Requirements:

- Commercial invoice, packing list, and bill of lading/air waybill.

- Certificate of Origin (COO) may be required for preferential tariff treatment (e.g., USMCA, RCEP).

- Import permits typically not required unless bundled with regulated components (e.g., compressors).

- Duties and Taxes: Vary by destination. Use HS code to determine applicable rates. Some countries may apply VAT, GST, or customs processing fees.

3. Packaging, Labeling & Marking Requirements

- Packaging:

- Use durable, moisture-resistant packaging to protect hoses and fittings during transit.

- Individual kits should be sealed in poly bags or clamshells to prevent contamination.

- Use corrugated cardboard boxes with internal dividers to prevent movement.

- Labeling:

- Include product name, model number, batch/lot number, and manufacturer details.

- Comply with country-specific labeling laws (e.g., bilingual labels in Canada).

- Include country of origin marking (e.g., “Made in China”) per 19 U.S.C. §1304.

- Warnings & Instructions:

- Provide basic installation warnings (e.g., “Do not exceed maximum pressure”).

- Multilingual instructions recommended for global distribution.

4. Transportation & Handling

- Mode of Transport:

- Suitable for air, sea, and ground freight.

- Air freight recommended for time-sensitive deliveries due to low weight and volume.

- Temperature & Humidity:

- Store and transport away from extreme temperatures (>60°C or <–20°C) to avoid rubber degradation.

- Avoid prolonged exposure to UV light and ozone sources.

- Stacking & Weight Limits:

- Do not stack beyond manufacturer-recommended limits to avoid crushing lower boxes.

- Max load per pallet: typically 1,000–1,500 kg, depending on packaging strength.

5. Regulatory Compliance

- RoHS (EU): Ensure no restricted substances (e.g., lead, cadmium) in plastic or metal components.

- REACH (EU): Confirm no SVHCs (Substances of Very High Concern) above threshold levels.

- Proposition 65 (California, USA): If components contain listed chemicals (e.g., phthalates in PVC), provide warning labels.

- Pressure Equipment Directive (PED 2014/68/EU): Generally not applicable to air hose kits alone unless part of a pressurized system assembly. Evaluate if integrated into a regulated subsystem.

- DOT / FMVSS (USA): Air hose kits for motor vehicles are indirectly regulated; ensure compatibility with DOT-approved suspension systems.

6. Quality and Safety Standards

- ISO Standards:

- ISO 1307: Rubber and plastics hoses — Hose sizes, minimum and maximum inside diameters, and tolerances.

- ISO 1436: Rubber hoses and hose assemblies for air brake systems.

- SAE Standards:

- SAE J517: Hydraulic hose performance requirements (if applicable).

- SAE J1402: Air brake tubing and fittings.

- Testing Requirements:

- Pressure burst testing (typically 3–4x working pressure).

- Flex and abrasion resistance testing.

- Temperature cycling and aging tests.

7. Documentation and Traceability

- Maintain records for:

- Batch/lot tracking for recall readiness.

- Test reports (pressure, material compliance).

- Supplier certifications (ISO 9001, IATF 16949 if automotive).

- Provide Material Safety Data Sheet (MSDS/SDS) if requested, especially for rubber or plastic components.

8. Environmental & End-of-Life Considerations

- WEEE (EU): Not applicable unless sold as part of electronic equipment.

- Recycling: Rubber and metal components are recyclable. Provide disposal guidance in documentation.

- Sustainability: Use recyclable packaging and minimize plastic content where possible.

9. Market-Specific Requirements

- United States:

- No EPA certification required for air hose kits alone.

- FTC labeling rules apply to country of origin claims.

- European Union:

- CE marking not required unless part of a CE-regulated assembly.

- Compliance with RoHS and REACH mandatory.

- Australia/NZ:

- Comply with AS/NZS 2278 (air brake hoses) if used in commercial vehicles.

- China:

- May require CCC certification if sold as part of a vehicle system (check CMVDR 206).

10. Risk Mitigation & Best Practices

- Use certified suppliers with quality management systems.

- Conduct periodic audits of manufacturing and packaging facilities.

- Perform pre-shipment inspections for large orders.

- Insure shipments against loss or damage.

- Maintain product liability insurance, especially for automotive applications.

By adhering to this logistics and compliance guide, businesses can ensure smooth international trade operations, reduce customs delays, and meet regulatory requirements for Air Hose Kits for Air Shocks across global markets.

Conclusion: Sourcing an Air Hose Kit for Air Shocks

In conclusion, sourcing the appropriate air hose kit for air shocks requires careful consideration of compatibility, durability, length, and ease of use. It is essential to select a kit that matches the specifications of your air suspension system, including correct valve types (such as Schrader or Presta), pressure ratings, and hose material (preferably high-quality, abrasion-resistant rubber or reinforced vinyl). Additionally, kits that include useful accessories—such as pressure gauges, quick-connect fittings, and mounting hardware—can significantly improve convenience and long-term performance.

Sourcing from reputable suppliers or manufacturers ensures product reliability and warranty support. Whether purchasing from automotive specialty stores, online retailers, or OEM providers, verifying customer reviews and technical specifications will help avoid compatibility issues. Ultimately, investing in a well-designed air hose kit contributes to the efficient maintenance and optimal functionality of air shocks, enhancing ride quality, vehicle performance, and system longevity.