The global aircraft cable market is experiencing steady growth, driven by rising aircraft production, increasing demand for fuel-efficient and lightweight components, and the expansion of commercial and military aviation sectors. According to a report by Mordor Intelligence, the aircraft cables market was valued at USD 1.85 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of over 4.2% from 2024 to 2029. This growth trajectory is further supported by Grand View Research, which highlights sustained demand from OEMs and MRO (Maintenance, Repair, and Overhaul) operations, alongside advancements in material science enhancing cable durability and performance under extreme conditions. As aerospace manufacturers prioritize safety, reliability, and compliance with stringent regulatory standards, the role of high-performance aircraft cables has become increasingly critical. In this evolving landscape, a select group of manufacturers has emerged as leaders, combining innovation, precision engineering, and global supply chain capabilities to meet the rigorous demands of modern aviation. Below are the top 9 aircraft cable manufacturers shaping the future of the industry.

Top 9 Air Craft Cable Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 High-Temperature Cable & Wire Manufacturer

Domain Est. 1996

Website: harbourind.com

Key Highlights: Harbour is a high-temperature cable and wire manufacturer for aerospace, military, industrial and commercial markets. Contact us today for more information!…

#2 Fehr Bros.

Domain Est. 1996

Website: fehr.com

Key Highlights: Fehr Bros. is an Industry-Leading Supplier of Aircraft Cable, Wire Rope, Chain, Garage Door and Industrial Hardware to Thousands of Wholesale Customers….

#3 Aircraft Cable

Domain Est. 1997

Website: loosco.com

Key Highlights: We manufacture and stock aircraft cable to commercial and military specifications in stainless steel, galvanized carbon steel, and a variety of other alloys….

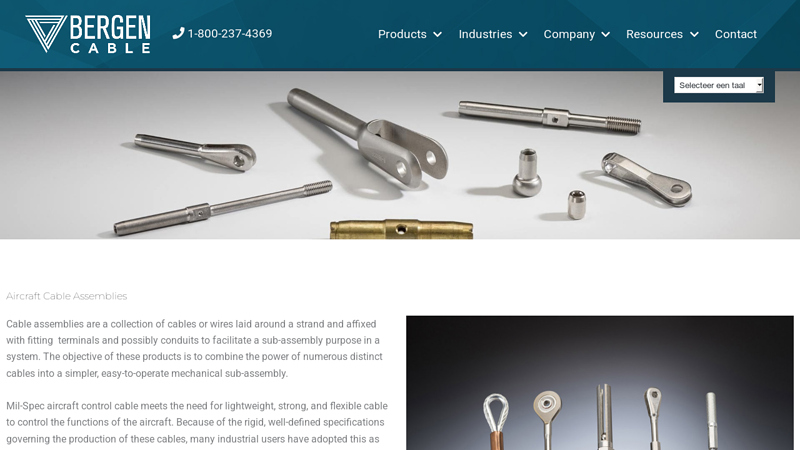

#4 Custom Aircraft Cable Assemblies

Domain Est. 1999

Website: bergencable.com

Key Highlights: Bergen Cable Technology offers a diverse portfolio of cable assemblies; and has over 80 years of experience manufacturing aircraft cable assemblies….

#5 Lexco Cable

Domain Est. 2002

Website: lexcocable.com

Key Highlights: Lexco Cable is a wire rope and cable manufacturer that provides custom solutions for a variety of industries including aircraft and architecture…

#6 Tailor

Domain Est. 1996

Website: habia.com

Key Highlights: Military-grade solutions designed for some of the world’s toughest defence applications. These include wires, cables and cable harnesses for use in radars, ……

#7 – Aero Assemblies

Domain Est. 1999

Website: aeroassemblies.com

Key Highlights: Your source for custom wire rope assemblies, eyeleting installation services & specialty fasteners. Our sourcing ability for new and excisting parts allow us to ……

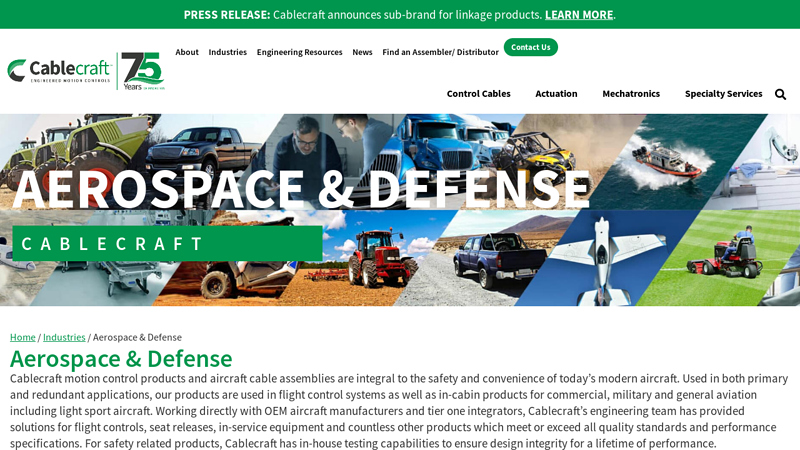

#8 Leading Aerospace Industry Supplier » Cablecraft

Domain Est. 2000

Website: cablecraft.com

Key Highlights: Actuation Products. Cablecraft offers the widest selection of aircraft cable assembly products available for a multitude of actuation requirements….

#9 Stainless Steel Aircraft Cables, Wires, Cords

Domain Est. 2021

Website: murphylift.com

Key Highlights: Free deliveryLooking for airplane cord and aircraft wires? Murphy offers stainless steel aircraft cables designed for safety and precision in various industries….

Expert Sourcing Insights for Air Craft Cable

H2: 2026 Market Trends for Aircraft Cable

The global aircraft cable market is poised for dynamic growth and transformation by 2026, driven by increasing aerospace production, technological advancements, and evolving safety standards. Aircraft cables—high-strength steel wire ropes used in critical control systems such as flight controls, landing gear, and engine operations—remain essential components in both commercial and military aviation. The following trends are expected to shape the market landscape in 2026:

-

Rising Demand from Commercial Aviation

With the projected recovery and expansion of global air travel post-pandemic, commercial aircraft manufacturers like Boeing and Airbus are ramping up production. This increased aircraft output directly fuels demand for high-performance aircraft cables. The growth of low-cost carriers and fleet modernization programs in emerging markets, especially in Asia-Pacific and the Middle East, will further boost market demand. -

Growth in Military and Defense Spending

Geopolitical tensions and modernization of defense fleets are prompting increased investments in military aviation. Unmanned aerial vehicles (UAVs), fighter jets, and transport aircraft require reliable cable systems for control actuation. Countries such as the U.S., China, and India are expected to drive defense-related procurement, supporting sustained demand for specialized aircraft cables. -

Adoption of Advanced Materials

While traditional stainless steel cables dominate the market, there is growing interest in lightweight, corrosion-resistant, and high-tensile alternatives. Innovations in coated cables, including polymer-jacketed or composite-reinforced designs, are gaining traction. These materials enhance durability and reduce maintenance costs—critical factors for next-generation aircraft. -

Emphasis on Safety and Regulatory Compliance

Aviation authorities such as the FAA and EASA continue to tighten safety regulations. By 2026, compliance with stringent testing, traceability, and quality assurance standards will be non-negotiable. This trend is encouraging manufacturers to invest in precision engineering, real-time monitoring, and digital documentation systems to meet certification requirements. -

Supply Chain Resilience and Localization

The disruptions caused by global events (e.g., pandemics, trade tensions) have prompted aerospace companies to reevaluate supply chain dependencies. There is a growing shift toward regional sourcing and nearshoring of critical components, including aircraft cables. North America and Europe are expected to strengthen domestic manufacturing capabilities, while Asia-Pacific countries like India and South Korea are emerging as secondary hubs. -

Integration with Smart Aircraft Systems

As aircraft become more connected and data-driven, there is increasing integration between mechanical systems and digital controls. While traditional cables remain vital, hybrid systems that combine cables with electronic sensors or fly-by-wire components are on the rise. This convergence may redefine the role of cables, focusing more on redundancy and fail-safe mechanisms. -

Sustainability and Lifecycle Management

Environmental regulations are pushing the aerospace industry toward sustainable practices. By 2026, manufacturers of aircraft cables are likely to face pressure to adopt eco-friendly production methods, improve recyclability, and reduce waste. Extended lifecycle management and predictive maintenance tools will gain importance to minimize downtime and environmental impact.

In conclusion, the 2026 aircraft cable market will be shaped by a confluence of production growth, technological innovation, and regulatory evolution. Companies that invest in R&D, ensure supply chain agility, and align with global aerospace trends will be best positioned to capitalize on emerging opportunities.

Common Pitfalls Sourcing Aircraft Cable (Quality, IP)

Sourcing aircraft cable—critical for safety and performance in aerospace, marine, rigging, and industrial applications—requires careful attention to quality and intellectual property (IP) considerations. Failing to address these can lead to safety hazards, compliance failures, and legal risks. Below are key pitfalls to avoid:

1. Prioritizing Cost Over Certified Quality

One of the most dangerous pitfalls is selecting aircraft cable based solely on price. Substandard cables may use inferior alloys, inconsistent strand construction, or poor surface finishes, compromising tensile strength and fatigue resistance. Always verify compliance with recognized aerospace standards such as:

- MIL-DTL-83420 (U.S. Military specification for stainless steel aircraft cable)

- AMS (Aerospace Material Specifications) like AMS 2269 (stainless steel quality)

- ASTM A364 or A416 (for structural applications)

Ensure suppliers provide mill test reports (MTRs) and Certificates of Conformance (CoC) traceable to the material batch.

2. Ignoring Material and Construction Specifications

Aircraft cables are not generic; they are engineered for specific loads, environments, and flex cycles. Common mistakes include:

- Selecting incorrect material grade (e.g., 304 vs. 316 stainless steel, where 316 offers better corrosion resistance)

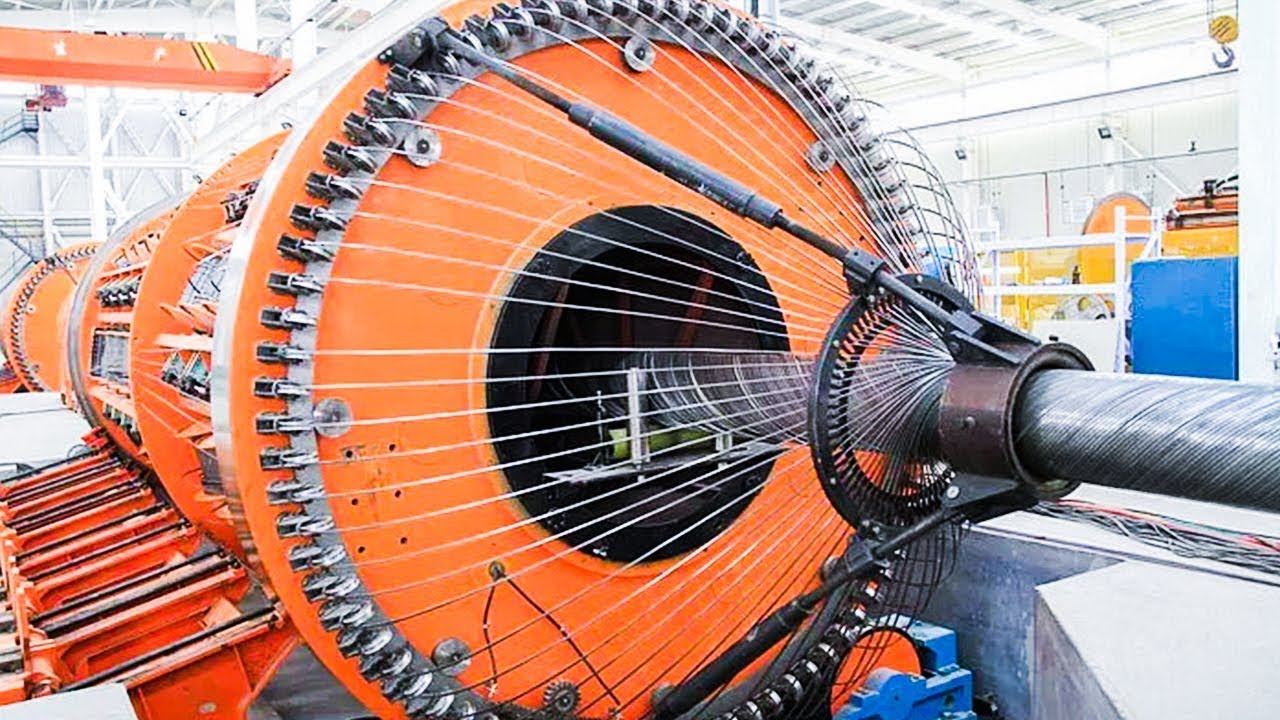

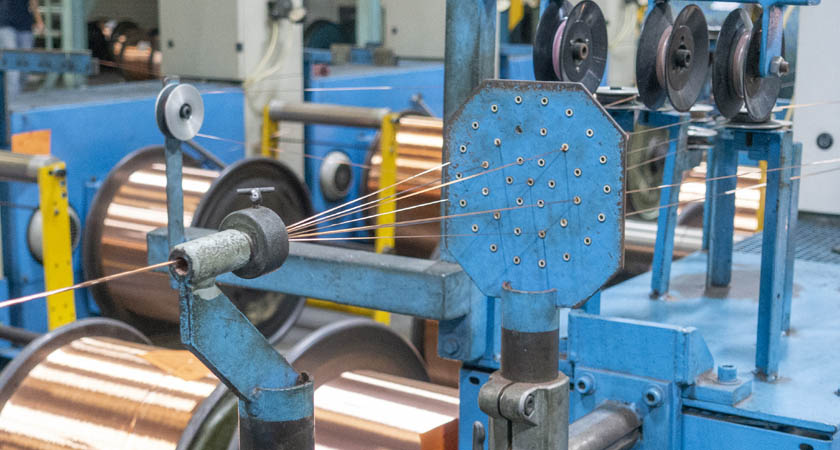

- Using improper construction (e.g., 7×7 vs. 7×19 strand configurations—7×19 offers greater flexibility but may be less abrasion-resistant)

- Overlooking core type (fiber core vs. independent wire rope core)

Misalignment with application requirements can lead to premature failure.

3. Sourcing from Non-Certified or Unverified Suppliers

Purchasing from uncertified vendors—especially through online marketplaces or third-party platforms—increases the risk of counterfeit or misrepresented products. These suppliers may:

- Rebrand commercial-grade cable as “aircraft cable” without meeting aerospace specs

- Lack proper quality control or traceability

- Provide falsified documentation

Always vet suppliers for AS9100 certification, industry reputation, and direct relationships with reputable manufacturers.

4. Overlooking Intellectual Property (IP) and Trademark Infringement

Some aircraft cable brands or proprietary designs are protected by trademarks or patents. Pitfalls include:

- Sourcing cables labeled with protected brand names (e.g., “Carl Stahl,” “Dyneema”) without authorization

- Using cables that infringe on patented construction methods or coatings

- Purchasing counterfeit goods that mimic branded packaging

Using such products can expose buyers and integrators to legal liability, recalls, or warranty voids.

5. Lack of Traceability and Documentation

In regulated industries, full material traceability is essential. Pitfalls arise when:

- Cables lack heat numbers or batch IDs for traceability

- Documentation is incomplete or missing (e.g., no CoC, MTR, or test data)

- Suppliers cannot provide audit trails for raw materials or manufacturing processes

Without documentation, compliance audits and failure investigations become impossible.

6. Assuming “Aircraft Cable” Means Aerospace-Grade

The term “aircraft cable” is often used generically, but not all cables labeled as such meet aerospace standards. Commercial or industrial cables may be marketed misleadingly. Always confirm:

- The exact specification met (e.g., MIL-DTL-83420 Type 3, Class A)

- Whether the cable is intended for aerospace certification or general use

- If it has been tested under relevant environmental conditions (salt spray, temperature extremes)

7. Failure to Validate Corrosion and Environmental Resistance

Cables used in marine or high-humidity environments must resist corrosion. Pitfalls include:

- Assuming all stainless steel cables are equally corrosion-resistant (e.g., 304 SS vs. 316 SS)

- Overlooking protective coatings (e.g., polymer jackets, dry film lubricants)

- Not testing for chloride stress corrosion cracking (SCC) in coastal applications

Conclusion

To avoid these pitfalls, rigorously vet suppliers, demand full certification and traceability, validate material specs for your use case, and ensure compliance with both quality standards and IP laws. When in doubt, consult with engineering or compliance experts before finalizing procurement.

Logistics & Compliance Guide for Aircraft Cable

Overview of Aircraft Cable

Aircraft cable, commonly referred to as stainless steel wire rope or control cable, is a high-strength cable designed for critical applications in aerospace, marine, automotive, and industrial settings. Typically constructed from 7×7 or 7×19 configurations of stainless steel (304 or 316), it is valued for its flexibility, corrosion resistance, and tensile strength. Proper logistics and compliance handling are essential due to its role in safety-critical systems.

Material Classification & Regulatory Framework

Aircraft cable is generally classified under the following international and regional frameworks:

- HS Code (Harmonized System): 7312.10 – Steel ropes, cables, and slings, whether or not fitted with fittings, of stainless steel.

- ITAR (International Traffic in Arms Regulations): May apply if the cable is specifically designed or modified for military or defense aircraft components. Check U.S. Department of State’s USML (United States Munitions List) Category VIII (Aircraft and Associated Equipment).

- EAR (Export Administration Regulations): Most commercial aircraft cables fall under EAR99 or ECCN 9A991 (civil aircraft parts), depending on performance characteristics and end use.

Always verify classification with current country-specific customs databases and consult with a customs broker when in doubt.

Packaging & Handling Requirements

Proper packaging ensures product integrity and compliance with shipping regulations:

- Coiling: Cables must be wound on non-kinking spools or reels to prevent deformation.

- Protection: Use moisture-resistant wrapping (e.g., VCI paper) and sealed plastic bags to prevent corrosion during transit.

- Labeling: Each package must include:

- Product specification (e.g., 3/16″ 7×19 316 SS)

- Lot/heat number for traceability

- Manufacturer name and part number

- Net weight and length

- Handling symbols (e.g., “Do Not Drop,” “Protect from Moisture”)

Transportation Logistics

Air Freight

- IATA Compliance: Aircraft cables are generally non-hazardous and permitted on passenger and cargo aircraft.

- Packaging: Must meet IATA packaging instructions for general cargo. Use sturdy crates or reels secured in containers to prevent movement.

- Documentation: Include air waybill, commercial invoice, packing list, and any export control documentation (e.g., ECCN statement).

Ocean & Ground Transport

- Containerization: Use dry, ventilated containers; avoid condensation with desiccants.

- Stacking: Limit stack height to prevent crushing lower reels.

- Temperature Control: Avoid prolonged exposure to extreme heat or freezing conditions.

Customs & Import Compliance

Ensure the following documentation is available for customs clearance:

- Commercial Invoice: Must include detailed product description, HS code, country of origin, value, and Incoterms® (e.g., FOB, DDP).

- Certificate of Origin: Required by many countries for tariff determination.

- Material Test Report (MTR): Often required for aerospace-grade cables to verify chemical and mechanical properties.

- Export Licenses: Required if the shipment is ITAR-controlled or subject to sanctions (e.g., destinations on BIS Entity List).

Industry-Specific Compliance

Aerospace (AS/EN 9100)

- Full traceability (batch/heat numbers) required.

- Supplier must be approved under AS9100 or equivalent.

- Documentation must support FAA, EASA, or other aviation authority standards.

ISO Standards

- ISO 2408:2017 – Steel wire ropes — Requirements

- ISO 4347:2018 – Aircraft — Steel wire ropes and cables — General requirements

Use only certified suppliers adhering to these standards.

Storage & Shelf Life

- Environment: Store in dry, climate-controlled areas (40–60% RH) away from corrosive chemicals.

- Shelf Life: Stainless steel aircraft cable has an indefinite shelf life if protected from moisture and physical damage.

- Inspection: Periodic visual checks for rust, kinks, or deformation are recommended.

End-of-Life & Disposal

- Recycling: Stainless steel cables are fully recyclable. Dispose through certified metal recyclers.

- Hazardous Waste: Not classified as hazardous unless contaminated with oils or chemicals.

Best Practices Summary

- Verify export classification before shipping.

- Use traceable, corrosion-protected packaging.

- Maintain full documentation for audits and customs.

- Partner with certified suppliers and freight forwarders experienced in aerospace materials.

- Train logistics staff on handling and compliance requirements.

Adherence to this guide ensures regulatory compliance, product integrity, and on-time delivery of aircraft cable across global supply chains.

Conclusion for Sourcing Aircraft Cable:

Sourcing aircraft cable requires a meticulous approach due to the critical role these cables play in the safety, performance, and reliability of aerospace systems. It is essential to procure cables that meet stringent industry standards such as MIL-DTL-87164, AS9100, and NASM compliance, ensuring they are manufactured from high-quality materials like stainless steel (typically 304 or 316) or galvanized steel with consistent tensile strength and corrosion resistance.

Key considerations in the sourcing process include verifying supplier资质 (certifications such as FAA AC 20-43, NADCAP, or ISO 9001), evaluating traceability and batch documentation, ensuring proper testing (e.g., tensile, fatigue, and corrosion resistance), and confirming the availability of different configurations (e.g., 7×7 or 7×19 strand constructions). Additionally, lead times, cost efficiency, and long-term supply chain reliability must be balanced without compromising on quality.

In conclusion, successful sourcing of aircraft cable hinges on partnering with reputable, certified suppliers who adhere to aerospace-grade specifications and regulatory requirements. Prioritizing quality, compliance, and traceability not only ensures airworthiness but also minimizes operational risks and maintenance costs over the lifespan of the aircraft.