The global demand for versatile and portable power solutions has propelled significant growth in the air compressor and generator combination market. According to a report by Mordor Intelligence, the global air compressor market was valued at USD 33.6 billion in 2022 and is projected to grow at a CAGR of over 5.5% through 2028, driven by increasing industrialization, construction activities, and the need for energy-efficient equipment. Parallel to this, the generator market continues to expand, fueled by rising energy demands in remote and off-grid locations. This convergence of demand has led to the emergence of hybrid units that integrate compressed air and electrical power generation in a single, efficient system—ideal for applications in construction, mining, agriculture, and emergency backup. As the need for multifunctional, mobile power solutions grows, especially in developing economies, manufacturers are innovating to deliver reliable, fuel-efficient, and compact combination units. In this landscape, nine key players have distinguished themselves through technological advancements, broad product portfolios, and strong global distribution networks—setting the benchmark in the air compressor and generator combination industry.

Top 9 Air Compressor And Generator Combination Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Combination Units

Domain Est. 1990

Website: deere.com

Key Highlights: Powered by an industrial-duty Subaru engine, the Welderator combines a 170A arc (stick) welder, a two-stage air compressor, and a 5,000 max watt generator all ……

#2 Power Technique

Domain Est. 1995

Website: atlascopco.com

Key Highlights: Our product offerings include electric and diesel mobile air compressors, submersible and surface pumps, portable and large generators, diesel and electric ……

#3 Air Compressor Generator Combo Units

Domain Est. 1996

Website: mitm.com

Key Highlights: The Mi-TM air compressor/generator combination unit is two pieces of equipment packaged in one convenient machine. Customers use the generator to power lights, ……

#4 Contractor

Domain Est. 1997

Website: vanair.com

Key Highlights: Vanair’s Contractor Reciprocating Air Compressor with Generator provides 20 CFM of air power at 150 PSI and a 5kW peak AC generator….

#5 Products

Domain Est. 1997

Website: campbellhausfeld.com

Key Highlights: Shop our wide range of Campbell Hausfeld air compressors and air tools to help you get the job done….

#6 Gas Air Compressor and Generator Combination Units

Domain Est. 2003

Website: imperialsupplies.com

Key Highlights: Free delivery over $400 365-day returns…

#7 Air Compressor / Generator / Welder Combination Combo Units

Domain Est. 2011

Website: mitmequipmentsales.com

Key Highlights: 30-day returnsShop for Combo Units | Air Compressor / Generator / Welder Combination near you. Located in Peosta, we provide the surrounding communities Combo Units | Air ……

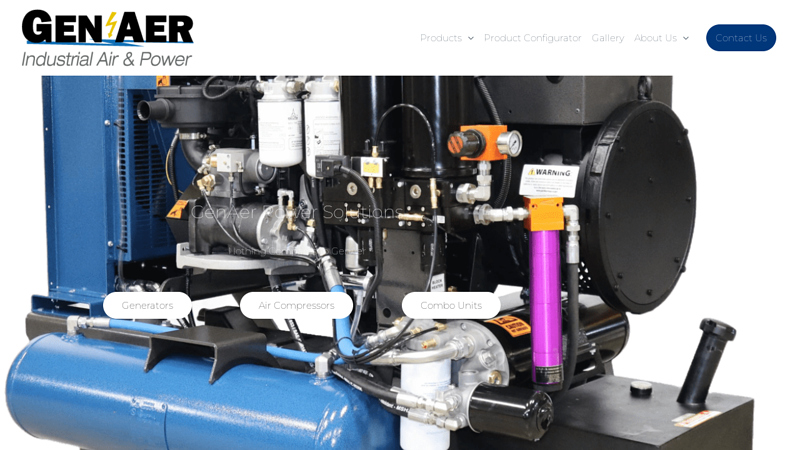

#8 GenAer

Domain Est. 2012

Website: genaer.com

Key Highlights: GenAer Manufactures Air Compressors, Generators & Generator Air Compressor Combination Units. Find your portable power solution with Genaer today!…

#9 Welder Generator Air Compressor Combo Units

Domain Est. 2014

Website: compressorpros.com

Key Highlights: Free deliveryElevate your job site efficiency with our versatile combo units. Explore top-quality air compressor generator combinations for contractors and DIY ……

Expert Sourcing Insights for Air Compressor And Generator Combination

H2: Market Trends for Air Compressor and Generator Combination Units in 2026

As the global demand for versatile, mobile, and energy-efficient power solutions continues to grow, the market for air compressor and generator combination units is poised for significant transformation by 2026. These hybrid systems—integrating compressed air generation and electrical power output into a single, portable unit—are gaining traction across industries such as construction, mining, emergency services, and oil & gas. Key trends shaping the 2026 market landscape include technological innovation, sustainability demands, regional expansion, and evolving end-user requirements.

1. Technological Advancements Driving Integration and Efficiency

By 2026, manufacturers are expected to leverage digitalization and smart technologies to enhance the performance of combination units. Internet of Things (IoT)-enabled monitoring systems, remote diagnostics, and predictive maintenance features will become standard, improving operational uptime and reducing lifecycle costs. Additionally, advancements in engine design—such as variable-speed drives and hybrid electric-diesel systems—are increasing fuel efficiency and reducing emissions, making units more attractive in emission-sensitive environments.

2. Rising Demand for Portable and Off-Grid Power Solutions

The growing need for reliable off-grid power in remote locations and disaster recovery operations is accelerating demand for mobile combo units. These systems offer dual functionality—supporting pneumatic tools and electrical equipment—making them ideal for temporary job sites and emergency response. By 2026, lighter, more compact models with improved noise reduction and fuel economy are expected to dominate the portable segment, particularly in developing regions with expanding infrastructure projects.

3. Sustainability and Regulatory Pressures

Environmental regulations, particularly in North America and Europe, are pushing manufacturers to develop low-emission and alternative-fuel models. By 2026, an increasing number of combination units are expected to run on biodiesel, propane, or even hydrogen-compatible engines. Electrification trends may also lead to the emergence of battery-hybrid models, especially for indoor or urban applications where noise and air quality are major concerns.

4. Growth in Emerging Markets

Asia-Pacific, Latin America, and parts of Africa are projected to be high-growth regions for combination units by 2026, driven by rapid industrialization, urban development, and investment in energy infrastructure. Local manufacturing and partnerships with global brands are enabling cost-effective solutions tailored to regional needs, further expanding market reach.

5. Industry-Specific Customization

End-users in sectors like mining and oil & gas demand rugged, explosion-proof, and high-capacity units that can operate in extreme conditions. By 2026, OEMs are expected to offer modular, customizable combo units with scalable output, enhanced safety features, and compliance with international standards (e.g., ATEX, ISO).

6. Competitive Landscape and Market Consolidation

The market is witnessing increased consolidation, with major players such as Atlas Copco, Ingersoll Rand, and Generac expanding their hybrid product portfolios. Strategic acquisitions and R&D investments are expected to intensify competition, driving innovation and price optimization.

In summary, the 2026 market for air compressor and generator combination units will be defined by smarter, cleaner, and more adaptable systems. As industries demand greater operational flexibility and sustainability, these integrated solutions will play a critical role in powering the future of mobile and off-grid applications.

Common Pitfalls When Sourcing Air Compressor and Generator Combination Units

When sourcing integrated air compressor and generator combination units, buyers often encounter critical challenges that impact long-term performance, safety, and cost-efficiency. Being aware of these common pitfalls helps ensure a reliable and compliant purchase.

Quality-Related Pitfalls

Substandard Component Integration

Many low-cost combination units use mismatched or under-spec components. For example, pairing a powerful generator with an undersized compressor can lead to overheating and premature failure. Always verify that both the generator and compressor are rated for continuous, simultaneous operation under expected loads.

Poor Build Quality and Materials

Units built with thin-gauge steel, low-grade fasteners, or inadequate vibration dampening suffer from accelerated wear and structural fatigue. Look for robust frames, industrial-grade hoses, and weather-resistant enclosures, especially for outdoor applications.

Inadequate Cooling Systems

Combination units generate significant heat. Inadequate cooling due to poor design or undersized radiators leads to thermal shutdowns or component damage. Confirm that the unit includes sufficient airflow management and thermal protection features.

Lack of Independent Performance Certification

Some manufacturers exaggerate output ratings. Always request third-party test reports or certifications (e.g., ISO, CE) that validate the actual power output (kVA/kW) and airflow (CFM/PSI) under load conditions.

Intellectual Property (IP) and Compliance Pitfalls

Counterfeit or Cloned Designs

The market includes units that replicate patented designs without authorization. These clones often lack engineering integrity and support. Verify manufacturer legitimacy through patents, brand registration, and customer references to avoid IP infringement and reliability issues.

Missing or Fake Compliance Certifications

Some suppliers provide falsified CE, UL, or EPA certification documents. Non-compliant units may fail safety inspections, be banned from worksites, or void insurance. Always cross-check certification numbers with official databases or request original documentation.

Ambiguous Warranty and Support Terms

Poorly defined warranties—especially those voided if parts are not serviced by authorized agents—can leave buyers stranded. Ensure the warranty covers both the generator and compressor, and confirm local service network availability.

Lack of Technical Documentation and Manuals

IP violations often result in missing or generic user manuals, schematics, and spare parts lists. This complicates maintenance and repairs. Require complete, brand-specific documentation in your language before purchase.

Avoiding these pitfalls requires due diligence: vet suppliers thoroughly, request performance data, verify certifications, and prioritize long-term reliability over upfront cost savings.

Logistics & Compliance Guide for Air Compressor and Generator Combination Units

Product Classification and Harmonized System (HS) Code

Air compressor and generator combination units are dual-function machines that integrate a power generator (typically gasoline, diesel, or propane-powered) with a built-in air compressor. For customs and international trade purposes, correct classification is essential.

- Recommended HS Code: 8502.11 or 8502.13 (depending on power output and fuel type)

- 8502.11: Generating sets and converters—Internal combustion piston-type prime movers—Reciprocating or rotary—With spark ignition engine—Rated output not exceeding 75 kVA

- 8502.13: Diesel or semi-diesel engine-driven generating sets

- Secondary Consideration: If the air compressor function is deemed dominant, classification under Chapter 84 (Compressors) may apply—specifically 8414.80. However, due to integration and primary power generation use, Chapter 85 usually takes precedence.

- Note: Classification can vary by country; consult local customs authorities or a licensed customs broker for definitive rulings.

Import/Export Regulations

Compliance with national and international regulations is required when shipping air compressor and generator combination units.

- Export Controls:

- U.S. (EAR): Most units fall under ECCN 9A991 (civil end-use), generally eligible for license exceptions (e.g., LVS or GBS) unless destined for embargoed countries or military applications.

- EU Dual-Use Regulation: Verify if power output or technical specs trigger controls under Annex I; most consumer-grade units are exempt.

- Import Requirements:

- Duty Rates: Vary by destination (e.g., 2.5%–5% in EU, 0%–4% in Canada under USMCA).

- Documentation: Commercial invoice, packing list, bill of lading/air waybill, certificate of origin, and technical specifications.

- Restricted Destinations: Avoid shipments to sanctioned countries (e.g., Iran, North Korea, Syria) without proper licensing.

Transportation and Shipping Logistics

Shipping combination units requires attention to size, weight, fuel content, and safety protocols.

- Packaging:

- Units must be securely crated or palletized with protective corner boards and stretch wrapping.

- Use moisture barrier bags for corrosion protection in humid environments.

- Fuel Handling:

- Empty Fuel Tanks: Most carriers require tanks to be fully drained and purged before transport (especially air freight).

- Residual Fuel: If allowed, only minimal residual fuel (per IATA/IMDG) may remain, with proper declaration.

- Mode-Specific Guidelines:

- Air Freight (IATA): Classify as “Engine-powered equipment” (UN3530, “Internal combustion engines”). Declare under Class 9 Miscellaneous Hazardous Materials if fuel is present.

- Ocean Freight (IMDG Code): Follow Packing Group II guidelines for engines containing fuel. Use proper marine-grade packaging.

- Ground Transport (DOT/ADR): For domestic U.S. shipments, comply with 49 CFR; in Europe, follow ADR regulations for engines with fuel residue.

Safety and Environmental Compliance

Combination units must meet safety and emissions standards in the target market.

- Electrical Safety:

- North America: UL 2200 (Standard for Engine-Driven Generating Sets) and CSA C22.2 No. 107.1.

- Europe: CE marking under Low Voltage Directive (2014/35/EU) and EMC Directive (2014/30/EU).

- Emissions Standards:

- U.S. (EPA): Comply with Tier 4 Final standards for diesel engines (40 CFR Part 1039).

- EU (Stage V): EN 1069 and EU Regulation 2016/1628 for non-road mobile machinery (NRMM).

- Noise Regulations:

- Ensure sound pressure levels meet local limits (e.g., OSHA in U.S., Directive 2000/14/EC in EU).

Certification and Labeling Requirements

Proper labeling ensures regulatory acceptance and safe operation.

- Required Labels:

- Manufacturer name, model, serial number

- Voltage, phase, frequency (for generator)

- Air pressure and flow rate (CFM/PSI) for compressor

- Fuel type and tank capacity

- Compliance marks (e.g., UL, CE, EAC, KC)

- User Documentation:

- Include multilingual operation and safety manuals.

- Provide EPA or EU emissions compliance labels as applicable.

Customs Clearance Best Practices

Facilitate swift customs processing with accurate documentation and preparation.

- Pre-Shipment Checklist:

- Confirm HS code with customs broker.

- Verify import permits or licenses (if required).

- Ensure all compliance certificates are available (e.g., test reports, COC).

- Duties & Taxes:

- Calculate landed cost including VAT (e.g., 20% in UK), GST (5% in Canada), or import VAT (EU).

- Leverage free trade agreements (e.g., USMCA, RCEP) where applicable.

- Inspection Readiness:

- Units may be subject to physical inspection for compliance with safety and emissions rules.

- Maintain traceability via serial numbers and batch records.

Maintenance of Compliance

Post-import compliance is critical for market access and liability protection.

- Record Keeping: Retain shipping documents, compliance certificates, and test reports for minimum 5–7 years.

- Recall Preparedness: Establish a product traceability and recall process per local consumer safety laws.

- Updates: Monitor changes in regulations (e.g., new emission tiers, updated safety standards) and revise product design or documentation as needed.

By adhering to this guide, importers, exporters, and distributors can ensure smooth logistics operations and maintain full regulatory compliance for air compressor and generator combination units across global markets.

Conclusion:

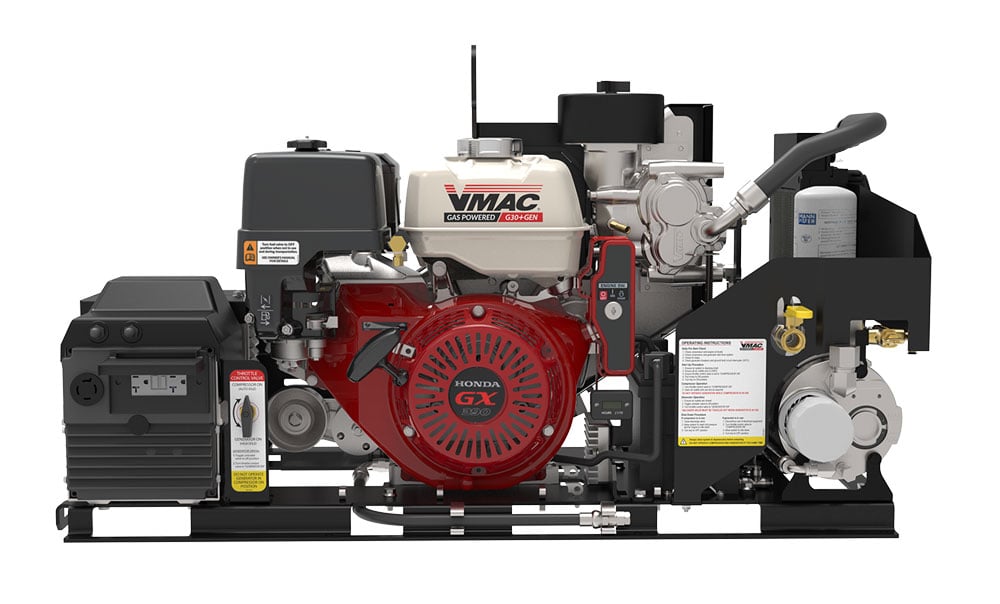

Sourcing an air compressor and generator combination is a strategic decision that offers enhanced operational efficiency, portability, and reliability—particularly in remote or off-grid applications such as construction sites, mining, agriculture, and emergency backup systems. The integration of both units into a single, often trailer-mounted system reduces equipment footprint, simplifies logistics, and ensures consistent power and compressed air supply where traditional infrastructure is unavailable.

When selecting the right combination unit, key factors such as power output, air delivery (CFM and PSI), fuel efficiency, noise levels, durability, and maintenance requirements must be carefully evaluated based on specific operational needs. Additionally, choosing reputable suppliers and considering after-sales support, warranty, and service networks is critical to ensuring long-term reliability.

Investing in a high-quality air compressor and generator combo not only improves productivity but also reduces downtime and total cost of ownership. With technological advancements in fuel efficiency and emissions control, modern units also align with environmental and regulatory standards, making them a sustainable and future-ready choice.

In conclusion, sourcing the right air compressor and generator combination requires a balanced assessment of technical specifications, application demands, and total lifecycle costs. With proper selection and maintenance, this integrated power solution delivers a robust, versatile, and cost-effective energy source across diverse industries.