The global aging machine market is experiencing robust growth, driven by increasing demand for reliable material testing across industries such as automotive, aerospace, and construction. According to Grand View Research, the global materials testing equipment market, which includes aging machines, was valued at USD 5.3 billion in 2023 and is projected to expand at a compound annual growth rate (CAGR) of 6.4% from 2024 to 2030. This growth is fueled by stringent regulatory standards requiring quality assurance and lifecycle performance validation of materials under thermal, UV, and environmental stress. As industries prioritize product durability and compliance, the need for advanced aging solutions has intensified. In this evolving landscape, manufacturers offering precision-engineered, data-accurate aging chambers are gaining strategic importance. Based on market presence, technological innovation, and global reach, the following nine companies stand out as leaders in the aging machine manufacturing sector.

Top 9 Aging Machine Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Aging

Domain Est. 1998

Website: ofite.com

Key Highlights: The OFITE Aging Cell is a patented (U.S. Patent No. 4,805,443) pressure vessel that enables samples to be subjected to temperatures higher than the boiling ……

#2 Aging Test Chamber

Domain Est. 2019

Website: mikrosize.com

Key Highlights: Aging test machine offered by China manufacturer Mikrosize. Buy high quality Aging test machine right now!…

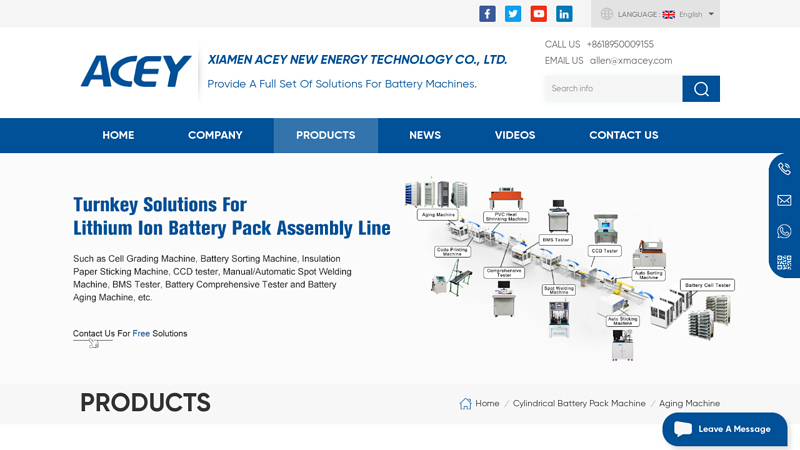

#3 Aging machine

Domain Est. 2020

Website: xmacey.com

Key Highlights: Aging machine is mainly used for lithium battery charging and discharging cycle test. The test items include battery charging protection voltage, discharging ……

#4 High-Performance Battery Aging Machines

Domain Est. 2024

Website: tertron.com

Key Highlights: Tertron is an excellent and renowned Battery Pack Aging Machine manufacturer based in China. We possess state-of-the-art equipment and utilize premium ……

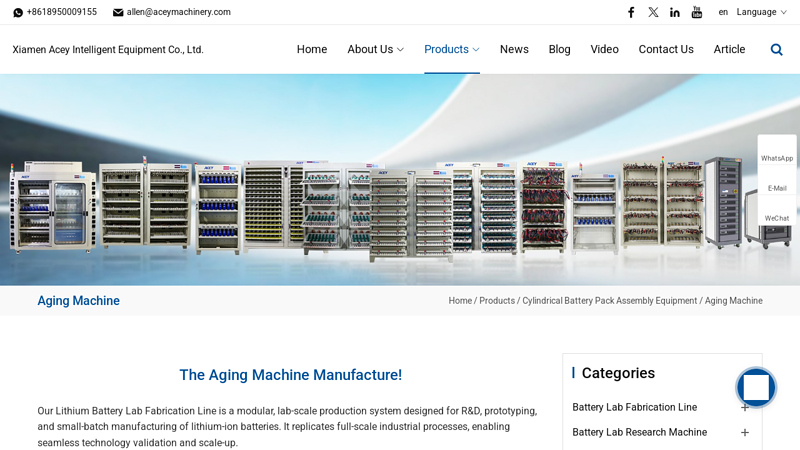

#5 China Aging Machine Manufacturers and Suppliers

Domain Est. 2024

Website: aceyintelligent.com

Key Highlights: ACEY is one of the most professional aging machine manufacturers and suppliers in China. If you’re going to buy customized aging machine, welcome to get ……

#6 Thermage

Domain Est. 1997

Website: thermage.com

Key Highlights: The Thermage® system is a non-invasive radiofrequency (RF) treatment that can smooth, tighten and contour skin for an overall younger-looking appearance….

#7 Aging Test Chambers

Domain Est. 2013

Website: haidatestequipment.com

Key Highlights: Aging Test chambers from Haida offer UV aging chamber,xenon aging chamber,ozone aging chamber,anti-yellowing chamber,etc….

#8 Accelerated Aging Test Chamber

Domain Est. 2015

Website: yuanyao-tech.com

Key Highlights: The accelerated aging test chamber is a testing equipment used to simulate and evaluate the aging process of a product under controlled conditions….

#9 aging

Domain Est. 2016

Website: tmaxcn.com

Key Highlights: Tmax Battery Equipments Limited. offers an extensive range of high quality Aging Machine and much more. Please visit: www.tmaxcn.com….

Expert Sourcing Insights for Aging Machine

H2: Projected 2026 Market Trends for Aging Machines

The global market for aging machines—equipment used to simulate long-term environmental exposure (such as heat, humidity, UV radiation, and thermal cycling) to evaluate the durability and lifespan of materials and products—is poised for significant evolution by 2026. Driven by rising quality standards, accelerated product development cycles, and increasing regulatory demands across industries, the aging machine market is expected to expand both in size and technological sophistication.

1. Rising Demand Across Key Industries

By 2026, industries such as automotive, aerospace, construction, electronics, and renewable energy are projected to be primary drivers of aging machine adoption. The automotive sector, in particular, will continue to demand rigorous testing of components under extreme conditions due to the growth of electric vehicles (EVs) and autonomous systems, which require enhanced material resilience. Similarly, the aerospace and defense sectors will invest in advanced aging chambers to test composites and lightweight alloys exposed to fluctuating altitudes and temperatures.

2. Technological Advancements and Automation

A key trend shaping the 2026 landscape is the integration of smart technologies in aging machines. Internet of Things (IoT)-enabled systems will allow real-time monitoring, remote control, and predictive maintenance. Artificial intelligence (AI) and machine learning algorithms will be increasingly used to analyze test data, predict material degradation patterns, and optimize testing protocols. Automation will reduce human error and enable unattended, high-throughput testing—critical for R&D and quality assurance departments seeking efficiency.

3. Growth in Sustainability and Regulatory Compliance

Environmental regulations, such as REACH, RoHS, and ISO standards, are pushing manufacturers to validate the longevity and environmental safety of their products. Aging machines will play a central role in demonstrating compliance, particularly in evaluating the performance of eco-friendly materials and recyclable components. Additionally, as sustainability becomes a competitive differentiator, companies will use aging tests to market the durability and lifecycle benefits of their products.

4. Expansion in Emerging Markets

Asia-Pacific, especially China, India, and Southeast Asia, is expected to witness the fastest growth in aging machine adoption by 2026. This surge will be fueled by expanding manufacturing bases, rising investments in infrastructure, and the establishment of local R&D centers. Government initiatives promoting self-reliance in high-tech industries will further boost demand for advanced testing equipment.

5. Customization and Modular Designs

Manufacturers of aging machines are increasingly offering modular and customizable solutions to meet specific industry needs. By 2026, we anticipate a shift toward multipurpose chambers capable of simulating combined stress factors (e.g., UV + humidity + thermal shock), enabling more realistic and accelerated aging profiles. Customization will be especially valuable for niche applications in medical devices, photovoltaics, and smart materials.

6. Market Consolidation and Competitive Landscape

The aging machine market is expected to see increased consolidation, with larger players acquiring specialized firms to broaden their testing portfolios. At the same time, new entrants focusing on cost-effective, compact, and energy-efficient models will challenge incumbents, particularly in price-sensitive markets. Competition will drive innovation, leading to more user-friendly interfaces, reduced energy consumption, and shorter test cycle times.

Conclusion

By 2026, the aging machine market will be characterized by intelligent, connected, and highly specialized testing systems serving a broad range of industries under increasing regulatory and performance demands. Companies that invest in digital integration, sustainability-focused testing solutions, and regional market expansion will be best positioned to capitalize on these emerging trends.

Common Pitfalls When Sourcing an Aging Machine: Quality and Intellectual Property Concerns

Sourcing an aging machine—used for testing the long-term reliability and durability of materials, components, or electronics—can present significant challenges, particularly regarding quality assurance and intellectual property (IP) protection. Overlooking these aspects may result in equipment failure, compromised test results, legal disputes, or loss of competitive advantage. Below are key pitfalls to avoid in both quality and IP domains.

Quality-Related Pitfalls

1. Inadequate Performance Validation

A common mistake is assuming that specifications provided by the supplier reflect real-world performance. Some aging machines may not consistently maintain required environmental conditions (e.g., temperature, humidity, vibration), leading to unreliable test data. Always request third-party validation reports or conduct on-site performance testing before purchase.

2. Poor Build Quality and Materials

Low-cost machines may use substandard components that degrade quickly—such as inferior heating elements, seals, or sensors—resulting in frequent downtime and maintenance. Verify material certifications and request references from existing users to assess long-term durability.

3. Lack of Calibration and Traceability

Without proper calibration documentation traceable to international standards (e.g., ISO/IEC 17025), test results may not be accepted for compliance or certification purposes. Ensure the machine comes with a calibration certificate and supports regular recalibration services.

4. Insufficient Safety and Compliance Features

Some suppliers may overlook critical safety mechanisms (e.g., over-temperature protection, emergency shutoffs) or fail to meet regional safety standards (e.g., CE, UL). Non-compliant machines pose safety risks and may be rejected by regulatory bodies.

5. Incomplete Documentation and Support

Missing or poorly translated user manuals, schematics, or maintenance guides hinder operation and troubleshooting. Confirm that technical documentation is comprehensive and available in your required language, along with accessible after-sales support.

Intellectual Property-Related Pitfalls

1. Risk of IP Infringement

Using or purchasing a machine that incorporates patented technologies without proper licensing can expose your organization to infringement claims. Conduct due diligence on the machine’s design and components to ensure they do not violate third-party IP rights.

2. Ambiguous Ownership of Customizations

If you request custom features or software modifications, unclear contracts may result in disputes over IP ownership. Ensure agreements explicitly state that any custom-developed elements are owned by your organization or appropriately licensed.

3. Exposure of Proprietary Test Methods

Some aging machines use embedded software or algorithms that may collect or transmit operational data. If not properly secured, this could expose your proprietary test protocols or product data to the supplier or third parties. Demand transparency on data handling and request offline operation options.

4. Reverse Engineering and Clone Risks

Sourcing from regions with weak IP enforcement increases the risk that your machine design (especially custom units) could be copied and resold. Work with reputable suppliers, include IP protection clauses in contracts, and consider filing provisional patents for novel machine features.

5. Software Licensing and Restrictions

Proprietary control software may come with restrictive licenses that limit usage, upgrades, or integration with other systems. Verify software terms in advance and, where possible, negotiate for open APIs or source code escrow to avoid vendor lock-in.

Mitigating these pitfalls requires thorough supplier evaluation, legal review of contracts, and proactive risk management. Engaging technical experts and IP counsel during the sourcing process is essential to ensure both equipment reliability and protection of your intellectual assets.

Logistics & Compliance Guide for Aging Machine

This guide outlines the essential logistics and compliance considerations for the safe, efficient, and legal operation, transport, and maintenance of an aging machine—equipment typically used in industrial, testing, or manufacturing environments to simulate long-term wear and stress on materials or components.

Regulatory Compliance

Ensure all operations involving the aging machine adhere to relevant local, national, and international regulations. This includes electrical safety standards (e.g., IEC, UL, CE), environmental regulations (e.g., emissions, noise levels), and workplace safety laws (e.g., OSHA, EU-OSHA). Maintain documentation of certifications, conformity declarations, and periodic inspection records. Assign responsibility for compliance monitoring to a designated safety or compliance officer.

Transportation & Handling

Plan transport logistics based on the machine’s weight, dimensions, and sensitivity. Use certified lifting equipment and trained personnel for loading/unloading. Secure the machine with appropriate restraints during transit to prevent shifting or damage. Protect sensitive components with padding or covers. Verify that transport vehicles meet weight and clearance requirements. Obtain required permits for oversized loads if applicable.

Installation & Site Requirements

Install the aging machine on a stable, level surface with adequate load-bearing capacity. Ensure proper clearance around the unit for ventilation, maintenance access, and safety. Confirm availability of required utilities—power supply (voltage, phase, frequency), cooling systems, exhaust ducts, or compressed air—as specified by the manufacturer. Conduct a site safety assessment prior to installation.

Operational Safety Protocols

Implement standard operating procedures (SOPs) for machine use, including startup, monitoring, and shutdown processes. Provide comprehensive training for all operators and maintenance staff. Install emergency stop mechanisms within easy reach and ensure they are regularly tested. Use warning labels and barriers to restrict unauthorized access. Conduct routine safety audits and maintain an incident reporting system.

Maintenance & Calibration

Adhere to the manufacturer’s recommended maintenance schedule. Keep a detailed log of all servicing, repairs, and part replacements. Regularly calibrate sensors, timers, and environmental controls to ensure accurate and repeatable aging tests. Use only approved spare parts and consumables. Schedule downtime for maintenance to minimize disruption to production or testing workflows.

Environmental & Waste Management

Assess potential environmental impacts such as heat output, noise, or emissions (e.g., outgassing from materials under test). Install mitigation systems like acoustic enclosures or exhaust scrubbers if necessary. Dispose of waste materials (e.g., worn test samples, filters, lubricants) in accordance with hazardous waste regulations. Monitor and document environmental parameters during operation.

Documentation & Recordkeeping

Maintain a centralized compliance and operations file including equipment manuals, maintenance logs, calibration certificates, operator training records, incident reports, and regulatory correspondence. Ensure records are up to date and accessible for audits or inspections. Digitize records where possible for improved traceability and backup.

International Shipping Considerations

For cross-border transport, verify customs requirements, import/export licenses, and conformity with destination country standards (e.g., CE marking for Europe, KC for South Korea). Prepare accurate commercial invoices, packing lists, and certificates of origin. Use freight forwarders experienced in handling industrial equipment. Insure the shipment against damage or loss.

Conclusion for Sourcing an Aging Machine:

After thorough evaluation of technical specifications, supplier reliability, cost-effectiveness, and long-term maintenance support, sourcing an aging machine is a strategic investment that will significantly enhance product quality, performance testing accuracy, and production efficiency. The selected aging machine meets industry standards, aligns with our operational requirements, and supports compliance with relevant testing protocols. By partnering with a reputable supplier offering strong after-sales service and technical support, we ensure minimal downtime and sustained equipment reliability. This acquisition not only strengthens our quality assurance processes but also positions us to meet current and future demands with greater confidence and consistency.