The global aerogel market is experiencing robust growth, driven by rising demand for high-performance insulation materials across residential, industrial, and energy sectors. According to Grand View Research, the global aerogel market size was valued at USD 390.4 million in 2023 and is expected to expand at a compound annual growth rate (CAGR) of 13.2% from 2024 to 2030. This surge is fueled by increasing energy efficiency regulations, growing construction activities, and the recognition of aerogels’ superior thermal performance—offering up to five times the insulating power per inch compared to traditional materials. As sustainability and net-zero building standards take center stage, homeowners and builders are increasingly turning to aerogel insulation for its lightweight, hydrophobic, and durable properties. Against this backdrop, a select group of manufacturers is leading innovation and commercialization, transforming the future of home insulation.

Top 8 Aerogel As Home Insulation Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Nano Tech Co., Ltd._Aerogel_Aerogel Insulation Blanket

Domain Est. 2006

Website: en.nanuo.cn

Key Highlights: Nano Tech Co., Ltd. is a domestic research and development and manufacturing base of aerogel thermal insulation materials that is engaged in an earlier, larger ……

#2 Jios Aerogel

Domain Est. 2013

Website: jiosaerogel.com

Key Highlights: At JIOS, we solve industry problems using advanced aerogels— delivering superior thermal protection, energy efficiency, and storage. We empower manufacturers, ……

#3 Aerogel as insulation Manufacturer & Supplier in China …

Domain Est. 2014

Website: china-aerogel.com

Key Highlights: Aerogel, a naturally powerful yet lightweight insulating material, is becoming increasingly popular for its ability to retain heat in the winter and keep it ……

#4 Aspen Aerogels

Domain Est. 1996

Website: aerogel.com

Key Highlights: For more than 20 years, we have applied our expertise in aerogel science to engineer, manufacture, and commercialize aerogel-based solutions….

#5 Aerogel Technologies, LLC

Domain Est. 2000

Website: aerogeltechnologies.com

Key Highlights: Aerogel Technologies provides custom aerogel solutions to meet the needs of the most demanding applications for industry, government, and academia….

#6 Strong and Flexible Aerogels

Domain Est. 2001

Website: aerogel.org

Key Highlights: Another product is aerogel blanket strips and aerogel wall wraps as home insulation that can help reduce heat loss through studs in the walls of a house….

#7 AeroShield

Domain Est. 2019

Website: aeroshield.tech

Key Highlights: AeroShield ultra-clear aerogel is the most insulating transparent material ever made, enabling better than triple pane performance inside a double pane window….

#8 Westwood Aerogel

Domain Est. 2023

Website: westwoodaerogel.com

Key Highlights: Aerogel is the lightest and most insulating material ever developed widely recognized for its exceptional thermal properties. Petri dish with aerogel powder ……

Expert Sourcing Insights for Aerogel As Home Insulation

H2: Market Trends for Aerogel as Home Insulation in 2026

By 2026, the use of aerogel as home insulation is poised to experience significant growth, driven by advancements in material science, rising energy efficiency standards, and increasing consumer demand for sustainable building solutions. Once confined to niche applications such as aerospace and industrial systems due to its high cost, aerogel technology has undergone substantial evolution, making it increasingly viable for residential construction.

One of the dominant trends shaping the aerogel insulation market in 2026 is the global push toward net-zero energy buildings. Governments and municipalities worldwide are enacting stricter building codes and energy performance regulations, such as the European Union’s Energy Performance of Buildings Directive (EPBD) and the U.S. Department of Energy’s Zero Energy Ready Home program. Aerogel’s ultra-low thermal conductivity—often as low as 0.013 W/m·K—makes it an ideal solution for achieving superior insulation with minimal thickness, especially in retrofitting older buildings where space is limited.

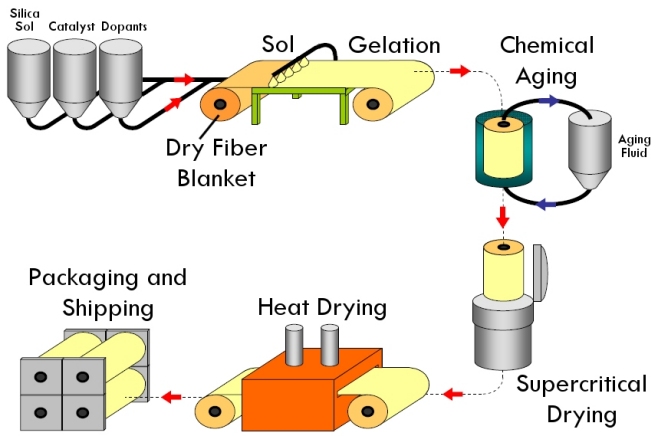

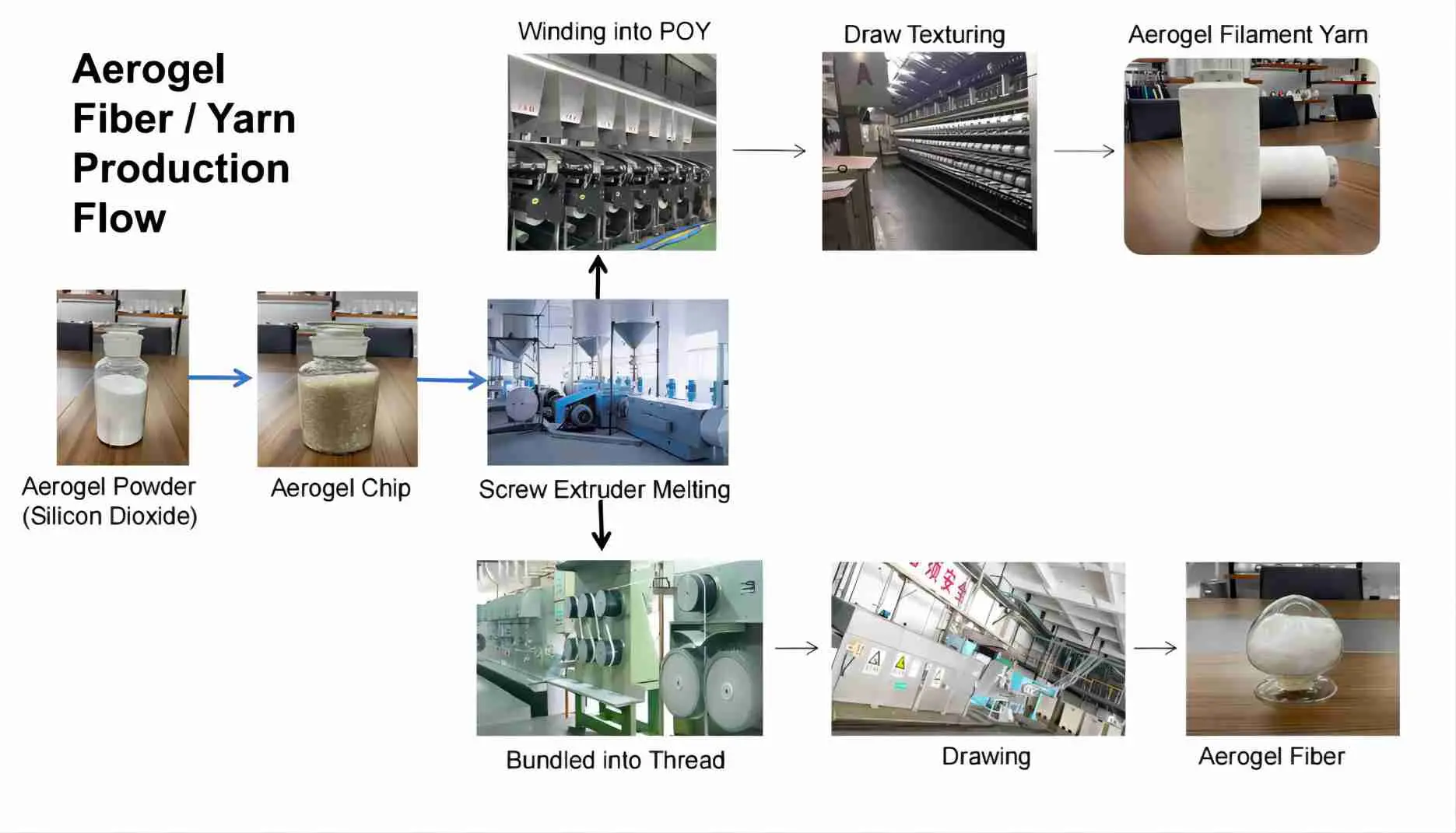

In parallel, manufacturing cost reductions and scalable production techniques are making aerogel more accessible. Innovations such as ambient pressure drying (APD) and the development of hybrid or composite aerogels (e.g., combining silica aerogel with flexible polymer matrices) have lowered production costs and improved handling, enabling easier integration into batts, blankets, and structural insulated panels (SIPs). These improvements are expected to drive down retail pricing, expanding aerogel’s appeal beyond luxury or demonstration homes into mainstream housing markets.

Another key trend is the rising emphasis on sustainability and life-cycle analysis in construction. Aerogel products, particularly those derived from recycled or bio-based materials, align well with green building certifications like LEED, BREEAM, and Passive House standards. By reducing heating and cooling loads, aerogel contributes to long-term energy savings and carbon emissions reductions, further enhancing its value proposition.

Additionally, partnerships between aerogel manufacturers and major construction material suppliers are accelerating market penetration. Companies like Aspen Aerogels, Cabot Corporation, and newer entrants in Asia and Europe are forming strategic alliances with insulation and facade system providers, facilitating product integration and distribution through established channels.

Consumer awareness is also growing, supported by increased media coverage and government incentives for high-performance insulation. In 2026, homeowners are more informed about long-term ROI from energy-efficient materials, and aerogel is increasingly recognized not just for its technical superiority but also for its durability, fire resistance, and moisture management properties.

In summary, the 2026 market for aerogel as home insulation is characterized by technological maturation, regulatory support, cost reduction, and sustainability alignment. While price remains a barrier compared to traditional insulation like fiberglass or foam, aerogel is transitioning from a premium novelty to a strategic component in high-performance and energy-efficient homes—positioning it for sustained growth in the residential construction sector.

Common Pitfalls Sourcing Aerogel as Home Insulation: Quality and Intellectual Property Concerns

Aerogel is a high-performance insulation material known for its exceptional thermal resistance and ultra-lightweight properties. While promising for home insulation, sourcing it comes with significant challenges related to quality consistency and intellectual property (IP) risks. Being aware of these pitfalls is crucial for contractors, builders, and homeowners considering aerogel.

Quality Inconsistency and Performance Gaps

One of the primary pitfalls when sourcing aerogel insulation is the wide variation in product quality and performance across suppliers. Not all aerogels are created equal, and inconsistencies can undermine the expected benefits.

-

Thermal Performance Variability: Aerogel products may claim extremely low thermal conductivity (e.g., 0.013–0.015 W/m·K), but actual field performance can differ due to manufacturing inconsistencies, aging, or improper handling. Some lower-tier suppliers may exaggerate performance data, leading to unmet energy efficiency expectations.

-

Mechanical Fragility and Handling Sensitivity: Aerogel blankets or panels are often fragile and prone to dusting or fracturing if not handled correctly. Poor-quality aerogels may degrade during installation, reducing effectiveness and creating health hazards from airborne particles.

-

Moisture Sensitivity and Long-Term Durability: While some aerogels are hydrophobic, others degrade when exposed to moisture. Sourcing from suppliers without rigorous environmental testing can result in insulation that loses performance in humid climates or when exposed to condensation.

-

Lack of Standardization and Certification: Unlike conventional insulation (e.g., fiberglass or foam), aerogel lacks universal performance standards for residential use in many regions. This makes it difficult to compare products objectively or verify compliance with building codes.

Intellectual Property (IP) and Sourcing Risks

Another major concern when sourcing aerogel insulation is the complex intellectual property landscape, which can pose legal and supply chain risks.

-

Patented Manufacturing Processes: The production of high-performance aerogels—especially silica-based types—often relies on proprietary sol-gel processes and supercritical drying techniques protected by patents. Sourcing from manufacturers that infringe on these patents can expose buyers to legal liability, especially in markets with strong IP enforcement (e.g., the U.S. or EU).

-

Counterfeit or Unlicensed Products: As demand for aerogel grows, so does the risk of counterfeit or unlicensed copies entering the market. These products may mimic reputable brands but use inferior materials or processes, compromising safety and performance. Buyers may unknowingly support IP violations.

-

Limited Authorized Distributors: Leading innovators in aerogel technology (e.g., Aspen Aerogels, Cabot Corporation) often license their products through authorized partners. Sourcing from unauthorized distributors increases the risk of receiving substandard or non-compliant materials.

-

Supply Chain Transparency: It can be difficult to trace the origin of aerogel products, especially when sourced through third-party suppliers or online marketplaces. Lack of transparency raises concerns about whether the product is genuinely manufactured under licensed IP, affecting warranty coverage and long-term support.

Mitigation Strategies

To avoid these pitfalls:

– Verify Certifications: Look for aerogel products with third-party testing (e.g., ASTM, ISO) and building code compliance (e.g., ICC-ES reports).

– Source from Reputable Suppliers: Choose suppliers with documented partnerships with major aerogel developers and transparent manufacturing practices.

– Request IP Documentation: Ask for proof of licensing or authorization from patent holders, particularly for high-volume or commercial projects.

– Conduct Pilot Testing: Test small batches for thermal performance, durability, and handling before large-scale procurement.

By understanding and addressing these quality and IP-related challenges, stakeholders can make informed decisions and fully leverage the benefits of aerogel insulation without compromising performance or legal compliance.

Logistics & Compliance Guide for Aerogel as Home Insulation

Overview of Aerogel Insulation

Aerogel is an advanced synthetic porous material known for its ultra-low thermal conductivity, making it one of the most effective insulation materials available for residential applications. Composed primarily of silica with up to 99.8% air content, aerogel offers high performance in thin profiles, ideal for retrofitting and space-constrained builds. Despite its benefits, handling, transportation, and regulatory compliance require careful planning due to its delicate nature and evolving regulatory landscape.

Regulatory Compliance Considerations

Building Codes and Standards

Aerogel insulation must comply with national and local building codes. In the United States, products should meet requirements under the International Residential Code (IRC) and International Energy Conservation Code (IECC). Key standards include:

– ASTM C177 – Standard Test Method for Steady-State Heat Flux Measurements.

– ASTM E84 – Surface Burning Characteristics (flame spread and smoke development).

– ICC Evaluation Reports (ICC-ES) – Third-party verification of code compliance is essential for acceptance by building officials.

Fire Safety Regulations

Due to its organic binder content, some aerogel products may require additional fire protection. Compliance with fire safety standards such as:

– NFPA 285 – For wall assemblies in high-rise residential buildings.

– Local fire marshals may require flame-retardant coatings or encapsulation in fire-resistant barriers.

Environmental and Health Regulations

- OSHA Guidelines: While aerogel is generally non-toxic, handling can produce fine dust. OSHA’s respiratory protection standards (29 CFR 1910.134) may apply during cutting or installation.

- REACH and RoHS (EU): Ensure material composition complies with substance restrictions if sourcing from or exporting to Europe.

- LEED and Green Building Certifications: Aerogel may contribute to points under Energy & Atmosphere (EA) and Materials & Resources (MR) categories due to its high R-value and potential for reduced material usage.

Transportation and Handling Logistics

Packaging and Storage

- Aerogel blankets or panels are typically vacuum-sealed or wrapped in moisture-resistant films to prevent degradation.

- Store in a dry, temperature-controlled environment; exposure to moisture or high humidity can reduce performance.

- Avoid stacking heavy materials on packaged aerogel to prevent crushing.

Shipping Requirements

- Use carriers experienced in handling fragile, high-value materials.

- Clearly label packages as “Fragile” and “Do Not Stack.”

- Consider climate-controlled transport if moving through extreme environments.

- International shipments may require Material Safety Data Sheets (MSDS/SDS) and customs documentation specifying non-hazardous classification.

On-Site Handling

- Installers should wear gloves and masks to minimize skin contact and inhalation of dust during cutting.

- Use fine-tooth saws or utility knives for precise cutting; avoid power tools that generate excessive dust.

- Seal cut edges with compatible tapes or coatings to preserve integrity.

Installation Best Practices

Substrate Preparation

Ensure substrates (walls, roofs, etc.) are clean, dry, and structurally sound. Aerogel performs best when applied with minimal gaps.

Seaming and Joint Treatment

- Overlap or tape seams with vapor-permeable, compatible tapes to maintain thermal continuity.

- Use compatible sealants at junctions with windows, doors, and other penetrations.

Encapsulation Needs

Some aerogel products require protective facing (e.g., fiberglass scrim or polymer membranes) to guard against moisture and mechanical damage. Verify manufacturer specifications before installation.

Certification and Documentation

Product Certification

- Ensure aerogel products carry valid certifications such as:

- UL (Underwriters Laboratories) classification.

- ICC-ESR (Evaluation Service Report).

- CE marking (for EU markets).

- Retain manufacturer data sheets, warranty information, and test reports for inspection and compliance verification.

Installer Training and Qualification

- Recommend or require installation by trained personnel familiar with advanced insulation systems.

- Maintain records of training and certification to support warranty claims and code compliance.

Disposal and End-of-Life Considerations

- Aerogel is non-biodegradable but typically inert and non-hazardous.

- Dispose of offcuts and waste in accordance with local solid waste regulations.

- Explore manufacturer take-back programs or recycling options where available.

Conclusion

Using aerogel as home insulation offers significant energy efficiency advantages but requires strict adherence to logistics protocols and regulatory standards. Proper handling, compliance with fire and building codes, and correct installation are critical to ensuring long-term performance and code acceptance. Engage with certified suppliers and trained professionals to ensure a compliant and effective application.

In conclusion, sourcing aerogel as home insulation presents a compelling option for those seeking high-performance thermal efficiency in a thin, lightweight material. Its exceptional insulating properties, with one of the lowest thermal conductivities of any known solid, make it ideal for retrofitting older homes or maximizing interior space in new constructions. Additionally, aerogel’s resistance to moisture, fire, and mold enhances long-term durability and safety.

However, several factors must be carefully considered. The high cost of aerogel compared to traditional insulation materials like fiberglass or mineral wool remains a significant barrier for many homeowners. Limited availability and the need for specialized installation may also affect accessibility and overall project feasibility.

Sustainability is another consideration—while aerogel enhances energy efficiency over the lifespan of a home, its manufacturing process is energy-intensive, particularly for silica-based aerogels. As production technologies improve and become more environmentally friendly, aerogel’s eco-footprint may decrease.

Ultimately, while aerogel offers cutting-edge insulation performance, its use in residential applications is currently best suited for niche projects where space constraints, energy efficiency goals, or performance demands justify the higher initial investment. As production scales and costs decrease, aerogel could become a more mainstream solution, revolutionizing the future of sustainable home insulation.