The global washing machine actuator market is experiencing steady growth, driven by rising demand for energy-efficient and smart appliances. According to Grand View Research, the global washing machine market size was valued at USD 86.5 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 6.1% from 2023 to 2030. As automation and precision control become critical in modern washing machine designs, actuators—responsible for managing drum movement, water flow, and door locking—have emerged as essential components. This increasing technological integration has elevated the importance of reliable, high-performance actuator manufacturers. Based on production capacity, innovation, global market share, and strategic partnerships with major appliance brands, the following four companies stand out as leading actuator suppliers in the washing machine industry.

Top 4 Actuator For Washing Machine Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Shift Actuators

Domain Est. 2013

Website: htitechnology.com

Key Highlights: The Shift Actuator consists of a synchronous motor that shifts the “splutch” cam ring to change the mode of the washing drum between spin and agitate. Request ……

#2 Whirlpool #326001220 Washer ACTUATOR

Domain Est. 1998

Website: parts.alliancelaundry.com

Key Highlights: Availability: This part is no longer available with no replacement. USD 32.10. Buy this residential Whirlpool part #326001220 replacement washer ACTUATOR here ……

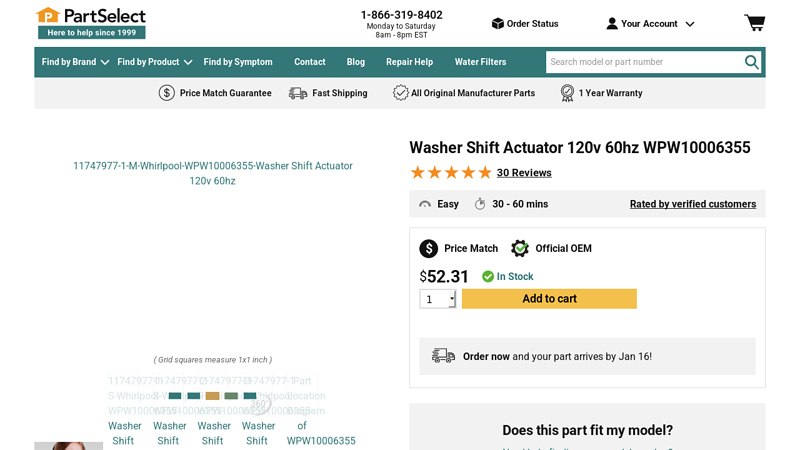

#3 Official Whirlpool WPW10006355 Washer Shift Actuator 120v 60hz

Domain Est. 1999

Website: partselect.com

Key Highlights: In stock Rating 4.8 (30) This shift actuator is a genuine replacement component designed for top-load washing machines. It plays a critical role in transitioning the washer betwe…

#4 Whirlpool Washer Shift Actuator(s) W10913953

Domain Est. 2021

Expert Sourcing Insights for Actuator For Washing Machine

H2: Market Trends for Actuators in Washing Machines (2026 Outlook)

The actuator market for washing machines is poised for significant transformation by 2026, driven by advancements in smart home integration, energy efficiency regulations, and evolving consumer preferences. As a critical electromechanical component responsible for managing door locks, water valves, and drum positioning, actuators are becoming more intelligent, compact, and reliable to meet the demands of next-generation appliances.

-

Smart and Connected Actuators

By 2026, the integration of IoT and AI into home appliances will propel demand for smart actuators capable of real-time diagnostics and predictive maintenance. Washing machines equipped with connected actuators will communicate performance data to cloud platforms, enabling manufacturers to monitor wear patterns and optimize functionality. This trend supports the broader shift toward smart laundry ecosystems, where actuators play a key role in enhancing user experience through automation and remote control. -

Emphasis on Energy Efficiency and Regulatory Compliance

Global energy efficiency standards (such as EU Ecodesign and ENERGY STAR) are pushing manufacturers to adopt low-power actuators. Electromechanical actuators with optimized motor designs and energy-saving modes are gaining preference over traditional solenoid types. By 2026, actuators consuming less than 1W in standby mode are expected to dominate premium washing machine models, aligning with stringent environmental regulations. -

Miniaturization and Design Integration

As washing machines become more compact and multifunctional, especially in urban environments, there is growing demand for smaller, lightweight actuators. OEMs are collaborating with component suppliers to develop space-saving designs that maintain durability and performance. This trend is particularly evident in stackable and all-in-one washer-dryer units where internal space is limited. -

Rise of Brushless DC (BLDC) and Precision Control Actuators

Actuators powered by BLDC motors are gaining traction due to their superior control, longevity, and efficiency. These actuators allow for precise movement control in advanced washing cycles (e.g., gentle fabric handling or adaptive drum adjustment), supporting premium features in high-end models. The adoption of BLDC technology is expected to grow at a CAGR of over 7% through 2026 in the washing machine sector. -

Regional Market Dynamics

Asia-Pacific will remain the largest market for washing machine actuators, driven by rising urbanization and appliance penetration in India, China, and Southeast Asia. Meanwhile, North America and Europe will lead in the adoption of high-value smart and efficient actuators, supported by strong consumer spending on premium appliances and government incentives for energy-efficient products. -

Supply Chain and Material Innovation

The shift toward sustainable manufacturing is influencing actuator design. By 2026, an increasing number of actuators will incorporate recyclable materials and reduced rare-earth content in motors. Additionally, localized production in response to supply chain disruptions will encourage regional sourcing, particularly in Europe and North America.

In summary, the 2026 market for washing machine actuators will be characterized by intelligence, efficiency, and integration. Manufacturers that invest in smart technologies, sustainability, and compact design will be best positioned to capture growth in this evolving landscape.

Common Pitfalls When Sourcing an Actuator for a Washing Machine

When sourcing an actuator for a washing machine, several critical pitfalls can impact performance, safety, and longevity. Two key areas where issues frequently arise are quality and Ingress Protection (IP) rating.

1. Compromising on Quality

One of the most common mistakes is selecting low-cost actuators without thoroughly evaluating their build quality and reliability. Poor-quality actuators may fail prematurely due to:

- Substandard materials: Use of low-grade plastics or metals that wear quickly under constant vibration and moisture exposure.

- Inconsistent manufacturing: Lack of precision in production leads to misalignment or improper fit, affecting the door lock mechanism.

- Insufficient load capacity: Choosing an actuator that cannot reliably withstand the mechanical stress of repeated locking and unlocking cycles.

- Lack of certification: Sourcing from suppliers without compliance to international standards (e.g., CE, UL, RoHS) can lead to safety hazards and regulatory non-compliance.

Always prioritize actuators from reputable manufacturers with verifiable quality control processes and product testing data.

2. Ignoring Ingress Protection (IP) Rating

Washing machines operate in high-moisture environments, making the IP rating of an actuator crucial. Overlooking this specification can result in:

- Water and dust ingress: An insufficient IP rating (e.g., less than IP65) may allow moisture or particles to penetrate the actuator, leading to electrical shorts or mechanical failure.

- Corrosion and rust: Without proper sealing, internal components degrade faster, especially in humid conditions.

- Reduced lifespan: Even minor exposure to water over time can compromise performance and lead to early replacement.

Ensure the actuator has an appropriate IP rating—typically IP65 or higher—to withstand the wash cycle environment and provide long-term reliability.

By carefully assessing both quality and IP rating, you can avoid costly failures and ensure the safe, efficient operation of the washing machine.

Logistics & Compliance Guide for Actuator For Washing Machine

Product Classification and HS Code

The actuator for a washing machine is classified under the Harmonized System (HS) Code, which is essential for international trade. The most relevant HS code for actuators used in washing machines is typically:

- 8501.31 or 8501.32 – Electric motors and generators (excluding generating sets), of an output not exceeding 75 kW.

- Alternatively, 8481.80 may apply if the actuator is considered a type of valve or mechanical actuating device.

Recommendation: Consult the local customs authority or a trade compliance expert to confirm the correct HS code based on technical specifications (e.g., voltage, power, function).

Import Regulations and Documentation

Required Documentation

To ensure smooth customs clearance, the following documents must be prepared:

- Commercial Invoice

- Packing List

- Bill of Lading (for sea freight) or Air Waybill (for air freight)

- Certificate of Origin (may be required for preferential tariff treatment)

- Technical Datasheet (detailing voltage, power, dimensions, and function)

- CE or IEC Certification (if exporting to the EU or other regions with safety standards)

- Import License (if required by the destination country)

Note: Some countries may require additional permits or pre-shipment inspections.

Packaging and Labeling Standards

Packaging

- Use anti-static bags for sensitive electronic components.

- Secure actuators in sturdy, corrugated cartons with internal cushioning (e.g., foam or bubble wrap).

- Palletize shipments for bulk transport; use stretch wrap and corner boards for stability.

Labeling

Each package must include:

– Product name and model number

– Quantity per box

– Net and gross weight

– Handling symbols (e.g., “Fragile”, “Do Not Stack”)

– Manufacturer and supplier information

– Country of origin

– HS code and customs tariff number

Compliance Tip: Ensure labels are durable and weather-resistant for international shipping.

Transportation Modes and Considerations

Sea Freight

- Most cost-effective for large volumes.

- Transit time: 2–6 weeks depending on route.

- Use dry containers; consider moisture-absorbing desiccants to prevent condensation.

Air Freight

- Faster delivery (3–7 days).

- Higher cost; suitable for urgent or high-value shipments.

- Ideal for sample units or small batches.

Land Freight

- Applicable for regional distribution (e.g., within Europe or North America).

- Requires coordination with certified carriers experienced in handling electronic components.

Environmental Sensitivity: Avoid exposure to extreme temperatures, humidity, and vibration during transport.

Regulatory Compliance

CE Marking (European Union)

- Required for electrical safety and electromagnetic compatibility (EMC).

- Compliance with:

- Low Voltage Directive (2014/35/EU)

- EMC Directive (2014/30/EU)

- Technical File and Declaration of Conformity must be maintained.

RoHS Compliance

- Restriction of Hazardous Substances Directive (2011/65/EU).

- Ensure actuator components do not contain lead, mercury, cadmium, or other restricted substances above permissible limits.

REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals)

- Confirm that materials used in the actuator comply with REACH SVHC (Substances of Very High Concern) requirements.

Other Regions

- USA: FCC compliance may be required if the actuator emits electromagnetic interference.

- Canada: CSA certification or recognition may be needed.

- China: CCC (China Compulsory Certification) may apply depending on product category.

Customs Duties and Taxes

- Duty rates vary by country and HS code classification.

- Typical duty range: 0% to 8% for electric motors/actuators in developed markets.

- Value Added Tax (VAT) or Goods and Services Tax (GST) is generally applied on the landed cost (product value + shipping + insurance + duties).

Tip: Leverage Free Trade Agreements (e.g., USMCA, RCEP, EU-South Korea) where applicable to reduce or eliminate tariffs.

Risk Management and Insurance

- Purchase all-risk cargo insurance covering loss, damage, or delay.

- Specify coverage for:

- Theft

- Water damage

- Accidental impact

- Retain proof of packaging compliance to support insurance claims.

End-of-Life and Environmental Responsibility

- Comply with WEEE (Waste Electrical and Electronic Equipment) Directive in the EU.

- Provide take-back or recycling instructions if the actuator is sold as a standalone component.

- Design for disassembly and recyclability to meet future environmental regulations.

Conclusion

Successful logistics and compliance for actuators used in washing machines require accurate classification, proper documentation, adherence to international standards, and careful handling during transport. Partnering with experienced freight forwarders and regulatory consultants ensures smooth global distribution while minimizing delays and penalties.

Conclusion for Sourcing Actuators for Washing Machines

In conclusion, sourcing the right actuator for a washing machine involves a careful evaluation of several key factors including reliability, durability, compatibility, cost-efficiency, and supplier credibility. The actuator plays a critical role in functions such as water inlet control, detergent dispensing, and door locking mechanisms, directly impacting overall machine performance and user safety. Therefore, selecting high-quality actuators from reputable suppliers who comply with international standards (such as ISO and IEC) is essential to ensure long-term reliability and customer satisfaction.

Additionally, considerations such as energy efficiency, noise levels, and ease of integration into existing designs should guide the sourcing decision. A balance between performance and cost must be achieved to remain competitive in the market without compromising on quality. Establishing strong partnerships with suppliers who offer technical support and consistent supply chain management further mitigates risks and supports scalability.

Ultimately, a well-sourced actuator contributes significantly to the efficiency, safety, and longevity of the washing machine, enhancing both product reputation and consumer trust. Strategic sourcing — combining technical evaluation with supply chain resilience — is key to ensuring sustainable success in the home appliance manufacturing sector.