The global acrylic coatings market is experiencing robust growth, driven by rising demand across construction, automotive, and industrial sectors. According to Grand View Research, the market was valued at USD 57.6 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. This growth is fueled by the increasing preference for water-based, low-VOC formulations due to stringent environmental regulations and a growing emphasis on sustainable materials. Acrylic coatings are favored for their durability, UV resistance, and color retention, making them ideal for both protective and decorative applications. As innovation continues and demand for eco-friendly solutions intensifies, manufacturers are investing in advanced formulations and scalable production technologies. In this evolving landscape, nine key players have emerged as leaders, combining market reach, R&D investment, and product performance to shape the future of the acrylic coatings industry.

Top 9 Acrylic Coating Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Arkema Coating Resins corporate website

Domain Est. 2001

Website: coatingresins.arkema.com

Key Highlights: Arkema Coating Resins is a leading supplier of waterborne, solventborne and powder resins along with additives and opacifiers….

#2 Allnex

Domain Est. 2000

Website: allnex.com

Key Highlights: Allnex, the global leader in industrial coating resins. A market-leading manufacturer of adhesives, sealants and specialty coatings….

#3 Gellner Industrial Waterbased Acrylic Polymers

Domain Est. 2007

Website: gellnerindustrial.com

Key Highlights: Gellner Industrial, LLC is the premier manufacturer of water based acrylic resins, bringing over forty years of industry experience to our client base….

#4 Polyurethane-Based Recreational Coatings & Protections

Domain Est. 1998

Website: advpolytech.com

Key Highlights: We are a leading manufacturer of polyurethane-based materials and acrylic coatings products. OUR PRODUCTS. We provide solutions according to your needs. COURTS….

#5 Acrylitex

Domain Est. 2001

Website: acrylitex.com

Key Highlights: We offer durable, eco-friendly acrylic coatings for drywall & painting. Our products can be used for commercial & residential projects….

#6 Joncryl® acrylic resins & emulsions

Domain Est. 1995

Website: basf.com

Key Highlights: BASF offers a wide range of JONCRYL acrylic polymer emulsions for 1-component (1K) and 2-component (2K) coatings systems….

#7 Acrylic Coatings

Domain Est. 1999

Website: generalcoatings.net

Key Highlights: GCMC formulates and manufactures multiple grades of acrylic roof coatings. Ultra-Flex acrylic coatings are ideal for over spray polyurethane foam repair….

#8 Acrylic Coatings

Domain Est. 2005

Website: scscoatings.com

Key Highlights: SCS Coatings is a global leader in acrylic conformal coatings. Learn about our acrylic coatings and how SCS can help your organization….

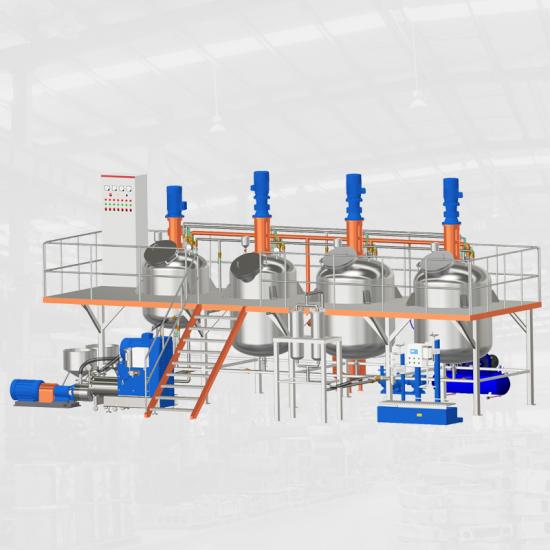

#9 Acrylic coating resin and PPMA manufacturing

Domain Est. 2017

Website: nouryon.com

Key Highlights: We offer a wide range of organic peroxide initiators that are used for (meth)acrylic resin and PMMA polymerization and production….

Expert Sourcing Insights for Acrylic Coating

H2: Market Trends in the Acrylic Coating Industry for 2026

The global acrylic coating market is poised for significant transformation by 2026, driven by technological innovation, sustainability demands, and shifting industrial needs across key end-use sectors. As environmental regulations tighten and consumer preferences increasingly favor eco-friendly solutions, the acrylic coating industry is adapting with water-based formulations, low-VOC (volatile organic compound) products, and bio-based raw materials.

One of the dominant trends shaping the 2026 landscape is the accelerated shift toward sustainable and green coatings. Governments worldwide—particularly in North America and Europe—are enforcing stricter emissions standards, prompting manufacturers to reformulate traditional solvent-based acrylic coatings. Waterborne acrylic coatings are expected to dominate growth, with rising adoption in architectural, automotive, and industrial applications due to their lower environmental impact and improved indoor air quality.

Another key trend is the expansion in emerging markets, especially in Asia-Pacific (notably China, India, and Southeast Asia), where rapid urbanization, infrastructure development, and growth in the construction and automotive sectors are fueling demand. Local production capabilities and cost-effective manufacturing are enabling regional players to capture market share, while multinational companies are forming strategic partnerships to enter these high-growth regions.

Technological advancements are also playing a pivotal role. Smart and functional acrylic coatings—such as self-cleaning, anti-microbial, UV-resistant, and thermochromic variants—are gaining traction, particularly in high-performance applications like healthcare facilities, transportation, and electronics. These innovations are supported by increased R&D investments from major chemical companies aiming to differentiate their product portfolios.

Moreover, consolidation and vertical integration among acrylic resin and coating suppliers are expected to rise by 2026. Companies are acquiring specialty coating firms or backward-integrating into raw material production to secure supply chains, improve margins, and respond faster to customer demands amid global supply chain volatility.

In summary, the 2026 acrylic coating market will be characterized by a strong emphasis on sustainability, technological performance, and geographic expansion. Companies that prioritize innovation, regulatory compliance, and strategic market positioning are likely to lead in this evolving landscape.

Common Pitfalls in Sourcing Acrylic Coating: Quality and Intellectual Property Risks

Sourcing acrylic coatings involves navigating complex technical specifications and legal considerations. Overlooking key aspects related to quality consistency and intellectual property (IP) can lead to significant operational, financial, and reputational damage. Below are the most common pitfalls in these two critical areas.

Quality Pitfalls

Inconsistent Raw Material Sourcing

Acrylic coatings rely on precise formulations of monomers, additives, and solvents. Suppliers using variable or low-grade raw materials—often to cut costs—produce batches with inconsistent viscosity, adhesion, color stability, or UV resistance. This variability leads to coating failures in the field, such as premature cracking or delamination, especially in demanding environments.

Lack of Rigorous Testing and Certification

Many suppliers provide only basic or self-reported test data. Without independent third-party certification (e.g., ISO 9001, ASTM, or EN standards), buyers cannot verify performance claims. Skipping accelerated weathering, salt spray, or chemical resistance tests increases the risk of premature degradation and non-compliance with industry standards.

Inadequate Batch-to-Batch Traceability

Poor documentation practices make it difficult to trace raw material origins and production parameters. When quality issues arise, suppliers may be unable to identify root causes or replicate successful batches, complicating corrective actions and recalls.

Insufficient Technical Support and Application Guidance

Some suppliers fail to provide detailed technical data sheets (TDS) or application guidelines (e.g., substrate prep, curing conditions). This leads to improper application, resulting in poor film formation, adhesion failure, or reduced durability—even if the coating itself is high quality.

Intellectual Property Pitfalls

Unlicensed or Infringing Formulations

Sourcing from low-cost suppliers, especially in regions with weak IP enforcement, increases the risk of acquiring coatings that replicate patented chemistries without authorization. Using such products can expose the buyer to litigation, import bans, or forced product recalls, particularly in regulated markets like automotive or aerospace.

Ambiguous Ownership of Custom Formulations

When developing a proprietary coating with a supplier, unclear contracts may leave IP ownership unresolved. Suppliers might claim rights to the formulation or reuse it for other customers, undermining the buyer’s competitive advantage and brand differentiation.

Reverse Engineering and Trade Secret Leakage

Sharing detailed specifications or samples with multiple suppliers during sourcing increases the risk of trade secret exposure. Unscrupulous suppliers may reverse-engineer formulations or leak data to competitors, especially if non-disclosure agreements (NDAs) are absent or poorly enforced.

Hidden Subcontracting Without Approval

Some suppliers outsource production to third-party manufacturers without buyer consent. This practice not only compromises quality control but may also result in IP infringement if the subcontractor uses unauthorized processes or materials, leaving the buyer legally exposed.

Conclusion

To mitigate these risks, buyers must conduct thorough due diligence: verify supplier certifications, audit production facilities, enforce robust IP agreements, and require full transparency in sourcing and manufacturing. Prioritizing long-term reliability and legal compliance over short-term cost savings is essential for successful acrylic coating procurement.

Logistics & Compliance Guide for Acrylic Coating

Product Overview

Acrylic coating is a water- or solvent-based protective and decorative finish widely used in construction, automotive, and industrial applications. It typically consists of acrylic resins, pigments, additives, and carriers. Due to its chemical composition, proper handling, storage, transportation, and disposal are essential to ensure safety and regulatory compliance.

Regulatory Classification

Acrylic coatings may be classified under various regulatory frameworks depending on their formulation (e.g., VOC content, flammability, hazardous components). Common classifications include:

– GHS (Globally Harmonized System): Acrylic coatings may carry hazard labels such as “Irritant” or “Flammable” if solvent-based.

– OSHA (Occupational Safety and Health Administration): Regulates workplace exposure and labeling under the Hazard Communication Standard (HCS).

– EPA (Environmental Protection Agency): Regulates VOC emissions under the Clean Air Act, especially in architectural and industrial coatings.

– DOT (Department of Transportation): Governs transportation of hazardous materials (49 CFR). Solvent-based acrylics may require hazardous materials designation (e.g., UN1263, Paint, 3, PG II or III).

Safety Data Sheet (SDS) Requirements

A current Safety Data Sheet (SDS) compliant with GHS and local regulations must accompany all shipments. The SDS must include:

– Product identifier and recommended use

– Hazard identification (physical, health, environmental)

– Composition/information on ingredients (including VOC content)

– First-aid and firefighting measures

– Accidental release measures

– Handling and storage guidelines

– Exposure controls and personal protective equipment (PPE)

– Regulatory information

Packaging and Labeling

Proper packaging and labeling are critical for safe transport and compliance:

– Use UN-certified containers for hazardous formulations.

– Ensure containers are sealed to prevent leakage and corrosion.

– Label packages with appropriate hazard communication: GHS pictograms, signal words, hazard statements, and precautionary statements.

– Include transport-specific markings (e.g., UN number, proper shipping name, hazard class) when required.

– For non-hazardous water-based acrylics, standard industrial labeling suffices.

Transportation Guidelines

Transportation requirements vary by formulation and region:

– Non-hazardous water-based coatings: Typically exempt from hazardous material regulations; standard freight rules apply.

– Solvent-based or flammable coatings: Subject to DOT, IATA (air), or IMDG (sea) regulations.

– Proper shipping name: “PAINT” or “PAINT RELATED MATERIAL”

– Hazard class: Class 3 (Flammable Liquid)

– Packing Group: II or III depending on flash point and ignition temperature

– Special provisions may apply based on quantity and packaging

– Always verify carrier-specific requirements and regional regulations (e.g., ADR in Europe).

Storage Conditions

Store acrylic coatings in accordance with manufacturer recommendations and safety standards:

– Keep in a cool, dry, well-ventilated area away from direct sunlight and heat sources.

– Maintain temperatures between 50°F and 80°F (10°C–27°C) to prevent freezing or degradation.

– Store flammable formulations in approved flammable liquid storage cabinets if quantities exceed local code thresholds.

– Segregate from oxidizers, strong acids, and bases.

– Ensure containers are tightly closed when not in use.

Handling Procedures

Safe handling minimizes exposure and accident risks:

– Use appropriate PPE: gloves (nitrile or chemical-resistant), safety goggles, and respirators if ventilation is inadequate.

– Avoid prolonged or repeated skin contact; wash hands after handling.

– Use in well-ventilated areas; consider local exhaust ventilation for spray applications.

– Prohibit eating, drinking, or smoking in handling areas.

– Ground containers during transfer to prevent static discharge (especially for solvent-based products).

Environmental Compliance

Acrylic coatings must comply with environmental regulations:

– VOC Limits: Adhere to regional VOC content limits (e.g., SCAQMD Rule 1113, EPA NESHAP, EU Directive 2004/42/EC).

– Waste Disposal: Dispose of waste coatings, contaminated materials, and empty containers per local hazardous waste regulations (e.g., RCRA in the U.S.).

– Spill Management: Use absorbent materials (e.g., spill kits) for leaks. Do not flush into drains or waterways. Report large spills as required by law.

Import and Export Considerations

Cross-border shipments require additional compliance:

– Verify import regulations in destination country (e.g., REACH in EU, TSCA in U.S., K-REACH in Korea).

– Provide accurate HS (Harmonized System) codes (e.g., 3208.10 for acrylic paints and varnishes).

– Include commercial invoice, packing list, and SDS in all shipments.

– For hazardous goods, prepare a Dangerous Goods Declaration (DGD) as per IATA/IMDG/ADR requirements.

– Ensure compliance with customs documentation and labeling in local language if required.

Training and Documentation

Maintain compliance through proper training and recordkeeping:

– Train employees on SDS interpretation, safe handling, and emergency procedures.

– Keep copies of SDS, shipping documents, permits, and training records for a minimum of 3–5 years, as required by jurisdiction.

– Conduct periodic audits to ensure ongoing compliance with safety and environmental standards.

Emergency Response

Prepare for incidents with clear procedures:

– Post emergency contact numbers (e.g., poison control, local fire department).

– Equip areas with spill control materials, fire extinguishers (Class B), and eyewash stations.

– In case of exposure:

– Inhalation: Move to fresh air.

– Skin contact: Wash with soap and water.

– Eye contact: Flush with water for at least 15 minutes.

– Ingestion: Do not induce vomiting; seek medical attention.

– Report significant incidents to relevant authorities as required.

Conclusion

Proper logistics and compliance management for acrylic coatings ensures safety, legal adherence, and environmental protection. Always consult the product-specific SDS and stay updated on evolving regulations in your region and supply chain.

In conclusion, sourcing acrylic coating requires a strategic approach that balances quality, cost, durability, and supplier reliability. Acrylic coatings offer excellent UV resistance, flexibility, and weatherability, making them ideal for a wide range of applications in construction, automotive, and industrial sectors. When selecting a supplier, it is essential to evaluate technical specifications, compliance with environmental and safety standards, and the ability to provide consistent product quality. Additionally, building strong relationships with reputable manufacturers or distributors can ensure timely delivery, competitive pricing, and access to technical support. Conducting thorough market research, obtaining samples for performance testing, and considering long-term supply agreements further enhance sourcing effectiveness. Ultimately, a well-executed sourcing strategy for acrylic coatings contributes to improved product performance, cost efficiency, and sustainability in end-use applications.