The global AC compressor control valve market is experiencing steady expansion, driven by rising demand for energy-efficient climate control systems across automotive, HVAC, and industrial sectors. According to Grand View Research, the global automotive HVAC market size was valued at USD 47.8 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 6.3% from 2023 to 2030—directly fueling the need for advanced compressor components like control valves. Similarly, Mordor Intelligence projects the HVAC market to grow at a CAGR of over 7% during the forecast period of 2023–2028, underpinned by urbanization, stricter energy regulations, and increased adoption of smart building technologies. As critical components regulating refrigerant flow and compressor efficiency, AC compressor control valves are becoming increasingly sophisticated, prompting Original Equipment Manufacturers (OEMs) to partner with innovative, high-precision suppliers. In this evolving landscape, a select group of manufacturers have emerged as leaders in technology, reliability, and global reach—shaping the future of thermal management systems. The following six companies represent the forefront of this specialized segment.

Top 6 Ac Compressor Control Valve Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Four Seasons

Domain Est. 1996

Website: 4s.com

Key Highlights: We are the largest aftermarket climate control parts supplier in the industry and the largest compressor remanufacturer in the world….

#2 China Compressor Control Valves Manufacturers & Suppliers.

Domain Est. 2004

Website: acparts.cn

Key Highlights: Full selection of A/C Compressor Control Valves at acparts.cn, Lowest prices, high quality air conditioner compressor control valve , welcomr to contact us….

#3 Air Cylinders, Solenoid Valves and Pneumatics

Domain Est. 1995

Website: smcusa.com

Key Highlights: LPV series is a 2-port solenoid normally closed or normally open pinch valve for fluid control. The LPV series pinch valve also comes with a u-shaped tube slot ……

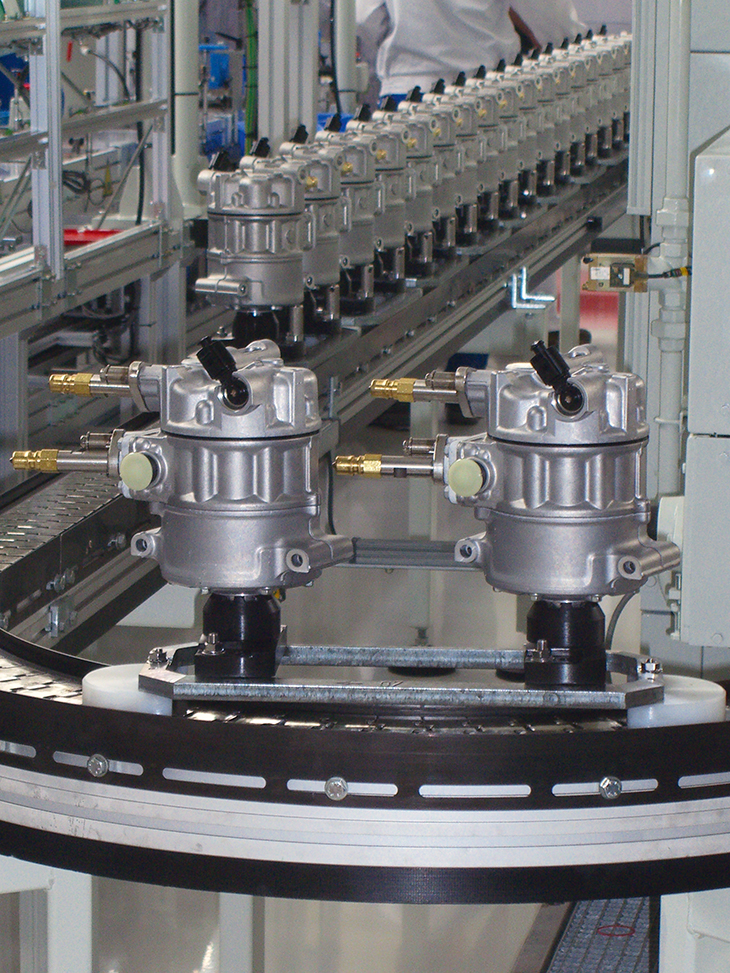

#4 mass produced control valve_cost effective control …

Domain Est. 2011

Website: puchenvalve.com

Key Highlights: We manufacture and distribute new energy auto parts , auto A/C compressor control valve,HPRV, speed sensor, thermal protectors and shock absorber solenoid valve ……

#5 Compressor Control Valve

Domain Est. 2018

Website: schrader-pacific.com

Key Highlights: A spool-style control valve that works with a capacity bypass port to affect capacity variation. The spool valve responds to low side pressure variations….

#6 Sanden Compressor Control Valves

Website: polarbearinc.com

Key Highlights: Partially accurate compressor electronic control valve for Sanden PXE16 and PXE13. Valve secured into body using hold down bolt instead of snap ring….

Expert Sourcing Insights for Ac Compressor Control Valve

H2: Market Trends for AC Compressor Control Valve in 2026

The global market for AC compressor control valves is poised for significant transformation by 2026, driven by technological innovation, regulatory shifts, and evolving consumer demands across key industries such as automotive, HVAC, and industrial refrigeration. Below is an analysis of the major market trends expected to shape the AC compressor control valve sector in 2026.

1. Growth in Electric and Hybrid Vehicle Adoption

The accelerating shift toward electric vehicles (EVs) and hybrid models is a primary driver for advanced AC compressor control valves. Unlike traditional internal combustion engine vehicles, EVs rely on electrically driven compressors, necessitating precise electronic control valves to manage refrigerant flow efficiently. By 2026, the integration of variable displacement and electronically controlled valves will become standard to optimize energy usage, extend battery range, and improve cabin climate control. This trend is particularly strong in regions with aggressive EV adoption targets, such as Europe, China, and North America.

2. Stringent Environmental Regulations and Refrigerant Transition

Regulations like the Kigali Amendment to the Montreal Protocol and regional initiatives (e.g., EU F-Gas Regulation) are pushing automakers and HVAC manufacturers to adopt low-global-warming-potential (GWP) refrigerants such as R-1234yf and CO₂ (R-744). These refrigerants require advanced control valves capable of handling higher pressures and variable operating conditions. As a result, the demand for robust, high-efficiency AC compressor control valves compatible with next-generation refrigerants is expected to surge by 2026.

3. Rise of Smart HVAC Systems in Commercial and Residential Buildings

In the HVAC sector, the growing deployment of smart thermostats and building energy management systems (BEMS) is increasing the need for intelligent compressor control valves. These valves integrate with IoT platforms to enable real-time monitoring, predictive maintenance, and adaptive cooling. By 2026, the demand for modulating and digitally controlled valves will rise significantly in both new constructions and retrofit markets, particularly in urban centers focused on energy efficiency and sustainability.

4. Advancements in Variable Capacity and Precision Control Technologies

Manufacturers are increasingly investing in variable capacity compressors paired with electronically actuated control valves to enhance system performance and energy efficiency. These systems allow for fine-tuned refrigerant flow based on cooling demand, reducing energy consumption and wear on components. Innovations such as pulse-width modulation (PWM) valves and stepper motor-driven controls are expected to dominate the market by 2026, especially in high-end automotive and industrial applications.

5. Regional Market Expansion and Localization of Supply Chains

Asia-Pacific, led by China and India, will remain a key growth region due to rising vehicle production, urbanization, and increasing demand for air conditioning. However, geopolitical factors and supply chain resilience concerns are prompting companies to localize production. By 2026, OEMs and suppliers are likely to establish regional manufacturing hubs, fostering innovation and reducing dependency on global logistics.

6. Sustainability and Circular Economy Pressures

End-of-life management and recyclability of components are gaining importance. AC compressor control valves made from recyclable materials and designed for easy disassembly will be favored. Additionally, manufacturers are expected to adopt green manufacturing practices to meet ESG (Environmental, Social, Governance) goals, influencing procurement decisions by major HVAC and automotive companies.

In conclusion, the AC compressor control valve market in 2026 will be defined by electrification, digitalization, regulatory compliance, and sustainability. Companies that invest in smart, adaptive, and environmentally compatible valve technologies will be best positioned to capture growth in this evolving landscape.

Common Pitfalls Sourcing AC Compressor Control Valve (Quality, IP)

When sourcing AC compressor control valves—especially in the context of intellectual property (IP) and quality—several critical pitfalls can compromise performance, reliability, and legal compliance. Being aware of these risks is essential for procurement teams, OEMs, and system integrators.

Poor Quality Materials and Manufacturing

One of the most frequent issues is receiving valves manufactured with substandard materials or inadequate processes. Low-quality seals, housings, or solenoid components can degrade quickly under high pressure and temperature cycles, leading to premature failure, refrigerant leaks, and system inefficiency. Suppliers may cut costs by using inferior-grade brass, plastic, or elastomers not rated for HVAC/R environments.

Inconsistent Performance and Calibration

Control valves must maintain precise refrigerant flow regulation. Poorly calibrated or inconsistently manufactured units can cause fluctuating superheat, reduced cooling capacity, or compressor damage. Batch-to-batch variability from unqualified or uncertified suppliers undermines system reliability and increases warranty claims.

Lack of IP Compliance and Counterfeit Risk

Sourcing from manufacturers that infringe on patented designs—such as those held by industry leaders like Denso, Sanden, or Emerson—poses serious legal exposure. Counterfeit or reverse-engineered valves may appear functionally similar but lack certified testing and IP licensing, potentially leading to litigation, product recalls, or import bans. Always verify IP ownership and request documentation of design licenses.

Inadequate Environmental and Safety Certification

Many suppliers fail to meet essential certifications like UL, CE, RoHS, or ISO 9001. Without these, valves may not comply with regional safety or environmental standards. Additionally, IP-rated enclosures (e.g., IP65 for dust/water resistance) are often misrepresented—confirming actual test reports is crucial for outdoor or harsh environment applications.

Insufficient Technical Support and Traceability

Low-cost suppliers may lack engineering support, detailed datasheets, or lot traceability. This becomes problematic during troubleshooting, failure analysis, or field recalls. Without traceable production records, identifying root causes or managing corrective actions becomes nearly impossible.

Supply Chain and Long-Term Availability Risks

Relying on suppliers without proven supply chain resilience can lead to interruptions. Some manufacturers discontinue models without notice, especially if they’re producing unlicensed copies. Ensure long-term availability commitments and avoid single-source dependencies without backup plans.

Avoiding these pitfalls requires thorough supplier vetting, rigorous quality audits, IP due diligence, and contractual safeguards to protect both product integrity and legal standing.

Logistics & Compliance Guide for AC Compressor Control Valve

This guide outlines essential logistics considerations and compliance requirements for the transportation, handling, and regulatory adherence of AC Compressor Control Valves throughout the supply chain.

Product Classification and Identification

AC Compressor Control Valves are precision components used in automotive and HVAC systems to regulate refrigerant flow. Proper identification is crucial for logistics and compliance. Ensure each valve has a unique part number, manufacturer details, and batch/lot traceability. Classify accurately under the Harmonized System (HS) Code—commonly under 8484.10 or 8413.30, depending on design and application—to ensure correct customs treatment.

Packaging and Handling Requirements

Use anti-static, moisture-resistant packaging to protect sensitive internal components. Valves should be sealed in vacuum or dry air packaging when possible to prevent corrosion. Use cushioning materials to avoid mechanical damage during transit. Label packages with handling instructions: “Fragile,” “Do Not Drop,” and “Keep Dry.” Orientation arrows should indicate correct upright positioning.

Transportation and Storage Conditions

Transport valves in temperature-controlled environments (typically 10°C to 30°C). Avoid exposure to extreme heat, humidity, or direct sunlight. Store in a clean, dry warehouse with controlled climate and low dust levels. Stack packages according to weight limits and avoid compression. Maximum recommended storage duration is 12 months unless otherwise specified by the manufacturer.

Regulatory Compliance

Comply with international and regional regulations. In the EU, ensure conformity with REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) and RoHS (Restriction of Hazardous Substances) directives. In the U.S., adhere to EPA regulations under Section 608 of the Clean Air Act regarding refrigerant handling components. Verify compliance with ISO 9001 (quality management) and IATF 16949 (automotive quality standards) where applicable.

Export and Import Documentation

Prepare complete shipping documentation including commercial invoice, packing list, bill of lading, and certificate of origin. For controlled shipments, include an Export Control Classification Number (ECCN) and obtain necessary export licenses if required under EAR (Export Administration Regulations). Importers must provide customs declarations and may need conformity assessment certificates depending on destination country rules.

Hazardous Materials Considerations

While the control valve itself is typically non-hazardous, verify if any internal residual substances (e.g., lubricants or refrigerants) are present. If so, classify under UN 3082 or appropriate hazard class and comply with IMDG (sea), IATA (air), or ADR (road) regulations. Most AC compressor control valves without residual refrigerants are not classified as hazardous goods.

Traceability and Recordkeeping

Maintain full traceability from manufacture to delivery. Record batch numbers, shipping dates, destinations, and quality inspection reports. Retain documentation for a minimum of 5 years to support warranty claims, recalls, or regulatory audits. Implement a digital tracking system for real-time visibility across the supply chain.

End-of-Life and Environmental Responsibility

Dispose of defective or obsolete valves in accordance with WEEE (Waste Electrical and Electronic Equipment) directives in applicable regions. Partner with certified recycling facilities to ensure environmentally sound recovery of metals and plastics. Avoid landfill disposal where regulated.

In conclusion, sourcing an AC compressor control valve is a critical step in ensuring the optimal performance, efficiency, and reliability of an air conditioning or refrigeration system. The selection process should carefully consider factors such as compatibility with the compressor and refrigerant type, precise control requirements, pressure and temperature ratings, durability, and compliance with industry standards. Evaluating suppliers based on quality certifications, technical support, lead times, and cost-effectiveness further contributes to a successful procurement decision. By prioritizing both technical specifications and supplier reliability, organizations can secure a control valve that enhances system efficiency, reduces energy consumption, and supports long-term operational stability. Ultimately, a well-sourced AC compressor control valve plays a vital role in maintaining consistent cooling performance and minimizing maintenance issues across diverse applications.