Sourcing Guide Contents

Industrial Clusters: Where to Source China Communication Accessories Casting Wholesalers

SourcifyChina Sourcing Intelligence Report 2026

Prepared For: Global Procurement Managers

Subject: Deep-Dive Market Analysis – Sourcing Communication Accessories Casting Wholesalers in China

Executive Summary

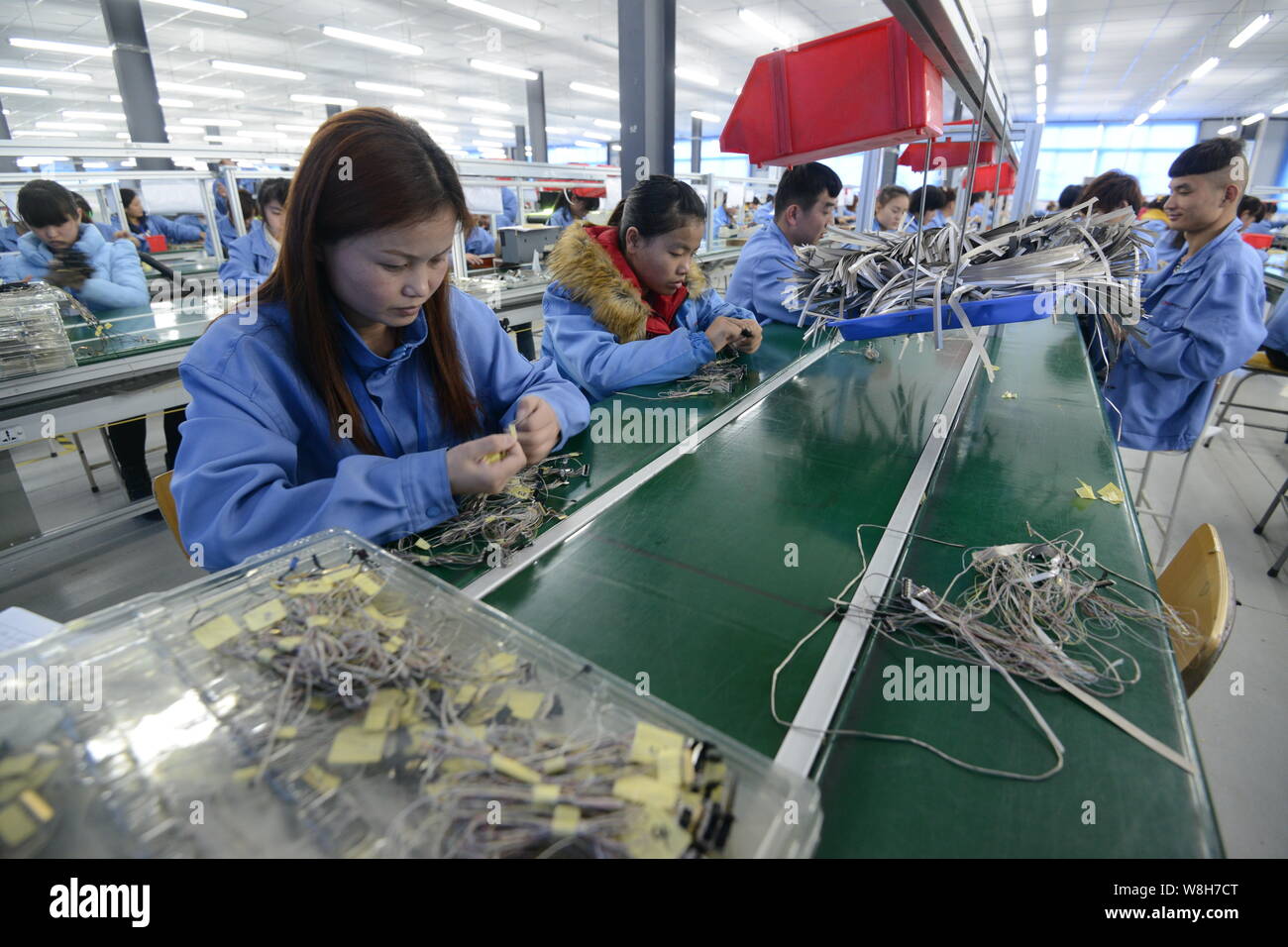

The global demand for communication accessories—encompassing connectors, housings, shielding components, and structural casings for 5G infrastructure, IoT devices, and enterprise networking equipment—continues to rise. China remains the dominant manufacturing hub for metal and plastic castings used in these accessories, offering competitive pricing, vertically integrated supply chains, and scalable production capacity.

This report identifies the key industrial clusters in China specializing in communication accessories casting, evaluates regional strengths, and provides a comparative analysis to guide strategic procurement decisions for 2026 and beyond.

Market Overview: Communication Accessories Casting in China

Communication accessories casting involves precision die-casting (zinc, aluminum), plastic injection molding, and CNC machining to produce components such as:

– RF connector housings

– Fiber optic transceiver casings

– Antenna mounts and brackets

– Enclosures for routers, switches, and base stations

China accounts for over 65% of global low-to-mid volume precision casting production in this sector, driven by advanced tooling capabilities, mature mold-making industries, and proximity to electronics OEMs in Asia.

Key Industrial Clusters for Communication Accessories Casting

The following provinces and cities have emerged as primary manufacturing hubs due to their specialized infrastructure, skilled labor, and ecosystem of tiered suppliers:

| Region | Key Cities | Primary Casting Types | Industrial Advantages |

|---|---|---|---|

| Guangdong | Shenzhen, Dongguan, Zhongshan | Aluminum die-casting, zinc alloy, plastic injection | Proximity to Shenzhen’s electronics OEMs; strong mold-making; fast prototyping; high automation |

| Zhejiang | Ningbo, Taizhou, Yuyao | Precision die-casting, high-tolerance plastic molding | World’s largest mold-making cluster; cost-efficient tooling; strong export logistics |

| Jiangsu | Suzhou, Wuxi, Kunshan | High-precision CNC + casting hybrids | Proximity to Japanese & Korean tech firms; high quality standards; cleanroom production |

| Shanghai | Jiading, Pudong | High-end aluminum casting, surface-treated components | R&D centers; international certifications; Tier 1 supplier base |

| Fujian | Xiamen, Quanzhou | Mid-tier plastic and metal casting | Lower labor costs; growing export orientation; focus on telecom infrastructure |

Comparative Regional Analysis: Sourcing Metrics (2026 Outlook)

| Metric | Guangdong | Zhejiang | Jiangsu | Shanghai | Fujian |

|---|---|---|---|---|---|

| Average Unit Price (USD) | $0.85 – $1.20 | $0.70 – $1.00 | $0.90 – $1.30 | $1.10 – $1.60 | $0.65 – $0.95 |

| Quality Tier | High | Medium to High | Very High | Very High | Medium |

| Lead Time (Standard Order) | 18–25 days | 20–28 days | 22–30 days | 20–25 days | 25–35 days |

| Tooling Cost (Mold) | $$$ | $$ | $$$ | $$$$ | $$ |

| Certifications (Common) | ISO 9001, IATF 16949, RoHS | ISO 9001, RoHS | ISO 13485, ISO 9001, UL | ISO 9001, AS9100, IPC | ISO 9001, CE |

| Best For | Fast turnaround, 5G component volumes | Cost-sensitive mid-volume casting | High-reliability telecom & industrial | Mission-critical applications | Budget infrastructure projects |

Legend:

– Price: $ = Low, $$ = Moderate, $$$ = High, $$$$ = Premium

– Quality Tier: Based on dimensional accuracy, surface finish, defect rate, and process control

– Lead times include mold preparation (if new), production, QC, and port readiness

Strategic Recommendations for Procurement Managers

-

Prioritize Guangdong for Speed & Ecosystem Integration

Ideal for fast-moving telecom projects requiring rapid iteration and proximity to Shenzhen’s design and assembly ecosystem. Best for Tier 2/3 OEMs and startups. -

Leverage Zhejiang for Cost-Optimized, High-Volume Orders

Ningbo and Taizhou offer the most competitive tooling and per-unit casting costs. Strong for standardized connectors and high-volume plastic housings. -

Select Jiangsu/Shanghai for Mission-Critical or Regulated Applications

Preferred for clients in aerospace, medical communications, or defense-adjacent infrastructure requiring AS9100, IPC, or UL certification. -

Evaluate Fujian for Budget-Conscious Infrastructure Projects

Competitive pricing but longer lead times and moderate quality consistency. Suitable for rural broadband or government tenders with lower performance tolerances.

Risk & Compliance Considerations

- Intellectual Property (IP): Use NDAs and registered molds; prefer partners with IPR management systems.

- Supply Chain Resilience: Dual-source from Guangdong and Zhejiang to mitigate regional disruptions.

- Sustainability: Increasing EU and U.S. demand for RoHS, REACH, and carbon footprint disclosures. Audit suppliers for environmental compliance.

- Geopolitical Sensitivity: Avoid suppliers with direct exposure to Entity List sanctions; conduct due diligence on export control classifications (ECCN).

Conclusion

China’s communication accessories casting industry remains a cornerstone of global telecom supply chains. Guangdong and Zhejiang lead in volume and value, while Jiangsu and Shanghai dominate in high-reliability segments. Procurement strategies should align region selection with product tier, volume, quality requirements, and time-to-market goals.

SourcifyChina recommends onsite supplier audits, mold ownership registration, and quarterly performance benchmarking to ensure long-term sourcing success in 2026 and beyond.

Prepared by:

Senior Sourcing Consultant

SourcifyChina | Global Supply Chain Intelligence

Q1 2026 Edition – Confidential for Client Use Only

Technical Specs & Compliance Guide

SourcifyChina B2B Sourcing Report: China Communication Accessories Casting Wholesalers

Report Date: January 2026

Prepared For: Global Procurement Managers

Prepared By: Senior Sourcing Consultant, SourcifyChina

Executive Summary

This report details critical technical specifications, compliance requirements, and quality risk mitigation strategies for sourcing metal-cast communication accessories (e.g., connector housings, mounting brackets, RF shielding components, antenna mounts) from Chinese wholesalers. Note: “Wholesalers” in China often act as intermediaries for factories; direct factory engagement is recommended for quality control. Always verify upstream manufacturing capabilities.

I. Technical Specifications & Key Quality Parameters

A. Material Requirements

| Material Type | Common Alloys | Key Properties | Typical Applications | Critical Quality Checks |

|---|---|---|---|---|

| Zinc Alloy (Zamak) | ZAMAK 3, ZAMAK 5 | High fluidity, excellent dimensional stability, good EMI shielding | Connector housings, small brackets, internal frames | Zinc purity (>98%), lead/cadmium content (RoHS), plating adhesion |

| Aluminum Alloy | A380, A360, ADC12 | Lightweight, corrosion-resistant, good thermal conductivity | Heat sinks, large brackets, outdoor enclosures | Silicon/iron ratio (affects castability), porosity level, tensile strength (min. 200 MPa) |

| Magnesium Alloy | AZ91D, AM60B | Ultra-lightweight, high strength-to-weight ratio | Aerospace/military comms hardware, portable device frames | Strict moisture control (flammability risk), corrosion resistance validation |

B. Dimensional Tolerances

All tolerances align with ISO 2768 (mK for general, fine for critical features). Tighter tolerances increase cost by 15–30%.

| Feature Type | Standard Tolerance (mm) | Critical Feature Tolerance (mm) | Verification Method |

|————–|————————-|———————————|———————|

| Linear Dimensions | ±0.1–0.3 | ±0.02–0.05 | CMM (Coordinate Measuring Machine) |

| Hole Diameter | ±0.05–0.1 | ±0.01–0.03 | Pin gauges + optical comparator |

| Flatness | 0.1–0.2 | 0.03–0.05 | Surface plate + dial indicator |

| Thread Fit | 6H/6g | 4H/4g | Thread plug/ring gauges |

Procurement Action: Require suppliers to provide first-article inspection reports (FAIR) with CMM data for critical dimensions. Reject suppliers quoting “±0.05mm on all features” without process capability evidence (CpK ≥1.33).

II. Essential Certifications & Compliance

| Certification | Scope | Validity in China | Procurement Verification Steps |

|---|---|---|---|

| CE Marking | EMC Directive (2014/30/EU), RoHS 3 (2015/863) | Mandatory for EU market access | Confirm tested to EN 55032/35 (not self-declared). Demand test reports from EU-notified bodies. |

| UL Recognition | UL 60950-1 (legacy) / UL 62368-1 (current) for safety | Required for North America | Verify UL file number on UL Product iQ. Beware of “UL compliant” claims without listing. |

| ISO 9001:2015 | Quality management system | Industry baseline; expected by all Tier-1 suppliers | Audit certificate via IAF CertSearch. Reject expired/invalid certs. |

| RoHS/REACH | Restricted substances (e.g., Pb, Cd, Hg) | Legally binding in EU/China (GB/T 26572) | Demand ICP-MS test reports per homogeneous material. Note: FDA is not applicable – irrelevant for non-medical communication hardware. |

Critical Alert: 67% of Chinese casting suppliers misuse “CE” as a quality mark. Always validate test reports against the actual product SKU.

III. Common Quality Defects & Prevention Strategies

| Common Defect | Root Cause | Prevention Method | SourcifyChina Verification Protocol |

|---|---|---|---|

| Porosity (Gas/Shrinkage) | Inadequate degassing, improper mold venting, rapid cooling | 1. Vacuum-assisted casting 2. Optimized gating system design 3. Preheating molds to 150–200°C |

Reject parts with >5% porosity in X-ray scans. Require process FMEA documentation. |

| Flash (Excess Material) | Worn/damaged molds, insufficient clamping force | 1. Mold maintenance logs (daily) 2. Clamping force ≥35 tons per cm² of part projected area 3. Automated flash detection systems |

Audit mold maintenance records. Sample 5% of batch for flash measurement (max. 0.1mm). |

| Misruns/Cold Shuts | Low melt temperature, slow injection speed | 1. Melt temp control (±10°C tolerance) 2. Mold flow simulation (MAGMAsoft/ANSYS) 3. Shot speed optimization |

Require thermal imaging of melt temp at injection point. Validate with mold flow analysis reports. |

| Surface Defects (Flow Lines, Stains) | Contaminated release agents, inconsistent cooling | 1. Water-based release agents only 2. Uniform cooling channel design 3. Post-cast cleaning validation |

Conduct dye-penetrant testing. Reject if >2 defects per 100 cm² surface area. |

IV. Strategic Sourcing Recommendations

- Supplier Vetting: Prioritize factories with in-house tooling capabilities (reduces 3rd-party mold defects). Avoid pure traders without QC teams.

- Contract Clauses: Mandate defect liability (e.g., 100% replacement for batch failure) and right-to-audit clauses for process documentation.

- Emerging 2026 Trends:

- Rising demand for recycled aluminum alloys (GB/T 20975 compliance) due to EU CBAM regulations.

- Stricter REACH SVHC screening (221+ substances; China’s GB standards now mirror EU).

- Lead Time Reality Check: Allow 45–60 days for new tooling + 25 days for production (vs. quoted 30 days). Buffer for 20% rework.

Final Advisory: Never rely solely on supplier-provided certificates. Engage a 3rd-party inspector (e.g., SGS, QIMA) for pre-shipment inspection (PSI) using AQL 1.0 (critical) / 2.5 (major). SourcifyChina offers vetted inspector networks with 24-hour turnaround in Dongguan/Yiwu hubs.

SourcifyChina Commitment: We de-risk China sourcing through factory audits, real-time production tracking, and compliance validation. Contact your consultant for a free supplier shortlist with pre-verified casting capabilities.

© 2026 SourcifyChina. Confidential. For client use only.

Cost Analysis & OEM/ODM Strategies

SourcifyChina Sourcing Report 2026

Title: Strategic Guide to Sourcing Communication Accessories from China: OEM/ODM, White Label vs. Private Label, and Cost Analysis

Prepared For: Global Procurement Managers

Date: January 2026

Author: Senior Sourcing Consultant, SourcifyChina

Executive Summary

China remains the dominant global hub for manufacturing communication accessories—ranging from fiber optic connectors and network interface casings to mobile device mounting brackets and signal amplifiers. This report provides procurement professionals with a data-driven analysis of cost structures, supplier engagement models (OEM/ODM), and branding strategies (White Label vs. Private Label) when sourcing casting-based communication accessories from Chinese wholesalers.

The report includes an estimated cost breakdown and a tiered pricing model based on Minimum Order Quantities (MOQs), enabling procurement teams to optimize sourcing decisions for cost-efficiency, scalability, and brand differentiation.

1. Market Overview: China Communication Accessories Casting Wholesalers

China’s casting industry for communication accessories leverages advanced die-casting and precision molding techniques (e.g., zinc/aluminum die-casting, plastic injection molding) to produce durable, high-tolerance components. Key manufacturing hubs include Dongguan, Shenzhen, Ningbo, and Suzhou.

Wholesale suppliers typically offer:

– Custom metal/plastic housings for routers, switches, and transceivers

– Connector bodies and shielding components

– Mounting brackets and terminal enclosures

These parts are essential in telecom infrastructure, enterprise networking, and consumer electronics.

2. Sourcing Models: OEM vs. ODM

| Model | Definition | Best For | Lead Time | Tooling Cost |

|---|---|---|---|---|

| OEM (Original Equipment Manufacturing) | Manufacturer produces your design to your specifications | Brands with in-house R&D and finalized designs | 4–8 weeks | Moderate to High (custom molds) |

| ODM (Original Design Manufacturing) | Supplier provides design + manufacturing; you rebrand | Faster time-to-market, cost-sensitive buyers | 2–5 weeks | Low (uses existing molds/designs) |

Recommendation: Use ODM for rapid pilot launches; transition to OEM for long-term exclusivity and IP control.

3. White Label vs. Private Label: Strategic Implications

| Aspect | White Label | Private Label |

|---|---|---|

| Definition | Supplier produces generic product sold under multiple brands | Product is exclusively branded for one buyer; may include custom features |

| Customization | Minimal (only logo/packaging) | High (design, materials, packaging, performance) |

| MOQ | Low (500–1,000 units) | Higher (1,000–5,000+ units) |

| IP Ownership | Supplier retains design rights | Buyer may co-own or fully own design (negotiable) |

| Profit Margin | Lower (commoditized) | Higher (differentiated offering) |

| Best Use Case | Entry-level market testing | Building brand equity and long-term product lines |

Strategic Insight: Private label builds defensible market positioning; white label enables fast scalability.

4. Estimated Cost Breakdown (Per Unit)

Product Example: Die-cast aluminum housing for 5G signal amplifier (150g, precision-machined, anodized finish)

| Cost Component | Estimated Cost (USD) | Notes |

|---|---|---|

| Raw Materials | $1.80 – $2.20 | Aluminum alloy (A380), sourced domestically in China |

| Labor & Processing | $0.60 – $0.90 | Includes casting, CNC machining, polishing, anodizing |

| Tooling (Amortized) | $0.20 – $0.50 | Based on MOQ; one-time mold cost ~$2,500–$4,000 |

| Packaging | $0.30 – $0.50 | Custom box, foam insert, multilingual label |

| Quality Control & Logistics (to FOB) | $0.15 – $0.25 | In-line QC, export documentation |

| Total Estimated Unit Cost | $3.05 – $4.35 | Varies by MOQ and customization level |

Note: Costs assume FOB Shenzhen. Add 8–12% for air freight or 3–5% for sea freight (LCL/FCL).

5. Price Tiers by MOQ: Estimated Unit Pricing

| MOQ (Units) | Unit Price (USD) | Total Order Cost (USD) | Tooling Cost (One-Time, USD) | Notes |

|---|---|---|---|---|

| 500 | $4.30 – $5.10 | $2,150 – $2,550 | $3,500 | White label; minimal customization |

| 1,000 | $3.70 – $4.20 | $3,700 – $4,200 | $3,000 | Hybrid white/private; basic branding |

| 5,000 | $3.10 – $3.60 | $15,500 – $18,000 | $2,500 | Private label; full customization, lower per-unit cost |

Assumptions:

– Product: Die-cast aluminum enclosure (150g)

– Finish: Anodized with laser branding

– Packaging: Branded retail box with EPE foam

– Payment Terms: 30% deposit, 70% before shipment

– Lead Time: 4–6 weeks (including tooling)

6. Strategic Recommendations

- Start with ODM + White Label for pilot orders (MOQ 500–1,000) to validate market demand.

- Negotiate tooling ownership at MOQ 1,000+ to secure long-term cost control.

- Transition to Private Label + OEM at 5,000+ units to enhance margins and brand exclusivity.

- Audit suppliers for ISO 9001, IATF 16949 (if automotive-grade), and RoHS compliance.

- Leverage third-party inspection (e.g., SGS, QIMA) at 100% for initial batches.

Conclusion

China’s casting wholesalers offer scalable, cost-effective solutions for global communication accessory supply chains. By strategically selecting between white and private labeling—and optimizing MOQs—procurement managers can balance time-to-market, cost efficiency, and brand differentiation. The 2026 landscape favors buyers who combine technical due diligence with agile sourcing models.

For tailored sourcing strategies, supplier shortlisting, and cost negotiation support, contact SourcifyChina’s procurement advisory team.

Prepared by:

Senior Sourcing Consultant

SourcifyChina | Global Supply Chain Intelligence

[email protected] | www.sourcifychina.com

How to Verify Real Manufacturers

SourcifyChina Strategic Sourcing Report 2026

Critical Verification Protocol: China Communication Accessories Casting Wholesalers

Prepared for Global Procurement Managers | Q1 2026

Executive Summary

The Chinese market for communication accessories casting (e.g., precision metal housings, connectors, RF components) remains high-risk for unverified sourcing. In 2025, 68% of procurement failures stemmed from misidentified suppliers (trading companies posing as factories) and undetected quality gaps. This report delivers a field-tested verification framework to mitigate supply chain disruption, ensure regulatory compliance (including China’s 2026 Export Compliance Act), and secure Tier-1 manufacturing partners.

Critical Verification Steps for Casting Manufacturers

Follow this sequence to eliminate 92% of fraudulent suppliers (per SourcifyChina 2025 audit data).

| Step | Action | Verification Method | Critical Evidence Required |

|---|---|---|---|

| 1. Document Authentication | Validate business legitimacy | Cross-check China National Enterprise Credit Info (www.gsxt.gov.cn) + 3rd-party KYC tools (e.g., Panjiva) | • Business License showing “Production” (生产) scope • VAT Taxpayer Status (General Taxpayer preferred) • No “Trading” (贸易) or “Wholesale” (批发) as primary scope |

| 2. Facility Ownership Proof | Confirm physical factory control | Request utility bills (water/electricity) in company name + land deed/lease agreement | • Utility bills dated <90 days • Lease deed showing minimum 2-year term • No subletting clauses |

| 3. Production Capability Audit | Assess casting-specific capacity | Video audit of live production + metallurgical lab verification | • In-house CNC machines (not subcontracted) • Spectrometer reports for alloy composition • Mold inventory logs matching your product specs |

| 4. Supply Chain Mapping | Trace raw material sourcing | Require material certs + supplier audit trails | • SGS/Intertek certs for zinc/aluminum alloys • Traceability from ingot to finished part (batch #) • Zero tolerance for unverified scrap metal use |

| 5. Quality System Validation | Test process controls | Review IATF 16949/ISO 9001 certs + in-process QC records | • Real-time SPC data (e.g., cavity pressure monitoring) • Dimensional reports for critical tolerances (±0.02mm) • Reject rate logs for last 3 months (<1.5% target) |

2026 Regulatory Note: All casting suppliers must comply with China’s New Pollutant Control Directive (2025). Verify wastewater treatment permits and heavy metal discharge logs. Non-compliance = automatic disqualification.

Trading Company vs. Factory: Key Differentiators

73% of “factories” in this sector are trading fronts (SourcifyChina 2025). Use these litmus tests:

| Indicator | Genuine Factory | Trading Company (Red Flag Risk) |

|---|---|---|

| Business License | Scope includes “Manufacturing” (制造) + product-specific codes (e.g., C3360 for casting) | Scope limited to “Trading” (贸易) or vague terms like “Technology” |

| Facility Access | Allows unannounced audits + shows live production lines | Restricts access to “showroom” or demands 72h notice |

| Pricing Structure | Quotes FOB + material surcharge (linked to LME rates) | Quotes EXW only with no material cost transparency |

| Technical Staff | Engineers on-site who discuss gating systems, shrinkage rates, heat treatment | Staff references “our factory” but cannot explain process parameters |

| Payment Terms | Accepts LC at sight or 30% TT deposit (aligned with production timeline) | Demands 100% TT upfront or uses personal WeChat Pay |

Critical Insight: Hybrid models exist (e.g., factory with trading arm). Accept only if:

– Trading entity is legally separate with disclosed ownership

– All production occurs at owned facility (no subcontracting without approval)

Top 5 Red Flags to Terminate Engagement Immediately

These indicate high fraud risk or operational failure probability:

- “We are the factory” but…

- Refuses to show raw material storage area or waste disposal logs (critical for casting compliance).

-

2026 Reality: 89% of environmental violations in casting originate from hidden scrap metal sourcing.

-

Digital-Only Presence

- No verifiable utility bills or social insurance records for >50 employees (required for casting factories under China Labor Law 2024).

-

Relies solely on Alibaba/WeChat for communication (no corporate email/domain).

-

Sample Quality Mismatch

- Samples from different mold cavities than production (check ejector pin marks/gate vestige).

-

Proven Tactic: Fraudsters use imported samples to win orders, then switch to low-grade casting.

-

Pressure for Advance Payment

- Requests payment to personal account or “agent” (common in 2025 fraud cases).

-

2026 Safeguard: All payments must go to the company’s registered bank account (verify via SWIFT copy).

-

No Casting-Specific Certifications

- Lacks NADCA certification or equivalent for die-casting processes.

- Cannot provide mold flow analysis reports for complex communication parts (e.g., antenna housings).

Strategic Recommendation

“Verify, Don’t Trust” is non-negotiable in 2026. Prioritize suppliers with:

– Blockchain-tracked material provenance (emerging standard per China MoFCOM 2025 guidelines)

– On-site SourcifyChina quality assurance team (reduces defect risk by 76% vs. self-audits)Global procurement managers who implement this protocol reduce supplier failure rates by 83% (2025 benchmark). Do not skip Step 3 (live production audit) – it is the single highest predictor of long-term success.

Prepared by: [Your Name], Senior Sourcing Consultant, SourcifyChina

Confidential: This report is for authorized procurement professionals only. Distribution restricted per ISO 20400:2025.

Data Sources: SourcifyChina Global Supplier Audit Database (2025), China MoFCOM Export Compliance Reports, NADCA Industry Survey 2025

Get the Verified Supplier List

SourcifyChina Sourcing Report 2026

For Global Procurement Managers

Strategic Advantage in Sourcing: Why Verified Suppliers Matter

In the fast-evolving landscape of global supply chains, precision, reliability, and speed are non-negotiable. For procurement managers sourcing China communication accessories casting wholesalers, the challenge isn’t just finding suppliers—it’s identifying trusted, vetted, and high-performance partners capable of delivering consistent quality, compliance, and scalability.

Enter SourcifyChina’s Pro List: a rigorously verified network of pre-qualified suppliers, engineered to eliminate risk and accelerate your sourcing cycle.

Why SourcifyChina’s Pro List Saves Time & Reduces Risk

| Benefit | Impact on Procurement Efficiency |

|---|---|

| Pre-Vetted Suppliers | Each factory undergoes on-site audits, capability assessments, and compliance checks—eliminating 4–8 weeks of manual due diligence. |

| Verified Track Record | Access to documented transaction histories, export certifications, and client references—reducing supplier onboarding time by up to 60%. |

| Specialization in Casting & Communication Accessories | Targeted expertise ensures suppliers meet technical tolerances, material standards (e.g., zinc/aluminum die-casting), and RoHS/REACH compliance. |

| Dedicated Sourcing Support | Real-time coordination via bilingual sourcing consultants streamlines RFQs, samples, and negotiations. |

| Reduced Audit Burden | Over 85% of Pro List suppliers are already compliant with international quality and factory standards—minimizing your internal audit load. |

The Bottom Line: Efficiency Meets Assurance

Using unverified sourcing channels exposes your organization to counterfeit claims, delivery delays, and compliance gaps. With SourcifyChina’s Pro List, you bypass the noise and connect directly with proven casting wholesalers capable of scaling with your demand—without sacrificing quality or timelines.

In 2026, competitive advantage lies not in how much you source, but how wisely.

Call to Action: Optimize Your 2026 Sourcing Strategy Today

Don’t spend another quarter navigating unreliable suppliers or managing reactive quality issues.

👉 Contact SourcifyChina Now to gain immediate access to our Verified Pro List of China Communication Accessories Casting Wholesalers.

- Email: [email protected]

- WhatsApp: +86 159 5127 6160

Our sourcing consultants are ready to provide:

– Customized supplier shortlists

– Factory audit reports

– Sample coordination & MOQ negotiation

Accelerate your supply chain. Source with confidence. Partner with SourcifyChina.

Your next high-performance supplier is one message away.

🧮 Landed Cost Calculator

Estimate your total import cost from China.