The global demand for 6/4 AWG cable—a heavy-duty electrical cable commonly used in power distribution, industrial applications, and renewable energy installations—has seen steady growth in recent years, driven by infrastructure expansion and increased investment in clean energy. According to Grand View Research, the global electrical, instrumentation, and control (EI&C) cables market was valued at USD 235.8 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 5.1% from 2023 to 2030. This growth is fueled by rising construction activities, urbanization, and the integration of solar and wind energy systems, all of which rely on high-capacity cabling like 6/4 AWG. Mordor Intelligence further supports this trend, noting that the North American and Asia-Pacific markets are leading demand, with utility modernization and grid resilience initiatives accelerating procurement. As industry needs evolve, selecting reliable manufacturers becomes critical. In this context, the following five manufacturers have emerged as leaders in producing high-quality 6/4 cable, combining strong R&D, adherence to UL and NEC standards, and proven performance across large-scale projects.

Top 5 6/4 Cable Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 AFC Cable Systems

Domain Est. 2010

Website: atkore.com

Key Highlights: AFC Cable Systems, Inc., a part of Atkore International, is a leading designer, manufacturer and supplier of electrical distribution products….

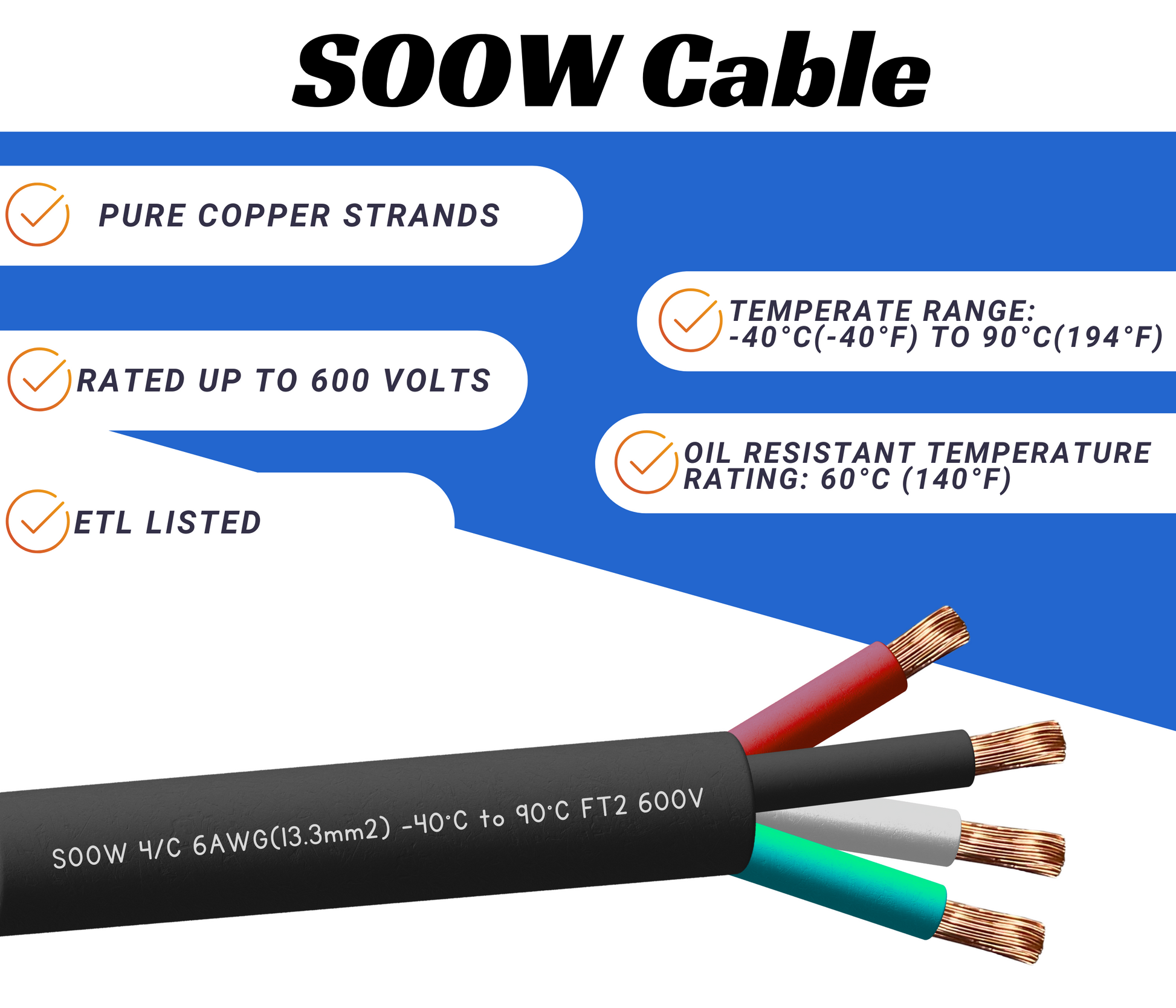

#2 SOOW/SJOOW

Domain Est. 1994

Website: southwire.com

Key Highlights: Get the right flexible cord for your power and automation needs with Southwire’s SJOOW vs SOOW comparison. Browse our selection and order now!…

#3 Cable, 6/4 SEOOW, (Black/White/Red/Green), Stranded Copper …

Domain Est. 1995

Website: summit.com

Key Highlights: Rating 5.0 (5) · Free deliveryPortable cord; type SEOOW; voltage rating 600 V; conductor material bare copper; jacket material chemical/oil/water resistant Seoprene thermoplast…

#4 Connecting

Domain Est. 1996

Website: hubersuhner.com

Key Highlights: The globally active Swiss company HUBER+SUHNER develops and produces components and system solutions for electrical and optical connectivity….

#5 6/4 SOOW Yellow Portable Cord 600V Non UL

Domain Est. 2015

Website: wireandcableyourway.com

Key Highlights: In stock Free delivery over $1,0006/4 SOOW Yellow Portable Cord 600V Non UL … $5.60 /ft. Min: 1 ft., Max: 1000 ft. To order multiple lengths, simply enter the desired footage int…

Expert Sourcing Insights for 6/4 Cable

H2: 2026 Market Trends for 6/4 Cable

The 6/4 cable, commonly referred to as 6 American Wire Gauge (AWG) with 4 conductors, is widely used in electrical installations, including residential, commercial, and industrial power distribution, HVAC systems, and subpanel feeders. As the global construction and energy infrastructure sectors evolve, several key trends are expected to shape the market for 6/4 cable through 2026.

-

Growth in Residential and Commercial Construction

The ongoing expansion of urbanization and housing developments—particularly in North America, Asia-Pacific, and parts of Latin America—is expected to drive demand for electrical wiring, including 6/4 cable. With increasing adoption of all-electric homes and the need for dedicated circuits for electric vehicle (EV) chargers, hot tubs, and high-capacity appliances, 6/4 NM-B (non-metallic sheathed) cable is becoming a standard in new builds and retrofits. -

Electrification and EV Infrastructure Expansion

One of the most significant drivers for 6/4 cable demand is the global push toward electrification and the deployment of EV charging stations. Level 2 EV chargers typically require a 60-amp circuit, for which 6/4 cable is often the preferred choice when run over moderate distances. As governments invest in EV infrastructure under climate initiatives (e.g., U.S. Bipartisan Infrastructure Law, EU Green Deal), installations of 6/4 cable in residential garages, multifamily dwellings, and public charging hubs are expected to rise steadily through 2026. -

Supply Chain Stability and Raw Material Costs

Copper remains the primary conductor material in 6/4 cables, and its price volatility directly impacts manufacturing costs. In 2026, the market will likely see stabilization in copper prices due to improved mining output and recycling efforts, though geopolitical factors and energy costs may still cause fluctuations. Cable manufacturers are increasingly adopting hybrid procurement models and long-term supplier contracts to mitigate cost risks. -

Advancements in Cable Materials and Efficiency

In response to energy efficiency standards and sustainability goals, manufacturers are exploring alternatives such as aluminum-conductor cables for certain applications. However, due to concerns over oxidation and connection reliability, copper-based 6/4 cables remain dominant in critical circuits. Innovations in insulation materials (e.g., cross-linked polyethylene or XLPE) are enhancing durability, heat resistance, and safety—making 6/4 cables more suitable for demanding environments. -

Regulatory and Safety Standards

Stricter electrical codes, such as updates to the National Electrical Code (NEC) in the U.S., are expected to influence installation practices and material selection. Requirements for arc-fault and ground-fault protection, along with proper grounding (provided by the fourth conductor in 6/4 cable), reinforce the relevance of this cable type in modern electrical systems. Compliance with these standards will remain a key market driver. -

Regional Market Dynamics

North America is expected to remain the largest market for 6/4 cable due to high construction activity and electrical code requirements. In contrast, emerging markets in Southeast Asia and Africa may see slower adoption due to preference for lower-cost alternatives, though growing middle-class urban development could present long-term opportunities.

Conclusion

The 2026 market for 6/4 cable is poised for steady growth, driven by residential electrification, EV infrastructure, and global construction trends. While material cost and supply chain challenges persist, technological improvements and regulatory support will sustain demand for reliable, code-compliant electrical cabling. Stakeholders across manufacturing, distribution, and installation sectors should prepare for increased volume and evolving technical requirements in the coming years.

Common Pitfalls When Sourcing 6/4 Cable (Quality and IP Ratings)

Sourcing 6/4 AWG cable—commonly used in high-current applications like solar installations, EV charging, and industrial power distribution—requires careful attention to both material quality and Ingress Protection (IP) ratings. Overlooking key factors can lead to safety hazards, system inefficiencies, and premature failure. Here are common pitfalls to avoid:

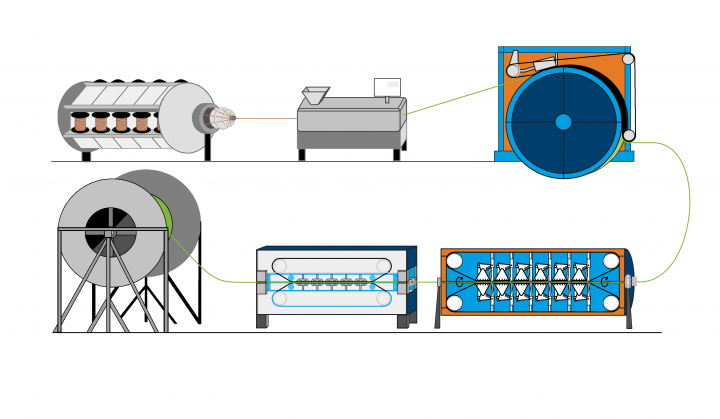

Inadequate Conductor Quality

One of the most frequent issues is receiving cable with substandard conductors. Some suppliers may use aluminum or copper-clad aluminum instead of pure electrolytic-tinned copper, especially in budget cables. This reduces conductivity, increases resistance, and can lead to overheating. Always verify conductor material through certifications (e.g., UL, CSA) and request mill test reports.

Misleading or Unverified IP Ratings

Many suppliers claim high IP ratings (e.g., IP67, IP68), but not all cables undergo proper third-party testing. A cable may be labeled “IP67” without being tested to withstand prolonged water immersion or dust ingress. Relying on unverified claims can compromise safety in outdoor or wet environments. Insist on certified test reports from accredited labs.

Poor Jacket Material and UV Resistance

In outdoor applications, UV degradation is a major concern. Low-quality PVC or untested polymer jackets can crack, harden, or split after months of sun exposure, exposing conductors. Ensure the cable jacket is rated for direct sunlight (e.g., UV-resistant, sunlight-resistant per UL 4703) and suitable for the installation environment.

Inconsistent Stranding and Flexibility

6/4 cable should use finely stranded conductors for flexibility and vibration resistance. Poorly stranded or solid-core cables are stiff, difficult to install, and prone to breakage at termination points. Check stranding specifications—look for Class K or Class 5 stranding in flexible power cables.

Counterfeit or Non-Compliant Markings

Some cables feature fake UL, CSA, or TUV marks to appear compliant. These markings may not correspond to actual certification. Always verify certification numbers in official databases (e.g., UL Product iQ) and purchase from authorized distributors to reduce counterfeiting risk.

Inaccurate Gauge and Dimensional Tolerances

“6/4” refers to 6 AWG phase conductors and a 4 AWG ground. However, some low-quality cables undersize conductors to cut costs. This increases resistance and fire risk. Use a caliper to verify conductor diameter or request cross-sectional area test results.

Lack of Temperature and Voltage Rating Suitability

Not all 6/4 cables are suitable for high-temperature environments. Standard cables rated at 90°C may fail in rooftop solar arrays where temperatures exceed 75°C continuously. Ensure the cable meets or exceeds the required temperature rating (e.g., 105°C, 125°C) and voltage class (e.g., 600V, 2000V for solar).

Ignoring Application-Specific Standards

Using general-purpose cable in specialized applications (e.g., photovoltaic systems, marine, or hazardous locations) can violate code requirements. For instance, PV installations require sunlight-resistant, double-insulated cables like USE-2 or PV Wire. Always match the cable type to the application code (NEC, IEC, etc.).

Poor Supplier Verification and Traceability

Sourcing from unknown manufacturers or brokers without traceability increases the risk of receiving inconsistent or non-compliant batches. Work with reputable suppliers who provide full product traceability, batch testing, and responsive technical support.

Overlooking Mechanical Protection Needs

Even with a high IP rating, cables exposed to physical stress (e.g., rodent damage, abrasion) may require additional conduit or armored variants. Assuming IP rating alone ensures durability can lead to unexpected damage—assess the full mechanical environment during selection.

Avoiding these pitfalls requires due diligence in supplier selection, verification of certifications, and alignment with application-specific standards. Investing time upfront ensures long-term reliability, safety, and compliance.

Logistics & Compliance Guide for 6/4 Cable

Overview of 6/4 Cable

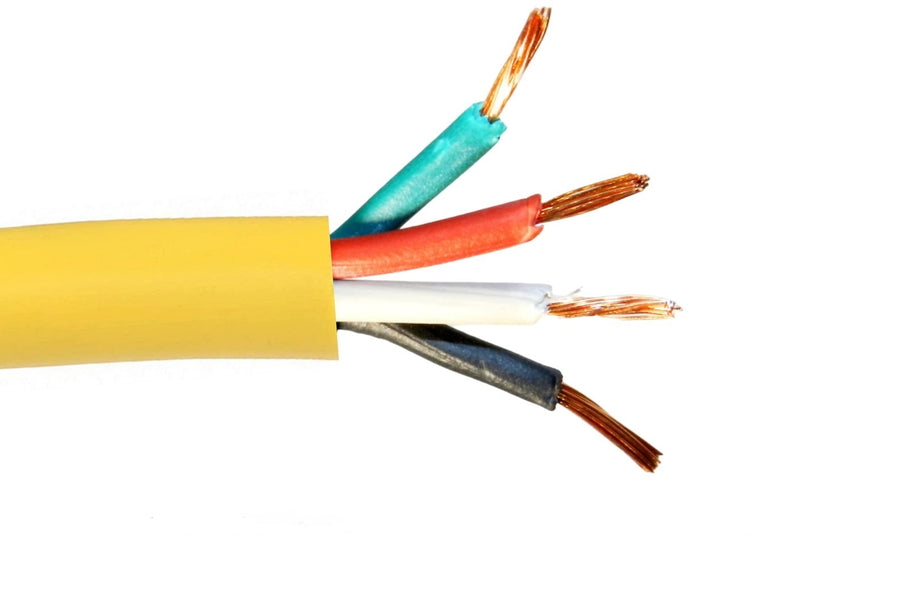

6/4 cable refers to a type of electrical cable with four conductors—typically three current-carrying conductors (hot wires) and one neutral or ground conductor—where each conductor has a cross-sectional area of 6 AWG (American Wire Gauge). The term “6/4” indicates the conductor count and size, commonly used in residential and commercial power distribution, such as feeder circuits for subpanels, hot tubs, and electric vehicle chargers. Proper logistics and compliance are critical for safety, code adherence, and project success.

Regulatory Standards and Compliance

6/4 cable must comply with national and international electrical standards. In the United States, compliance with the National Electrical Code (NEC), published by the National Fire Protection Association (NFPA 70), is mandatory. Key compliance considerations include:

– NEC Article 338: Covers service-entrance cable (SE cable), commonly used for 6/4 outdoor applications.

– NEC Article 334: Applies to non-metallic sheathed cable (NM-B), when used indoors.

– UL Certification: Cables must be listed by Underwriters Laboratories or a recognized testing laboratory.

– Temperature Ratings: 6/4 cables typically support 60°C, 75°C, or 90°C ratings, affecting ampacity and installation methods.

– Local Building Codes: Always verify compliance with state and municipal regulations, which may impose additional requirements.

Cable Types and Applications

Different types of 6/4 cable are suited to specific applications:

– 6/4 SER (Service Entry Cable): Used for overhead or underground service entrances; flexible and weather-resistant.

– 6/4 UF-B (Underground Feeder): Suitable for direct burial; moisture and sunlight resistant.

– 6/4 NM-B (Non-Metallic Sheathed Cable): Used indoors for dry locations only; not permitted for outdoor or wet environments.

Selecting the correct cable type ensures both performance and code compliance.

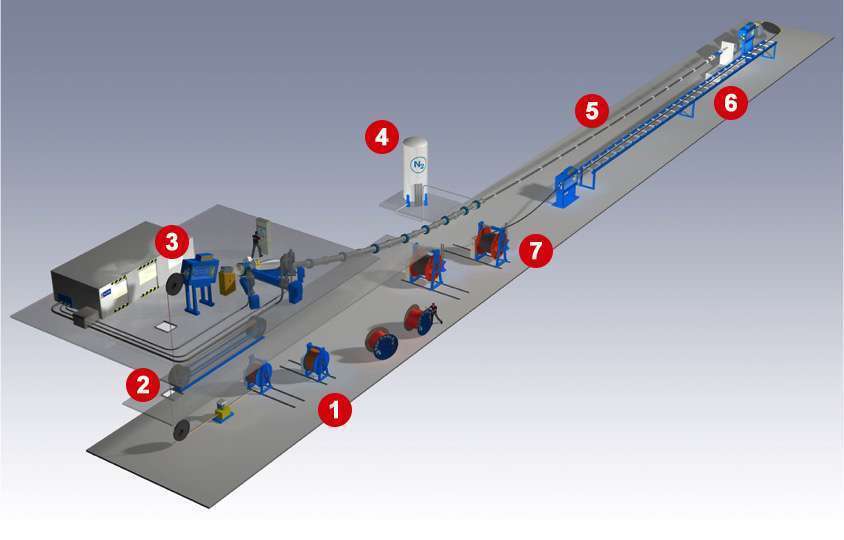

Transportation and Handling

Proper logistics begin with transportation:

– Spool Handling: 6/4 cable is typically shipped on reels. Use proper lifting equipment (e.g., cable reel dollies or forklifts) to avoid damage.

– Weather Protection: Protect cable from moisture and extreme temperatures during transit, especially for NM-B and SER types.

– Avoid Kinking: Never drop or sharply bend cable reels, as this can damage conductors and insulation.

– Storage: Store reels vertically in a dry, covered area. Elevate off damp ground to prevent moisture absorption.

Installation Best Practices

Installation must adhere to safety and code requirements:

– Ampacity: Per NEC Table 310.16, 6 AWG copper has an ampacity of 55A at 60°C, 65A at 75°C, and 75A at 90°C. Use appropriate overcurrent protection (typically 60A breaker for 6/4 circuits).

– Conduit Use: When required (e.g., exposed runs, high-traffic areas), use EMT, PVC, or rigid conduit sized per NEC Table 1 (Chapter 9). For three 6 AWG conductors plus ground, a minimum 1″ conduit is typical.

– Bending Radius: Maintain a minimum bending radius of 5 times the cable diameter to prevent insulation damage.

– Grounding and Bonding: Ensure proper grounding conductor connection and bonding at both ends, especially in service-entrance applications.

Inspection and Certification

Before energizing a 6/4 cable installation:

– Visual Inspection: Check for cuts, abrasions, or compression damage.

– Continuity and Insulation Resistance Testing: Use a multimeter or megohmmeter to verify conductor integrity and insulation quality.

– Permit and Inspection: Schedule a local electrical inspection to verify compliance with NEC and local codes. Obtain certification before system activation.

Environmental and Safety Considerations

- Disposal: Follow local regulations for disposal of damaged or surplus cable. Recycle copper conductors when possible.

- Worker Safety: Use PPE (gloves, eye protection) during handling and installation. Avoid manual lifting of heavy reels to prevent injury.

- Environmental Exposure: Use UV-resistant and moisture-protected cable types (e.g., UF-B or SER) for outdoor installations.

Documentation and Recordkeeping

Maintain detailed records for compliance and future maintenance:

– Cable Specifications: Record manufacturer, model, date of installation, and compliance certifications (UL, NEC).

– Inspection Reports: Keep copies of inspection approvals and test results.

– As-Built Drawings: Update electrical schematics to reflect final cable routing and connections.

By following this logistics and compliance guide, stakeholders can ensure safe, efficient, and code-compliant deployment of 6/4 cable in electrical systems.

Conclusion for Sourcing 6/4 Cable:

After evaluating available options, supplier reliability, pricing, and delivery timelines, sourcing 6/4 gauge electrical cable from reputable electrical supply distributors or manufacturers is both feasible and practical for projects requiring high-current applications, such as feeder lines for subpanels, large appliances, or commercial installations. It is recommended to procure the cable from certified suppliers that comply with NEC standards and provide UL-listed products to ensure safety, performance, and code compliance. Additionally, considering bulk pricing, lead times, and the availability of both stranded and solid conductors will help optimize cost-efficiency and project scheduling. Proper verification of insulation type (e.g., USE-2, THHN/THWN) based on the installation environment—whether underground, in conduit, or exposed—will further ensure long-term reliability. In conclusion, with due diligence in supplier selection and adherence to electrical codes, sourcing 6/4 cable can be completed effectively to meet project requirements.