The global 5-axis CNC machining market is experiencing robust growth, driven by rising demand for high-precision components in aerospace, automotive, medical, and energy sectors. According to Grand View Research, the global CNC machine market size was valued at USD 78.5 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 7.8% from 2023 to 2030, with 5-axis systems accounting for an increasing share due to their ability to enhance productivity and accuracy in complex part manufacturing. Similarly, Mordor Intelligence projects a CAGR of over 7% for the 5-axis CNC machine market through 2028, citing advancements in automation, Industry 4.0 integration, and growing investments in smart manufacturing across North America, Europe, and Asia-Pacific. As manufacturers seek greater operational efficiency and tighter tolerances, leading machine tool builders are pushing the boundaries of innovation in kinematics, control systems, and hybrid manufacturing technologies—setting the stage for the rise of the top 10 5-axis CNC manufacturers shaping the future of advanced machining.

Top 10 5Axis Cnc Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Makino

Domain Est. 1996

Website: makino.com

Key Highlights: Achieve superior results with Makino’s CNC machining. Makino machines and engineering services provide precision and reliability across applications….

#2 Haas Automation Inc.

Domain Est. 1996

Website: haascnc.com

Key Highlights: Haas Automation is the largest machine tool builder in the western world, manufacturing a complete line of CNC vertical machining centers, ……

#3

Domain Est. 1999

Website: snkamerica.com

Key Highlights: SPECIAL APPLICATION MACHINES · BRIDGE TYPE 5-SIDED MACHINING. RB-MII Series · VERTICAL 5-AXIS MACHINING. CMV Series Machining Centers · HORIZONTAL 5-AXIS MACHINING….

#4 Homepage

Domain Est. 2015

Website: 5thaxis.com

Key Highlights: “At 5th Axis, innovation drives everything we do. Our mission is to empower machinists and manufacturers with the most advanced, reliable, and user-friendly ……

#5 American Made CNC Routers for Wood, Plastics, Aerospace and …

Domain Est. 1995

Website: thermwood.com

Key Highlights: Our five-axis American-made CNC machining centers deliver precision and versatility for complex applications, including: High-precision trimming of formed parts ……

#6 to Mazak Corporation

Domain Est. 1998

Website: mazak.com

Key Highlights: Mazak’s machine tool continues to evolve by multiple technologies such as process integration by five-axis multi-tasking, gear machining, grinding, and laser….

#7 5 axis CNC milling machine CNC routers

Domain Est. 2002

Website: mecanumeric.com

Key Highlights: 5-axis machining with a CNC machine. MÉCANUMÉRIC manufactures and markets the NORMAPROFIL range of 5-axis CNC milling machines designed for large parts….

#8 Diversified Machine Systems

Domain Est. 2006

Website: dmscncrouters.com

Key Highlights: Diversified Machine Systems builds U.S. CNC routers, specializing in 3 and 5 axis machines for composites, metals, wood, foam, and plastics….

#9 Maximum productivity with 5

Domain Est. 2013

Website: us.dmgmori.com

Key Highlights: 5-axis CNC milling machines by DMG MORI ✓ Benefit from high cutting performance, maximum precision and high dynamics….

#10 DN Solutions

Domain Est. 2017

Website: dn-solutions.com

Key Highlights: Welcome to official website of DN Solutions! Here you can view our wide range of products from the very latest machines to our most popular models….

Expert Sourcing Insights for 5Axis Cnc

2026 Market Trends for 5-Axis CNC Machines

The 5-axis CNC machine market is poised for significant evolution by 2026, driven by technological advancements, shifting industrial demands, and global economic dynamics. Key trends shaping the landscape include:

1. Accelerated Adoption of Automation and Integration (Lights-Out Machining)

By 2026, seamless integration with automation systems—such as robotic part loading/unloading, automated tool changers, and pallet pools—will become standard for high-volume 5-axis CNC operations. The push for “lights-out machining” will drive demand for machines with enhanced IoT connectivity and compatibility with Manufacturing Execution Systems (MES) and digital twins. This trend will be especially prevalent in aerospace, medical, and automotive sectors seeking to reduce labor costs and increase throughput.

2. Rise of Hybrid Manufacturing and Additive Integration

5-axis CNC platforms will increasingly incorporate additive manufacturing (3D printing) capabilities, enabling hybrid machines that combine precision subtractive machining with complex geometry deposition. This convergence allows for on-demand repair of high-value components (e.g., turbine blades) and rapid production of near-net-shape parts, reducing material waste and lead times—critical for defense and energy industries.

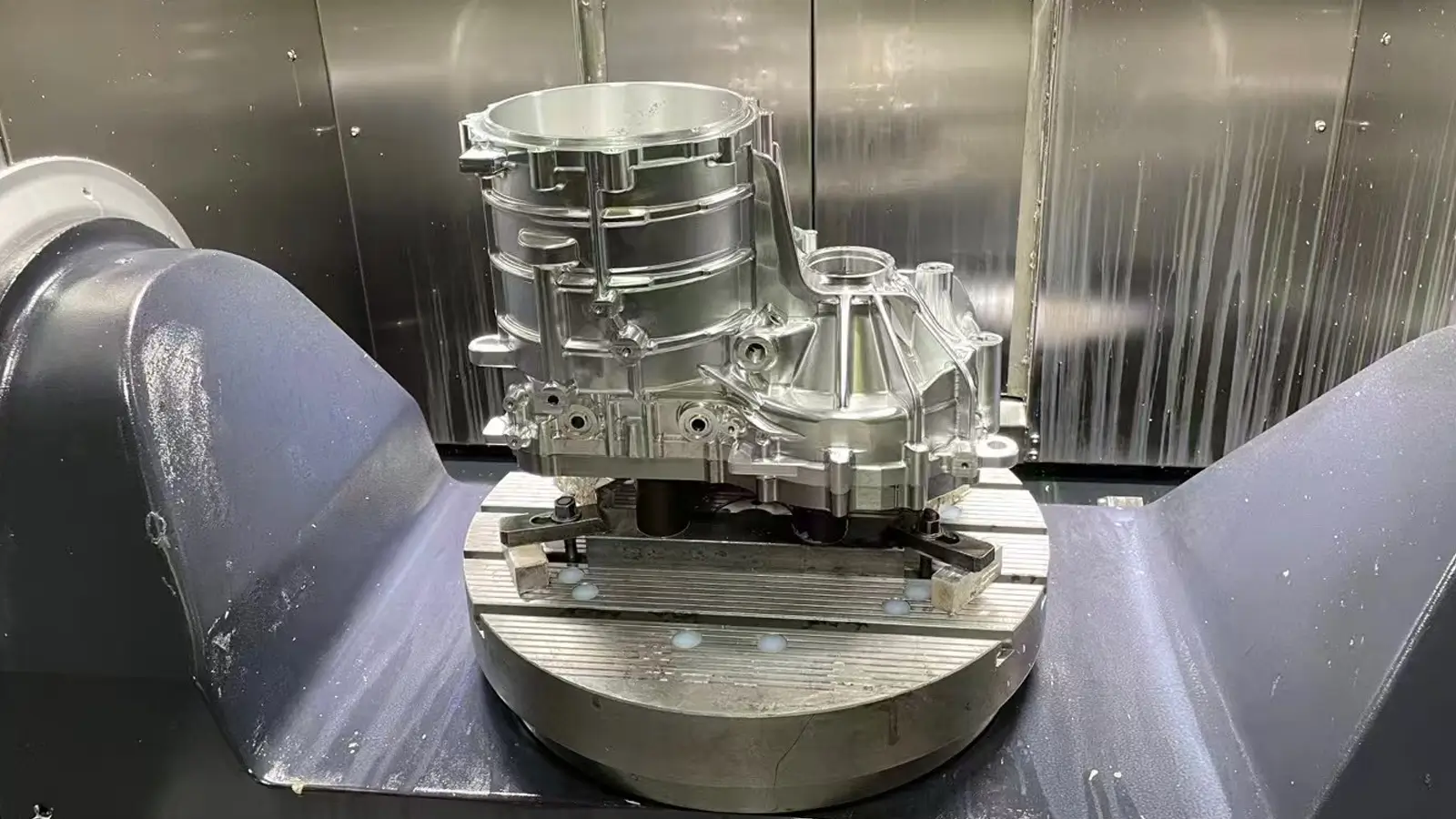

3. Expansion in High-Growth Sectors (EVs, MedTech, and Renewable Energy)

The surge in electric vehicle (EV) production will drive demand for complex, lightweight components requiring 5-axis precision, such as motor housings and battery trays. Similarly, the medical device industry will rely on 5-axis machining for intricate implants and surgical tools. Additionally, components for wind turbines and hydrogen fuel cells will push the need for large-format 5-axis machines capable of handling oversized, high-tolerance parts.

4. Advancements in Software and AI-Driven Optimization

By 2026, AI-powered CAM software and machine learning algorithms will optimize toolpath generation, reduce cycle times, and predict tool wear in real time. Cloud-based simulation platforms will allow remote programming and validation, improving uptime and reducing setup errors. Smart CNC controls will enable adaptive machining, automatically adjusting parameters based on sensor feedback for consistent quality.

5. Regional Shifts and Supply Chain Resilience

Geopolitical factors and supply chain disruptions will prompt companies to reshore or nearshore manufacturing, boosting 5-axis CNC demand in North America and Europe. Meanwhile, Asia-Pacific—led by China, Japan, and India—will remain a dominant market due to rapid industrialization and government support for advanced manufacturing initiatives like “Made in China 2025” and “Industry 4.0.”

In conclusion, the 5-axis CNC market in 2026 will be characterized by smarter, more connected, and versatile machines serving increasingly complex and sustainable manufacturing needs. Companies investing in integrated, future-ready solutions will gain a decisive competitive edge.

Common Pitfalls When Sourcing 5-Axis CNC Machines: Quality and Intellectual Property Concerns

Logistics & Compliance Guide for 5-Axis CNC Machining

Overview

5-axis CNC machining enables high-precision manufacturing by allowing the cutting tool to move across five axes simultaneously. While offering superior flexibility and accuracy, it introduces unique logistics and compliance challenges across procurement, transportation, operations, and regulatory adherence. This guide outlines best practices and requirements to ensure efficient and compliant 5-axis CNC operations.

Equipment & Facility Requirements

Ensure your facility supports the technical and spatial demands of 5-axis CNC systems.

– Space & Layout: Allow for larger footprints due to increased machine size and multi-axis movement. Include space for tooling storage, fixturing, and material handling.

– Power & Utilities: Verify stable 3-phase electrical supply, proper grounding, and adequate coolant and air filtration systems.

– Environmental Controls: Maintain temperature and humidity control to prevent thermal expansion affecting precision.

– Safety Zones: Establish clear operational boundaries with emergency stops, light curtains, and interlocks.

Tooling & Material Logistics

Efficient tool and material flow is critical for uninterrupted 5-axis production.

– Tool Management: Implement a digital tool library with calibration records. Use RFID or barcode systems for tracking inserts, holders, and probes.

– Material Handling: Use automated systems (e.g., pallet changers, robotic arms) to reduce setup time and human error.

– Raw Material Storage: Store materials in climate-controlled areas to prevent warping. Segregate materials by alloy type and grade.

– Inventory Management: Integrate CNC scheduling with ERP/MES systems for real-time stock tracking and reordering.

International Trade & Export Compliance

5-axis CNC machines and parts may be subject to export controls due to dual-use potential.

– Classification: Determine Export Control Classification Number (ECCN) under the U.S. Commerce Control List (CCL) or equivalent (e.g., EU Dual-Use Regulation). Most 5-axis CNC machines fall under ECCN 2B001 or 2B002.

– Licensing Requirements: Obtain appropriate export licenses (e.g., from BIS in the U.S.) when shipping to controlled destinations or for sensitive applications (e.g., aerospace, defense).

– End-Use Screening: Conduct due diligence on customers and end-users to prevent diversion to unauthorized programs.

– Documentation: Maintain accurate records including commercial invoices, packing lists, and export declarations for at least five years.

Regulatory & Safety Compliance

Adhere to local and international safety and environmental standards.

– OSHA/Workplace Safety (U.S.) or equivalent (e.g., EU Machinery Directive): Ensure machine guarding, lockout/tagout (LOTO) procedures, and operator training.

– ISO Standards: Comply with ISO 2768 (geometric tolerances), ISO 9001 (quality management), and ISO 14001 (environmental management) where applicable.

– Noise & Emissions: Monitor and mitigate noise levels and coolant mist using enclosures and filtration systems.

– Waste Management: Properly dispose of metal shavings, used coolant, and worn tooling in accordance with environmental regulations (e.g., EPA, REACH).

Data Security & Intellectual Property Protection

Protect sensitive design and programming data integral to 5-axis operations.

– Secure CAM Software: Restrict access to CNC programming files using role-based permissions and encryption.

– Network Isolation: Keep CNC machines on a segmented network to prevent cyber threats (air-gapped if possible).

– NDAs & IP Agreements: Require signed non-disclosure agreements with employees, contractors, and clients.

– Audit Trails: Log all program uploads, edits, and machine access for traceability.

Maintenance & Calibration Protocols

Regular upkeep ensures precision and compliance.

– Preventive Maintenance: Follow manufacturer-recommended schedules for spindle, bearings, and linear guides.

– Calibration: Perform periodic calibration using laser interferometers or ball bars to verify axis alignment and accuracy (e.g., per ISO 230-2).

– Tool Presetters: Use automated tool presetters to ensure consistent tool length and diameter data.

– Documentation: Maintain logs of all maintenance, repairs, and calibrations for audit purposes.

Training & Operator Certification

Qualified personnel are essential for safe and compliant operation.

– Certification Programs: Train operators in G-code, CAM software (e.g., Mastercam, Siemens NX), and machine-specific controls.

– Safety Training: Include hazard recognition, emergency procedures, and PPE usage.

– Continuing Education: Provide updates on new techniques, compliance changes, and software upgrades.

Quality Assurance & Traceability

Implement robust QA processes to meet industry standards.

– In-Process Inspection: Use on-machine probing for real-time dimensional verification.

– Final Inspection: Employ CMM (Coordinate Measuring Machine) or optical scanners for critical features.

– Documentation: Generate first-article inspection (FAI) reports, PPAP documentation, and material certifications when required.

– Lot Traceability: Track raw material batches, machine runs, and operators for full part traceability.

Conclusion

Managing 5-axis CNC operations requires coordinated logistics and strict compliance with technical, safety, and regulatory standards. By implementing structured processes for equipment, materials, data, and personnel, manufacturers can achieve high-precision output while minimizing risk and ensuring legal adherence. Regular audits and staff training are key to maintaining continuous compliance and operational excellence.

Conclusion for Sourcing a 5-Axis CNC Machine

Sourcing a 5-axis CNC machine is a strategic investment that can significantly enhance manufacturing capabilities, improve part accuracy, and reduce production time for complex components. When making this decision, it is essential to evaluate key factors such as machine precision, build quality, software compatibility, after-sales support, and total cost of ownership.

Choosing the right supplier involves thorough due diligence—assessing reputation, technical expertise, warranty terms, and service network. While domestic suppliers may offer faster support and easier communication, international suppliers can provide cost-effective options, especially from regions like Europe or Asia known for advanced manufacturing technology. However, potential challenges such as shipping delays, import regulations, and language barriers must be considered.

Ultimately, the best sourcing decision balances performance requirements with long-term operational efficiency and support. Investing in a reliable 5-axis CNC system not only improves competitiveness in high-precision industries—such as aerospace, medical, and mold-making—but also future-proofs manufacturing capabilities. A well-sourced machine, backed by strong vendor support and integrated into existing workflows, will deliver a strong return on investment and sustained production excellence.